Journal of Aeronautics & Aerospace Engineering

Open Access

ISSN: 2168-9792

ISSN: 2168-9792

Research Article - (2016) Volume 5, Issue 2

A computational prediction of combustion is a challenging task due complexity involved in the flow parameters. The design of can-type combustor has been considered for a special purpose using producer gas as fuel to run the turbine blades of a turbocharger. Producer gas used for power generation has zero effect, even though it emits CO2 into the atmosphere. The application has its background in finding an optimal turbocharger for matching the requirements of an IC engine. Non-premixed combustor is taken into account because producer gas having high temperature around 300 K when entering into combustion chamber, thus it is unsafe to operate in the premixed mode to prevent explosion in the air-fuel inlet and also simplifies the design. By changing the inlet air injection angle will affect the combustion parameters like low pressure drop, NOx level, outlet temperature, and wall temperature not to exceed 700 K. A mild steel material has been selected for computational prediction of flow behaviors under typical engine condition in can-type combustor. Thus for the initial consideration, basic design of a can-type combustor without a liner has been modeled. The specifications were met and checked for different combination of primary and secondary air injection duct and a most feasible configuration is obtained. The main aim is to optimize the characteristics of a combustor for a turbocharger test rig, i.e. the combustor designed has to be meet optimum condition, which is prevailing in the producer gas engine (formerly diesel engine).

<Keywords: Combustor; Turbocharger; Combustion; Producer gas; NOx; Mild steel

The global demand for clean energy has to be increased; the turbocharger needs an efficient engine technology to develop high efficiency, lower emission, non-hazardous and clean combustors.

The gas turbine combustor is one of the most complicated systems in design of gas turbine because complexity arises to meet desire requirement of turbine and compressor. In gas turbine Combustion chamber fuel is combined with high compressed air and burnt in a combustion chamber. Then its results in high temperature exhaust gas, which is used to run the power turbine or produce thrust when passed through a nozzle. The design and development of can-type combustors is crucial. Fluid dynamics play a vital role in the design of can-type combustor. Along with fluid dynamics others fundamental considered of heat and mass transfer and chemical kinetics is taken into account. Taking these consideration complex combustors are carefully designed for better mixing, dilution processes to ignite the air and fuel in order to improve burning rate and to minimize soot and nitric oxide formation and then additional air is mixed to meet the temperature requirements [1-10].

Combustors play a vital role in determining many operating characteristics of an engine, such as efficiency, levels of emissions and transient response. The development of a preliminary combustion chamber design and the methodology of the design process would help to meet these demands. The objective of paper is to be optimized combustor for turbocharger application [11-15].

Mentioning technical specifications and initial dimensions from simple to complex geometries and geometry were established. A computational prediction of variation air inlet angle is considered. The CFD model is made up of a complex combustion chamber of 250 mm length with 8 primary and 16 secondary air inlets at an angle of 30, 40, 45 degrees. A baffle plate is provided at the center of the combustion chamber for generation of the flow recirculation, it helps flame stabilization for enhanced mixing, hence plate act as a flame holder. The mass flow rate has been chosen based on to the calorific value of fuel and power requirement of the combustor. A lean mixture has been considered due to the constraints with both wall and outlet temperatures. The combustor had to be modeled in such a way that where the analysis results yields the required conditions at the outlet of the combustor. Complete combustion the air-fuel mixtures have to take place within the can-type combustor, also the exhaust gases has to contain very small or no traces of CH4 and CO as well as NOx emissions. The CATIAV5 wireframe and surface module is used to design integrated combustor with fuel inlet pipe, primary, secondary air inlet pipe, baffle plate (act as a flame holder hence improve the stability of flame), wall and outlet. Using ICEM CFD geometry cleanup is done, which includes removing of free edges, scar line, duplicate surfaces, small holes and intersection of parts (assembly of combustor). Generated unstructured grid i.e. tetrahedral element of size 3014733. Figure 1 shows the Mesh generation on Combustor [16-25].

The constituents of producer gas are CH4, CO, N2, CO2 and H2. These were specified while assigning the boundary conditions in ANSYS CFX. Producer gas density is specified as 1 Kg/m3 for complete combustion, ideal gas mixture and also achieves the mass flow rate of fuel as 12 g/s. The mathematical model of combustion process is based on Renolds-Averaged Navier-Stokes equations. The chemical reactions equation is considered as source in terms of continuity equation for each species.

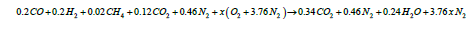

For producer gas the combustion equation is as follows:

The theoretical A: F ratio is obtained as 1.143. The amount of air initially amount of air considered around 2-3 times the mass of fuel. To obtain uniform temperature at the outlet and also to maintain wall temperatures, the mass of air required has been calculated and increased to around 18 times of that of fuel. Then, using the determined heat output from the combustion chamber, the initial dimensions are arrived at from the concept of conduction through cylinders.

The basic configuration of the model considered for the analysis, scheme of computation, code validation and other basic aspects of the study have been brought out in detail. A 3D-RANS code having up winding implicit scheme is used for the numerical solution.

The main considerations for the flow simulations were to get pressure and temperature at the outlet in the range of 0.3-0.5 bar and 500-600 K respectively. The temperature difference is expected to be within 100 K to avoid thermal stresses on the turbine blades (Figures 2 and 3). A subsonic flow with average Mach number less than 0.3 is optimum to avoid choking inside the combustion chamber. For the producer gas considered, with its low energy density having the A: F ratio of about 1.2 for equivalence ratio of 1, to get the desired dilution for getting the desired temperature was theoretically about 18. In the above process a computational predictions of the primary and secondary air inlet angles were varied to 30, 40 and 45 degrees respectively and an optimal configuration with the primary and secondary air inlet angles is found to be around 45° [26-32].

The material, producer gas has been created considering it as a reacting mixture with the gas phase combustion. The constituents of producer gas are CH4, CO, N2, CO2 and H2. Assuming adiabatic flame temperature to be equal to the required exhaust gas temperature the excess air required at the inlet is calculated by trial and error method. The air mass flow rate is fixed to be 216 g/s which have later split for primary and secondary air flow rates of 36 g/s and 180 g/s respectively. The primary air is mainly used for creating the combustion zone at the center of the combustion chamber. The secondary air partly involves for the same and majorly contributes in maintaining the wall and outlet temperature since the primary and secondary air have a lot of inlets as mentioned earlier, a common duct, which has been modeled separately for both primary and secondary to simplify the inlet boundary conditions. The fuel mass fractions were provided at the inlet keeping Nitrogen as constraint and oxygen was taken as zero. For the air mass fractions the oxygen as 0.23 and the other components were considered as zero. The outlet was made to be a fixed condition with static pressure taken 0.3 bars since the required pressures was around 0.3-0.5 bar.

The dominant flows are not closer to the walls indicating the reduced convective heat transfer to the wall. There is small variation pressure at inlet and outlet of combustor i.e. pressure at fuel inlet is 0.5 bars and air inlet is found to be approximately 0.6 bar. During the experimentation on compressor in the laboratory and found that compressor achieved 0.5 bar pressures at the inlets.

From the various plots we can conclude following characteristics on combustor:

1. The velocity considered for air and fuel at the point of ignition is 30 m/s, as good as necessary for a stable ignition. Baffle plate creates the wake hence helps in proper mixing of air and fuel (Figures 4-8). From Figure 9 and Figure 10 velocity streamlines and vector respectively, its shows the proper mixing of fuel and air.

2. From Graph 1, there were the temperature and axial length of combustor, which shows configuration i.e. 30° , 40° and 45° respectively. By comparatively the above plots from the graph is obtained from 45° above configuration.

3. From Figures 4-7 show mass fractions of H2, CO, CH4 and CO2 are below traceable limits indicating that no unburned gases are escaping.

4. With the required air splits as primary for stable combustion and secondary air is injected subsequently for the dilution from an annular chamber, a good mixing and required temperature is achieved.

5. The optimized configuration is achieved and the desired feature of wall temperatures are not exceeding 700 K, which is shown in Figures 2 and 3 and also cut section of combustion length which is shown in the Figures 8-10.

Based on a computational predictions, optimum design of combustor configuration were obtained, further modification can done, to meet good agreement with the typical engine performance. Three dimensional computations made on can-type combustor in order to capture the emission parameter and also capture the detailed functional features of fluid flow in the combustor are considered. Producer gas taken as fuel because generate renewable power, convert waste to useful fuels and reduction of emission from engines. A combustion analysis is made with a RANS code and k-ε based turbulent model. The CFD based predictions of the combustion process in cantype combustor and the performance has been evaluated for optimal design of the Producer gas burner. The desirable features have been achieved with the combustion analysis used for the results has shown complete combustion and better mixing can be seen and also provide lower variation in temperature at outlet.