Journal of Physical Chemistry & Biophysics

Open Access

ISSN: 2161-0398

ISSN: 2161-0398

Research Article - (2022)Volume 12, Issue 4

The aim of this work was to study the effects of an Organo montmorillonite or organoclay on the properties of a Poly Vinyl Chloride (PVC) polymer used in the fabrication of electrical cable sheath in order to replace the chalk by organoclay in the cable PVC sheath manufacturing. The resulted nanocomposite blend, based on organoclay and PVC polymer, was prepared by melt blending. The results obtained showed a slight improvement of the blend mechanical properties (tensile strength, and elongation at break) when the amount of the organoclay was 1 wt %. The thermal stability (deshydrochloration test) is maximal when the concentration of the organoclay was equal to 1 wt %. The water uptake study reveals that the amount of the absorbed water does not exceed 0.1 wt % when the concentration of the organoclay is 1.5 wt %. A rheological test revealed that the addition of organoclay had not increased the melt viscosity of the PVC /OMMT nanocomposite blend.

Organoclay; PVC; Mechanical properties; Thermal stability; Rheological test

Poly Vinyl Chloride (PVC) is the leading polymeric material used in medical device and packaging applications. It offers a uniquely broad range of properties for a wide variety of applications in the medical, health care industry and electric cable fabrication. It fulfills an extensive range of performance and processing requirements such as gloss, transparency, chemical resistance, scuff resistance, flexibility, bondability, sterilizability by steam, and high energy irradiation [1]. Various medical applications are made from, or contain PVC, including:

• Containers for blood and urine continence products

• Containers for intravenous solution giving sets

• Catheters and cannulae

• Surgical and examination gloves

• Inhalation masks

Most of studies on polymer/clay nanocomposite preparations report the applicability of the invented method to a variety of polymers and their blends [2,3]. Furthermore, some focus on the use of blends as a matrix for the modification of performance, e.g., improving stiffness, permeability control, or a good balance of performance [2,3]. The main objective to add organoclay to a thermoplastic polymer or to a polymer blend is to improve the mechanical properties (stiffness and hardness) and thermal stability The aim of this work is to study the effects of Organically Modified Montmorillonite (OMMT) as nanofiller able to improve the strength and hardness of a Poly Vinyl Chloride (PVC) thermoplastic polymer and, above all, to check the possibility to replace, in the future, the chalk commonly used in the manufacturing of PVC based shealted electrical cable. The organoclay concentration was varied from 0.5 to 7 wt %.

Materials

A commercially available poly vinyl chloride (SE 1200) was used as the blend major component. It was in powder form with a 100 μm mean dry particle size and it had a linear structure. The plastifier used was DOP (45 wt %) and the thermal stabilizer was Ca/Zn. The reinforcement used is BENTONE 38® (BENTONE SUD, France), it is an Organically Modified Montmorillonite (OMMT) clay and it was used, as received, without washing (Cationic exchange capacity=120 mEq/100g). As mentioned by the manufacturer, the quaternary ammonium salt used for the clay organic modification is: Di-Methyl Dihydrogenated Tallow salt: 2M2HT (HT=C18H37). The organoclay was in powder form with a 20 μm mean dry particle size.

Preparation of the samples

Before blending, clay and poly vinyl chloride were dried in oven at 80°C during 24 hours. The components were first blended, at 175°C, in a dry blender (VEM MSH 25) operating at 3000 rpm. Afterwards, the resulted blend was mixed in a two roll mill (BRABENDER POLYMIX 200P). The twin roll mill possesses a nip clearance of 0.5 mm and friction ratio equal to 1.3 (20/15 rpm) and the blending was carried out for 15 minutes. The twin roll mill was operated at 145°C and 25 rpm. Finally, the blend was extruded in a single screw extruder. The extruder used is SCHWABENTHAN PLE 330; it has a ratio length/diameter equal to 21, a diameter of 20 mm, a thread thickness of 5.4 mm and the step between two successive threads equal to 15 mm. The barrel temperatures (from feed zone to die) and screw speed were set, respectively, at 170-180-190°C and 45 rpm. The screw used is conventional. Six formulations have been studied.

Characterizations

Tensile tests were done at ambient temperature (25 ± 2°C) according to ASTM D 417 with a ZWICK ROELL Z100 testing machine interfaced with a computer. The dumb-bell shaped specimens were extended at a cross head speed of 100 mm/min. The reported values of the tensile properties represent averages of the results from test runs on five specimens. The standard deviation was 2% for the maximal tensile strength and 5% for the elongation at break. The dumb-bell shaped specimens (gauge length 24 mm, width 5 mm, thickness 2 mm) were cut with a special cutting machine from sheets having 2 mm thickness. These sheets were obtained by compression moulding 35 g of each sample at 175°C in a SCHWABENTHAN POLYSTAT 300S hydraulic press, according to the following program: Preheating during 7 minutes; 50 Bars pressure applied for 2 minutes; 200 Bars applied for 3 minutes and finally, 350 bars applied for 4 minutes.

Shore A hardness tests were carried out by ZWICK ROELL HPE apparatus according to ISO 868 norm. The standard deviation for the Shore A hardness was 3%. The thermal stability of the PVC/clay composites and neat PVC were investigated by deshydrochloration test apparatus at 200°C. The thermal stability was evaluated by evaluating the time for the occurrence of the deshydrochloration (HCl releasing).

The water uptake measurements were done according to the gravimetric method (ASTM D 2765-95, Method C). The samples (circular film having 1mm thickness obtained by compression moulding) were immersed in distilled water for 3 days at 25°C. The results were averaged for five measurements. The rheological analysis was done with a Monsanto Rheometer, model 100/4308, in order to get the exerted torque vs. time. For each formulation, samples of 4.5 g weight were analyzed under temperature equal to 175°C.

Mechanical properties

It can be observed from Table 1 that the 1 wt % loading organoclay blend possesses balanced mechanical properties, i.e., the stiffness (expressed by the tensile strength and hardness) as well as the ductility (expressed by the elongation at break) are maximal. The maximal values of tensile strength, hardness, and elongation at break obtained for 1 wt % organoclay loading can be explained by the intercalation of the PP/NR chains between organoclay platelets. The improvements (up to 1 wt % organoclay loading) of tensile strength and hardness show that organoclay acts as reinforcing filler. The increase of elongation at break (up to 1 wt % organoclay loading) can be explained by the improvement of the ductility due to the compatibilization effect of the organoclay [4]. The improvements of the mechanical properties, up to 1 wt % organoclay loading, can be explained by the two step processes used in the present study (extrusion followed by compression moulding) since it has been reported that such two-step process can improve notably the properties of composites [5]. Therefore, in the present study, the inclusion of 1 wt % organoclay rigid filler leads to a better balance between strength and ductility.

| Sample | Organoclay (OMMT) (wt %) | Tensile strength (MPa) | Shore A hardness | Elongation at break (%) |

|---|---|---|---|---|

| PVC | 0 | 5.82 | 65.35 | 117.48 |

| PVC/OMMT (99.5/0.5) | 0.5 | 7.16 | 65.4 | 152.86 |

| PVC /OMMT (99.25/0.75) | 0.75 | 7.26 | 65.5 | 157.19 |

| PVC /OMMT (99/1) | 1 | 8.27 | 65.7 | 243.26 |

| PVC /OMMT (87.75/1.25) | 1.25 | 7.14 | 63.2 | 151.07 |

| PVC /OMMT (87.5/1.5) | 1.5 | 7.11 | 60.15 | 150.72 |

Table 1: Mechanical properties values of neat PVC and PVC/ Organoclay nanocomposites.

Thermal analysis

The information that seems to be important to characterize thermal stability is the time of the degradation, which is measured by the deshydrochloration duration of the tested samples. The results obtained are summarized in Table 2. One can see that the composite containing 1 wt % of organoclay the time of degradation is maximal and equal to 70 minutes. Table 2 shows clearly that the 1 wt % organoclay based blend is the more thermally stable since it presents the maximal deshydrochloration duration; this is due to the high degradation resistance of the intercalated-confined blend chains and also to the reduction of the diffusion rates of volatiles out of the material.

| Sample | Organoclay (OMMT) (wt %) | Deshydrochloration duration (min) |

|---|---|---|

| PVC | 0 | 45 |

| PVC/OMMT (99.5/0.5) | 0.5 | 48 |

| PVC /OMMT (99.25/0.75) | 0.75 | 54 |

| PVC /OMMT (99/1) | 1 | 70 |

| PVC /OMMT (87.75/1.25) | 1.25 | 34 |

| PVC /OMMT (87.5/1.5) | 1.5 | 31 |

Table 2: Mechanical properties values of neat PVC and PVC/Organoclay nanocomposites.

Rheological study

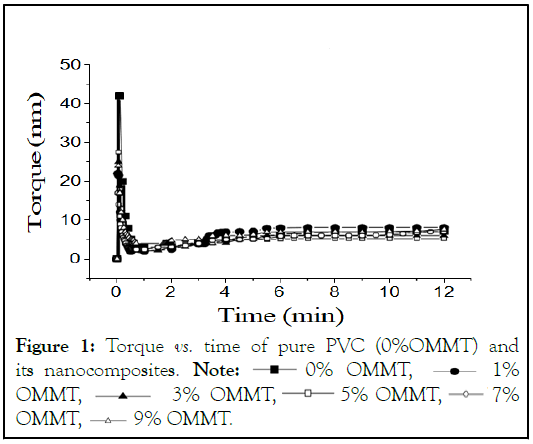

Many researchers reported that Brabender torque-time curves can be used to analyse the processing characteristics of polymer melt mixing. The equilibrium torque (stabilization torque) reached at the completion of melt mixing was used to assess the processability of the polymer mixing which is related directly to the viscosity of the blend [6,7]. On the other hand, the maximal torque (MH) can be regarded as a measure of the blend stiffness or Young’s modulus [8], and the minimal torque (ML) is related to the melt viscosity of the blend [8]. Figure 1 shows the plastograms of pure PVC and PVC/ Organoclay nanocomposites and their related results are summarized in Table 3. It can be deduced from Figure 1 and Table 3 that the incorporation of organoclay has increased the MH and MH-ML difference, whereas, the ML remains constant on the whole (approximately 3 dN.m). It can be noted that, for all formulations, the introduction of organoclay into the PVC/ Organoclay blend has not increased the torque in the steady state (BT). Furthermore, the melt viscosity, expressed by ML [8] and BT [6,7], of organoclay based formulations does not increase relatively to the pure PVC one. It can be concluded that the processability of the PVC/OMMT blend is not notably affected by the addition of the organoclay.

| Organoclay content (phr) | MH (dN.m) | ML (dN.m) | MH-ML (dN.m) | BT (dN.m) |

|---|---|---|---|---|

| 0 | 16.5 | 2.5 | 14 | 7 |

| 1 | 22 | 2 | 20 | 8 |

| 3 | 24 | 4 | 20 | 7.5 |

| 5 | 25 | 2.5 | 22.5 | 6 |

| 7 | 27.5 | 2.5 | 25 | 5.5 |

| 9 | 42 | 2.9 | 39.1 | 7 |

Table 3: Torque maximum (MH), Torque minimum (ML), torque difference (MH-ML) and Balanced Torque (BT) vs. time for PP/NR (90/10) blend and its nanocomposites.

Figure 1: Torque vs. time of pure PVC (0%OMMT) and its nanocomposites. Note:  0% OMMT,

0% OMMT,  1%

OMMT,

1%

OMMT,  3% OMMT,

3% OMMT,  5% OMMT,

5% OMMT,  7%

OMMT,

7%

OMMT,  9% OMMT.

9% OMMT.

Water uptake properties

The results of the water uptake measurement are shown in Table 4. It can be seen that the formulation containing 1.5 wt % of organoclay presents the highest water uptake rate 0.1%. The increase of the water uptake as the organoclay content increase can be explained by the aggregation of the organoclay particles. The formation and the increase of these organoclay aggregates facilitate the permeation of the solvent (water) and as a consequence increase its uptake effect [9,10].

| Organolay content (%) | Water uptake rate a(wt %) |

|---|---|

| 0 | 0.018 |

| 0.5 | 0.036 |

| 0.75 | 0.053 |

| 1 | 0.073 |

| 1.25 | 0.083 |

| 1.5 | 0.1 |

Table 4: Water resistance properties (measured in water at 25°C for 3 days)a of neat PVC and PVC/Organoclay nanocomposites. Note: a The water uptake rate was calculated as follow: Water uptake rate=(W2-W1)/W1 × 100%, where W2 is the weight of the wet sample and W1 is the weight of the dry sample.

In this study it was observed that the improvements of the mechanical and thermal properties of the prepared blend are realised for 1 wt % organoclay loading. The stiffness (expressed by the tensile strength and hardness) and ductility or toughness (expressed by the elongation at break) is well balanced for 1 wt % organoclay concentration. The thermal stability of PVC/ Organoclay blends is maximal when the concentration of the organoclay was equal to 1 wt %. The water uptake study reveals that the amount of the absorbed water does not exceed 0.1 wt % when the concentration of the organoclay is 1.5 wt %.

The rheological study revealed that the viscosity of the studied formulations does not increase with the addition of organoclay. The major finding of this study is that for the PVC/Organoclay blend, the stiffness and toughness are well balanced for 1 wt % organoclay loading and the compatibilization and reinforcement effects of the organoclay are highest for the same concentration.

[Crossref] [Google Scholar]

Citation: Bendjaouahdou C (2022) Characterization and Properties of Poly Vinyl Chloride (PVC)/Organoclay Nanocomposites. J Phys Chem Biophys. 12:334.

Received: 05-Sep-2022, Manuscript No. JPCB-22-19087; Editor assigned: 07-Sep-2022, Pre QC No. JPCB-22-19087 (PQ); Reviewed: 21-Sep-2022, QC No. JPCB-22-19087; Revised: 28-Sep-2022, Manuscript No. JPCB-22-19087 (R); Published: 05-Oct-2022 , DOI: 10.35248/2161-0398.22.12.334

Copyright: © 2022 Bendjaouahdou C. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.