Advances in Automobile Engineering

Open Access

ISSN: 2167-7670

ISSN: 2167-7670

Research Article - (2017) Volume 6, Issue 1

The article presents contemporary ultrasonic methods that can be applied to evaluate the quality of transmission drive components of motor vehicles. The issues of non-destructive analysis of discontinuities in manufactured drive shafts, consisting currently of thin-walled tubes, were investigated in this study. The driveshaft elements were joined by using innovative method called Magnetically Impelled Arc Butt Welding (MIAB). For many years, a major challenge for engineers working with ultrasonic techniques was joining of thin-walled components (having thickness below 3 mm). In addition of this limitation, the problem of variable geometry of the weld flash on the weld perimeter was highlighted. To reduce the impact of mentioned factors the pseudo-surface waves (also known as lateral waves) have been applied in this study. In order to select optimal parameters of the ultrasonic beam propagation and to understand the physical-acoustic phenomena, the Finite Elements Method modelling was performed. The phenomena of wave transformation on medium boundary and reflections from artificial flaw have been analyzed by numerical modelling.

The results of numerical analysis were confirmed by UT experimental research. The manufactured MIAB welded joints were tested with using in-house made experiment set-up. The selected configurations with various shapes and dimensions of samples, and various process parameters have been investigated. The results confirm the usefulness of pseudo-surface ultrasonic waves in UT quality evaluation of MIAB welded elements of drive shafts of motor vehicles.

<Keywords: Magnetically impelled arc but welding (MIAB); Nondestructive testing (NDT); Ultrasonic testing (UT); Sub-surface wave; Ultrasonic wave propagation

Magnetically Impelled Arc Butt (MIAB) welding is a novel technology for the manufacture of butt joints in the automotive industry, especially thin-walled circular cross-section components. The heat required to achieve the plastic state of front surfaces of components is obtained as a result of an electrical arc, which is forced to rotate by an external magnetic field. This field may be generated by the use of coils (or permanent magnets), which at the same time control the current flow, allowing smooth control of the welding process [1]. The rotating electric arc reaches speeds of up to 200 m/s, which enables plasticizing the edge of the bonded components evenly [2-4]. The idea of MIAB technology is presented in (Figure 1) [3-6].

The automotive industry, like any other rapidly growing industry, seeks to minimize costs while improving the quality of manufactured components. One of the basic directions of development in the manufacture of drive shafts is to minimize the weight of the product. This in turn results in using increasingly thinner walls of tubes used in the manufacture of these elements. In the case of the analyzed transmission components, wall thickness of the pipes was reduced to below 3 mm (in many cases even 1.5 mm) [5]. The characteristics of the MIAB welding process makes this technology fit very well in the current trends in the automotive industry, where through the use of materials with increased strength and reduced thickness, the aim is to reduce the unsprung weight of vehicles. That is the major reason for the leaders of the automotive sector, specializing in the manufacture of driveline components to decide in recent years to change the butt bonding technology for thinner components from friction welding to MIAB welding.

Apart from the economic benefits of these actions, it should be remembered that ensuring the safety of vehicle design remains a priority. In a situation where the thickness of bonded elements is reduced, the need to ensure the quality of manufactured items becomes all the more important. The risk of technological incompatibilities greatly reduces the effective cross-section of the weld, which clearly limits its strength ratios. Analysis of the correctness of the welds can be divided into two main groups: the control of process parameters during the welding and testing of ready joints. Procedures for the welded joints are usually the result of a company’s experience and the arrangements with the client.

Analyzing the current quality control procedures for the manufactured joints, it is well-known that Destructive Testing (DT) predominate. It therefore seems reasonable to use Non-Destructive Testing (NDT), especially ultrasonic, which have for many years been used in the production of motor vehicles [7-9]. The possibility of using the component after non-destructive testing (including ultrasonic testing) in the further stages of production process, high repeatability and efficiency makes the NDT desirable to use them at almost every stage of production. Destructive methods (eg. metallographic examination, bending and tensile strength tests) cause the scrapping of the examined components which generates high costs for the manufacturer. In relation to other non-destructive testing techniques (e.g. radiographic, magnetic particle, liquid penetrant), the ultrasonic method does not affect to the natural environment and do not require any special protection for operator against, e.g. X-ray radiation.

Currently, these mainly include applications related to the inspection of spot welds [10-13] and adhesive joints [13-18]. Due to the uncomplicated design of these joints and relatively easy access to the test surfaces, longitudinal wave, which is not transformed, is most commonly used. The presence of flashes on the surfaces of MIAB welds (as well as friction welds) significantly limits the application of the wave perpendicular to the surface of the weld, where the energy is dispersed on the surface of the flash. MIAB weld joints are usually not further processed, as even in incidental cases of uneven flash, possible problems related to the beating are eliminated during the balancing process. One of the methods to circumvent this limitation is to use pseudo surface (quasi subsurface) waves, sometimes known as a lateral. According to many theories [19,20], that kind of wave is associated with the phenomena of interference and dissipation of energy in the propagation media. As a result of the above phenomena, according to the laws of geometric acoustic, pressure distribution of the reflected wave changes, and the pressure reflectance decreases rapidly as a result. At the water-air interface, this corresponds to an angle of approx. 31.5° compared to normal [21].

border of media with different physical parameters in ultrasonic immersion measurement, it can be assumed that the propagation of transverse waves is not possible in liquid - only the longitudinal wave reflects from the interface of media. In the case when the speed of the incident wave in a liquid is less than the speed of both waves broken in solids, it is possible that there are three critical angles: θ ',θ ",θ "".

Angle values can be calculated on the basis of Snell’s law:

where:

cT – Ultrasonic wave velocity in liquids,

cT– Transverse wave velocity in solids,

cR– Longitudinal wave velocity in solids,

cR– Rayleigh surface wave velocity.

Each critical angle corresponds to a special case of the full internal reflection when movement propagation goes along the border. Then, as a result of the superposition of volume and surface components, heterogeneous waves are formed along the border, known as leaky waves. Leaky subsurface waves are also called LCR waves, frontal, lateral or crawling, since their propagation is associated with an energy flow in a tangential direction to the plane of the interface [22-25].

As a result of the occurrence of attenuation and interference (limited by the beam width), according to the laws of geometric acoustics, the pressure distribution of the reflected beam changes, and as a result the pressure reflectance decreases rapidly (Figure 2) [22-24]. The mathematical model proposed by Becker-Richardson [23] and Bertoni-Tamir [24] supplements with high accuracy the imperfections of the pressure ratio of wave reflection by Schoch theory within the range of angles.

The sharp decline in reflectance in the area of the third critical angle corresponds to the generation of subsurface wave – the energy is not reflected, but propagates in the solid medium.

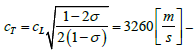

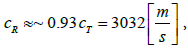

Knowing the parameters characterizing the media (water - steel), i.e.

Knowing the parameters characterizing the media (water - steel), i.e.

speed of the transverse wave in steel:  the calculated value for Poisson’s ratio σ = 0.28 ,

the calculated value for Poisson’s ratio σ = 0.28 ,

Rayleigh surface wave speed for:

we can define a third critical angle, which is 31.5°.

Non-destructive analysis involved selected drive shafts of 3 sections: the tube, the left tip (body or complete joint) and the right tip (stubshaft, i.e. the shaft end - stub shaft) (Figure 3). During the welding process, the two ends are welded to the pipe at the same time. Depending on their type, the components are usually fitted with special 3-jaw chucks or hydraulic slide mechanisms.

The development of a modern and effective system to study the resulting joints requires the use of numerical methods for optimal selection of research parameters and the constituent components of the test station. Proper visualization and a better understanding of the phenomena associated with the propagation of ultrasonic waves in the joints are possible with the finite element method.

As part of the analyses, the most important parameters of nondestructive testing were chosen and verified e.g. the angle of the ultrasonic beam, the frequency of the transducer and the focal length.

Simulations were performed in the LS-DYNA program. This program is used primarily in the automotive, construction and aviation sectors, as it allows e.g. analyzing the dynamic phenomena with the finite element method.

All simulations were performed for the same dimensions of the weld joint, that is, a steel pipe with a wall thickness of 1.6 mm with a stubshaft. The ultrasound head was modeled as a spherical surface that generates a mechanical wave. It adheres to the coupling element in the form of a “wedge” with the properties of a water delay line. The spherical contact surface between the sensor and the coupling element initiates an ultrasonic wave with focused beam geometry, the focus of which is on the surface of the test piece (tube).

As previously shown, the beam’s angle of incidence is equal to the third critical angle. This allows generating the desired subsurface wave in the tested material through the phenomenon of transformation at the media interface.

The selection of the transducer center frequency is based on previous empirical experiments determining the depth of subsurface wave penetration in the material tested. It is imperative that a wave created in the tested material (pipe) includes the entire thickness to ensure maximum detection of imperfections, and therefore, a limit value of 10 MHz was applied.

Ensuring appropriate conditions for the simulation required selecting the right size of the finite element mesh and time step. When selecting these parameters, the natural transducer frequency was taken into account (fmax=20 MHz), as was the speed of wave propagation in the medium (cmax=7000 m/s). Discretization of the model is constructed taking into account these factors. For unambiguous interpretation of the results, this means that the size of the mesh element should represent significantly less than 50% of the wavelength (λmin=0.35 mm), so for the correct interpretation of the results, element size of Δx=0.05 mm was assumed. Likewise, for the sake of clarity of the results, a maximum time step should not exceed Δtmax=5 ns, which results from the general theory of sampling signals.

Figure 4 shows the discrete FEM 2D model of the major components of the measurement system. The model consists of a MIAB-welded test joint. In addition, the test piece adjoins a coupling layer, wherein the ultrasonic wave beam is formed.

The actual measurement of the quality of the welds was performed using an ultrasonic transducer oriented at an angle of 31.5° and perpendicular to the water/steel interface. Tests were performed using the non-contact, immersion, method, where the coupling agent was water. Figure 5 shows a diagram of orientation of the ultrasonic transducer relative to the test weld.

For joints without flashes, it would be possible to use the incident wave perpendicular to the interface between the media (water-steel). Figure 6 shows the schematic signals from the transducer mounted at an angle of 0° to normal in case of weld with flash (Figure 6a) and without flash: when the weld is correct (free of defects, Figure 6b) and when the weld has a defect (Figure 6c). In such case, during the measurement, the ultrasonic transducer (labelled PP1, Figure 5) sends a short pulse oriented perpendicular to the tested weld. For welds without flaws (Figure 6b), the measurement window records reflections from the water-steel and the steel-air interfaces. When there is a discontinuity in the weld (Figure 6c), the measuring window shows an impulse, which indicates a lack of joint continuity. It should be noted that the measurement using a transducer oriented perpendicular to the surface of the test item is useful only when the weld area is free of flashes. In view of the presence of flashes (Figure 6a), very common in MIAB, which dissipates the greater part of the wave energy, the use perpendicular ultrasonic wave is of limited use.

Measurement using transducers arranged obliquely relative to the plane of the weld is schematically illustrated in Figure 7. A precise angle of wave incidence on the water-steel interface guarantees the creation of subsurface waves in the test piece (angle of 31.5° calculated and empirically confirmed using numerical analysis). Figure 7a shows the transmitted waveform, and Figure 7b shows the wave received by the ultrasonic transducer.

The focused ultrasonic wave (1) generated by the angled transducer (labelled PP2, Figure 5) falls on the surface of the workpiece measured outside the joint. Part of the transmitted wave (2) is reflected from the outer surface; some of it, however, penetrates the material where it refracts (3) and propagates inside it as a wave guided in the material (the so-called subsurface wave). The angles of mounting of the transducers are selected so that you can observe the weld area in a wide range (much greater than its width) and make the most of the transformation from longitudinal wave to subsurface wave (3). If the weld has a defect (4), this will create an additional reflection echo, which goes back to the acoustic transmitter the same way (5, 6).

A study on the quality of MIAB welds found in the elements of the transmission system (drive shafts and axle shafts) were performed in a laboratory equipped with a universal scanner with ultrasonic focusing transducer with the frequency F = 21mm and focus of F = 21mm , focal diameter Fz ≈ 6.1mm , and its length Fz ≈ 6.1mm. During the scan of a test piece, the transducer was set at an angle of α = 31.5°which guaranteed a subsurface wave is generated in the test piece. The ultrasonic beam was focused on the surface of the pipe at a distance of h ≈ 4mm from the flash. After passing through the focal point, the wave is dispersed and refracted at the air-steel interface; it then moves inside the steel along the surface of the drive shaft parallel to the axis of rotation. Since the system is in its testing phase, artificial defects (cuts) were made and then tested to explore the possibility of detection of defects in the delivered items. Figure 8 shows a view of a laboratory testing station to test MIAB weld joints.

Numerical analysis

A quality inspection for thin-walled welded steel (g < 3 mm) requires special methods that are not standardized. Due to the small wall thickness of the test pieces (1.5-3 mm) and the relatively complex geometries of stubshafts, non-destructive testing using ultrasonic techniques is a challenge of a very high degree of difficulty.

The first stage of research was to conduct a series of numerical simulations, which allowed optimizing the parameters of the model (the size of the finite elements, time step) and the operating parameters of the ultrasonic waves (angle of wave introduction, the diameter of the transducer). Numerical calculations are then carried out for an optimized model in two cases: joints with incompatibilities and joints without them. The test results shown herein present the possibility of using a subsurface wave to detect the discontinuity in MIAB welds.

Fig. 9. shows the results of ultrasonic wave propagation in the considered configuration of the measuring system. This is the case for a uniform welded joint in selected stages of wave propagation in the tested media. The time of the ultrasonic wave front propagation (t1 = 2.9 μs) is calculated from the moment it appears on the spherical surface of the transducer (Figure 9). With the right shape of said surface, a trend can be observed, where wave beam tends to focus. The distance from the transducer to the test piece has been chosen so as to focus the ultrasonic wave beam on the surface of the material.

After the time t1 = 6.39 μs (Figure 10) has passed, the propagating ultrasound wave is transformed to a subsurface wave. The wave front moves further in the tested material.

The front of the ultrasonic wave reaches the location of the MIAB weld joint after 12.39 microseconds (Figure 11). For homogenous welds, the wave passes through the joint without clear backward refraction. However, due to the irregular shape of the joint, some signal scattering can be seen on the walls of the flash, which causes noise in the registered A-scan signal (Figure 11 blue). This allows to assume the necessity of proper calibration of the actual measurement system to eliminate the risk of errors associated with the deceptive indication derived from the irregular geometry of the joint.

Figure 12 shows an example of simulated defect in the MIAB weld joint. The presented example is a discontinuity having a size of 1 x 0.1 mm. The visible front of the ultrasonic wave propagates in the material with numerous places of wave concentration, resulting from the multiple reflections from the surfaces of the test material, as well as their mutual interference.

Figure 13 shows the results of numerical simulations for a joint model with an internal defect, and for a homogeneous joint (free of defects). The results showed that for the final adopted conditions of simulation (the angle of 31.5° and a UT wave beam with focused geometry) we can clearly detect non-compliance in the welded joint. For other angles of beam incidence, satisfactory results were not achieved as to the detection of imperfections.

Numerical simulations have allowed to pre-select and verify the designated analytical parameters of ultrasonic testing. This allowed to significantly reduce the number of performed experiments and enabled a better knowledge and understanding of the phenomena of the propagation of subsurface ultrasonic waves while testing MIAB welded joints.

Non-destructive ultrasonic testing

Apparatus for testing friction welds in the transmission elements made using MIAB welding use subsurface waves propagating along the walls of the test tube parallel to its axis. In the case of defect-free pieces, the ultrasonic pulse generated by transducer excitation is reflected only on the flash and produces a response characteristic of the item type, which depends on the geometry of the measurement system and the measured item. Any deviation from the reference measurement may be regarded as reflection or scattering of the ultrasonic beam from a defect or deviation in the shape of the tube geometry. The ultrasonic beam from a transducer in the measuring head is focused in a controlled manner so as to detect defects of an approximately circular cross section whose diameter is not less than 0.2 mm. Tests were carried out using the station shown in Figure 8. During a full rotation of the piece, A-scan presentations were recorded, that in a software made up the two-dimensional image, i.e. B-scan presentations.

Figure 14 shows the actual results of ultrasonic measurement (i.e. A-scans) of the MIAB welded tubes by means of a transducer oriented relative to the weld at an angle of 0°.

The results obtained from measurements indicate that MIAB joints with a flash, the use of the incident wave perpendicular to the surface is of limited use. In the present case, reflection wave pulses, indicating the presence of defects in the test joint, were not observed in the entire perimeter of the weld. It should be noted that the irregular shape of the joint makes the incident ultrasonic wave considerably dispersed, hence the energy of the reflected wave, returning to the transducer is relatively small, and even in the presence of defect in the joint it is very difficult to detect it.

Figure 15 shows a view of the presentation of the A-scan of a transducer oriented at an angle of 31.5° in the case of detecting two discontinuities at the weld periphery.

Different time, after which the sent impulse is registered by the receiver is due to the location of defect. In the case shown in Figure 15a there is no welding on the pipe oriented closer to the transducer; Figure 15b - further away.

Figure 16 shows the B-scan presentation of ultrasonic signal obtained through rotating the pipe by 360o. In contrast to the A-scan presentation, a B-scan presentation allows for the analysis of test results around the circumference of a single two-dimensional image.

Presented in the form of A-scan and B-scan presentation, the results of ultrasonic testing of MIAB welded joints indicate their possible practical application in actual manufacturing systems. In terms of industrial practice, the presented visualization process is not advantageous for analysis since it requires a large knowledge of physical and acoustic phenomena that occur during ultrasonic wave propagation in the tested MIAB welded pieces. Therefore, the intended operator interface should consist of a simplified visualization method for the detected defects (e.g. green - OK, red NOK).

The main objective of this study was to verify the usefulness of ultrasound to assess the quality of MIAB welded joints. As part of the work undertaken, we made a series of numerical and experimental studies that clearly demonstrated the efficacy of these methods. On the basis of simulation and analysis of the experimental results, one may draw the following conclusions:

1. The possibility to use ultrasonic subsurface waves for testing thin-walled components was demonstrated, and their use in the pieces of tubular section allows for detection of MIAB joints.

2. The orientation of the ultrasound transducer at the third critical angle (31.5° for low-carbon steel) enables the transformation of a longitudinal wave to a subsurface wave, and thus provides the opportunity to study friction welds and MIAB welds without removing the flash.

3. The use of numerical methods can serve as a tool to assist the selection of appropriate parameters of ultrasonic testing. With custommade numerical calculations, the appropriate parameters of the ultrasonic transducer (frequency, size) and the angle of the ultrasonic wave beam were selected to ensure the highest detection of noncompliances in the MIAB joint, as well as to provide the best noisesignal ratio.

4. The simulations allow for a better understanding of the research process and the method of wave propagation in bonded joints, thus providing a precise interpretation of the results from tests on actual objects.

5. The conducted numerical analyses were confirmed by ultrasonic inspection in the laboratory.

Ultrasonic testing of thin-walled tubular elements such as drive shafts and axle shafts are a challenge for designers, constructors and scientists. The test results are an important addition to this narrow area of technology.

This paper is part of the project “The criteria and methodology for determining the quality of Magnetically Impelled Arc Butt welding joints” co-financed by the National Centre for Research and Development (NCBR, Poland) under the 3rd Program of Applied Research.