Advances in Automobile Engineering

Open Access

ISSN: 2167-7670

ISSN: 2167-7670

Research Article - (2016) Volume 5, Issue 2

The purpose of this research is to analyze different types of disc brake rotors, which are commonly used in automobile industry and to propose a new design of brake rotor. Analysis of brake rotor includes Structural analysis and Steady state Thermal analysis for each design. A comparison between the existing brake rotors and proposed new design is carried out and based on the results the best design is found out by ANSYS software.

<Keywords: Mechanical device; Electrical devices; Disc brake rotors; Heat energy

Brakes are mechanical or sometimes electrical devices or components that help to decelerate the vehicle and eventually stop the vehicle in a certain time and certain distance called the stopping distance or the braking distance. The automotive brake is basically a mechanical device which inhibits motion, slowing or stopping a moving object, here, the automobile, and thereby preventing its motion [1]. Brakes are one of the most significant safety systems in any automobile. Functioning of brakes is based on the conservation of energy. Most commonly used brakes are frictional brakes, where the friction produced between two objects convert the kinetic energy of the moving vehicle into heat energy.

Theory of brakes

Frictional brakes: Friction brakes are the most commonly employed braking system in commercial or special purpose vehicles. They generally are rotating devices with a rotating wear surface like Disc or drum and a stationary pad or a shoe. Here, the kinetic energy of the moving vehicle is utilized to stop the vehicle by conversion of this kinetic energy into heat energy/frictional energy [2]. A few common configurations of this type of braking are disc brakes, drum brakes and hydrodynamic brakes.

Disc brakes: Shoes or pads contract and provide compressive frictional force on the outer surface of a rotating Disc. It is a circular metal Disc on which the pads are mounted. Usually it is made up of cast iron material. The design of Disc brakes is varied depending on the application, amount of exposure, thermal properties of the material and the amount of heat dissipation required when brakes are applied and the total mass to be stopped [3].

This project report will contain the design of a Disc brake rotor, and analyze results of Structural and Thermal Analysis at a later stage.

Drum brakes: Shoes or lining expand and rub against the inside surface of a rotating drum. Drum is again made up of cast iron material and mounted in the wheel hub in such a manner that the liner pads attach themselves to the inner surface of the drum and during the braking process, the shoe or brake lining expand or move outwards, due to the cam and spring action, to attach themselves to the brake drum which provides friction and causes the drum to retard or stop its rotating motion. Drums are usually heavier than Disc brakes and occupy significantly more space due the lining and drum it and hence its application in commercial vehicles is somewhat restricted [4].

Generally it is noticed and observed that Disc brakes provide a better stopping performance and at the same time are safer and cost efficient, the incorporation of 4 wheel Disc brakes have been increased from the former front Disc brakes and rear drum brakes system. However, the drum type brakes are better at performance when the mass of the automobile increases, and thus, drum brakes are common in heavy automobiles (Figure 1).

Pumping brakes: As the name suggests, pumping brakes are used where a pump is already one of the components of equipment or the machinery system. For example, an internal-combustion piston motor can have the fuel supply stopped, and then internal pumping losses of the engine create some braking. Pumping brakes dump energy losses into heat energy. At times, some pumping brakes can act as regenerative brakes that can recharge a pressure reservoir called the hydraulic accumulator.

Electromagnetic brakes: Here, again, as the name goes, Electromagnetic brakes are equipped in systems in which an electric motor is pre-installed. For instance, hybrid gasoline and electrical automobiles use an electrical motor for the purpose of battery charging. This motor is in turn used as a regenerative brake. Electromagnetic brakes or Electro-mechanical brakes, as formerly referred, retard or stop the motion using electromagnetic force which applies a mechanical resistance or friction.

The working principle of the electromagnetic brake is based on an electric retarder. This electric retarded works on the creation of eddy currents [5]. Electromagnetic brakes also use metal Discs or drums. The eddy currents are generated within the metal Disc or drum rotating between two electromagnets. These generated eddy currents set up a force opposite to the direction of the rotating Disc/ drum. When the electromagnet is energized, retardation of the rotating element takes place and as a result heat energy is produced in the process of electromagnetic energy absorption. The braking is directly proportional to the generation of the current. More the current, higher the braking torque.

Major applications of this type of braking are in trains, trams, industrial electric motors and robotic applications. Recent developments and innovations in designs have made the use of electromagnetic brakes possible even in aircraft industries (Figure 2).

Working of electromagnetic brakes

Engagement: Electromechanical brakes work through an electric activation, however transmit torque mechanically. At the point when voltage/current is provided, the curl is energized making an attractive field. This transforms the curl into an electromagnet that creates attractive lines of flux. The attractive flux pulls in the armature to the substance of the brake. The armature and center are typically mounted on the pole (client supplied) that is turning. Since the brake loop is mounted decidedly, the brake armature, center and shaft arrive at a stop in a short measure of time [6].

Disengagement: When current/voltage is withdrawn from the brake, the armature becomes free to turn along with the shaft. Armature is held by the springs away from the brake surface as the power is released and a small air gap is created [7].

Cycling: Cycling is obtained by turning the voltage/current to the coil on and off. Slippage should occur only during deceleration. When the brake is engaged, there should be no slippage once the brake comes to a full stop.

Hydraulic brakes: This type of braking system is one of the basic types of braking and as per its name; this braking system uses a fluid called the brake fluid for its braking mechanism. Ethylene Glycol is one common and most typically used brake fluid. The brake fluid helps in transferring pressure applied by the operator/driver on the brake pedal to the actual braking mechanism which is located near the wheels of the vehicle.

The most common arrangement of hydraulic brakes consists of the following:

(i) A lever or a brake pedal

(ii) Pushrod or actuating rod

(iii) Master cylinder assembly

(iv) Hydraulic lines

(v) Brake caliper assembly

Working of hydraulic brakes: As the driver presses the brake pedal or the lever, the push rod exerts a force called the braking force on the pistons placed in the brake master cylinder located just behind the brake pedal of the vehicle causing the brake fluid to flow into the pressure chamber [8]. Consequently, overall pressure in the entire system increases which in turn forces the fluid to flow through hydraulic lines, which are nothing but pipes through which through which the fluid can easily flow, towards one or more calipers based on the hydraulic braking system design. The calipers are also designed accordingly that sufficient force is applied to the Discs or drums to provide required frictional force for braking (Figure 3).

Introduction to disc brakes

Fredrick William Lanchester, a Birmingham car maker, designed the first Disc brakes in 1902. This first design, the original design, was made in such a way that there were two Discs that pressed against each other to generate friction and slow down a moving vehicle. Only in 1949, production of Disc brakes was incorporated and acknowledged by the automotive industries. Disc brakes are a two-part system, first being Disc/rotor and the second being the brake caliper assembly. One or sometimes more hydraulic action pistons are a part of the caliper assembly that push against the back of a brake pad thereby, clamping them around the spinning or the rotating Disc/rotor from both the sides. And naturally, harder the clamping action, more the magnitude of frictional force, more the generation of friction, more the heat generation and equally, more the transfer of kinetic energy. Hence, the Disc brake rotor design is mainly based on these crucial factors like heat generation, heat dissipation, amount of force applied by the operator/driver (Figure 4).

The main components of a Disc brake are:

• Brake pads

• Calipers, containing piston(s)

• Disc brake rotor

The brake pads squeeze the rotor mounted in the brake hub along with the wheel. The rotor rotates or spins along with the wheel at the same rotational velocity (rpm) as that of the wheel. Force, in this case, from the pads to the rotor is transmitted through the hydraulic action of a fluid called the brake fluid as described earlier in the project report. Friction is created between the rotors and the pad resulting into retardation action and stopping of the vehicle (Figure 5).

Types of disc brakes

Opposed piston type disc brake: These types of disc brakes are generally classified as dual piston type. And as the name says, the two pistons are placed on the opposite sides of the brake rotor. Apart from the two pistons, no other moving parts are present. One advantage of this type is that it provides an even pressure distribution between the rotors and the pads, thus providing better braking performance especially under severe braking conditions.

The number of pistons equipped in a Disc brake system is referred to as number of pots. In order to increase the performance even more, the number of pots can be increased depending on the type of vehicle, nature of braking condition and comfort considerations. For example, there exist, apart from a 2-pot model, 4-pot and 6-pot models in both commercial as well as high performance vehicles (Figure 6).

Floating caliper type disc brake: Floating Caliper type Disc brakes have piston(s), generally two, only on the inner side of the rotor. While the brake is engaged, the rotor is pressed against the inner brake pad by the piston. Consequently, a reaction force is generated that moves the caliper along an attached slide pin which in turn pushes outer pad against the rotor to achieve two side clamping action and thereby, achieve braking action.

Many commercial vehicles have floating caliper type Disc brake as it simple, occupies lesser weight than the its counterpart, has lower manufacturing cost and requires lesser space in the vehicle (Figure 7).

More about disc brakes: Brake rotors are an important component in the braking system that stops your vehicle. Brake rotors (also called the brake discs) are what any vehicle’s brake pads clamp against on to stop the wheels from spinning or rotating. It may be surprising to learn that the brake rotors are actually as important to stopping their vehicle as the brake pads are. Like other brake parts, there are several different types of brake rotors available. We’ll take a look at a variety of them below in this project report, listing out the strong advantageous points and drawbacks of each along the way.

Also, earlier it was mentioned that factors like amount of heat released while braking and amount of heat dissipation are considered as crucial factors in deciding the design and material of the braking system. Elaborating on the same we can say that, any vehicle moving at any certain velocity has kinetic energy. And in order to stop the vehicle, the velocity of the vehicle must be bought down to zero and hence the brakes have to remove this generated kinetic energy due to the initial velocity [9]. So basically, every time when brakes are applied and the brake pedal is pushed, conversion of the stored kinetic energy into heat energy takes place due to the generation of friction between the rotor and the brake pads.

As a conclusion, it wouldn’t be wrong to say that cars moving at a higher velocity generates larger amount of kinetic energy and requires correct and proper heat dissipation while braking. So as to provide the automobiles with the required heat dissipation, the design of Disc brake rotors is altered and innovations and changes are incorporated. And therefore, in most vehicles, Disc brakes are vented, that is provided with vents through the entire Disc thickness. These Discs have a set of vanes between the two sides of the Disc which helps to pump air through the Disc to provide cooling while braking (Figure 8).

• The discs of brakes are generally made of pearlitic gray cast iron. The material is cheap and has good anti-wear properties.

• Cast steel discs have also been employed in some cases, which wear still less and provide higher coefficient of friction; yet the big drawback in their case is the less uniform frictional behavior.

• Two types of discs have been employed in various makes of disc brakes, i.e., the solid or the ventilated type.

• Disadvantages of ventilated type discs:

a) Usually thicker and even sometimes heavier than solid discs.

b) In case of severe braking conditions, they are liable to wrap.

c) Dirt accumulates in the vents, which affects cooling, resulting in wheel imbalance.

d) Expensive.

e) Difficult to turn. Turning produces vibrations which reduces the life of the disc.

Types of disc brake rotors

Mainly, disc brakes can be vented or non-vented. Vented have two discs or rotors connected to one another via vents or protrudes and thus have larger surface area while non-vented are just a single disc having relatively smaller surface area. Also, depending on the use, performance required and amount of heat to be dissipated; different types of Disc rotors are equipped in an automobile. Essentially, there are four types of brake Disc rotors:

Normal disc rotors: These are the most standard, flat faced Disc rotors and are generally equipped on almost every commercial use vehicle. These rotors provide the maximum surface area touching the brake pads while braking and thus, have a better braking power. However the disadvantage of this type if rotors is that there is no way for the built up gas during braking to escape which in turn causes brake fade and pad glazing.

Brake fade is nothing but loss of partial or total braking power used in a vehicle braking system while pad glazing is the formation of certain oxides on the pad material or the rotor surface. Brake fading occurs when there is no sufficient mutual friction between the pads and the rotor surface. In normal Disc rotors, sometimes the excessive heat which is generated and cannot be escaped wrap the Disc and cause the rotor to wear if it is poorly manufactured or is paired with inappropriate rotors (Figure 9).

Drilled disc rotors: As the name implies, drilled Disc rotors have holes drilled through the entire Disc thickness. Now drilling holes through a metal especially something like rotors may seem to be counterintuitive as having holes reduces the surface attachment area for the pads and rotors. However there are a few reasons for it to make sense having drilled rotors.

As we know that the heat developed due to friction needs to be escaped, holes through the Disc rotor help the heat to dissipate and escape as the overall surface are of the rotor increases. Also the gas build up due to heat can escape out through these holes and not be trapped between the rotor and the pads. As the result of the above two, brake fading and pad glazing are reduced considerably. Also, when the vehicle passes through a puddle, rain or any wet surface, the rotor and other braking components may get wet and slippery, causing improper friction and thus reduced braking performance. Having drilled holes on a brake rotor makes it easy for heat, gas and water to be quickly moved away from the rotor surface, keeping the brake performance strong.

The only downside of using drilled rotors on your vehicle is that all of those holes tend to weaken the rotors - just like punching holes in the wall of a house would weaken the wall [10]. After repeated stressful driving, the rotors can even crack. And these drilled rotors have a limited life even after providing better performance (Figure 10).

A part of drilled Disc rotors are the cross-drilled Disc brake rotors. The only difference between the drilled and the cross drilled rotors is that in the former one, holes are drilled normal (perpendicular) to the Disc surface, while in the later, they are drilled at an angle. Cross drilled rotors have the only advantage over normal drilled rotors that the overall surface area of the rotor is more and thus a better heat dissipation take place.

Slotted/grooved disc rotors: Slotted brake rotors use slots carved into the flat metal surface to move gas, heat and water away from the surface of the rotors. Slotted brake rotors are popular with performance car drivers because the type of driving they do puts a lot of stress on the rotors. They also eject brake pad dust to stop glazing of the pad. This keeps the pad face fresh allowing better braking. But even slotted rotors aren’t perfect either. The problem is that grooved discs have a tendency to be louder when the brakes are applied due to the scrubbing of the pads. They tend to wear down brake pads very quickly. Because of this, the most common type of performance brake rotors found on production performance cars are of the drilled variety. While that type of construction is seen as too weak for racing applications, most everyday drivers should have no trouble with drilled rotors on their street cars and can save the slotted rotors for cars that are racetrackbound. Also, there is a certain way in which the slotted Disc rotors should be installed as the requirement of dust removal is to be met. As the Disc rotates or spins in its normal direction, the spinning of grooves/ slots should be outwards allowing the dust and other foreign particles to be ejected out away from the hub and brake lining; otherwise the dust might accumulate towards the center and damage the rotor and other important brake parts (Figures 11 and 12).

Miscellaneous types: The other random Disc rotors which cannot be classified as a broad category but are commonly used are:

• Bicycle brake rotors

• Motorcycle brake rotors

• Truck brake rotors

• Performance brake rotors

• Combined brake rotors

Bicycle and Motorcycle brake rotors are light weight as they do not experience the automobile’s heavy weight. As a measure of safety and custom looks, rotors used in bicycle and motorcycle brakes are either slotted or drilled. Trucks and other heavy automobiles required a larger stopping force that is a higher braking force. In order to withstand this large braking force, larger and heavier brake rotors are used as high amount of friction is required to be generated. Heavy automobile rotors need frequent replacements due to additional stress on the rotors and pads due to high vehicle weigh. Talking about high performance rotors, slotted, and not drilled, rotors are the choice of most racers. The benefit of the slots is that they allow hot gases, water and other debris to move off of the face of the rotor; however, they do tend to wear the brake pads down faster. That’s likely not a problem for most performance drivers. Most probably already have ceramic or carbon fiber brake pads which are pretty long-wearing anyway.

Combined brake rotors are typical combinations of the basic types of brake rotors, the most common combination is the drilled and slotted brake rotors. Combining two types of rotors adds up the pros of the two individual rotors and tries to reduce their cons. As in the case of drilled and grooved rotors, both help the surface area to increase significantly, avoid dust accumulation and debris formation, prevents brake fading and pad rubbing. However, with providing a great braking performance, the strength of such combined type rotors reduces as they have both slots and drilled holes that reduce the volume of the material used. The image below shows the typical drilled and grooved combined Disc brake rotor (Figures 13 and 14).

Before proceeding with the design of the disc brake, it is of utmost importance to first understand the brake requirements, following mentioned are a few of them:

• Brakes must be strong enough to stop the vehicle within a minimum distance in an emergency.

• Brakes must have good ant fade characteristics i.e., their effectiveness should not decrease with constant prolonged application.

• They should have well anti wear properties.

• The material should be selected such that it is able to withstand high temperatures and heat.

Definition of the problem

The objective/specification of the present work are to design and analyze disc rotors made of gray cast iron. Cast Iron materials are used to design the disc rotors. The rotor will be then be optimized based on some parameters to get the best possible design. The rotor was created in Solid Works and imported to ANSYS for analysis.

Material selection

Brakes are of utmost importance in an automobile and safety of the operator and passengers depend directly on the braking system, the material for the disc rotors must be chosen appropriately (Figure 15). Many materials are widely available in the market like ceramic components, carbon-carbon composites, stainless steels and cast iron components; gray cast iron is apt for rotors because of its strength and thermal properties, high temperature resistance and availability. Properties of gray cast iron are listed in the Table 1 below.

| Density (kg/m3) | 7200 |

| Young’sModulus (GPa) | 125 |

| Poisson’s ratio | 0.25 |

| ThermalConductivity (W/m-K) | 54.5 |

| SpecificHeat (J/kg-K) | 586 |

| Coefficient of friction | 0.25 |

Table 1: Properties of gray cast iron.

Design calculations for disc brake rotor

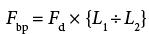

The brake pedal: The brake pedal exists to multiply the force exerted by the driver’s foot. From elementary statics, the force increase will be equal to the driver’s applied force multiplied by the lever ratio of the brake pedal assembly:

where,

Fbp = the force output of the brake pedal assembly

Fd = the force applied to the pedal pad by the driver = 370 N

L1 = the distance from the brake pedal arm pivot to the output rod clevis attachment

L2 = the distance from the brake pedal arm pivot to the brake pedal pad

(L1/L2 = 4)

The master cylinder: Assuming incompressible liquids and infinitely rigid hydraulic vessels, the pressure generated by the master cylinder will be equal to:

where,

Pmc = the hydraulic pressure generated by the master cylinder.

Amc = the effective area of the master cylinder hydraulic piston = 0.000285 m.2

Brake fluid, brake pipes and hoses: Assuming no losses along the length of the brake lines, the pressure transmitted to the calipers will be equal to:

Pcal = Pmc

where,

Pcal = the hydraulic pressure transmitted to the caliper.

The caliper, Part I: The one-sided linear mechanical force generated by the caliper will be equal to:

Fcal = Pcal × Acal

where,

Fcal = the one-sided linear mechanical force generated by the caliper.

Acal = the effective area of the caliper hydraulic piston(s) found on one half of the caliper body = 0.0007068 m.2

The caliper, Part II: The clamping force will be equal to, in theory, twice the linear mechanical force as follows:

FClamp = Fcal × 2

where,

FClamp = the clamp force generated by the caliper.

The brake pads: The clamping force causes friction which acts normal to this force and tangential to the plane of the rotor. The friction force is given by:

Ffriction = FClamp × μbp

Ffriction = the frictional force generated by the brake pads opposing the rotation of the roftor.

μbp = the coefficient of friction between the brake pad and the rotor = 0.4 (assumed).

The rotor: This torque is related to the brake pad frictional force as follows:

Tr = Ffriction × Reff

where,

Tr = the torque generated by the rotor.

Reff = the effective radius (effective moment arm) of the rotor (measured from the rotor center of rotation to the center of pressure of the caliper pistons).

This torque generated by the rotor will be equal to the torque required to stop the vehicle. In this report, they follow

• Mass of the vehicle = 300 kg.

• Maximum velocity of the vehicle = 80 km/hr or 22.22 m/s.

• Stopping Distance = 11.69 m.

• Tire Size = 23 in diameter that is 584.2 mm with 7 mm thickness

• Disc flange or thickness = 16 mm.

• 50-50 wheel bias that is equal braking force is generated in all the 4 wheels of the vehicle.

Total force generated during braking to stop the car,

F = m*a, a = deceleration during braking = v2/2s = 22.222/2 x 11.69 = 21.12 m/s2

F= 300 x 21.12

F= 6336 N.

Torque required stopping the vehicle,

Tr = F/4 * Rw

Tr = 6336/4 x 0.2921

Tr = 462.54 N-m.

As mentioned in above formulae,

Fbp = Fd * (L1/L2)

Fbp = 370 x 4

Fbp = 1480 N.

P = Fbp/Amc

Pmc = 1480/0.000285

Pmc = 5192982.456 Pa

Pmc = Pcal = 5192982.456 Pa

Fcal = Pcal * Acal

Fcal = 5192982.456 x 0.0007068

Fcal = 3670.4 N.

Clamping Force = 2Fcal.

Fclamp = 7340.8 N.

Ffriction = Frictional force generated on the rotor during braking process,

Ffriction = 7340.8 × 0.4

Ffriction = 2936.32 N

Torque generated by the rotor during braking = Ffriction* Reff = 462.54 Therefore, the effective rotor radius Reff = 0.1575 m.

Thus, the Effective Rotor Radius is 0.1575 meters that is 6.2 inches or 157.5 mm. And thus, the effective diameter is 315 mm.

Based on this effective diameter, the outer diameter of the disc is decided to be 381 mm and the inner diameter to be 125 mm.

Kinetic Energy developed during braking,

KE = ½ mv2

KE = ½ x 300 x (22.22)2

KE = 74059.26 J

Total Braking Energy/Heat required for the vehicle is equal to the total Kinetic Energy generated by the vehicle,

Thus Heat (Q) generated,

Qg = 74059.26 J

Since assumption of 50-50 wheel bias is made, this heat will be equally distributed in the 4 wheels of the car, thus equally distributed in the 4 rotors. So, heat generated in 1 rotor, Qg = 18514.815

Now, the stopping time of the vehicle will be velocity/deceleration,

t = v/a

t = 22.22/21.12

t = 1.05 sec.

Hence, power generated in one rotor

P = Qg/t

P = 18514.815/1.05

P = 17633.16 Watts.

Thereby, we can calculate the heat flux through one disc rotor with 0.381m outer diameter and 0.125m inner diameter.

Heat flux = 4 * P/3.14 * (Do2-Di2)

Heat flux = 4 x 17633.16/3.14 x (0.3812 – 0.1252)

Heat flux = 173408.3233 Watts/m2.

Calculations for heat transfer coeffcient

We consider warping temperature of Gray Cast Iron to calculate the film temperature, assuming the ambient or surrounding temperature to be 300 K. Warping temperature is the temperature at which deformation just begins and it is generally numerically equal to 70% of the melting temperature of the metal.

Tmelt for gray cast iron = 1538°C.

Twarp for gray cast iron = 70% (1538)

Twarp for gray cast iron = 1077°C. = 1350 K

Ambient temperature = Tamb = 300 K.

Film temperature = (Twarp + Tamb)/2

Film temperature = 825 K

Thus, for the required calculations for the heat transfer coefficient at the film temperature, the air properties at this film temperature, 825 K or approx. 552°C will be considered (Figures 16 and 17). The required properties of air are summarized in the Table 2 below.

| Temperature (T) (°C) | 552 |

| Density (p) (kg/m3) | 0.430 |

| AbsoluteViscosity (u) (Ns/m2) | 37.66 x 10-6 |

| ThermalDiffusivity (a) (m2/s) | 126.96 x 10-6 |

| PrantdlNumber (Pr) | 0.693 |

| SpecificHeat (Cp) (J/kg-K) | 1103.5 |

| ThermalConductivity (k) (W/m-K) | 0.059835 |

Table 2: Properties of air at 552oC.

Relative velocity of air (v) = 22.22 m/s

Diameter of the rotor = 0.381 m

Reynold’s Number, Re = p*v*d/u

Re = (22.22 x 0.430 x 0.381)/(37.66 x 10-6)

Re = 96662.31

Nusselt Number, Nu = 0.0266 (Re)0.805 x (Pr)0.333

Nu = 0.0266 (96662.31)0.805 x (0.693)0.333

Nu = 242.65

Forced Convective Heat Transfer Coefficient, h,

h = (Nu*k)/d

h = 242.65 x 0.059835/0.381

h = 38.11 Watts/m2-K

Modeling in solid works

In order to obtain a 3D model of the disc brake rotor, a 2D sketch was initially prepared in the part sketch in the modeling software Solid Works. 2 disc rotors were prepared to compare the results for. One a normal, non-vented solid disc rotor and a drilled disc rotor of same circular dimensions and flange thickness. Given below are few illustrations of steps followed in the computer/software aided designing (Figures 18-22).

Finite element analysis

The finite element method is a powerful tool to obtain the numerical solution of wide range of engineering problems. The method is generally sufficient to handle any complex shapes or geometries, for any material under different boundary and loading conditions. The generality of the finite element method fits the analysis requirement of present day’s complex engineering systems and designs where solutions of governing equilibrium equations are usually not available. In addition, it is an efficient design tool by which designers can perform parametric design studies by considering various design cases, (different shapes, materials, loads, etc.) and analyze them to choose the optimum design.

The method originated in the aerospace industry as a tool to study stress in a complex airframe structures. It grows out of what was called the matrix analysis method used in aircraft design. The method has gained increased popularity among both researchers and practitioners. The basic concept of finite element method is that a body or structure is divided into small elements of finite dimensions called “finite elements” through generation of meshes. The original body or the structure is then considered, as an assemblage of these elements connected at a finite number of joints called nodes or nodal points. This analysis employs the technique of vibrations and calculus to produce accurate results.

In this project, structural and thermal analysis of two disc rotors, i.e., normal solid disc rotor and a drilled disc rotor are performed to compare the results and derive inferences and conclusions. However, the methodology followed for the analysis of both the rotor are the same.

Static structural analysis

Total deformation, total equivalent stress and equivalent elastic strain are obtained for this analysis. A static analysis is performed over a structure when the loads & boundary conditions remain stationary and do not change over time it is assumed that the load or field conditions are applied gradually, not suddenly. The system under analysis can be linear or nonlinear. Inertia and damping effects are ignored in structural analysis. In structural analysis following matrices are solved [K].[X] = [F], where K is stiffness matrix, X is displacement matrix and F is the force matrix. The above equation is called the force balance equation for the linear system. Nonlinear systems include large deformation, plasticity etc.

Generation of mesh: Creating a mesh in the imported geometry is an important step in ANSYS analysis as the size of the finite element is decided by the mesh properties. Finer the mesh is, more accurate are the results (Figures 23-25).

Applying boundary conditions: The next step in the static structural ANSYS analysis is to apply the boundary conditions. Since the analysis is performed for deformation, displacement, stress and strain, the boundary conditions of force and rotational velocity is applied. Frictional force of 2936.32 Newton is applied on both the faces of the rotor where the pads would attach and clamp themselves. Rotational velocity is also given to the entire body equal to the value of N = 1000*v/3.14*(d0-di) which is equal to 27.63 rpm and thus, w = 2N* 3.14/60, which implies w = 2.895 rad/sec. Also since the disc has to be fixed at its centers, fixed supports are given to the hub bolts and the inner portion of the entire inner circle. Thus, overall there are 4 initial boundary conditions given to the disc rotors model or geometry before proceeding to the solution.

Solving the model: Once the conditions are applied, the model is solved for three factors:

1. Total deformation

2. Equivalent stress

3. Equivalent elastic strain

Normal solid disc rotor

(Figures 26-29).

Drilled disc rotor

(Figures 30-33).

Steady state thermal analysis

Temperature variation and heat flux throughout the geometry of the rotor are calculated and analyzed here. Due to the application of brakes on the car disc brake rotor, heat generation takes place due to friction and this temperature so generated has to be conducted and dispersed across the disc rotor cross section. The condition of braking is very much severe and thus the thermal analysis has to be carried out.

A steady state thermal analysis determines the temperature distribution and other thermal quantities under steady state loading conditions. A steady state loading condition is a situation where heat storage effects varying over a period of time can be ignored.

Generation of mesh: Meshing here also is done in the similar manner as the previous case with fine mesh relevance with element sizing of 0.1 m. The mesh behaves in the same manner and thermal results are evaluated in the same mesh.

Applying boundary conditions: The following table gives a brief description about the initial boundary conditions applied on the disc rotor, both solid and drilled, for the steady state thermal analysis (Table 3).

| Heat flux (W/m2) | 173408.3233 |

| Film convective heat transfer coefficient (W/m2-K) | 38.11 |

| Radiation (K) | (K) 22-27°C |

Table 3: Thermal loads on disc brake rotor.

Solving the model: Once the conditions are applied, the model is solved for two factors:

1. Temperature range

2. Total heat flux

Normal solid disc rotor

(Figures 34-36).

Drilled disc rotor

(Figures 37-39).

Brakes are of utmost importance in an automobile. Design of brakes, later in this project, is completely based on pure mechanical modeling and calculation. Brakes in commercial or performance vehicles are used depending on the specifications required and the braking force required.

It is also seen that Disc Brakes are the most popular brakes among all brake types and have a wide range of application. Various types of Disc brakes and Brake Disc Rotors are studied and the design is understood.

Solid and Drilled Rotors of 381 mm outer diameter, 125 mm inner diameter and 16 mm flange thickness are made using computer aided design software Solid works and analyzed on an analysis software ANSYS. Due to limitations in time and software knowledge and resource, analysis is performed only for static structure and steady state thermal toolbox in ANSYS. The table below summarizes the results observed for these two mention analysis (Table 4).

| Normal Solid Rotor | Drilled Rotor | |

|---|---|---|

| Total Deformation (m) | 0 - 1.13x10-6 | 0 – 9.73x10-7 |

| Equivalent Stress (Pa) | 6050.8 – 2.27x106 | 4374.9 – 2.04x106 |

| EquivalentElasticStrain | 9.12x10-8 – 2.12x10-5 | 1.19x10-7 – 1.91x10-5 |

| Temperature (°C) | 321.26 – 498.24 | 305.63 – 492.47 |

| Total Heat Flux (W/m2) | 714.4 – 2.06x105 | 621.39 – 3.21x105 |

Table 4: Result summary of the analysis.

On the basis of the analysis and the results, it is observed that that solid as well as the drilled rotor are structurally safe as the total maximum stress is within the ultimate stress limits for the material used which is gray cast iron. Also, the rotor can be equipped in a real time automobile as its total maximum deformation are 0.00113 mm and 0.000973 mm respectively for solid and drilled rotor. The temperature variation and heat flux is nearly the same for both rotors, however for the drilled rotor, maximum temperature and the overall heat flux is slightly lesser due to increased surface area for heat dissipation while braking due to the drilled holes.

As a final conclusion and inference, it wouldn’t be wrong to say that drilled rotors have a better performance when compared to nonvented solid rotors due to reduced stress, strain, overall deformation and thermal stability. Hence, drilled rotors are generally used in performance cars like sports cars, ATV’s and UTV’s. However, drilled rotors are generally weak and at times difficult to manufacture and hence, usual commercial vehicles on roads prefer solid disc rotors.

Future scope

Once the design and analysis is done, as in this project report, there is always a scope for improvement and optimization of the design based on the available present results. The design can further be optimized and further analysis can be done so as to reduce the overall total stress, deformation and temperature variation. As a result of further optimization in the design, the best possible design can be obtained as a result of dimensional variation and practical application.