Journal of Thermodynamics & Catalysis

Open Access

ISSN: 2157-7544

ISSN: 2157-7544

Research Article - (2016) Volume 7, Issue 2

This work concerns a second prototype of solar still combined with a heat pump HP. It is characterized by having separated by a partition, the steam generator compartment of the HP from the compartment evaporator (where the condensate is collected). The results of the test measures concern three configurations with HP according to whether the distiller is fixed to the south or constantly oriented to the sun and it is placed outside (in the sun) or inside (no sun). The measurements concerning the water temperatures at the condenser, the wet and ambient air, and the relative humidity. The distillate flow rate is also measured and the energy efficiency and the COP of the HP are evaluated. When the effects of the sun and HP combine to heat the water and then distilling it, we see that the sun contributes to 2/3 due to the HP and the remaining 1/3. In the sun, the heating and therefore the evaporation of water are higher than simply heating the condenser of the HP, which leads to a greater flow of distillate. The solar still can also operate both day and night.

Keywords: Solar energy; Still; Performance; Heat pump; Sea water; Brackish water

Cond: Condenser; Evap: Evaporator; HP: Heat Pump; COP: Coefficient of Performance.

| Cp Lv m mt P Q S T W h ϕ ΔT |

Specific heat water (J.kg-1K-1) Latent heat of evaporation (J.kg-1) Mass of evaporated water per hour (kg) Total mass of the water of the still (kg) Electric power of the compressor (W) Quantity of heat (J) Collect or surface area (m2) Temperature (K) Energy yielded to the compressor (J) Efficiency Solar flux density (W.m-2) Rise in temperature of water (K) |

It is known that the scarcity of water in many countries, especially in tropical countries like North Africa is facing a threat to the mankind. The drinking water need is directly proportional to the population growth. Desalination of sea water is an efficient method of producing drinking water. Desalination or distillation using solar energy is an acceptable method and it is a research area accepted by many scientists which is clear from the work mentioned below. Al Hayek et al. compared two greenhouse type solar stills, one symmetrical and other asymmetrical. He concluded in his results with the remark that the efficiency of the asymmetrical type is 50% more than that of the symmetrical one [1]. Potoglou et al. tested the distillation of the margin in a solar still for staged purpose of asymmetrical greenhouse. The flow of distillate is to the maximum of 1.8 l/m2/d under the best conditions [2]. As for Porta et al. with a still for purpose of greenhouse of 8.3 m2 area, it reaches a flow of 0.115 l/mn, that is to say 6.9 l/h or 0.83 l/m2/h to the maximum [3]. Further, Farid et al. always for a still for purpose of no symmetrical greenhouse, it reaches a flow of 750 ml/h for a 1.5 m2 area [4]. For all these studies, the optimal one the thickness of water to be distilled is located at 2 cm. More recently, Esteban et al. uses a still for purpose of greenhouse provided with a storage tank with hot water [5]. Its production exceeds of 70% the usual still and 20% a coupled still to a solar flat collector. Al-Shammiri et al. studies the influence of salinity on the evaporation of water at various air velocities [6]. As for Slesarenko et al. he made a thermodynamic analysis on the importance of the introduction of a Heat Pump with compression into desalination and showed a going profit on the performances from 2 to 3 [7]. Hawlader et al. in the same way studied the interest of the assistance of a solar still by a heat pump with compression [8]. The efficiency varies from 0.77 to 1.15 and the COP from 5 to 7. It is known that the heat pumps have an unquestionable interest where they are used. They are to some extent amplifiers of energy since their efficiency, named then coefficient of performance, exceeds three. Recently, Liu Cie et al. was created a novel integrated solar desalination system with multi stage evaporation/heat recovery processes [9]. We have already publish, concerning a first model, some papers in international congress and Scientific Journals [10-21]. It is known that heat pumps have some interest where they are used. These are sort of power amplifiers since their efficiency, and then called coefficient of performance exceeds three hundred percent. The extra cost of the HP is amortized by the increased production of distilled water. In remote areas, the power consumption of the HP compressor can be by photovoltaic modules [22-41].

Description

pThe solar still greenhouse type, designed and produced at the university of Gabes, Tunisia (latitude 33.85°, longitude 10.1°), incorporates here a heat pump, used twice: the condenser to heat water and the evaporator to condense the steam produced. Unlike the first prototype where the evaporator is placed in the same compartment as the distiller and the condenser, the evaporator is here isolated by a bulkhead separating this compartment (Figures 1 and 2). The dimensions (length, width and depth) of the prototype are of one meter. The walls are made of wood doubled with polystyrene. The glazing is constituted by double polycarbonate.

Computation of the sizes formulae

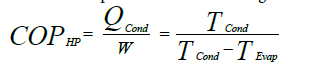

Coefficient of performance concerning the Heat Pump:

(1)

(1)

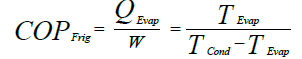

Coefficient of performance concerning the refrigerating part:

(2)

(2)

Solar flux:

Φ=ϕ. S (3)

- Latent heat of water evaporation:

QLV= Lv.M (4)

Sensible heat of water:

Qwater= m.Cp. ΔT (5)

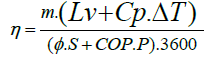

Energetic efficiency of the still with an integrated heat pump:

We will hold account of incidental solar energy and the thermal power consumed by the condenser.

(6)

(6)

S: absorption surface [0.4 m2]

P: compressor power=200 watts

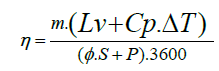

Efficacy of the still combined with the heat pump:

Here, it will hold account of the incidental solar radiation and the electric power consumed by the compressor.

Preamble: Parameters test: Testing configurations in the sun:

Fixed position (0) or variable (1)

Without heat pump (0) or with hp (1)

With another configuration: inside (away from the sun or at night)

The temperatures are measured by sounds except for the interior humid air where a mercury thermometer is used, accuracy ± 0.5°C.

The quantity of distilled water is measured by using a graduated test-tube. The Solar flux is calculated according to the amperic model of Brichambault, which is very similar to the pyranometer measurements (Ben Slama).

In absence of sunlight (inside):

Evolution of the temperatures: without solar heating, the heating by the condenser has to raise the water temperature from 25 to 48°C end of five operating hours (Figure 3).

Relative hygrometry: Figure 4 shows the changes in the humidity of moist air inside the distiller versus time.

Despite the evaporation of water from the distiller by the heat from the condenser of the heat pump, humidity does not rise too much. This is due to the fast condensation of the water vapor produced to the level of the evaporator of the HP, thereby forming dew surface.

Distillate flow rate obtained: The hourly flow rate obtained is shown in Figure 5. In the morning, the setting sun of the distiller does not allow to raise enough water temperature and thus its evaporation. It was only after a few hours of sunshine we begin to collect the distillate. Indeed, for negative temperatures of the evaporator, it is covered with ice, avoiding the distillate collection.

Evolution of the COPHP: Figure 6 shows the variation of the COPHP versus true solar time. The values of the COPHP calculated starting from the temperatures of the condenser and the evaporator are theoretical; actually they are to be divided by two.

Energetic efficiency: The curve of the energetic efficiency (Figure 7) follows the same pattern as that of the distillate production flow. Being weak, because it is taken account here of all the heat yielded by the condenser and not only of the electric power consumed by the compressor.

Distiller placed at the sun, orientation towards the south, (configuration 01): Here the distiller is constantly oriented to the south.

Evolution of the temperatures: With the sun, even without tracking, the temperatures increase by ten degrees compared to the tests inside profiting for the heating only from the heat yielded by the condenser. It is the same for the temperatures on the level of the evaporator (Figure 8).

Relative hygrometry: With the sun, even without tracking, evaporation is significant (more 20% compared to the inside), so that even by having a fast condensation of the vapor, moisture remains high. It may be that it would be interesting to add a ventilator to activate the wet air flow towards the evaporator of the heat pump (Figure 9).

Distillate flow rate obtained: With the sun, even without tracking, the flow rate of the distillate passes from 160 to 600 ml/h/m2 compared to an interior site of the distiller, that is to say a daily output of 4 liters approximately. At the beginning, by negative temperature, this one overlaps with ice (Figure 10).

Evolution of the COPHP: In the same way, the COP is higher than without sun (Figure 11).

Energetic efficiency: The energetic efficiency passes approximately from 18 to 30% under an exposure to the sun, even without continuation (Figure 12). The flow rate of distillate reaches its maximum (700 ml/h/ m2) at 14 h (Figure 10) because of the increase of the brackish water temperature which reaches its maximum (61.5°C) per same TST hour 14 h (Figure 8). The various performances are definitely better for an exposure to the sun than with the shelter of the sun, where only the condenser of the Heat Pump heats water to be evaporated.

Distiller constantly directed towards the sun (conf. 11): Here the distiller is constantly tracking the position of the sun.

Evolution of the temperatures: While placing the distiller at the sun, with in more the tracking, the temperature goes up more quickly and is stabilized until the end of the day, contrary to a fixed orientation towards the south (Figure 13).

Relative hygrometry: The hygrometry is raised and remains in the same order of magnitude as for the configuration with fixed position and southern orientation (Figure 14).

Distillate flow rate obtained: The production of distillate is quickly stabilized, practically since 10 H up to 17 H, due to the continuation of the sun (Figure 15). After midday, the flow could be higher if salinity is maintained constant by the evaporated water addition. The daily output of distillate is four liters approximately.

Evolution of the COPHP: It is given here by to the measured temperatures on the condenser and the evaporator levels. The theoretical thermal COP remained almost constant with a value of 7 (Figure 16).

Energetic efficiency: The energetic efficiency tends towards an asymptote of 35% in the same way that the configuration with fixed position (Figure 17). It is true that the production of distiller is more significant but incidental solar energy also, with the result that the energetic efficiency is not varied. The performances reached for the configuration with tracking of the sun appear to be comparable with the configuration without continuation, since by having a lower ambient temperature the thermal losses are more significant. Therefore under identical climatic conditions, the tracking of the sun will make it possible to the distiller to be more productive.

However, the tracking of the sun made it possible to reach the same performances as with the fixed position, but with a profit rather the morning and later after midday. The flow rate of distillate reaches its maximum (600 ml/h/m2) with 13 h (Figure 15), because of the successive increase in the temperature of the brackish water which reaches its maximum (63°C) per same hour (Figure 13).

Comparison between the three configurations: After having made all the tests, we are brought to make a comparison between the various configurations (00, 01, 11) to identify that which is most profitable and effective in practice.

Temperature of heated water: The values of water heating temperature of differ from one configuration to another. With the shelter of the sun (conf.00), the temperature is low, at the sun with a position fixes (conf.01) it is higher but thus varies with time with the height of sun, whereas if the distiller follows the sun (conf.11) the temperature increases the morning more quickly and preserves this value until the end of the day. This result confirms the positive effect of the tracking of the sun compared to the fixed orientation of the distiller (Figure 18).

Relative hygrometry: With the sun, the distiller contains more moisture because the evaporation of water to be distilled is activated jointly by the condenser of the HP and the solar radiation (Figure 19).

Distillate flow rate obtained: It is true to note that with configuration 11, with tracking of the sun, evaporation is more significant at the end of the day, which explains the increase in relative moisture due to the evaporation of water (Figure 20). We see that the flow rate varies from one configuration to another, consequently the great water mass is obtained while tracking the sun (conf.11) although the maximum value of flow relates to configuration (01) for external reasons of parameters (higher ambient temperature with the configuration (01) than with configuration (11). With the tracking of the sun, the flow rate of distillate is higher early the morning because the distiller is directed better to collect the solar radiation. At the end of the day, water thus becomes more brackish and difficult to vaporize.

COPHP: It is that the coefficient of performance is better for the configuration (01) than for the two other configurations because the variation in temperature between the two sources cold and hot is less low (Figure 21).

Energetic efficiency: The energetic efficiency follows practically the same pattern as that of the flow of produced distillate (Figure 22). The fluctuations are due to the same reasons. The energetic efficiency is improved by the use of the CAP in the same way that the flow (triple).

Efficacy: Without taking account of the COP for the heat yielded to the level of the condenser and by taking account only of the electric power consumed by the compressor and of incidental solar flux, the concept of effectiveness gives a new result (Figure 23).

Influence of brackish water thickness: The thicknesses of brackish water used are: 5 cm, 3 cm, 2.5 cm and 2 cm. According to Figure 24, it is clear to see the difference between the curves load to various thicknesses from brackish water at the entry, the maximum value of flow (1000 ml/ m2) is obtained with a 2 cm thickness, whereas with other thicknesses (2.5 cm, 3 cm and 5 cm) the flow of distillate decreases gradually.

The flow of distillate and the energetic efficiency can be improved by adding a ventilator which drives back the humid air towards the evaporator of the heat pump. The first prototype reaches better performances because its surface of collecting is more significant enabling him to reach higher temperatures than the second prototype and thus evaporate more water. To be compared, the two prototypes must have the same dimensions, design and constitution (Table 1).

| 1st prototype |

2nd prototype | |||

|---|---|---|---|---|

| Inside (configuration 00) |

Distiller placed at the sun, orientation towards the south:(configuration 01) | Constantly directed towards the sun(configuration 11) | ||

| Water Temperature(°C) Ambient Temperat.(°C) Wet air Temperat. (°C) Evaporator Temper. (°C) Eelative Hygrometry (%) Distillate Flow (ml/h/m2) Efficiency COP Solar Flux(W/m2) |

80 40 60 30 20 1200 0.7 6 700 |

48 25 28 0 65 170 0.18 6.5 * |

62 30 30 15 80 600 0.32 8 700 |

62 27 50 15 90 600 0.3 7 700 |

Table 1: Comparison between the Prototypes.

The second constructed prototype, object of this article, is distinguished compared to the precedent prototype by insulation from the compartment evaporator from the condenser by an insulating partition. Thus the thermal transfer between the two compartments is tiny room in favour of the transfer of matter (wet air flow, aspired by the evaporator of the Heat Pump which condenses the water vapor contained in the humid air). This transfer can be improved, in the future, by the addition of a small ventilator to activate the wet air circulation towards the evaporator.

The produced water vapor condenses on the evaporator and keeps the internal surface of the glazing transparent, without mist. By comparing the three configurations tested, it is logical to note that with a tracker system of the sun, we gains over time as well very early the morning as in end according to midday. The temperatures reached for distillation in presence and absence of sun is respectively 60 and 46°C. Moisture is also higher in the presence of sun. The distillate flow rate is three to four times more significant in the presence of sun than in the shade. However, even in absence of sun (the night) the production of distilled water by the heating due to the Heat Pump can continue (configuration 00), but with a less productivity (the third) and half for the energetic efficiency. With the assistance of the heat pimp, the solar still can operate both day and night to produce fresh water.