International Journal of Advancements in Technology

Open Access

ISSN: 0976-4860

+44 1478 350008

ISSN: 0976-4860

+44 1478 350008

Research Paper - (2022)Volume 13, Issue 2

Future space transportation systems; Non-complex engines; Kinetic energy; Earth-to-orbit missions; Average velocity

A nozzle is a device used to control the direction and, at the same time, characteristics of a fluid flow. It is used primarily to increase velocity as it exits or enters a closed chamber or pipe [1]. A nozzle is often a pipe or tube of a varying cross-sectional area, and it can be used to modify the flow of a fluid and is frequently used to control flow, speed, direction, and mass when the mixture of fuel and propellant is burnt in a combustion chamber [2]. Energy is obtained (for producing thrust). This energy is added to the induced air, and when this hot air passes through the nozzle, its kinetic energy increases, but its pressure and internal energy get used up in this process. A nozzle has a converging area or diverging area or both. Thus, fluid passes through it first converges and then diverges or includes only one. It has a minimum diameter in the throat where it reaches the highest velocity, i.e., sonic velocity. This phenomenon is also known as choking of the nozzle. When the area decreases continuously from the entrance to exit, it is known as a converging nozzle.

In contrast, when the area increases from the entrance to the exit, it is the diverging nozzle. When the cross-sectional area first decreases from the entrance to the throat and then expands from the throat to exit, then it is known as the convergent-divergent nozzle. The convergent nozzle comes into play when Backpressure is equal to or more than the critical pressure ratio. The divergent nozzle is used when back pressure is less than the critical pressure ratio.

We cannot increase Mach number beyond unity by increasing the nozzle pressure ratio. But after exiting from the nozzle outlet, the gas flow is free to expand to supersonic velocities. As we know, the Mach number is directly proportional to the square root of temperature. Thus, speed at the throat of the nozzle is way more than that of sound at sea level. By this, we can also say that Mach number 1 denotes a very high speed for hot gas. This helps us in generating a hypersonic flow. Also, we select propellant mixtures for increasing the sonic speed to a further extent.

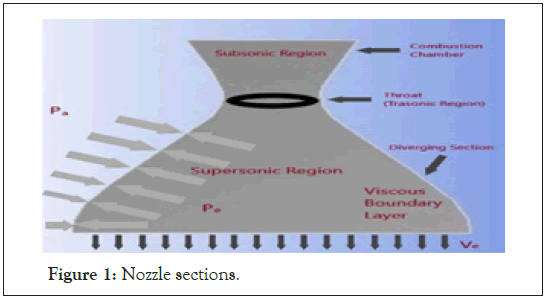

Sections in a nozzle

A nozzle consists of three sections [3].

• Converging section

• Throat

• Diverging section

Firstly, the combustion exhaust gases enter the converging part, having subsonic velocity accelerating with the decrease in the nozzle area. After that, when it passes through the throat (minimum cross-sectional area), it attains supersonic velocity as the discharge is constant. It also accelerates with expansion. When exhaust gases come to the nozzle throat, pressure increases. After that, when they come to the other side of the throat to expand, their pressure decreases, and their kinetic energy increases. They pushed against the wall creating thrust. Also, as the discharge is the same so as the cross-sectional area at the throat decreases, velocity increases, and in this way, exit velocity increases. So, the nozzle gives extra thrust to the jet to travel with high efficiency and high power to a sufficient height (Figure 1).

Figure 1: Nozzle sections.

We must prioritize expansion area ratio in a nozzle design, i.e., fixing other variables (primarily chamber pressure). Hence there is only one ratio that optimizes performance for a given altitude (or atmospheric pressure). However, we must know that rocket travels at variable altitudes, so we should know the trajectory to select an expansion ratio that maximizes performance over a range of ambient pressures. Thus, for traveling in space, variable expansion ratio nozzles are designed [4].

Basic utilities of a nozzle

• To increase the kinetic energy at the expense of pressure and internal energy.

• To increase the velocity of fluid passing through it.

• To provide sufficient thrust to the engine or appliance in which it is used.

Working of a rocket

When we hear the word ‘Rocket,’ the thing that comes to our mind is Sky. So, a rocket is a type of vehicle or a vehicle that uses an engine to go into space for different purposes and applications. In the rocket, there is a combustion chamber in which the fuel and oxidizers are burnt together [4]. Then these exhaust gases are then passed through a nozzle, increasing the velocity of gases at the back of the rocket, thus creating a lot of momentum. The gas thus makes the rocket moves upward. Some of the rockets use liquid fuels, and some used solid fuels. Rockets are of both types, i.e., Internal combustion types and non-combustible types [5].

Role of nozzle in a rocket

A rocket will perform in the best way only if the pressure at the nozzle’s end is equal to the ambient pressure. If the exhaust’s pressure is higher, then the pressure will not convert into thrust, and energy is not fully utilized. In the same way, if pressure is lower, then because of the difference in pressure between engine top and exit, the vehicle will slow down. Therefore, for making exhaust pressure remain equal to the ambient pressure, the nozzle diameter would change (increase) when going to higher altitudes. A longer nozzle would be available for the pressure to act, thus reducing exit pressure and temperature. A lightweight nozzle is generally used in a rocket, and when throttling occurs, the atmospheric performance is compromised. For rectification, different designs of nozzles are used. Each designed as per the atmospheric conditions giving extra higher thrust and velocity at high altitudes [6].

But certainly, there are two problems:

• The performance is compromised by the weight of the nozzle (heavyweight).

• Freezing of chemicals in engine because of the adiabatic expansion of exhaust gases resulting in snow production inside the jet.

A nozzle is used to eliminate these problems in which exhaust gas detachment occurs in an over-expanded nozzle. The detachment point is not axial. This non-axial point detachment will create a side force over the engine. This side force will vary with time resulting in controlling problems inside the vehicle.

Types of nozzles

We can differentiate them based on either speed or shape.

(i) Based on the speed

• Spray nozzles

• Ramjet nozzles

(ii) Based on the shape

• Conical nozzle (Conventional)

• Bell nozzle

• Annular nozzle (Figure 2)

Figure 2: Types of nozzles.

Conical nozzle

• Simple and easy to construct because of its normal design used in previous applications.

• Constant angle of divergence of the wall.

• High impulse produced, and maximization of axial velocity occurs.

• A small angle produces greater thrust.

• Because of the large nozzle angle, performance is reduced because high ambient pressure causes flow separation and over- expansion (Table 1).

| Inlet diameter | 25 |

| Outlet diameter | 35 |

| Inlet pressure | 2268000 Pa |

| Total temperature | 1200 K |

Table 1: Conical nozzle’s dimensions and boundary conditions.

Bell and dual bell nozzle

• It is designed to have a large angle of expansion for the gases right after the throat.

• Design and construction are complex.

• It can operate efficiently over high and low altitudes.

• The dual-bell nozzle is an altitude adaptive nozzle concept.

• Bell-shaped nozzle linked to extension nozzle.

• Under high ambient pressure conditions, at low altitude, the flow is attached in the base nozzle and separates at the inflection point.

• From the inflection point, the flow separation started, which goes up to the end of extension; the nozzle is then flowing full, and the dual-bell nozzle has reached its altitude mode (Tables 2 and 3).

| Inlet diameter | 55 |

| Outlet diameter | 65 |

| Inlet pressure | 2268000 Pa |

| Total temperature | 1200 K |

Table 2: Bell nozzle’s dimensions and boundary conditions.

| Inlet diameter | 25 |

| Outlet diameter | 45 |

| Inlet pressure | 2268000 Pa |

| Total temperature | 1200 K |

Table 3: Double bell nozzle’s dimensions and boundary conditions.

Annular nozzle

• It is best when we think about theoretical calculations.

• It is very much complex in design.

• It has the main advantage, i.e., Altitude compensation. Thus, it operates along with wide range of altitudes.

• Two major types of annular nozzles are radial in-flow nozzle; spike nozzle; linear-aerospike nozzle.

•Annular is that in which combustion occurs along the ring, or annulus, i.e., around the base of the nozzle

• Plug: refers to the center body that blocks flow from what would be the center portion of a traditional nozzle.

How are nozzles designed?

Certain factors on which the designing of nozzle depend, such as the amount of thrust it should produce, exit velocity, pressure at the engine’s exit, the mass flow rate through the engine [7]. All these flow variables are determined by the rocket design. A nozzle has small dimensions in comparison to a rocket. However, it effectively increases the efficiency of a rocket by increasing Thrust, which further depends upon its exit velocity, exit pressure, and mass flow rate. The type of nozzles used in a rocket is a convergent-divergent nozzle. It means that firstly, the cross- sectional area of the nozzle decreases to a minimum area at the throat, followed by an increase in cross-section. In a CD rocket nozzle, the hot exhaust after leaving the combustion chamber converges down to the nozzle’s minimum area, or throat. In the throat, the flow choked, and Mach number at the throat is one which means that the flow is sonic.

After that, when the flow diverges, the flow velocity reaches supersonic velocity by isentropic expansion, but its Mach number depends upon the ratio of area at exit to area at the throat. When the gases expand in the diverging part, their pressure and temperature also decrease. This is because of the expansion process. The exit temperature determines the exit speed of sound, which determines certain factors on which the designing of nozzle depend, such as the amount of thrust it should produce, exit velocity, pressure at the engine’s exit, the mass flow rate through the engine. All these flow variables are determined by the rocket design. A nozzle has small dimensions in comparison to a rocket. However, it effectively increases the efficiency of a rocket by increasing thrust, which further depends upon its exit velocity, exit pressure, and mass flow rate. The type of nozzles used in a rocket is a convergent-divergent nozzle. It means that firstly, the cross-sectional area of the nozzle decreases to a minimum area at the throat, followed by an increase in cross- section. In a CD rocket nozzle, the hot exhaust after leaving the combustion chamber converges down to the nozzle’s minimum area, or throat. In the throat, the flow choked, and Mach number at the throat is one which means that the flow is Sonic.

After that, when the flow diverges, the flow velocity reaches supersonic velocity by isentropic expansion, but its Mach number depends upon the ratio of area at exit to area at the throat. When the gases expand in the diverging part, their pressure and temperature also decrease. This is because of the expansion process. The exit temperature determines the exit speed of sound, which determines the exit velocity. The exit velocity, pressure, and mass flow through the nozzle determine the amount of thrust produced by the nozzle. The exit velocity, pressure, and mass flow through the nozzle determine the amount of thrust produced by the nozzle.

Software used

The software that we used in designing of different types of nozzles is named as ANSYS fluent 2021 R1. It consists of five parts, geometry, mesh, setup, solution, and result (Figure 3) [8].

Figure 3: Ansys fluent.

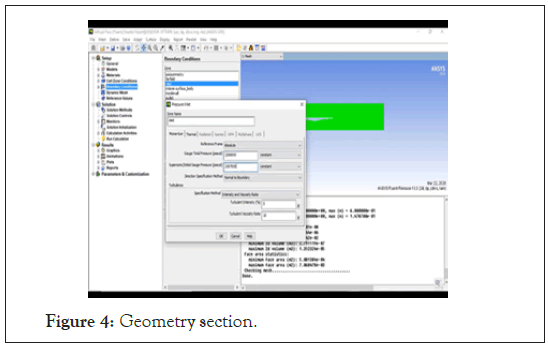

• In the geometry part, the dimension of nozzle is defined in 2D and after that, it is converted to 3D. Special care should be taken while designing in geometry past because if it is not defined properly then we will not get the required solutions.

• In the mesh part, the 3D nozzle is divided further into parts and then these parts are meshed for proper spreading of heat. The domain broken into pieces and each piece represents an element.

• In setup and solution part, we add different materials and boundary conditions. After that, iterations are made, and calculations occur.

• In the results part, as the name suggests, various contours are obtained such as pressure, velocity, kinetic energy, temperature, etc.

Plotting the key points: First, we need to create the correct dimensions suing the coordinate points given.

Making edges: Join these key points to create edges, we must be sure that right key points are joined with each other because it is very critical part of the process.

Making faces: The 2D figure which is formed is not given some thickness such that it can be converted to 3D figure (Figure 4).

Figure 4: Geometry section.

Meshing: Now we close the geometry part and open mesh part, in the mesh part we divide the figure into distinct elements and then apply proper sizing and then meshing to each part and then generate the required mesh (Figure 5).

Figure 5: Mesh section.

Applying boundary conditions: Now in the setup and Solution Part, we define boundary conditions given above such as temperature, inlet pressure, outlet pressure, viscosity is set to sutherland method as it gives realistic and proper results. We will turn on energy equations and defined the material as air and set its density to ideal. At last, we will run iterations and calculations (Figures 6 and 7).

Figure 6: General solutions settings.

Figure 7: Settings boundary conditions.

At last, we will enter the solutions part and obtain different contours such as velocity contours, temperature contours, velocity vector, pressure contours and kinetic energy.

The CFD analysis of different nozzles is done by ANSYS Software to calculate temperature, velocity and other parameters of mass flowing through the nozzles of different dimensions and shapes. The energy method is turned on as well as density based calculations are made because we consider fluid to be compressible. K-epsilon-2 equation model is selected. Second order upwind is selected for both turbulent dissipation rate and turbulent kinetic energy. CFD ANSYS is a great method of testing because experimental methods are very costly and results in the loss of money as well as time.

(i) Conical conventional nozzle results (Figure 8 and Table 4).

| Nozzle type | Exit velocity |

|---|---|

| Conical nozzle | 1.428e+0.3 |

| Bell nozzle | 1.424e+0.3 |

| Dual bell nozzle | 1.460e+0.3 |

Table 4: Conical nozzle’s dimensions and boundary conditions.

Figure 8: Settings boundary conditions.

(ii) Bell nozzle results (Figure 9 and Table 5).

| Nozzle type | Average velocity |

|---|---|

| Conical nozzle | 1274.20 |

| Bell nozzle | 957.68 |

| Dual bell nozzle | 1333.77 |

Table 5: Bell nozzle’s dimensions and boundary conditions.

Figure 9: (a) Velocity contour; (b) Pressure contour; (c) Temperature; (d) Kinetic energy.

(iii) Double bell nozzle results (Figure 10).

Figure 10: (a) Velocity Contour; (b) Pressure Contour; (c) Temperature; (d) Kinetic Energy.

As per our results it is showing that greater value for exit velocity is in the case of double bell nozzle. So, we can conclude that double bell nozzle can show better performance than conical nozzle and bell nozzle. It is shown that significant performance gains results from the adaptation of the exhaust flow to the ambient pressure. All the advanced nozzle concepts have been subjected to the analytical work and gave much better results, but double bell nozzle stands as best among the nozzles we analyzed so far.

[Crossref]

Citation: Asthana Y (2022) CFD Analysis of Different Types of Advanced Rocket Nozzles in Ansys. Int J Adv Technol. 13:174.

Received: 07-Mar-2022, Manuscript No. IJOAT-22-16148; Editor assigned: 10-Mar-2022, Pre QC No. IJOAT-22-16148; Reviewed: 21-Mar-2022, QC No. IJOAT-22-16148; Revised: 28-Mar-2022, Manuscript No. IJOAT-22-16148; Published: 04-Apr-2022 , DOI: DOI:10.35248/0976-4860.22.13.174

Copyright: © 2022 Asthana Y. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.