Journal of Nutrition & Food Sciences

Open Access

ISSN: 2155-9600

ISSN: 2155-9600

Research Article - (2016) Volume 6, Issue 5

Gac fruit (Momordica cochinchinensis, Spreng) aril contains extraordinarily high levels of β-carotene, lycopene and unsaturated fatty acids, especially oleic and linoleic acids. These bioactive compounds have been proven to be beneficial to human health and are linked with a reduced risk of cardiovascular disease and cancers. There were previous researches which were carried out to encapsulate Gac oil using maltodextrin, whey protein and gum arabic. However, no reports have been found to study cyclodextrin and sodium caseinate as a carrier or encapsulating agent for producing Gac oil powder. The aim of this study using spray drying method was therefore to investigate the impacts of wall concentration on Gac oil microencapsulation. The data showed that 25% of maltodextrin (or cyclodextrin); ratio of maltodextrin (or cyclodextrin) and sodium caseinate of 0.6:1 resulted in high microencapsulation productivity. The figure of MEY, MEE and DY accounted for 92.4%, 66% and 70.3% respectively and higher than that of other samples. Gac powder is saffron color of turmeric, specific odor and completely dissolved in water. The moisture content reduced from 3.67% to 3.03% when increasing the rate of maltodextrin/ sodium casenate and cyclodextrin/sodium casenate, and more than 86% dissolved in water. Sodium casenatecyclodextrin matrix as the wall material was effectively used for spray-drying encapsulation of Gac oil.

Keywords: Gac oil; Cyclodextrin; Sodium caseinate; Microencapsulation; Gac powder

Gac (Momordica cochinchinensis , Spreng) is found throughout the region from Southern China to Northeastern Australia, including Thailand, Laos, Myanmar, Cambodia and Vietnam [1]. The aril of Gac fruit, 1-3 mm thick, covering black seeds, accounting for 25% of fruit weight, contains a significant amount of fatty acids, at 102 mg/g of edible portion [2]. According to Kubola et al. [1] gac aril has high concentration of oleic (29%), palmitic (32.3%) and linoleic acids (20.3%), of the total fatty acids in gac aril. Furthermore, the highest concentrations of β-carotene and lycopene are found in the fresh aril, at 101 μg/g and 380 μg/g, respectively [3].

Spray drying has been widely utilized for commercial production of dried fruits and vegetables due to economy, flexibility, and good quality of encapsulated products. Furthermore, it is a highly appropriate process for heat sensitive components such as carotenoids [4]. The encapsulation of fatty acids and carotenoids in plant materials has been reported by numerous studies. However, very little information is published on Gac oil encapsulation and no reports on spray drying using combinations of maltodextrin and sodium caseinate; or cyclodextrin and sodium caseinate as the carrier agents for producing Gac oil powder has been reported.

Maltodextrin is one of the supported material for spray drying owing to its beneficial role as a carrier or an encapsulating agent in increasing the stability of carotenoids. Cyclodextrins are cyclic oligosaccharides consisting of six α-cyclodextrin, seven β-cyclodextrin, eight γ-cyclodextrin or more glucopyranose units linked by α-(1,4) bonds. In food related application, cyclodextrins are also used to improve stability of flavor and/or oil which are being encapsulated for better retention and protection from various possible means of deterioration [5,6].

The aims of this research must be evaluated the effect of wall material formulation on encapsulation efficiency, encapsulation yield, physicochemical property, color characteristics and the changes in lycopene and β-carotene in Gac oil powder under storage condition.

Wall and core material

Maltodextrin and cyclodextrin used as wall material were obtained from Qinhuangdao Lihua Starch Co., Ltd. Deionized water was employed in the preparation of all of the formulations. Core material used in this study was Gac oil, which was extracted by hexane according to a method described by Kubola et al. [1].

Preparation of the oil-in-water emulsions and spray drying conditions for Gac oil

Emulsions were prepared using a method from Kha et al. [7]. Aqueous stock solutions (500 mL) with different concentrations of wall materials with were prepared using a homogenizer (Wilmington, DE, USA) at 6000 rpm for 10 min. In the homogenizer, the solution samples were axially drawn into the dispersion head and then forced radially through the slots in the rotor/stator arrangement. The stock solutions were then kept at 4°C for at least 12 h to ensure complete hydration of proteins. Then these samples (about 500 mL) were spray-dried. The operating conditions of the spray drying were inlet air temperature of 180°C, and pressure of 2 bars, and the feed flow rate was about 400 mL/h.

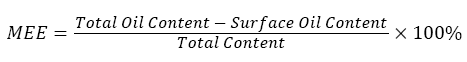

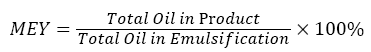

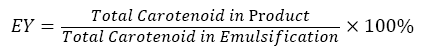

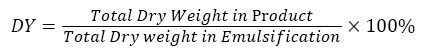

Microencapsulation efficiencies (MEE) were determined based on the retention of Gac oil, β-carotene, and lycopene contents in the encapsulated powder as follows:

The total oil content, surface oil, β-carotene, and lycopene content were determined described by Kha et al. [7].

Storage treatments for gac oil powder

Gac powder was stored at 55°C for 7 days. The color of Gac fruit powder sample was determined by using a Minolta Chroma Meter that calibrated with a white standard tile.

Water insolubility index (WII)-TCVN 6511:2007

Spray-dried Gac fruit powder (2.5 g) and (30 mL) were vigorously mixed in a 100 mL centrifuge tube, incubated in a 37°C water bath for 30 min and then centrifuged for 20 min at 10,000 rpm. The supernatant was carefully removed; distilled water was added and stirred again. Centrifuge this solution again and calculate the insoluble volume.

Moisture content

The moisture content (MC) of the samples was determined by drying at a temperature of 105°C in an oven until a constant weight was obtained.

Statistical analysis

The experiments were carried out in triplicate and results were presented as mean values with standard deviations. Different mean values were analyzed by analysis of variance (ANOVA) and least significant difference (LSD) using the software Stagraphics Centurion XV.

Effects of wall material on total carotenoid content and encapsulation efficiency

The effects of maltodextrin and cyclodextrin concentration on encapsulation and total carotenoid content (TCC) of Gac powder are presented in Figure 1, respectively. Results showed that higher MEE, MEY and DY were observed when increasing maltodextrin and cyclodextrin concentration.

As maltodextrin concentration increased from 15-25%, MEE, MEY, DY enhanced 17%, 44% and 30%, respectively. However, no difference in MEE, MEY and DY between concentration of 25 and 30% was observed. A different trend was observed in study of Kha et al. [4], while maltodextrin concentration rose from 20 to 30%, there was no significant difference in encapsulation efficiency. For spay drying using cyclodextrin, MEE, MEY and DY raised 22%, 15% and 25%, respectively while cyclodextrin concentration increased from 15 to 20%, and no difference in MEE, MEY and DY between concentration of 20, 25 and 30% was observed.

As well as the MEE, carotenoid encapsulation yield (EY), which is one of the major parameters of the spray-drying operation. EY of encapsulated powder is presented in Figure 2. In general, the result showed that the highest EY was obtained when maltodextrin or cyclodextrin concentration of 25%. In addition, data also shows that the yield, which using cyclodextrin as supported material was higher than 5% in compared to using maltodextrin. However, maltodextrin or cyclodextrin alone could not effectively cover oil droplets because EY only increased nearly 25% in comparison with MEE increasing approximately 44%.

Results from Figure 3 showed that as increasing maltodextrin/ sodium caseinate ratio from 0.2/1 to 0.6/1 resulted in increasing MEE, MEY and DY from 48.05% to 66%, 59.44% to 70.31%, and 76.87% to 92.46% respectively. However, microencapsulation efficiency and microencapsulation yield were decreased when maltodextrin/sodium caseinate ratio exceeded 0.6/1. Dian et al. [6], Hogan et al. [8], Kobula and Siriamornpun [9] suggested that the higher protein load values observed at low oil/protein ratios may have conferred enhanced stability on emulsion oil droplets during atomization. It would appear also that the ability of sodium caseinate to effectively encapsulate soy oil at high oil/protein ratios is limited. A similar trend was obtained when we blended sodium caseinate with cyclodextrin but microencapsulation efficiency of carotenoid (Figure 4) were improved by 6% compared to mixture of sodium caseinate and maltodextrin.

Effects of wall material on physical property of Gac powder

The effects of wall materials on physicochemical property of Gac powder are showed in Table 1. Results showed that increasing maltodextrin or cyclodextrin concentration resulted in decreasing moisture content of samples. As maltodextrin concentration increased from 15 to 30% the moisture content of sample significantly reduced from 4.54 to 3.45%. Similarly, Abadio et al. [10], Grabowski et al. [11] reported that moisture content in pineapple juice powders, sweet potato puree powder. Similar trend was observed while increasing cyclodextrin from 15 to 30%. These findings could be explained by the fact that additional concentrations of maltodextrin resulted in an increase in feed solids and a reduction in total moisture for evaporation [4].

| Formula | 15% | 20% | 25% | 30% | 0.2:1 | 0.4:1 | 0.6:1 | 0.8:1 | 1:1 |

|---|---|---|---|---|---|---|---|---|---|

| Gac oil (%) | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Maltodextrin/Cyclodextrin (%) | 15 | 20 | 25 | 30 | 20.83 | 17.86 | 15.62 | 13.89 | 12.5 |

| Sodium Caseinate (%) | 0 | 0 | 0 | 0 | 4.17 | 7.14 | 9.38 | 11.11 | 12.5 |

Table 1: Formulation of all concentration using for spry-drying.

Moisture content of samples obtained at different ratio of maltodextrin (or cyclodextrin) and sodium caseinate also presented in Table 2. Statistical evaluation of results indicated that moisture content was not affected by ratio of support. However, when increasing the carriers support from 25 to 30%, water insolubility is lower than of the other samples (15%, 20%). According to Kha et al. [7], increasing carrier support lead to form thick and flexible firms, also increased coalescence. This phenomenon is similar to previous studies were carried out by Dian et al. [6]. The authors suggested that moisture content was not affected by the type of carriers, as well as the ratio of carriers/oil.

| Wall material | Moisture content | Water insolubility index | |

|---|---|---|---|

| Maltodextrin | 15% | 4.54 ± 0.05i | 91.15% ± 0.04a |

| 20% | 4.06 ± 0.13h | 91.55% ± 0.03a | |

| 25% | 3.76 ± 0.15fg | 90.15% ± 0.04b | |

| 30% | 3.45 ± 0.05bc | 89.73% ± 0.03cb | |

| Cyclodextrin | 15% | 3.43 ± 0.05i | 90.24% ± 0.03b |

| 20% | 3.86 ± 0.17gh | 91.23% ± 0.03a | |

| 25% | 3.67 ± 0.15d-g | 89.15% ± 0.04bc | |

| 30% | 3.5 ± 0.05cd | 89.73% ± 0.03bc | |

| Sodium Caseinate/Maltodextrin | 0.2/1 | 3.70 ± 0.15d-g | 91.33% ± 0.01a |

| 0.4/1 | 3.75 ± 0.15e-g | 91.18% ± 0.06a | |

| 0.6/1 | 3.67 ± 0.145d-g | 89.05% ± 0.04bc | |

| 0.8/1 | 3.55 ± 0.10c-e | 87.03% ± 0.02d | |

| 1/1 | 3.6 ± 0.12c-f | 86.30% ± 0.05d | |

| Sodium Caseinate/Cyclodextrin | 0.2/1 | 3.67 ± 0.15d-g | 91.43% ± 0.02a |

| 0.4/1 | 3.45 ± 0.14bc | 91.28% ± 0.03a | |

| 0.6/1 | 3.27 ± 0.13b | 89.45% ± 0.02bc | |

| 0.8/1 | 3.28 ± 0.13b | 88.13% ± 0.03d | |

| 1/1 | 3.03 ± 0.12a | 86.23% ± 0.02d | |

Table 2: Effects of wall material on physical property of Gac powder [ai].

In addition, it is important to improve the water solubility for ease of application in the food industry. In this study, water insolubility index (WII) <0.1 mL (at 50°C) indicated that Gac products microencapsulated by matrix of maltodextrin (or cyclodextrin) and sodium caseinate absolutely dissolved in water. The high solubility could be explained by the positive effects of between protein and carriers on the oil droplets containing carotenoids [7,12-22].

In conclusion, the effect of wall material on the property of Gac powder was investigated. Moisture content, colour characteristics, total carotenoid content, microencapsulation efficiency were significantly affected by maltodextrin (or cyclodextrin) concentration and ratio of maltodextrin (or cyclodextrin) and sodium caseinate. The ability of dissolved in water and the content of β-carotene and lycopene reduced insignificantly. Sodium casenate-cyclodextrin matrix as the wall material effectively protected β-carotene and lycopene from thermal degradation during storage.