Journal of Ergonomics

Open Access

ISSN: 2165-7556

ISSN: 2165-7556

Research - (2022)Volume 12, Issue 3

Background: Ergonomic risks are abounding in the manufacturing industry where work may be fast-paced, repetitive, and sedentary and performed in awkward postures. Work related musculoskeletal disorders (WRMSDs) have become prevalent and impact productivity and raise costs. Despite the significant burden of WRMSDs, workplace interventions for prevention remain varied and differ in effectiveness. This study aimed to reduce the incidence of WRMSD at a manufacturing facility with significant biomechanical risks through an integrated multi-component ergonomic intervention programme.

Methods: Guided by a detailed risk assessment, an ergonomic intervention programme was conceptualized and implemented in phases for the primary prevention of musculoskeletal disorders. Musculoskeletal injury incidence rates were used to evaluate programme effectiveness.

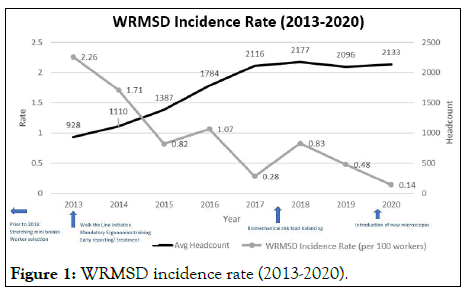

Results: Biomechanical risks from prolonged sewing under the microscope were identified. Programme Components related to work process engineering, worker selection, education and training, and prevention and early intervention were then designed and operationalized in a contextual manner. A sustained decline in the incidence of WRMSDs from 2.26% in 2013 to 0.20% in 2020 was observed.

Conclusion: A multi-component programme guided by a comprehensive risk assessment was successful in reducing ergonomic risks. Critical success factors included active worker participation, sustained management commitment and a strong organizational safety culture. The programme was associated with a reduction in the incidence of musculoskeletal injuries and WRMSDs and may guide the design of future workplace ergonomic interventions.

Industrial ergonomics; Musculoskeletal disorders; Ergonomics programme; Risk assessment and management; Occupational health

Musculoskeletal disorders are painful injuries or disorders of the muscles, nerves, tendons and joints. It is deemed to be workrelated when the performance of work contributes significantly to the condition or where the condition is aggravated due to work [1]. The prevalence of Work-Related Musculoskeletal Disorders (WRMSD) in specific working populations and/or occupational sectors is significantly higher than in the general population [2].

Significant ergonomic risks and a high prevalence of WRMSDs have been reported in industries involving manual sewing. Sewing machine operators adopt awkward work postures for long periods of time while executing high numbers of unvaried tasks which require both speed and repetition [3]. Long working hours [4] and standardized workstations [5] have also been cited as contributory factors for musculoskeletal complaints in the neck, shoulders, hands and wrists [6,7]. Prevalence of physical pain and discomfort arising from work was 95% in a sample of sewing machine operators from Norway [8] and consistently raised in comparison to control groups [6,9] and office workers [9].

A variety of interventions have been suggested in the prevention of WRMSDs in sewers including work rotation, reorganization of work and work duties, change in work processes, stretching and exercise programmes, work station redesign, improved work tools, ergonomics training and education, stress and psychological support programmes and early medical intervention [10-12].

Separately, microscope work has been recognized to be straining both to the visual system and the musculoskeletal system [13]. Operators are forced into an unusual exacting position, with little possibility to move the head or the body. They are often forced to assume an awkward work posture such as the head bent over the eye tubes, the upper part of the body bent forward, the hand reaching high up for a focusing control, or with the wrists bent in an unnatural position [14]. The awkward posture can produce significant muscle contractions, fatigue and pain [13]. Workers using microscopes are hence at risk of injury of the upper extremities, neck and back. In addition, they often perform eye-straining tasks for prolonged periods of time and carry out fine manipulation activities that require the use of flexor and extensor muscles of the fingers and wrist [13]. These repetitive motions may lead to stress injuries and or carpal tunnel syndrome [14].

Ergonomically designed workstations and microscopes have been suggested as preventive strategies [13] Process changes and training programmes to reduce musculoskeletal and visual fatigue have also been reported as possible risk reduction measures [15].

Although previous studies report workplace interventions specific to sewing and microscopic work separately, there has been no study conducted on ergonomic interventions in settings where workers perform prolonged manual sewing under the microscope. More importantly, knowledge about real-world operationalization of evidence-based ergonomic interventions in such workplaces can be valuable and applied to other relevant settings.

This paper reports the design, implementation and evaluation of an integrated multi-component ergonomic intervention programme for the primary prevention of musculoskeletal disorders in a manufacturing facility.

Profile and setting

The facility is a Medical Device (Class III) manufacturer in Singapore, with sister facilities in multiple global locations. The Singapore plant commenced operations in 2005 and its workforce had grown from approximately 900 in 2013 to over 2000 in 2020. One thousand seven hundred worked on the manufacturing line and 300 worked in administrative,support and engineering roles. Eighty percent of the workers were females and 20% were males. The majority of workers were between 20-60 years of age. The factory operated on 2 shifts. The first shift was from 06:30 h to 15:15 h and the second shift from 15:30 h to 00:00 h.

The manufacturing lines were housed within environmentally controlled clean rooms. Each clean room had multiple workstations arranged along long tables. Each workstation had a microscope and local exhaust ventilation beneath the tabletop. Each worker had an assigned workstation. The workers were divided into teams of approximately 12-18 people. The assembly of the heart valve was designated into discrete manufacturing steps which were then grouped together to be performed at different stations. Hence a worker at a single station would perform multiple sewing steps. As the production line was a flow line (i.e., serial/tandem production line), each valve under manufacture was passed from station to station in sequence till completion.

The heart valves were assembled by manual sewing, performed under the microscope and/or magnifying lamps. The workers used straight needles and other sewing tools such as forceps, dental hooks, and scissors. Although sedentary, the job required fine, forceful, precise, and repetitive hand movements, throughout the shift.

Design, implementation and evaluation

With a clear mandate from senior management to mitigate ergonomic risks at the workplace, a team was formed to conduct ergonomics risk assessment, design and prioritize the implementation targeted initiatives, and conduct monitoring and evaluation of intervention effectiveness.

A comprehensive risk assessment was conducted through nonintrusive observations of workers performing different activities along the manufacturing line. A subsequent hands-on trial of the sewing process allowed the team to better appreciate the risks.

Based on the risks identified, programme domains were conceptualized with inputs from the diverse team and workers. Specific interventions under each domain were developed based on evidence in the literature as well as feedback from workers on practical application and contextualisation to the workplace.

The programme components were implemented in phases from 2013. Middle management, supervisors and line workers were briefed on intervention objectives and operational details. Programme related policies and procedures guided and supported implementation. Throughout the implementation phase, active feedback was sought, and a participatory approach was adopted.

Programme effectiveness was quantitatively measured using the annual WRMSD incidence rate. The annual incidence rate tracked all workers that were medically assigned light duties or sickness absence due to work-related musculoskeletal complaints.

Risk assessment

Given that the workers in the company sewed for prolonged durations under microscopes or magnifying lamps, the main ergonomic risks were identified to be:

• Repetitive wrist rotations of both hands with extremes of postures adopted (i.e. Wrist extension, radial and ulnar deviation).

• Tight pinch grip of the heart valve with the non-dominant hand and forceful bilateral pinch grip when tying and fastening knots.

• Sedentary and static body postures as workers are seated throughout work tasks.

• Static positioning of the neck, shoulder, upper arms and back during microscope use.

Multi-component ergonomic intervention programme

A multi-component programme contextualized to meet the operational demands whilst optimizing risk prevention was formulated. The components were categorized into four domains:

• Work process engineering

• Worker selection

• Worker education and training

• Prevention and early intervention

Work process engineering

The Company performed pinch force measurements for the different sewing steps over a sample of the workforce. The average pinch force per sewing step was calculated and steps were subsequently ranked by biomechanical risk levels. Load balancing was performed by re-grouping steps based on biomechanical risk levels, average station duration and sewing step complexity. The intent was to distribute the ergonomic risk as evenly as possible, across the various stations.

Based on the load balancing above, a traffic light system was developed to triage the different sewing stations by biomechanical risk. “Red”, “Yellow” and “Green” signified high, intermediate, and low risk respectively. Each sewing station was categorized accordingly. Each worker was rotated through three different stations per day. Job rotations were planned such that a worker would not be required to work at more than two “Red” stations in a day and not consecutively.

Sharper needles, sewing aids and templates were introduced to reduce musculoskeletal strain on the hands. Customized valve holders were utilized to reduce the need for a tight pinch grip of the non-dominant hand while sewing.

The Company commissioned a bespoke microscope which was designed for greater user comfort. The microscope had several key features, including an adjustable (length, tilt and height) binocular tube, front access for frequently used knobs,and an eyepiece which featured a pupillary aberration control mechanism which allowed the image to remain visible even when the worker’s eyes moved. As the traditional sewing microscope is a stage-less microscope, focusing involved movement of the entire objective mount, which also changed the height of the binocular tubes. This resulted in suboptimal postures, especially in the taller workers. The bespoke microscope introduced a feature that allowed focusing to be achieved while keeping the binocular tubes at their optimally adjusted position.

Worker selection

Job applicants underwent a 3-day work trial where they were assessed for aptitude in sewing, as well as musculoskeletal hand symptoms. This allowed the selection of individuals more adept at sewing and with sufficient hand strength and stamina to meet the sewing demands of the job. It was also used as a functional test for individuals with a history of neck or upper limb injuries to experience line work and improved job match.

Worker education and training

All sewers had to undergo mandatory ergonomics training. The training package was standardized and included an explanation of the ergonomic risks of sewing, seating postures for microscope use, and common ergonomic mistakes made by sewers. The training also included education on signs and symptoms of musculoskeletal disorders of the upper limb, with the intention of promoting early detection and treatment seeking behavior.

Prevention and early intervention

Structured periodic stretch breaks were introduced in the clean room. Stretching exercises led by team leaders were performed four times per shift for approximately three minutes each time. The standardized routine involved stretching of the neck, shoulders, forearms, wrists, hands, and fingers.

Workers were encouraged to report musculoskeletal symptoms early. Supervisors and senior management supported and promoted the early reporting culture. The affected workers would be scheduled to consult a doctor (Occupational Medicine specialist), at the Company’s expense. Subsequent light duties or work restrictions were communicated back to line supervisors and compliance was monitored.

A doctor (Occupational Medicine specialist) visited all the clean rooms once a fortnight where the workers would be observed in production (“Walk-the-Line” initiative). This was opportunity to provide real-time preventive ergonomic advice (e.g., the correction of suboptimal upper limb or seating postures), as well as triage physical complaints for clinic consultation. The frequent and familiar presence of the doctor was a nudge technique used to encourage workers to adopt more optimal postures at work and to reduce barriers to symptom reporting and early treatment.

Programme evaluation

The phased introduction of the ergonomics intervention programme from 2013 to 2020 was associated with a reduction in the WRMSD incidence rate. There was a sustained decline in the incidence of WRMSDs from a rate of 2.26% in 2013 to 0.20% in 2020 (Figure 1). Most frequently reported WRMSDs included carpal tunnel syndrome, De Quervain’s tenosynovitis, epicondylitis (medial and lateral) and trigger fingers.

Figure 1: WRMSD incidence rate (2013-2020).

The phased introduction of an ergonomics intervention programme to mitigate biomechanical risk in workers was associated with the reduction in the incidence rate of WRMSDs. A multi-component programme was required as WRMSDs are multifactorial in nature and multiple contributory risk factors needed to be addressed [16]. The programme thus included elements addressing engineering and administrative controls which has been a consistent approach in addressing ergonomic hazards [17]. The four domains of the intervention programme were subsequently developed, guided by a comprehensive ergonomics risk assessment, which included studying available literature of risks in similar industries, objective quantification of risk through pinch force measurements, workplace observations and worker feedback.

The effectiveness of multi-component ergonomic programmes which are guided by a comprehensive risk assessment has been reiterated in other studies. In a review article, it was recommended that interventions should target individual susceptibility, environmental and work organization factors simultaneously. The most effective interventions were reported to be multiple component initiatives which include engineering, administrative and person-focused interventions. In addition, interventions should be implemented based on injury and hazard surveillance and analysis of the activities to be targeted, as well as on current scientific knowledge [18].

A sustained decline in the incidence of WRMSDs from 2.26% in 2013 to 0.20%

2020 was observed in our study. Comparisons are made with other studies reporting workplace ergonomic interventions within industries involving manual sewing and microscope work. Comparison is not straightforward given heterogenous initiatives, different implementation methods and dissimilar outcomes tracked. Availing literature on ergonomics in industries involving manual sewing are also largely from the developing world where workplace interventions are less common. Nevertheless, similar to our study, there have been reports of successful workplace initiatives in both industries. An ergonomics education programme in a study of 278 sewing machine operators in Ankara was found to reduce scores for exposure to risk factors for WRMSDs [10]. A quasi-experimental study of microscope workers reported observing more ergonomically sound workstations and improved body-positioning after a multi-component ergonomics programme [19].

In our study, upper limb disorders were most frequently reported in keeping with the nature and demands of the job. Although the prevalence of upper limb medical conditions was not reported, the prevalence of musculoskeletal symptoms were highest in the shoulders, wrists and arms among hand-woven shoe workers and sewing machine operators [20,21] In contrast, the most affected site was the neck and the back in microscope workers [22,23]. As the workers in our study were exposed to risks from both manual sewing and microscope work, our interventions were targeted to address all hazards related to both activities.

The success of our programme was facilitated by sustained management commitment for the programme and unambiguous communication of ergonomic goals and efforts to the workforce. Employees at all levels understood the biomechanical risks of the job and were actively engaged in partnership to develop and implement the programme. This approach is consistent with the belief that safety culture is a product of interactions between psychological (people), behaviour (jobs) and situational (organisational) factors [24].

Possible enhancements to the programme include moving upstream on the hierarchy of controls. For example, a trial of automation (through robotics) of a single sewing step has been planned. This could potentially eliminate ergonomic risks associated with production steps requiring considerable pinch forces. However, the transition to complete automation of the entire production line would require continued technological advances and manual sewing is predicted to remain the primary mode of production in the medium term.

The data presented reinforces the impact of a multi-component intervention programme to address biomechanical risks. The programme components described would be relevant in settings where manual sewing and microscopic work feature prominently. There is also a broader application to workplaces where fine, precise, and repetitive upper limb tasks are performed. Contextualized appropriately, programme elements introduced in this paper could improve the physical well-being of workers who face ergonomic risks at the workplace.

This paper describes a multi-component ergonomics intervention programme at a manufacturing facility with biomechanical risk (manual sewing) in the production line. Over a period of eight years, the programme was associated with a sustained decline in WRMSD incidence rates. Programme success was attributed to a multi-component design based on rigorous risk assessment, active worker participation, sustained management commitment and a strong organizational safety culture. This progressive and sustained programme may guide the design of future workplace ergonomic interventions to tackle the growing problem of WRMSDs.

Ethics approval from Saw Swee Hock School of Public Health Departmental Ethics Review Committee had been obtained in accordance with the institution’s research policies and regulations for the study conduct.

Musculoskeletal disorders remain a leading occupational disease and prevalent across a wide-range of industries. A methodological approach from designing to review of a workplace ergonomics programme is reported and useful as reference for organizations planning primary prevention interventions. Workplace ergonomics programmes are most effective when guided by rigorous risk assessment, contextualized and multi-component.

The authors report there are no competing interests to declare.

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

[Cross Ref] [Google scholar] [Pub Med]

Citation: Tan ML, Tong WNG (2022) A Multi-Component Ergonomic Intervention Program for the Prevention of Work-Related Musculoskeletal Disorders. J Ergonomics. 12: 307.

Received: 25-Jul-2022, Manuscript No. JER-22-18547; Editor assigned: 28-Jul-2022, Pre QC No. JER-22-18547 (PQ); Reviewed: 11-Aug-2022, QC No. JER-22-18547; Revised: 18-Aug-2022, Manuscript No. JER-22-18547 (R); Published: 25-Aug-2022 , DOI: 10.35248/2165-7556-22.12.303

Copyright: © 2022 Tan ML, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.