Advances in dairy Research

Open Access

ISSN: 2329-888X

ISSN: 2329-888X

Research Article - (2016) Volume 4, Issue 2

Keywords: Cholesterol; Commercial yogurts; Cow milk; Goat milk; Lipolysis

Yogurt is a major fermented dairy product, resulting from the symbiotic cultures of Streptococcus thermophilus and Lactobacillus delbrueckii subsp. bulgaricus, characterized by a smooth, viscous gel with delicate walnutty flavor [1-3]. It is especially popular in Europe, North America and the Middle East. The popularity and consumption of yogurt are attributable to its well-known nutritional and health benefits [4-6]. Yogurt has various therapeutic values in human health including treatment of constipation, diarrhea, and infantile gastroenteritis [7-9]. In addition, yogurt made from goat milk would have further significance in human health, because goat milk has been known for hypoallergenic and therapeutic significance in human nutrition and medicine [10-12].

Dietary intake of high levels of dietary fat and cholesterol has been correlated with incidences of artherosclerosis and coronary heart diseases, which is a great concern over health conscious consumers [13,14]. Animal foods such as meat and dairy products contain high saturated fats and cholesterol which may cause the elevation of blood cholesterol [15]. Thus, it has been recommended that fat content should be no more than 30% of the diet, and also less than one-third of dietary fat should be saturated fat [16].

Quality of dairy products is significantly influenced by levels of peptides, amino acids and free fatty acids in the products resulting from proteolysis and lipolysis [17,18]. Volatile compounds produced by lipolysis and proteolysis play major roles in flavor and sensory characteristics of yogurts [19,20]. A myriad of biochemical and physical changes can occur in goat milk products including cheeses and yogurts during storage due to ripening and degradation of nutrients in the products [10-12]. Positive correlations have been found between lipolyzed flavor and free fatty acid contents in cheese and yogurt products during prolonged storage periods [7,9,13,19]. Flavor deterioration resulted from lipolysis of dairy products creates serious problem in storage stability. Lipolysis and lipid oxidation are affected by free fatty acids, lipolytic microorganisms and enzymes, temperature, storage time, oxygen concentration, moisture content, antioxidant or pro-oxidant, etc. [19].

Cholesterol concentrations of bovine milk products including yogurts have been reported, and effects of storage conditions on lipolysis and shelf-life of bovine dairy products have been elucidated [3,5,6,8,20]. However, little data have been available on cholesterol contents and lipolytic properties of goat milk yogurts. Furthermore, studies on comparison of cholesterol contents and lipolytic characteristics of commercial yogurts between bovine and caprine products during extended storage are almost non-existent. Therefore, the objectives of the present study were to: (i) determine cholesterol and basic nutrient contents of commercial cow and goat milk yogurts, and (ii) compare extents of lipolysis occurred between commercial bovine and caprine milk yogurt products stored under refrigeration at 4°C for 0, 2 and 4 weeks storage periods.

Experimental design and samples

The study was conducted in a 3 × 2 × 3 factorial arrangement. Three batches of 2 species of products [commercial cow milk yogurt (CCY) and goat milk yogurt (CGY)] were purchased at a local retail store located at Warner Robins, GA. All experimental yogurt samples were subjected to 4°C refrigeration storage immediately after purchase for 0, 2 and 4 weeks to evaluate cholesterol concentrations and lipolytic changes in all experimental yogurt products.

Chemical and nutrients analyses

pH: The pH of all yogurt samples was determined by a pH meter (Accumet No. 910; Fisher Scientific, Pittsburgh, PA).

Total solids: Total solids content of the yogurt samples were determined by the oven drying in a laboratory oven at 105°C for 24 hr [21]. All samples were analyzed in triplicate.

Protein: Total nitrogen content was assayed using the vario MAX CN (Model Elementar, Analysensysteme GmbH, Americas, Inc., Mt. Lauel, NJ, USA) according to the manufacturer’s procedure. In this instrument, nitrogen is separated from combustion gas (oxygen) with the help of specific adsorption columns and determined in succession with a thermal conductivity detector (TCD). Helium served as flushing and carrier gas. Total protein was calculated by % total N × factor of 6.38.

Fat: Percent fat in fluid and condensed milk samples were determined by Babcock method as described by Richardson [22] and AOAC [21].

Ash: Ash content was quantitated by dry ashing yogurt samples in a muffle furnace at 550°C for 8 hours (overnight) as described in AOAC [21].

Cholesterol assay

Cholesterol extraction: Fat extraction was performed by the modified procedure of Folch et al. [23]. A 5 g of yogurt sample and 75 mL of chloroform-methanol solution (v/v, 2:1) were placed in a Waring blender cup and homogenized for 3 min. The homogenates were filtered through Whatman No. 42 filter paper on a Buchner funnel with slight suction. The residue was re-homogenized for 3 min with 50 mL of chloroform-methanol. The combined filtrates were transferred into a 250 mL separatory funnel, and 25 mL distilled water was added. Separatory funnel was allowed to separate for aqueous and chloroform layers. The bottom chloroform layer was collected in a 100 mL volumetric flask, and the flask was placed in the refrigerator overnight. After removing small water fraction from the top of the flask and chloroform addition to the volume, the extract was stored in the freezer until cholesterol determination.

Cholesterol analysis: Cholesterol was determined using GC-17A (Shimadzu Scientific Inc., Columbia, MD) equipped with flame ionization detector (FID) and a fused silica capillary column (HP-5, 30 m × 0.32 mm inner diameter × 0.25 μm thickness). The temperatures of the injector and detector were 270°C and 300°C respectively. The GC chamber temperatures was programmed at 10°C/min to increase from 200 to 300°C and held for 20 min at 300°C. Helium was used as a carrier gas at a flow rate of 2 mL/min with a split ratio of 1/50. Quantification of cholesterol was carried out by the software program of the GC according to the manufacturer’s instruction and Gupta [24].

Evaluation of lipolysis

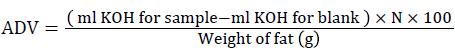

The degrees of lipolysis of all experimental yogurt samples were evaluated by acid degree value (ADV) using the procedure of Richardson [22]. Approximately 10 g of yogurt samples were placed into a Babcock cheese bottle for fat extraction. One ml of the final extracted fat was titrated against the standard alcoholic 0.2N KOH solution. The calculation of ADV was performed using the following formula:

Where N = normality of alcoholic KOH solution in methanol.

Statistical analysis

The experimental data were analyzed for analysis of variance, least square means, correlation coefficients and Duncan’s multiple mean comparisons by Steel and Torrie [25]. All experimental data of unbalanced observations were also analyzed by GLM procedure of SAS program [26].

Basic nutrient compositions

The basic nutrient compositions (%) of commercial goat and cow milk yogurts are shown in Table 1. The protein content of CCY was higher (P<0.05) than that of CGY, while there was no difference in fat contents between the two species yogurt products. These data indicates that the commercial cow yogurt products may have been produced with low-fat milk, whereas the goat counterpart products were manufactured with the whole (full-fat) milk. The ash, carbohydrates and total solids contents of goat milk yogurt were higher (P<0.05) than those of cow milk yogurt (Table 1).

| Protein | Fat | Ash | Carbohydrate | Total solids | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| CCY | 3.69a | 0.07 | 2.83a | 0.15 | 0.78b | 0.03 | 4.19b | 0.22 | 11.49b | 0.22 |

| CGY | 3.25b | 0.11 | 2.97a | 0.2 | 0.85a | 0.22 | 4.89a | 0.17 | 11.95a | 0.22 |

Table 1: Summary of basic nutrient contents (%) of commercial goat and cow milk yogurts. All observations are means of 6 samples (3 batches in duplicates). SD: Standard deviation. CCY: Commercial cow milk yogurt. CGY: Commercial Goat milk yogurt. a,bMeans with different superscripts within a same column is different (P<0.05).

The difference in carbohydrate concentration (%) between the CGY and CCY products (P<0.05) indicate that there would have been a supplementation of gums or textural stabilizers in the CGY. The actual experimental product label of the CGY revealed that tapioca and pectin gums were included as parts of the ingredients in the CGY product. These ingredients appeared to be added in the caprine product in order to improve the texture of the CGY product. This gum additions apparently increased the carbohydrate content of the CGY product, while such supplementation was absent in the experimental CCY product. The supplementation of these gums also appeared to increase the ash and total solids contents of the commercial CGY product (Table 1). The major component of the carbohydrates in yogurts is considered as lactose, while majority of the lactose in the milk would have been fermented or catabolized to lactic acid.

Since goat milk has been reported to form weak or soft gel in cultured products, several methods have been applied to improve the texture of caprine yogurts [9]. One of the main problems in manufacture of goat milk yogurt is weak and lack of consistency in curd tension or viscosity compared to cow yogurt counterpart [9]. Due to the lack of αs1-casein content in goat milk proteins compared to that in cow milk, goat milk usually coagulates for soft gel formation. This weak and soft gel formation of goat milk yogurt can cause syneresis in the final products. In order to prevent syneresis or whey separation, several methods have been used in the dairy industry, including supplementation of skim milk powder to increase total solids, enzymatic crosslinking of amino acids in the milk, and addition of stabilizer such as polysaccharides, natural or synthetic gums in the milk [9,27,28]. In the present study, the addition of those polysaccharide ingredients apparently increased the levels (%) of carbohydrate, ash and total solids in the CGY, compared to those levels in CCY counterparts (Table 1).

Cholesterol contents

Mean cholesterol concentrations (mg/100 g) of the commercial caprine and bovine milk yogurts for 0, 2 and 4 weeks storage were: 19.8, 18.4; 20.3, 17.9; 22.0, 19.7, respectively (Figure 1 and Table 2). The results showed that the goat milk yogurts contained slightly higher levels of cholesterol than those of cow counterparts for all three storage periods. The higher contents of cholesterol in the CGY than those of the CCY in this study was different from the previous reports or expected values, since caprine milk reportedly contain lower cholesterol than bovine milk (11 vs. 14 mg/100 g) [11,29,30].

| Yogurt type | Storage Period (wk) | pH | ADV | Cholesterol | |||

|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | ||

| Cow yogurt | 0 | 3.89 | 0.04 | 1.06a | 0.719 | 18.44 | 5.53 |

| 2 | 3.92 | 0.02 | 0.61c | 0.153 | 17.92 | 2.69 | |

| 4 | 3.88 | 0.02 | 0.59c | 0.123 | 19.68 | 2.02 | |

| Goat yogurt | 0 | 3.66 | 0.02 | 1.06a | 0.418 | 19.80 | 5.92 |

| 2 | 3.75 | 0.03 | 0.59c | 0.092 | 20.34 | 1.09 | |

| 4 | 3.72 | 0.03 | 0.66b | 0.068 | 22.0 | 0.88 | |

Table 2: Statistical summary of pH and ADV values of the experimental commercial cow and goat milk yogurts stored for 0, 2, and 4 weeks under refrigeration. a,b,cMeans with different superscripts within a same column is significantly different (P<0.05 or 0.01).

On the other hand, in the commercial goat milk and cow milk yogurt samples of this study, the differences in the original milks used for manufacture of the two species yogurt products may have been resulted in the differences observed in cholesterol values between the two products in the present study. These outcomes of cholesterol values appeared to be attributable to the fact that whole goat milk was used for the CGY, whereas skim or low-fat cow milk would be used to produce the CCY. This is simply because cow milk has been known to contain higher cholesterol content than goat milk [11,13]. Thus, it is expected that the higher fat contents of the goat milk yogurt would have higher levels of cholesterol in the experimental commercial goat yogurts compared to the corresponding commercial cow yogurt products. Apparently the cow yogurts were manufactured using low fat or skim cow milk. However, the differences in cholesterol contents between the two species products were not significant, while the commercial bovine products contained lower fat and cholesterol contents compared to those of the caprine counterpart products.

The variability in cholesterol levels were higher in the original (0 week) products compared to those of the 2 and 4 weeks stored yogurt samples (Figure 1), while the reason why the original yogurts of both species yogurt products had higher variability between batches than the refrigerated 2 and 4 week stored samples are not known.

pH changes in the experimental yogurts

The pH values of the two species experimental yogurts during 4 weeks refrigerated storage are shown in Table 2. The general trend of pH values revealed that the commercial bovine milk yogurt had slightly higher pH than the caprine yogurt throughout the storage period. The trend in pH values was similar for all storage periods, indicating that the goat milk yogurt was slightly more acidic than the cow counterpart. However, the differences in pH between the two species products were not significant. The pH values results of this study were in agreement with the report by Hernandez et al. [31], and also there were no significant differences in pH levels between the Universities made and commercial goat yogurt products. The variations in pH between different batches of yogurt for both species yogurts were also minimal (Table 2).

In a study of different varieties of goat and cow milk cheeses, Jin and Park [25] observed that the pH values of soft goat cheeses were initially declined at 4 weeks storage at 4°C, and then thereafter steadily increased up to 6 months of the storage. They found that the slow coagulation and natural draining without pressing for the soft cheese processing processes resulted in increased lactic acid and decreased in pH values in the soft goat milk cheeses compared to those of hard type goat cheeses. The manufacturing steps of the soft goat milk cheeses in their study may account for much lower pH values in goat products compared to those of the cow milk cheeses which contained less whey due to the pressing procedure.

Lipolysis in the yogurt products

Lipolysis of the two species experimental yogurts has been evaluated by determining acid degree values (ADV), which measures the amount of free fatty acids generated in the products. ADV can measure rancidity of milk products by de-emulsification and separation of free fat [22,31]. ADV also indicates the storage stability of the market yogurt products as well as in dairy products in general. The rancidity is closely related to the amount of free fatty acids present in the sample, suggesting that ADV is the index of the degree of lipolysis in the dairy product in question. Lipolysis or lipid hydrolysis also generates aroma compounds which are significantly related to flavors and sensory characteristics of yogurt products [32-35].

Table 2 and Figure 2 show the means and standard deviation values of ADVs for all 2 species commercial yogurt samples stored under refrigeration for 0, 2 and 4 weeks. The data displays that there were similarities in the trend of the ADV values in CCY and CGY samples throughout the storage experiment. The levels of ADV in both bovine and caprine yogurts of the initial products were significantly (P<0.05) higher than those of 2 and 4 weeks stored samples (Table 2 and Figure 2). The initial products of both species yogurts also showed high variability between batches of samples, compared to those 2 and 4 weeks stored samples. On the other hand, there were negligible changes in ADV occurred in both yogurts during 2 and 4 weeks storage. The reason why the ADV values significantly decreased after 2 weeks refrigerated storage for both commercial bovine and caprine yogurts is not clear. The initial amounts of free fatty acids in both species yogurts may have been catabolized as the storage time progressed. This phenomenon may imply that both species yogurt products had minimal lipolysis occurred during the 4 weeks refrigeration storage. Although the decreased lipolysis in cow yogurt may not be clear, the reduced lipolysis in goat yogurt could account for the supplemented tapioca and pectin, which would have stabilized the textural integrity of the caprine product, and it might have slowed down the lipolytic process of the goat yogurt products (Table 2 and Figure 2).

With respect to the analysis of variance on the main factors and their interaction effects on the pH, ADV and cholesterol levels (Table 3), there were significant effects (P<0.01) of the main factors (yogurt types and storage period) on ADV values. This means that lipolysis of the experimental yogurts was influenced by the species type of yogurt and storage times. However, the effects of main factors on the differences in pH and cholesterol content between yogurt types as well as between storage periods were not significant (Table 3). Among the interaction effects, only 2-way interaction effect of yogurt type × storage period on ADV value was significant (P<0.05). Hernandez et al. [31] also found that similar results of storage period and yogurt type × storage period interaction effects on ADV values in their yogurt studies. However, all other 2-way and 3-way interactions on pH, ADV and cholesterol contents were was not significant. None of the 3-way interaction, yogurt type × storage time × batch effect, showed any significant impact on the three tested parameters of both species commercial yogurt products (Table 3).

| df | pH | ADV | Cholesterol | |

|---|---|---|---|---|

| Yogurt type | 1 | 0.004 | 7.352** | 0.845 |

| Batch | 2 | 0.189 | 0.460 | 2.753 |

| Storage period | 2 | 0.624 | 8.167** | 1.077 |

| Type x batch | 2 | 0.023 | 0.238 | 0.161 |

| Type x storage | 2 | 0.002 | 4.875* | 0.093 |

| Type x batch x storage | 4 | 0.019 | 0.077 | 0.415 |

Table 3: Analysis of variance (F values) for the effects of main factors and their interactions on levels of pH and ADV of the two experimental yogurt products. **Significant at P<0.01, *Significant at P<0.05.

The commercial goat yogurt (CGY) contained higher levels of total solids, fat, carbohydrates and ash contents than the commercial cow yogurt (CCY), which may account for the added tapioca and pectin in the CGY product. The supplementations of such polysaccharides appeared to stabilize textural integrity and pH of the commercial goat milk yogurt during the 4 weeks storage under refrigeration. No significant changes occurred in cholesterol contents of the two species commercial yogurt products throughout the four weeks storage period.

The decreases in ADV values from the beginning (0 week) to 2 and 4 weeks storage in both CCY and CGY products suggest that lipolysis of the two species yogurt products was declined after 2 weeks storage. Further studies may be necessary to examine the effect of stabilizer (gums) addition on storage stability of two species commercial yogurt products that are produced under the identical processing conditions.

This research was supported by the Evan-Allen Grants Funds (No. GEOX-3217) of the National Institute of Food and Agriculture, the United States Department of Agriculture.