Journal of Pollution Effects & Control

Open Access

ISSN: 2375-4397

ISSN: 2375-4397

Research Article - (2014) Volume 2, Issue 2

This is the first type of study that has been undertaken where mushrooming of brick kilns (more than 15 brick kilns just in 2 km diameter) is deteriorating the air quality. Although industrialization is very important for the development of a country, this is a bitter fact that it speeds up the process of environmental degradation as was observed at the Panzan village of district Budgam in Jammu and Kashmir state (India). The monitoring of brick kiln emissions was carried out on 8 hourly basis to estimate the pollution level of gaseous pollutants like oxides of sulphur (SOx), oxides of nitrogen (NOx), particulate pollutants (Respirable particulate matter-RSPM) and (Non-Respirable Suspended particulate matter- NRSPM) during the non-operational and operational phases of brick kilns in the months from April to September 2012. The results revealed that all the pollutants SOx, NOx, RSPM, NRSPM and SPM (sum of RSPM and NRSPM) were crossing the limits prescribed by National Ambient Air Quality Standards (NAAQS) during the operational phase of brick kilns. Further, the air quality index (AQI) was calculated and the study sites were categorized from severe to high pollution including residential areas which is of most concern in respect to health conditions of the local people. Inter correlations of SOx, NOx, RSPM, NRSPM and SPM showing very strong correlations (p < 0.01) with each other indicated that their sources are the same i.e. brick kilns. To minimize the emission level of air pollutants from brick kilns, possible air pollution mitigation measures are suggested.

Keywords: Air quality; Environmental pollution; Brick kiln; Sulphur dioxide; Nitrogen dioxide; Particulate pollutants; Fossil fuel

Brick production is a very large and traditional industry in many parts of Asia. The brick sector in India, although unorganized, is tremendous in size. India is the second largest brick producer (China dominates with 54% share) in the world [1]. Now, it is an established fact that small scale industries are one of the major contributors to atmospheric pollution in environment. Among small scale industries, the brick kiln industry is a booming industry as the demand for bricks is increasing almost universally due to fast economic growth, urbanization and prosperity. The raw materials used for brick productions are soil clay or sediments from river, which are rich in fine particles. Most of the brick kilns use Assam coal, Slack coal and/or lignite which contain high level of sulphur and high ash content (25-30%) [2]. About 70% of coal, 24% saw dust and remaining 6% wood and others are used as fuel by brick kilns [3]. Burning of this coal produces high level of sulphur dioxide and black carbon. In certain areas low grade carbonaceous materials such as rice husk, bagasse and wood/saw dust are also used as a part or full replacement of coal. In India, fire clay bricks are produced in about 42000 small and medium scale brick kilns which operate normally using 4–5 million metric tonnes of coal each year [4,5], while as estimation of Heierli and Maithel [6], has shown new figure i.e. 110 million tons of coal-without counting the electricity used to produce 1,000 billion bricks per annum.

Production of bricks results in environmental degradation due to emission of significant quantities of gaseous and particulate pollutants. All the brick kiln operations right from digging of earth to unloading of fired bricks from the kiln are accompanied by generation of dust which leaves the whole nearby and workplace dusty (Figure 1). Air pollution in brick kiln is produced both through the stack emission as well as the fugitive emissions. Use of thermally low efficient kilns, outdated technology such as Bull’s Trench kilns and inefficient firing technologies contributes to particulate and gaseous emissions. Brick kilns emission consists of mainly fine particles of coal, dust particles, organic matters and small amount of gases such as SO2, NOx, H2S, CO etc. The quantum of the dust evolved from non-chimney sources in brick kiln area is very high. These runaway dusts in workplace contribute to the highly dusty conditions in and around the brick kilns and are further aggravated when the wind speed is high [7-9]. Emission of individual air pollutants from brick kilns varied significantly during a firing batch (7 days) and among different types of kilns. Average emission factors per 1,000 bricks were 6.35–12.3 kg of CO, 0.52–5.9 kg of SO2 and 0.64–1.4 kg of particulate matter (PM) [10]. The total emissions from the brick manufacturing in the Greater Dhaka region has been estimated at 23,300 t of PM2.5, 15,500 t of sulfur dioxide (SO2), 302,000 t of carbon monoxide (CO), 6,000 t of black carbon and 1.8 million tons of CO2 emissions from the clusters of brick kilns, to produce 3.5 billion bricks per year [11]. The releases of toxic substances from these brick kilns are adversely affecting soil, plants, animals and people in their surroundings being the most severe for brick workers, children and women [12-14].

Study area

The State of Jammu and Kashmir, located in the northwestern Himalaya lies between 33º 20’ and 34º 54’N latitudes and 73º 55’ and 75º 35’E longitudes with temperate type of climate and covering an area of 15,948 km2 is experiencing an increase in the air pollution levels during last two to three decades due to increase in transportation and industrial activities. In Jammu and Kashmir, Central Kashmir’s district Budgam where numerous brick kilns are operational has been dubbed as “Buthgam” (village of brick kilns) for its ubiquitous brick kilns that have virtually brought this district on the verge of environmental catastrophe. In a brazen violation of environmental laws and in the absence of regulatory guidance, the mushroom growth of brick kilns in the district has been threatening the environment and posing a threat to public health. The phenomenal growth of brick kilns in district Budgam is almost in tune with the growth of brick kilns in the valley, through registering highest levels in the district. Therefore the study area is selected for the investigation where about 205 brick kilns are operational (Total >400 brick kilns in the Kashmir valley). All the brick kilns are of the Bull’s trench kiln type. The estimated amount of coal consumed by each brick kiln (functional only for six months) varies between 2.5 and 3 tonnes per season. Emissions from these industries vary with respect to quantity in relation to production capacity, quality and quantity of fuel used.

The literature on the assessment of ambient air quality and emissions of brick kilns is meager in the state of Jammu and Kashmir (India). Besides, research on systematic air pollution impact assessment for brick kiln is not widely attempted, though few infrequent studies were reported but remain unpublished till date. With this backdrop, the present study was undertaken for monitoring the existing levels of SOx, NOx and particulate matter (PM) from the surrounding air environment of the brick kilns. Further, air quality index (AQI) has also been calculated with an aim to suggest suitable mitigation measures for reduction of air pollution levels.

Panzan village (1,651 m a.s.l) is included in the block Chadoora of district Budgam. There are approximately more than 15 brick kilns just within a diameter of 2 km. A detailed survey of Panzan brick kiln area was done and their effects on the air quality were analyzed. The description of 3 study sites in the Panzan village is given in Table 1. The monitoring of brick kiln emissions was carried out at 8 hourly basis to estimate the pollution level of gaseous pollutants like sulphur dioxide (SO2 or SOx), nitrogen dioxide (NO2 or NOx), particulate pollutants (Respirable particulate matter (RSPM) and Non-Respirable Suspended particulate matter (NRSPM) during the non-operational and operational phases of brick kilns in the months from April to September 2012. (Figure 2)

| Sites | Latitudes and longitudes | Remarks |

| Site-1 (S1) | 33º57'57.31"N and74º46'15.88"E | Centre of the Kiln |

| Site-2 (S2) | 33º57'56.51"N and 74º46'19.06"E | Near the vegetable garden(50m away from brick kiln) |

| Site-3 (S3) | 33º57'50.32"N and 74º46'17.49"E | Residential Area, (100maway from brick kiln) |

Table 1: Location of the sampling sites for air quality status in around brick kiln area.

Monitoring of particulate and gaseous pollutants

To evaluate the air quality in and around brick kiln area, high Volume EnvironTech air sampler was used. The main pollutants considered for the study include respirable suspended particulate matter (RSPM/PM10), non-respirable suspended particulate matter (NRSPM), nitrogen dioxide (NO2) and sulfur dioxide (SO2). The sampling instrument was set up 3 meters above ground and 8 hourly values for all pollutants were measured at each site.

The particulate matter (PM10) collected on glass fiber filter paper was determined by weighing the filter before and after exposure to ambient air. The mass of PM larger than PM10 was determined from the initial and final weight of the dust cup vial. Total suspended particulate matter (TSP/SPM) was determined from the sum of PM10 and particles larger than PM10(non-respirable particulate matter).

The method for measuring SO2 was adapted from West and Gaeke [15]. In this method, air-exposed samples are treated in a solution of potassium tetrachloro-mercurate (TCM). A dichlorosulphitomercurate complex is formed, which subsequently reacts with pararosaniline and formaldehyde to form the intensely coloured pararosaniline methylsulphonic acid. The absorbance of the coloured solution was measured with spectrophotometer at 560 nm.

The principle of NO2measurement in atmospheric samples was described by Jacob and Hochheiser [16]. Ambient nitrogen dioxide (NO2) is collected by bubbling air through a solution of sodium hydroxide and sodium arsenite. The concentration of nitrite ion (NO2 -) produced during sampling is determined colorimetrically by reacting the nitrite ion with phosphoric acid, sulfanilamide, and N-(1- naphthyl)-ethylenediamine di-hydrochloride (NEDA) and measuring the absorbance of the highly colored azo-dye at 540 nm.

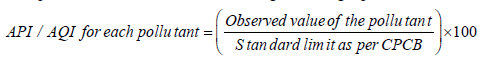

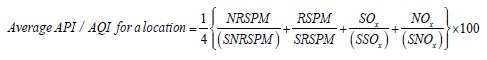

The air pollution/quality index (API/AQI) is a measure of the ratio of the pollutant concentration in ambient air to the national standards of the pollutants. The averages of the sum of the ratios of three chief pollutant concentrations to their respective air quality standards were obtained. The average was then multiplied by 100 to get the index [17,18]. Air pollution/quality Index (API/AQI) (Table 2) was calculated for a pollutant as well as a location using following equations:

| API/AQI | Remarks |

| 0-25 | Clean air |

| 26-50 | Fairly clean |

| 51-75 | Moderate air pollution |

| 76-100 | Heavy air pollution |

| >100 | Severe air pollution |

Table 2: Air Quality Category Based on Air Quality Index.

Where SNRSPM, SRSPM, SSOx and SNOx represent the ambient air quality standards for NRSPM, RSPM, SOx and NOx (Table 3) [19].

| Pollutants | Time Weighted Average | Concentration in Ambient Air | |

| Industrial, Residential, Rural and other Areas | Ecologically Sensitive Area (Notified by Central Government) | ||

| Sulphur dioxide (SO2), μg/m3 | Annual * | 50 | 20 |

| 24 Hours ** | 80 | 80 | |

| Nitrogen dioxide (NO2), μg/m3 | Annual * | 40 | 30 |

| 24 Hours ** | 80 | 80 | |

| Particulate matter (size less than 10μm) or PM10, μg/m3 | Annual * | 60 | 60 |

| 24 Hours ** | 100 | 100 | |

| Particulate matter (size less than 2.5μm) or PM2.5, μg/m3 | Annual * | 40 | 40 |

| 24 Hours ** | 60 | 60 | |

Table 3: National ambient air quality standards (NAAQS), CPCB, [19].

Statistical analysis: Standard deviation was calculated by using M.S Excel software. Association between pollutants was done by Pearson correlation. The whole analysis was performed on log10 transformed data. A two-tailed (α=2) probability p < 0.01 was considered to be statistically significant. SPSS (Statistical Product and Service Solutions) were used for the analysis.

Brick kilns are known to be a leading cause of ambient air pollution in rural areas. The levels of SOx, NOx, and SPM (RSPM+NRSPM) are major problems in Panzan village of district Budgam because the levels of these are significantly higher than NAAQS guidelines. High air pollution levels in the atmosphere have shown significant negative importance, as they do not only pose serious occupational health hazards but also adversively affect the surrounding environment [20-26].

The average concentrations of SOx for the non-operational phase were 14.42 ± 2.63 μg/m³, 17.74 ± 2.94 μg/m³ and 19.95 ± 1.60 μg/ m³ at sites S1, S2 and S3 respectively; whereas these values reached 125.39 ± 6.18 μg/m³, 118.18 ± 6.76 μg/m³ and 99.08 ± 5.18 μg/m³ at the respective sites during the operational phase of brick kilns (Figure 3). Similarly, NOx values were found to be 20.46 ± 2.20 μg/m³, 25.92 ± 2.44 μg/m³ and 23.38 ± 1.61 μg/m³ during non-operational phase and in subsequent operational phase the values came to be 109.44 ± 5.05 μg/m³, 98.29 ± 5.38 μg/m³ and 74.99 ± 5.05 μg/m³ at respective sites (Figure 4).

Compared with the limiting values, as defined by National Ambient Air Quality Standards (NAAQS) CPCB, [19], the concentrations of SOx and NOx at sites S1, S2 and S3 were beyond the permissible limits during operational phase of the brick kilns. Similar trends were also observed by Tuladhar and Raut [27] and Fatima [28]. Brick kilns play significant role in elevating the SO2 concentration in the ambient air, as they are fed with sulphur rich, inferior quality of coal (2.5 and 3 tons per season) [29-31], besides the use of inefficient and outdated technology such as Bull’s Trench kilns. Further, it has been revealed that biomass is responsible for the emission of both trace and non-trace gases such as SOx, NOx and CO2 from traditional brick industries [32].

The formation of NO is favoured at high temperature, usually attained during severe combustion processes involving air (1210ºC to 1763ºC). It is also formed by photolytic reaction. The NO2 levels depend mainly on chemical reactions and not on direct emissions [33]. Nitrogen Oxide (NOx) emissions in brick making mainly originate from the Oxidation of nitrogen in the atmosphere by burning and thus NOx giving off from the brick kilns has a major role in the formation of ozone. Besides the presence of NOx is very essential since NO2 can be the only potential source of ozone in the brick kiln areas [34,35]. Several studies have also shown that the emission of NOx in brick making has not been found to be significant [36], but cumulative concentration can be high in a clustered brick kiln areas as observed in the present study case.

It has also been calculated that the average values of RSPM in the non-operational phase were 37.50 μg/m³, 55.80 μg/m³ and 52.08 μg/m³ at sites S1, S2 and S3 respectively, whereas these values rose to 258.33 μg/m³, 231.25 μg/m³ and 139.58 μg/m³ at the respective sites during the operational phase of brick kilns (Figure 5). Similarly, NRSPM values were 43.75 μg/m³, 72.54 μg/m³ and 58.33 μg/m³ at sites S1, S2 and S3 during non-operational phase and 300.00 μg/m³, 218.75 μg/m³ and 91.67 μg/m³ during the operational phase at the respective sites (Figure 6). Thus, the overall concentration of particulate matter i.e. total suspended particulate (SPM) at all the three sites was calculated to be 81.25 μg/m³, 128.35 μg/m³ and 110.42 μg/m³ during the nonoperational phase and 558.33 μg/m³, 450.00 μg/m³ and 227.08 μg/m³ during the operational phase of brick kilns respectively at sites S1, S2 and S3 (Figure 7). On the basis of air quality index (AQI), the values of AQI ranged from 26 to 37 μg/m³ during non-operational phase and 84- 148 μg/m³ during the operational phase, thereby depicting that all the three sites turned to be severe air pollution sites during the operational phase of brick kilns (Table 4). Inter correlations of SOx, NOx, RSPM, NRSPM, and SPM (Table 5), show very strong correlations (p < 0.01) with each other.

| Sites | AQI (μg/m3) | Air Quality Non-operational phase |

Sites | AQI (μg/m3) | Air Quality Operational phase |

| S1 | 26 | Fairly clean | S1 | 148 | Severe air pollution |

| S2 | 37 | Fairly clean | S2 | 130 | Severe air pollution |

| S3 | 34 | Fairly clean | S3 | 84 | Heavy air pollution |

Table 4: Quality of air at the different study sites on the basis of Air Quality Index

(AQI).

| Parameters | SOx | NOx | RSPM | NRSPM | SPM |

| SOx | 1 | ||||

| NOx | 0.973(**) | 1 | |||

| RSPM | 0.900(**) | 0.912(**) | 1 | ||

| NRSPM | 0.715(**) | 0.712(**) | 0.897(**) | 1 | |

| SPM | 0.818(**) | 0.822(**) | 0.967(**) | 0.980(**) | 1 |

Table 5: Correlation between different pollutants in ambient air of all the study sites

** = Significant (p < 0.01).

The average values of RSPM, NRSPM and sum of these values (i.e. SPM) have shown increased trend during the operational phase of brick kilns. This is a matter of emission of greater quantities of particulate matter. Similar results indicating the high level of dust in the atmosphere had been observed by Joshi and Dudani [24] and Tuladhar and Raut [27] during the operational phase of brick kilns. According to a study conducted by the World Bank [37] in Kathmandu valley, the main annual mean of contributing sources for total suspended particles (SPM) are brick kilns (31%). However, the particulate matter of a size less than 10 microns (PM10 or RSPM) concentration is of a more apprehension as these particles can enter the respiratory system. Contribution of brick kilns towards air pollution was found to be more than other sources (28%). It was observed that coal combustion is the main source of airborne particles [38], as the main source of energy in brick kilns is coal thus giving rise to air borne particles. Finally, as per the air quality index (AQI), it was found that during the operational phase of brick kilns the air quality was severely polluted (Figure 8), but remained fairly clean in the non-operational phase of brick kilns. On the whole, the greater the AQI, the more is the pollution. Air pollution has also been associated with a variety of illnesses. Every year an estimated 800,000 people die prematurely from illnesses (lung cancer, cardiovascular and respiratory diseases), caused by outdoor air pollution worldwide [39] and approximately 150,000 of these deaths are estimated to occur in South Asia alone [40]. A lower AQI, therefore, is beneficial for human health and the overall environment. From the statistical point of view there is strong correlation between the air pollutants, indicating their sources to be same (i.e. brick kilns).

Production of brick results in environmental degradation due to emissions of significant quantities of particulates and gaseous pollutants. It is clearly visible that brick kilns operating in Panzan village of district Budgam are emitting large quantities of air pollutants. The level of different air pollutants (gaseous and dust) in the ambient air was higher during the operation of brick kilns. This was considered as the major air pollution problem in the study area. On the basis of air quality index (AQI), all the three sites turned to be severe air pollution sites during the operational phase of brick kilns. On the whole, the greater the AQI, the more is the pollution. A lower AQI therefore is beneficial for human health and the environment. The level of gaseous and dust pollutants may be reduced by providing the better quality coal. The use of pulverized coal of 10 mm sizes may facilitate better combustion and lesser emission of smoke. Mechanical feeders should be used for coal feeding as these would ensure most effective burning of the coal and lower the emission and introduction of cleaner technologies such as vertical shaft brick kilns (VSBK) in place of Bull trench kilns. Air pollution control equipment consisting of baffle arrangement inside the chimney with a gas bypass system may be installed in the chimney to arrest pollution. Utilization of fly-ash for brick manufacture through cost effective technology will save the precious top soil required for agricultural production. Development of green belt around the brick kilns may be an effective mitigation mechanism for fugitive emissions. At the same time environmental awareness programs should be organized. In absence of effective air quality management, air pollutant concentrations will increase in the future, so enforcement of air quality standards is necessary.

The first author is highly thankful to Prof. Azra N. Kamili, Ex-Head of P. G. Department of Environmental Science, University of Kashmir for providing necessary laboratory facilities as well as the transportation. Thanks are to Brick kiln owners for their kind help and permission to carry out the whole sampling process. Further authors and co-authors don’t have any kind of conflict of interest.