Journal of Ergonomics

Open Access

ISSN: 2165-7556

ISSN: 2165-7556

Research Article - (2019)Volume 9, Issue 6

India is the largest manufacturer of farm equipment like tractor, harvester and tiller. It accounts one third global tractor production. Tractor sale in the country is expected to increase 11-13 per cent in the financial year 2019 while the tractor industry is expected to grow at 8-10 per cent during 2019-23. In the country, the agricultural tractors used for different farm operations starting from land preparation up to harvesting and transportation of agricultural products. Due to this various types of random vibrations, generated from terrain and tractor engine, is transmitted to the operator through seat suspension. Most of the tractors available in India, are attached with a passive type vertical seat suspension which is found to decrease vibration in vertical direction. Many research works have been done in optimisation/modification of the seat suspension parameters alone and development of new seat suspension. But none of them optimize the seat suspension parameters in combination. Hence, the following study was conducted to determine the optimized value of seat suspension parameters for which the vibration transmitted to the operator could be minimum. For this a seat suspension model was developed in AMESim software. The model requires input signal which was tractor seat mounting vibration data and gives the model output data as seat cushion vibration. When the model output data was compared with the test result data for the same vibration input, it was found to have 77.93 per cent correlation. The optimization result of seat suspension parameters alone, spring stiffness of 12000 N/m damping coefficient of 4225 N.s/m was observed to have minimum vibration. While optimizing both the suspension parameters, the combination of 3000 N/m and 2225 N.s/m was found to have minimum vibration. However, it was only 10.79 per cent less than the measured vibration value which might not be an economical decision though there is reduction in vibration.

Tractor; Seat suspension; Vibration; Spring stiffness; Suspension

India is one of the largest manufacturer of farm equipment like tractor, harvester and tiller. It accounts for one third of total global tractor production. Tractor sale in the country is expected to increase 11-13 per cent in the financial year 2019-2020 while the tractor industry is expected to grow at 8-10 per cent during 2019- 23 [1]. In the country, the agricultural tractors are mainly used for tillage operations, seeding and planting operation, spraying and fertilizing operation and transportation of agricultural goods as well as people in the country. The tractor operated machines and equipment used in farming generate vibrations which are more detrimental than the physical work to generate fatigue and discomfort in operators [2,3]. These vibrations, generated from the engine and ground surface, is transmitted to the operator through seat suspension system attached in tractors [4,5]. The modern days’ high power agricultural tractors are equipped with suspension at front axle, rear axle, cabin and at seat [6]. However, in most of the Indian tractors due to its lower rated power (less than 55 hp), fitted with passive type seat suspension system which is less costly as compared to other off-road vehicle seat suspensions. This type of seat suspension has two springs attached in parallel and a damper in series. It is a vertical type suspension system and its effectiveness to reduce vibration depends on operator weight and spring stiffness adjustment [7].

The vibration in the frequency range of 2-6 Hz was reported to be most harmful for the operator due to resonance of different body parts. Hence, the seat must be designed to lower the vibration within these ranges [8]. A study was conducted to analyse the SEAT (Seat Effective Amplitude Transmissibility) value of different tractor seats with discomfort value when a subject was exposed to vibration in the frequency range of 0-50 Hz. The result confirmed that corresponding frequency for highest SEAT value was observed to be 2.5-6 Hz. Exposure of occupational whole body vibration for longer duration resulted in low back pain and other degenerative pathologies among the tractor operators [9].

There is no definite relationship between amount of vibration and risk disorder. However, it was concluded from some research work that the vibration resulted in micro-damage of intervertebral disc and eventually resulted in lower back pain [10]. Lienhard et al. conducted a study on lower limb activity and reported that it was directly and strongly related to whole body vibration exposure [11]. McCann et al. conducted research on vibration exposure from platform and found that excessive dynamic loading induced by repeated vibration exposure resulted in knee injuries [12].

Many research works have done on measurement and reduction of vibration in vehicle level [13,14]. Paddan and Griffin conducted a research work on vibration measurement of different vehicles including tractors [15]. The vehicles were operated on standardized track and the mean vibration values were reported along with the standard deviation. However, it was not possible to conclude that the deviation was due to the influencing factors like vehicle speed, terrain or operators weight, posture and movement. Pinto and Stacchini investigated on uncertainty in whole body vibration exposure [13]. The source of uncertainty were machine type and work rest cycle. Rakheja et al. evaluated the whole body vibration exposure with different seat setups like variation in seat height, backrest inclination and pan angles with different hand position [16]. The seat pan height was observed to have higher vibration response whereas the seat pan orientation was found to have negligible effect. Toward and Griffin observed that the transferred vibration to the operator through seat suspension depends on seat impedance and seat occupant apparent mass [17]. Many research works have done on effect of damper in seat on whole body vibration exposure. Zohu and Griffin verified damping capacities of seat through vibrating bench in laboratory condition. Some researchers found that the damping was effective only in vertical direction and it had negligible effect on horizontal and longitudinal vibration reduction [18-21]. Langer et al. analysed occupational whole body vibration exposure experimentally on agricultural tractors and observed that the longitudinal dynamics has greater effect on vibration during downward movement of 4WD tractors [5]. Most of the tractor vibration related studies from the reviews was found to be confined to tractor dynamics, working posture of operator, effect of seat suspension damper or spring alone on whole body vibration exposure and health effect of vibration. Therefore, it is of great interest to analyze the effect of combined seat suspension parameters on vibration reduction.

The primary objective of this study were 1) to develop a tractor seat model and to correlate the measured data with model output data and 2) to analyze the effect of different combination of seat suspension parameters on transmitted vibration to the operator. The hypothesis behind this study is the model output data and measured data would be significantly and positively correlated. The final hypothesis is that though there would be difference in transmitted vibration for different combination, but they were not significantly different.

Selection of tractor seat for modeling

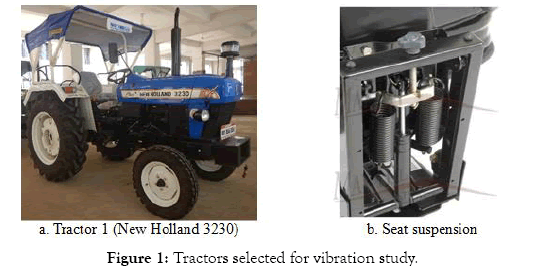

The NH 3230 tractor available in College of Agricultural Engineering and Technology was selected for the vibration modelling. The detailed specification of the tractor was given in Table 1. The tractor is fitted with a passive type seat suspension system which is shown in Figure 1. The seat suspension consists of two springs attached in parallel and a hydraulic damper, attached to the springs in series. The spring constant is 9600 N/m and the damping value was 4225 N.s/m. As mentioned by the manufacturer, the tractor seat was designed to seat operator weight of 50 kg to 120 kg.

| Particulars | Details |

|---|---|

| Make | New Holland |

| Model | 3230 (2018) |

| Rated power, kW | 42 |

| Number of cylinder | 3 |

| Rated rpm | 2000 |

| Air filter | Oil bath |

| Clutch | Diaphragm type single clutch |

| Gear box | 8F + 2R |

| Brake | Oil immersed multi disc brake |

| Steering | Power |

| PTO type | Live PTO |

| PTO rpm | 540 |

| Fuel tank capacity, L | 60 |

| Weight, kg | 1810 |

| Wheel base, mm | 1920 |

| Overall length, mm | 3415 |

| Overall width, mm | 1700 |

| Ground clearance, mm | 380 |

| Hydraulic lifting capacity, kg | 1500 |

| Drive | 2 WD |

| Front tyre | 6.00 X 16 |

| Rear tyre | 13.6 X 28 |

Table 1: Specification of selected tractor.

Figure 1: Tractors selected for vibration study.

The AMESim model

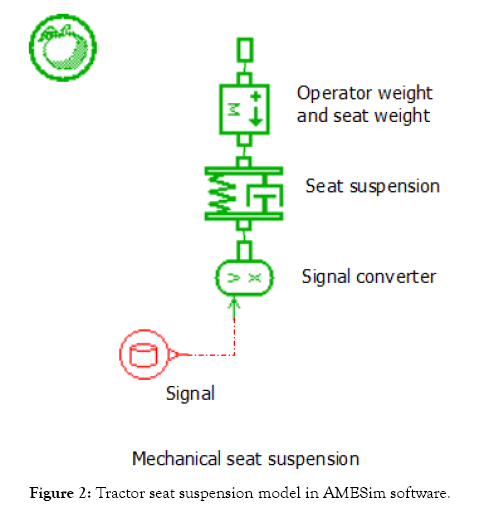

The model for the seat suspension system was developed using AMESim (Advanced Modeling Environment for Simulation of engineering systems) software. It is a one dimensional lumped parameter time domain system. It uses symbols to represent individual component of the system which are based on standard symbol in engineering field like ISO symbols for hydraulic components, block diagram symbols for control environment. When standard symbols are not available for a specific system, it uses pictorial representation of the individual components.

The tractor seat under consideration consists of two springs, one damper and provision for seating. The total weight of the seat was 18.3 kg. The weight of operator supported by seat is not constant. It varies depending on the posture and working environment. The average faction of operator weight coming to the seat is 0.6-0.7 [22]. The seat cushion was assumed to have no vibration reduction. As it was reported that it can reduce vibration up to 3 Hz and after that it has no role in vibration transmissibility [23].

Based on the above consideration a model was developed. The model (Figure 2) consisted of a mass block (51.9 + 18.3=70.2 kg) which represents the weight of operator coming to seat and seat weight; seat suspension block which indicates the springs having stiffness 1000 N/m and hydraulic damper having damping coefficient of 4225 N.s/m and a signal to give the input to the model. For this the input vibration signal was measured seat mounting vibration and the output signal was seat cushion vibration. The vibration was measured during tractor operation on a tar road 1-ton load attachment on the tractor trailer. The measured vibration data and model output data were analysed as per stated in ISO 2631:1997 standard. For measurement of vibration, a tri-axial accelerometer was used. The detailed specification of the accelerometer used is given in Table 2. After development of the model, the model output data and test result data was correlated in 1/3rd octave band frequency domain.

Figure 2: Tractor seat suspension model in AMESim software.

| Make | Bruel and Kjaer |

|---|---|

| Mass, g | 30 |

| Frequency range, Hz | 0-1000 |

| Measurement range | 50 g (g=9.81 m/s2) |

| Temperature range, °C | -55 to 125 |

| Sensitivity, g/v | 0.002 |

Table 2: Detailed specification of Tri-axial accelerometer.

Variation of seat suspension parameters

The primary objective of seat suspension parameters is to reduce the peak amplitude of vibration and also duration of dampening of vibration. This will help in reduction of overall vibration reduction. If the spring stiffness is more than the designed value, then it will act like a hard surface and can’t reduce vibration. Similarly, if the reverse is the case, then it will increase the amplitude of vibration. Hence, these suspension parameters need to be selected accurately. To check the effectiveness of the seat suspension system in the present study, the spring stiffness and damping coefficient was changed at eight and five different levels, respectively (Table 3) and for each combination the overall weighted seat output vibration was analyzed.

| Sl. No | Spring Stiffness | Damping coefficient |

|---|---|---|

| 1 | 3000 | 2225 |

| 2 | 5000 | 3225 |

| 3 | 6000 | 4225 |

| 4 | 7400 | 5225 |

| 5 | 9600 | 6225 |

| 6 | 12000 | - |

| 7 | 15000 | - |

| 8 | 18000 | - |

Table 3: Different levels of spring stiffness and damping coefficient.

Correlation of measured vibration data with model output data

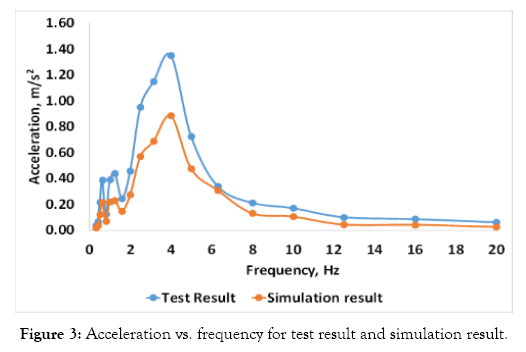

The validation of the developed seat suspension model was done by correlating the test data with the model output data. Figure 3 shows the correlation of weighted acceleration on seat cushion for test result and simulation result. The peak vibration occurred at 3.15 Hz for both simulation and test result. The correlation between test result and simulation result in frequency domain was found to be 86.70 per cent. The overall acceleration values for the test result was 1.58 m/s2 whereas for simulation was 1.37 m/s2. Comparing the data in overall vibration was found to be 77.93 per cent. The deviation of the model output result from test result was due to presence of longitudinal and lateral vibration as well as other vibration sources due to wear and tear of the tractor.

Figure 3: Acceleration vs. frequency for test result and simulation result.

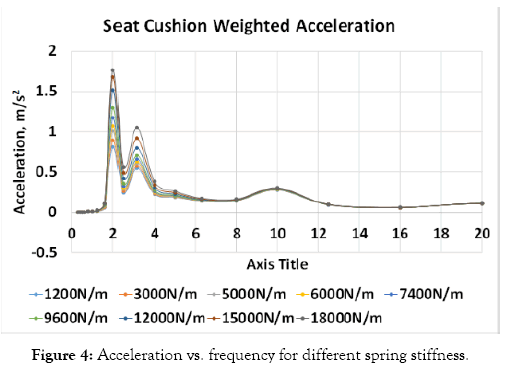

Effect of different spring stiffness

To analyze the effect of spring stiffness alone on transmitted vibration, the values were varied as shown in Table 3. From the model output result, it was observed that the peak vibration values were only changed (Figure 4). The maximum peak vibration found at 2 Hz frequency followed by 3.25 Hz for a particular stiffness. This was due to resonance of tractor seat suspension. For a particular frequency, the maximum vibration was found for spring constant 18000 N/m whereas the minimum value was at 12000 N/m.

Figure 4: Acceleration vs. frequency for different spring stiffness.

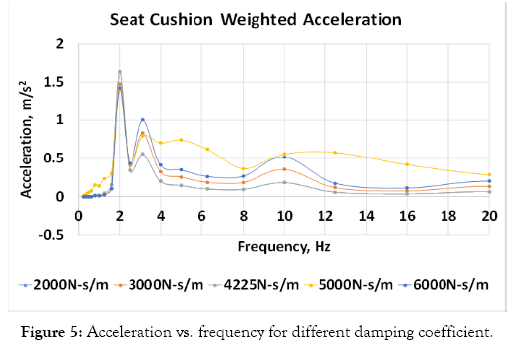

Effect of different damping value

To analyse the effect of damper alone on transmitted vibration, the values were varied as shown in Table 3. During this the spring stiffness was kept constant at 9600 N/m. From the model output result, it was observed that there the peak values were only changed (Figure 5). The maximum peak vibration found at 2 Hz frequency followed by 3.25 Hz for a particular stiffness. This was due to resonance of tractor seat suspension. For 2 Hz frequency, the maximum vibration was found in case of 4225 N.s/m. However, changing the damper value didn’t result in significant difference in vibration acceleration at this frequency. While considering the 3.5 Hz frequency, maximum vibration amplitude was found in 6000 N.s/m and minimum was in 4225 N.s/m. The 5000 N.s/m damping value gave different pattern seat cushion vibration after 3.5 Hz frequency, which was due to change in seat dynamics of seat cushion.are sent to the corresponding author only.

Figure 5: Acceleration vs. frequency for different damping coefficient.

Optimization of seat suspension parameters

The optimization results of existing seat suspension model are given in the Table 4. The maximum value of vibration was found in case of spring constant 18000 N/m and the damping value 2225 N-s/m whereas the minimum vibration was found in case of 3000 N/m and 2225 N.s/m. With this optimization result, 10.79 per cent was observed from the actual value, however this value was also in uncomfortable region when compared with ISO standard.

| Spring Stiffness, N/m | Damping Coefficient, Ns/m | 2225 | 3225 | 4225 | 5225 | 6225 |

| 3000 | 0.785 | 0.83 | 0.856 | 0.865 | 0.874 | |

| 5000 | 0.813 | 0.844 | 0.863 | 0.871 | 0.878 | |

| 6000 | 0.827 | 0.851 | 0.867 | 0.873 | 0.879 | |

| 7400 | 0.848 | 0.861 | 0.872 | 0.877 | 0.882 | |

| 9600 | 0.882 | 0.876 | 0.88 | 0.883 | 0.886 | |

| 12000 | 0.918 | 0.894 | 0.889 | 0.889 | 0.891 | |

| 15000 | 0.961 | 0.914 | 0.9 | 0.897 | 0.896 | |

| 18000 | 0.999 | 0.934 | 0.911 | 0.905 | 0.902 |

Table 4: Overall Weighted Acceleration for Existing Seat Optimization.

From this study, the following conclusions can be drawn:

1. The vibration correlation of the test result and model output result was found to be 79.9 per cent. The deviation was due the vibration produced due to wear and tear of different tractor parts.

2. While considering the spring stiffness alone, the transmitted vibration was found to be nonlinear with increase or decrease of vibration.

3. Similar results were observed when considering the damping coefficient alone.

4. The minimum vibration was found for 3000 N/m spring stiffness and 2225 N.s/m damping coefficient. However, it was 10.79 per cent less than the actual measured value. If this modification will be made to the seat, then there is need of change in seat design which may not be an economically suitable decision.

Citation: Pradhan RR, Behera D, Goel AK, Mohanty SK (2020) Effect of Tractor Seat Suspension Parameters on Vibration Exposure. J Ergonomics 9:258. doi: 10.35248/2165-7556.20.9.258

Received: 05-Dec-2019 Accepted: 09-Jan-2020 Published: 16-Jan-2020

Copyright: © 2020 Pradhan RR, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.