Journal of Geology & Geophysics

Open Access

ISSN: 2381-8719

ISSN: 2381-8719

Research - (2024)Volume 13, Issue 1

As a result of the development of deep-lying deposits, additional volumes of gas and gasoline can be extracted from fields with declining production, and new production methods can be introduced. New methods of intensifying production are required when well productivity decreases during the development of gas condensate fields. Deep- lying deposits can be increased by Hydraulic Fracturing (HF), which can be considered one of the main methods of improving well productivity. To maintain reservoir rock flow characteristics and create large fractures with high permeability, hydraulic fracturing is essential for low-permeability deep deposits. As part of this work and for the development of deep deposits with low permeability, Multi-Stage Hydraulic Fracturing (MSFH) is used as the most effective technique for intensifying gas and condensate production. There were two types of hydraulic fracturing processes used: Large-volume hydraulic fracturing, where 300 tons of proppant were injected, and HiWay hydraulic fracturing, where 200 tons of proppant were injected. According to the study, HiWay technology significantly reduces the proppant required to secure hydraulic fractures, by less than 38.5% compared with high-volume technology. A 2.5-fold increase in flow rate is observed at the wells of the deep-lying deposits of the studied field after these geological and technical measures are carried out, and the hydraulic fracturing effect lasts for three years.

Multi-Stage Hydraulic Fracturing (MSFH); Deep-lying deposits; Low-permeability; Proppants; HiWay technology

Developing new technologies for intensifying reservoir fluid inflows and well completion is one of the main ways to maintain profitable levels of oil and gas production [1-4].

To carry out successful stimulation of inflow in the studied hydrocarbon field from low-permeability reservoir rocks, the technology of Multi-Stage Hydraulic Fracturing (MSHF) is used, which is carried out when completing horizontal and directional wells. In practice, two types of multi-stage hydraulic fracturing are used; the first type of Hydraulic Fracturing (HF) is carried out using the technology of lowering packer assemblies [5-9].

When using the first hydraulic fracturing technology, a special device is lowered into the well, which performs multiple fracturing of the formation in the horizontal, cemented part of the column, which leads to an influx of hydrocarbons from the productive formation.

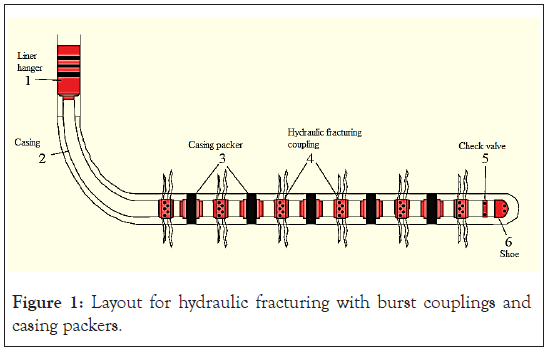

When using the second hydraulic fracturing method, an assembly equipped with burst couplings and casing packers is lowered into a horizontal section of the wellbore to separate hydraulic fracturing intervals (Figure 1).

Figure 1: Layout for hydraulic fracturing with burst couplings and casing packers.

As hydraulic fracturing fluid is pumped, soluble balls of a specified diameter are introduced (starting at the minimum diameter), which, when seated in the saddles of rupture couplings, open them so they can communicate with the productive formation and perform hydraulic fracturing.

In order to activate the next burst sleeve opposite the next hydraulic fracturing interval after the first stage of hydraulic fracturing, a soluble ball with the smallest diameter is introduced into the liquid. As a result of repeated release of balls of various diameters, all rupture couplings are activated, and the planned multi-stage hydraulic fracturing in the horizontal section of the well is ensured [10-13].

A multi-stage hydraulic fracturing method is employed in the hydrocarbon field under consideration, consisting of three to seven stages, which create fracture systems to increase hydrocarbon flow.

As a result of the development of deep-lying deposits, it is possible to extract additional volumes of hydrocarbons from gas fields during a period of declining production, as well as implement strategies to introduce new methods for increasing the production of oil, gas and condensate [14-17]. In the studied oil and gas condensate field, the oil and gas content of productive formations is determined from Cenomanian to Lower Jurassic deposits. In the deep-lying deposits of this field, there are oil rims along the edges of these deposits.

Geological exploration data indicate that the layers of these deposits have a lens-shaped discontinuous distribution. These layers were formed under conditions of avalanche sedimentation and represent fondomorphic parts of the Valanginian clinoform complexes [18-21].

In the deposit field, there are a number of bearing formations that developed and are located at different locations, A1-2, A3-4, A4, and A5. The highest productivity and largest size are found in the productive formations A3-4 and A5. Average gas condensate flow rates in various modes in many wells vary from 300 to 400 thousand m3/day.

The studied deposits are one of the most complex geological objects. These deposits have very low reservoir properties. Permeability ranges from 1.0 × 10-3 µm2 to 10.0 × 10-3 µm2, porosity ranges from 0.16 to 0.20, and there are fractured and porous-fractured types of reservoirs [22-25].

The sandy-shaly deposits of the studied field are everywhere overlain by Lower Valanginian clays and mudstones of considerable thickness, which ranges from 150 m to 300 m. The development of the field began in 2013, and the gas condensate deposits of the A3-4 and A5 formations became the priority development targets. The A1, A2, and A6 formations are secondary objects of exploitation due to insufficient knowledge and will be developed at a later stage of the field development.

Within the studied field, in the section of the deep-lying deposits, four oil and gas condensate objects have been identified: The first object is a group of formations A1 and A2, the second object is the A3-4 formation, the third object is the A5 formation, the fourth object is the A6 formation [26-29].

It is recommended to drill three types of wells in order to contribute to the development of the studied field's deposits:Vertical wells, S-shaped wells, and sub-horizontal wells. It is 4,194 m deep for wells with an S-shaped profile, and 4,517 m for those with a sub-horizontal profile [30-33].

In BU10–BU16 formations, the reservoir pressures are not compatible with the simultaneous opening of the layers of the studied deposits, since the anomaly coefficient in the studied deposits is 1.66, while the anomaly coefficient in the overlying strata is not more than 1.15, requiring the liner to be run at intervals of 3,490 m up to 3,770 m and 3,904 m to 4,194 m. For sub-horizontal wells, the liner is run in intervals from 3,430 m to 3,740 m and from 3,782 m to 4,517 m.

The liner is run to isolate and develop productive formations. In order to suspend the tubing string and seal the annulus at the head of the liner, a suspension device with packers is used. The liner is secured with cement mortar in vertical wells with an S-shaped profile along the entire length. In sub-horizontal wells, the liner is cemented from the top of the productive formation to the liner hanger.

Production casing is lowered to cover Neocomian sediment layers (BU) and transitional unstable zones with anomaly coefficients of up to 1.15.

The casing depth is assumed to be 3,580 m vertically, 4,004 m along the wellbore for S-shaped wells, and 3,530 m vertically and 3,937 m along the wellbore for sub-horizontal wells (Figures 2 and 3) [34-37].

Figure 2: Profile of an S-shaped production well.

Figure 3: Profile of a production sub-horizontal well.

In the interval of Cenomanian deposits at a depth of 1,400 to 2,200 m, absorption of drilling fluid is possible during the drilling of a well; this is prevented and eliminated by lowering an intermediate column, while geophysical investigations (well logging) can still be conducted there. The distance between the bottoms of production wells in production areas varies between 1,200 m and 1,700 m depending on the distribution of gas-saturated thicknesses in the deposits.

The development of deep-lying studied deposits makes it possible to produce additional volumes of gas and condensate from fields that have entered the stage of declining production. These deposits can be classified as hard-to-recover reserves. For their successful development, the method of intensifying the influx of hydrocarbons through hydraulic fracturing should be used, which provides an effective process for extracting hydrocarbons from a low-permeability reservoir [38-41].

Hydraulic Fracturing (RF) can increase efficiency significantly when it is utilized as the primary method of field development rather than just for individual wells. In addition, the size and orientation of formation fractures must be considered when designing oil and gas field development systems. Successful hydraulic fracturing is determined by the degree of optimality of the hydraulic fracturing program, which depends on the reliability and completeness of the parameters included in the work program [42-45].

Hydraulic fracturing is designed based on geological and geophysical studies, and information about the design and operation of wells. The effect of hydraulic fracturing activities is achieved by increasing the hydrodynamic connection between the well and the formation, which determines the productivity of the well [46,47]. Moreover, establishing the productive characteristics before and after hydraulic fracturing is the most accurate assessment of the effect of its implementation. Calculations of the hydraulic fracturing process have shown that RF significantly changes the direction of fluid flows of the gas-condensate mixture in the bottom-hole zone of the formation and, accordingly, the nature of the accumulation of retrograde condensate in this zone of the formation.

The maximum condensate saturation is observed in the hydraulic fracture and the adjacent zone. The saturation of retrograde condensate in this zone depends on the ratio of formation and fracture conductivities for different phases. It is the phase permeability’s of reservoir rocks and hydraulic fractures that play a significant role in determining the critical values of phase saturation as well as the rate at which gas and condensate permeability’s change as their saturation changes. Depending on the type of phase permeability’s of rocks and fractures adopted in the calculations, the efficiency of hydraulic fracturing of gas condensate formations may be higher or lower than the efficiency of this process in gas formations. If, at the same saturation values, the relative phase permeability’s of the hydraulic fracture are higher than the average for the formation, then the multiplicity of the increase in the flow rate of gas condensate wells is higher than that of gas wells. In the case of more deteriorated relative phase permeability’s of the hydraulic fracture, lower efficiency of hydraulic fracturing is noted compared to gas formations [48-50].

Hydrodynamic studies carried out in individual wells of the studied field, which penetrated the A3-4 and A5 formations, made it possible to establish the dependence of their flow rate on the type of penetration, well completion and method of inflow stimulation (Table 1).

| Type of opening | Type of HF | Number of wells | Average flow rate of wells, 1000 m3/day | Drawdown reservoir pressure, MPa | Average productivity, 1000 m3/day/MPa2 |

Average condensate-gas factor (GOR), g/m3 |

|---|---|---|---|---|---|---|

| Vertical | Without HF | 2 | 257 | 9,0 | 0,3 | 458 |

| Vertical | HF | 31 | 751 | 11,0 | 0,8 | 395 |

| Horizontal | Without HF | 1 | 950 | 13,0 | 0,8 | 356 |

| Sub-horizontal | Without HF | 14 | 759 | 11,0 | 0,7 | 361 |

| Sub-horizontal | HF | 1 | 850 | 12,0 | 0,6 | 400 |

| Sub-horizontal | MSFH | 6 | 1346 | 5,0 | 2,7 | 396 |

Table 1: The average operating parameters of wells with different penetration types.

According to the graph shown in Figure 4, it can be noted that the highest drawdown reservoir pressure is observed during the operation of horizontal wells after multi-stage hydraulic fracturing, which have higher productivity than all other wells.

Figure 4: Average production rate of wells with different types of opening. Note:  Gas condensate

flow rate,

Gas condensate

flow rate,  (dP).

(dP).

Among the 62 production wells drilled in the studied deep-lying deposits, nine hydraulic fracturing operations were performed in the A3-4 formation, and 50 hydraulic fracturing operations were conducted in the A5 formation. Over half of all hydraulic fracturing processes were carried out using high-volume hydraulic fracturing technology, and 24 hydraulic fracturing processes were carried out using HiWay technology. To form the internal structure of the fractures, the following proppants were used: BorProp 20/40, Fores 20/40, and to secure the fractures in the near-wellbore zone in order to prevent the reverse flow of proppants, the following proppants were used: ForesRCP 16/20 and ForesRCP 20/40 (Figure 5).

Figure 5: Distribution of the number of operations with different types of proppant. Note:  Number

of operations by type of proppant that secure the fracture.

Number

of operations by type of proppant that secure the fracture.

The total amount of the mixture injected into productive formations by operation is 44.8 thousand m3, and the mass of proppant injected into hydraulic fractures is 12.35 thousand tons (Figure 6).

Figure 6: Mass distribution of proppant injected into hydraulic fractures. Note:  Mass of proppant, ton.

Mass of proppant, ton.

Based on the well testing analysis of the wells, the effectiveness of hydraulic fracturing was assessed, and it was found that almost all wells achieved or exceeded the expected gas condensate flow rates. According to the results of well logging carried out after hydraulic fracturing, it is noted that the main gas-releasing intervals are confined to the roof of the productive formations (Figure 6).

At the production wells of the studied field, hydraulic fracturing processes were carried out using two technologies: Large-volume hydraulic fracturing, where the mass of injected proppant reached 300 tons, and HiWay technology, where the mass of proppant exceeded 200 tons. HiWay technology is designed to create highly conductive fractures with a significantly lower proppant mass than during high-volume hydraulic fracturing [51-54]. A comparison of the masses of proppant injected into hydraulic fractures using two different techniques is shown in Figure 7.

Figure 7: Comparative analysis of proppant mass using HiWay technology and high-volume hydraulic fracturing technology. Note:  HiWay

technology,

HiWay

technology,  Standard high-volume hydraulic fracturing technology,

Standard high-volume hydraulic fracturing technology,  Maximum.

Maximum.

It can be seen in Figure 7 that 38.5% less proppant was pumped into wells developed using HiWay technology than wells developed using high-volume hydraulic fracturing.

When comparing the half-lengths of fractures based on the results of hydraulic fracturing planning, it is evident that the HiWay technology has a larger deviation (Figure 8).

Figure 8: Comparison of the half-length of hydraulic fracturing using HiWay technology and high-volume hydraulic fracturing technology. Note:  Standard high-volume hydraulic fracturing technology,

Standard high-volume hydraulic fracturing technology,  Maximum.

Maximum.

In addition, when carrying out hydraulic fracturing, the structure- forming material J954 is used to create fractures, which have a mass of about 125 tons for hydraulic fracturing with the HiWay technology. Therefore, compared to high-volume hydraulic fracturing, the HiWay technology can significantly reduce the mass of proppant required to secure hydraulic fractures.

After carrying out these geological and technical measures at the wells of the deep-lying deposits of the studied field, a 2.5- fold increase in flow rate is observed, and the duration of the hydraulic fracturing effect persists for three years.

For low-permeability and deep-lay deposits, Multistage hydraulic fracturing is a powerful tool for creating large, permeable fractures and preserving the flow characteristics of the reservoir rocks surrounding the fracture, thereby creating favorable conditions for gas and condensate to flow into the wellbore.

Analysis of the productivity of wells in the studied low- permeability and deep-lying deposits showed that the productive characteristics of the A5 and A6 formations are significantly lower than those of the A3-4 formations. In spite of that, A5 and A6 formations are important production targets despite their low reservoir properties since their condensate yields are twice as high as those from the A3-4 formation at the same bottom-hole pressures.

In comparison with high-volume technology, HiWay technology significantly reduces the proppant needed to secure hydraulic fractures by less than 38.5%. In the deep-lying low permeability deposits of the studied field, hydraulic fracturing is effective for a period of three years after these technical and geological measures are implemented, and the flow rate has increased 2.5- fold as a result.

Citation: Chang WJ, Al-Obaidi SH, Smirnov VI (2023) Application of Multi-Stage Hydraulic Fracturing (MSFH) in the Development of Deep-Lying Deposits with Low Permeability of Hydrocarbon Fields. J Geol Geophys. 12:1154.

Received: 30-Oct-2023, Manuscript No. JGG-23-27835; Editor assigned: 01-Nov-2023, Pre QC No. JGG-23-27835 (PQ); Reviewed: 15-Nov-2023, QC No. JGG-23-27835; Revised: 22-Nov-2023, Manuscript No. JGG-23-27835 (R); Published: 30-Nov-2023 , DOI: 10.35248/2381-8719.24.13.1154

Copyright: © 2023 Chang WJ, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.