Journal of Ergonomics

Open Access

ISSN: 2165-7556

ISSN: 2165-7556

Research Article - (2024)Volume 14, Issue 4

Ropemaking is a traditional craft known for its manual labor-intensive process. This study aimed to give corrective actions to the risk factors associated with the different work postures of lampakanay rope makers in Basak- Sudtunggan, Lapu-Lapu City. Rapid Entire Body Assessment (REBA), Cornell Musculoskeletal Discomfort Questionnaire (CMDQ), and Ovako Working Posture Analysis System (OWAS) were the ergonomic tools used to assess the risk level of the worker’s postures. The mean scores for each of the tools disclosed that their bad work postures using the current method put workers at high risk of developing work-related musculoskeletal disorders. Thus, two ergonomically designed methods were proposed. A t-test was utilized to statistically compare the scores of the current method and the two proposed method. Results showed that there is a significant difference between the current method and the proposed methods. Overall, the second proposed method proved to be best used by lampakanay rope makers.

Risk; Rope makers; Ergonomic tools; Postures; Discomfort; Lampakanay rope makers

CMDQ: Cornell Musculoskeletal Discomfort Questionnaire; OWAS: Ovako Working Analysis System; REBA: Rapid Entire Body Assessment; WMDs: Work-Related Musculoskeletal Disorders

Ropemaking is based on the twisting or weaving of several strands of diverse natural materials into a line with tensile strength greater than the component element. In some tribes of India, families work along in making ropes having no special equipment. Rope making process is entirely done by hand. It is what some tribes in some parts of the Philippines do for a living. They use the manual or traditional method in the process of making rope. Making rope by hand is a past art. In the Philippines, hand labor is cheap and machines are not so much used [1].

In Basak-Sudtungan, Lapu-Lapu City, most of the residents there are known to be lampakanay rope makers. However, based on the initial investigation made by the researchers, it was found out that the lampakanay workers were experiencing back pains and muscle fatigue due to working long hours and not having proper tools for supporting postures. It was observed that the makers have experienced Work-Related Musculoskeletal Disorders (WMDs) due to their bad posture while making the ropes. Manual handling of each activity resulted in repetitive motions wherein repetitive motions caused fatigue and injury to nerves, muscles, and tendons. Donisi, et al. asserted that high workrelated physical exposure was identified as a risk factor associated with poor health and illness absence, increasing musculoskeletal complications, and decreasing working lifespans. In the study of Madhwanim, et al. researchers claimed that WMSDs lead the list of work-related illnesses in developing countries due to a lack of appropriate ergonomic measures to prevent accidents and remove bad working conditions. According to Montakarn and Nuttika and Reddy, et al. MSDs are a serious public health concern in developing nations, and they are one of the top causes of sickness absenteeism, disability, days of work missed, and hinder productivity at work. Yazdanirad, et al. said that WRMSDs are the leading cause of occupational injury and disability in developed nations, impacting not only individuals but also organizations and society [2].

The preceding contentions prompted the researchers to assess the problems of WMDs experienced by the lampakany rope makers in Basak-Sudtunggan Lapu-Lapu City. The researchers have proposed methods that rope makers could use in the process of making lampakanay ropes. This study aimed to examine the lampakanay rope maker’s postural scores with the proposed methods, using ergonomic tools namely: Rapide Body Entire Assessment (REBA), Ovako Working Analysis System (OWAS), worker’s discomfort score using the ergonomic tool Cornell Musculoskeletal Discomfort Questionnaire (CMDQ), and evaluate if there are postural improvements on the workers, hence, a t-test was used to test if there are significant difference between the current method and the proposed methods. Moreover, the purpose of this study is to determine which method from the proposed would provide better improvements and would be best used by the workers. The result also served as a basis for the researchers to recommend changes that decrease the risk of developing musculoskeletal disorders, and injuries that boosted worker’s productivity [3].

Research significance

The result of this study would be beneficial to lampakanay rope makers for this would help them improve their working posture to minimize the risk of developing musculoskeletal disorders. This would also help the researchers in improving their skill, strategy, and knowledge in engaging future research. And apply the knowledge gained in this study to realworld settings. Moreover, professors could benefit to this study in using this as their reference in teaching and learning ergonomic’s importance in the working environment. Lastly, the results of this study would serve as a reference for future researchers studying the same field of study [4].

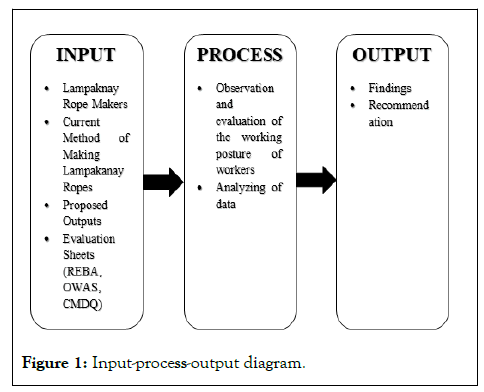

Figure 1 showed the flow of the study. This study aimed to determine if there is significant difference between the current method and the proposed methods. It used the three components which are the inputs, process, and outputs to categorize the flow. The input reflected the different aspects to consider in the study, the process showed the procedure in making the study, and the output entailed the findings and recommendations made.

Figure 1: Input-process-output diagram.

Research environment

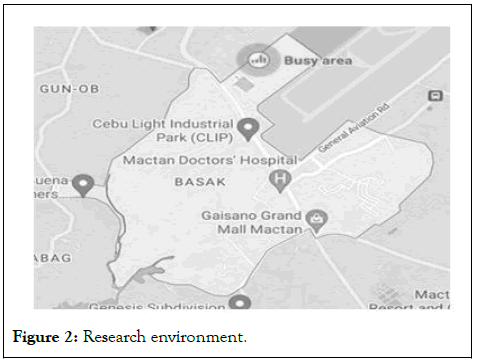

Figure 2 showed the where the study takes place. The study was conducted in Basak, Lapu-Lapu Cty, Cebu. Basak is a barangay in Lapu-Lapu City with 71,990 people, according to the Concencus in 2020. It is located on the island of Mactan at roughly 10.2967, 123.9643. At these coordinates, the elevation is estimated to be 5.1 meters or 16.7 feet above the average sea level. In Basak-Sudtunggan, Lapu-Lapu City, almost 25% of the total population is lampakanay rope makers. Thus, the researchers chose this place as the local of the study as most of the residents in this area are a maker of lampakanay ropes. Moreover, one of the researchers is a resident in this area hence gathering of data would be convenient [5].

Figure 2: Research environment.

Research respondents

The research respondents of this study would be the lampakanay rope makers residing in Barangay Basak-Sudtungan, Lapu-Lapu City. The researchers selected respondents with a minimum age of 25 and above with at least two (2) to fifteen (15) years of experience in making lampakanay ropes. Thus, the researchers believed that these people were the most likely to experience Work-Related Musculoskeletal Disorders (WRMSDs). Only thirty (30) of the lampakanay rope makers were chosen to be observed and evaluated in the study. Conforming to central limit theorem, when the sample size n is sufficiently enough, the distribution of sample mean Xn is approximated to the normal distribution. In reality, statisticians and researchers have adopted the sample size n ≥ 30 requirements to assume a sample mean distribution that is close to the normal distribution. In the study of Barri in 2019, he asserted that the central limit theorem guarantees that the mean of one decently large randomly chosen sample, regardless of population size or form, will be near to the ideal mean of the intended population [6].

Research instruments

The data were obtained through observation on the work posture of lampakanay makers during the process of the product. The researchers used the following ergonomic tools and research-made data sheets to tally the scores.

Rapid Entire Body Assessment (REBA)

Rapid Entire Body Assessment (REBA) is a commonly used tool for measuring and evaluating the hazards associated with working postures as a component to ergonomic workload (Table 1).

| REBA score | Risk level | Action levels |

|---|---|---|

| 1 | Negligible | No change |

| 2-3 | Low | Maybe necessary |

| 4-7 | Medium | Change necessary |

| 8-9 | High | Change soon |

| 11-15 | Very high | Change urgently |

Table 1: REBA risk assessment level.

Table 1 showed the risk level and action level equivalent for Rapid Entire Body Assessment (REBA) score. This was used on assessing the risk factors of the lampakanay rope makers in each of the processes of creating ropes [7].

Ovako Working Analysis System (OWAS)

OWAS is a method for assessing working position based on observation. The Ovako Working Posture Analysis System (OWAS) approach is a simple way to assess work attitudes that are not ergonomic and contribute to musculoskeletal disorders.

Table 2 showed the Ovako Working Analysis System (OWAS) action categories, the description and the actions needed to be done for each. This tool was used category level of the work postures of rope makers as to the back, arms, legs, and the weight of load [8].

| Action category | Description | Action levels |

|---|---|---|

| 1 | Normal and natural postures with no harmful effect on musculoskeletal. | No action required. |

| 2 | Postures with some harmful effects on the musculoskeletal system. | Corrective actions required in the near future. |

| 3 | Posture with some harmful effects on musculoskeletal system. | Corrective actions should be done as soon as possible. |

| 4 | The load caused by these postures have a very harmful effect on the musculoskeletal system. | Corrective actions for improvement required immediately. |

Table 2: OWAS risk assessment level.

Cornell Musculoskeletal Discomfort Questionnaires (CMDQ)

The Cornell Musculoskeletal Discomfort Questionnaire (CMDQ) was developed to evaluate office worker’s musculoskeletal discomfort in relation to their ergonomic environment.

Table 3 showed the risk level assosciated with each score of Cornell musculoskeletal discomfort questionnaire. This tool was used to assess the level of musculoskeletal discomfort among the lampakanay rope makers during the process of making the product [9].

| CDMQ score | Risk level |

|---|---|

| 0 | No discomfort |

| 1.5 | Mild discomfort |

| 1.6-10.5 | Moderate discomfort |

| >10.5 | Severe discomfort |

Table 3: CMDQ risk assessment.

Data gathering procedure

The researchers sent a request letter to the barangay official of Basak-Sudtunggan, Lapu-Lapu City to ask for the consent to conduct the study and gather data to lampakanay rope makers through observation and evaluation [10].

Upon approval, the researchers oriented the respondents about the nature of the study, they were informed of their freedom to accept or decline the participation in the study. With their consent, the researchers observed their rope making process and listed all the postures for each of the activities. Using REBA, OWAS, and CMDQ, the researchers evaluated and gave a score to the postures listed. After the data were gathered, the research collected and secured it for the data analysis and interpretation process [11].

Analytical investigation

Statistical treatment: Below are the treatments used by the researchers upon treating the gathered data.

• Mean: The mean is used for summarizing the results of the REBA, OWAS and CMDQ for both current and proposed methods. The formula is as follows:

Where, x̄=Grand Σx=Frequency/number of objects N=Total number of Subjects

•T-test: It is used to test whether the current met hod and the proposed methods have significant differences with an alpha (α) of 0.05.

H0=There is no significance difference Accept null hypothesis: p value>0.05 H1=There is a significant difference Reject null hypothesis: p value<0.05

Where: x ̄=Population μ=Mean S=Standard deviation n=Sample size

In making lampakanay rope, there are five processes namely: Finishing, stringing, coiling, and finishing. The researcher aimed to evaluate the working posture using Rapid Entire Body Assessment (REBA), Cornell Musculoskeletal Discomfort Questionnaire (CMDQ), and Ovako Working Analysis System (OWAS) for each of the process in terms of their current method of making ropes.

Current method

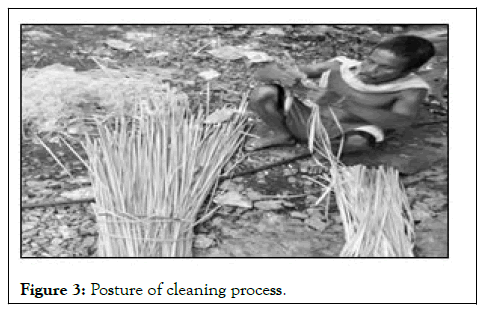

Figure 3 showed the posture of the lampakanay rope makers in performing the first process-cleaning process. The illustration showed that the worker was squatting with no chair for posture support when doing the process. In the study of Pal and Dhara, the findings of several methods of posture analysis indicated that squatting was an awkward posture that causes tension in many joints and muscles of the lower part of the body. Work in a squatting posture causes static postural strain on the lower body parts, resulting in musculoskeletal disorder in those regions [12].

Figure 3: Posture of cleaning process.

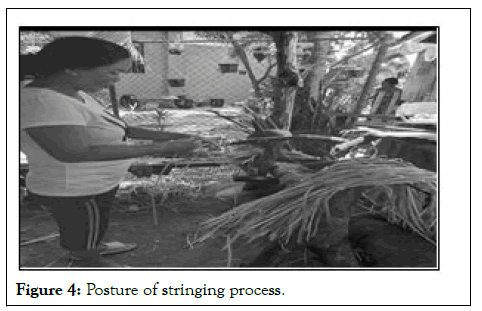

Figure 4 showed the posture of the lampakanay rope maker in performing the second process- stringing process which is adding up all the cleaned leaves. The illustration showed that the worker was making the process while standing while bowing the heads to look into the leaves. Long periods of standing for various jobs result in significant MSDs in the lower limbs and lower back but not in other upper body regions. However, the Nagaraja, et al. found a significant prevalence of musculoskeletal problems in both the lower and upper bodies of SSMOs, which was consistent with previous research. This was attributable to extremely repeated upper-limb motions and extended standing together [13].

Figure 4: Posture of stringing process.

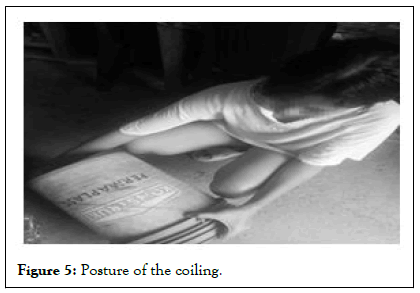

Figure 5 showed the posture of the lampakanay rope maker in performing the third process-coiling process. The illustration showed that the worker was squatting with no posture support while performing the process.

Figure 5: Posture of the coiling.

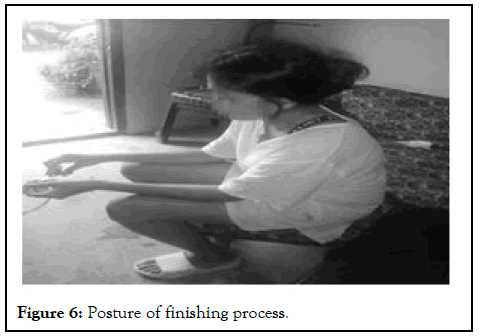

Figure 6 showed the posture of the lampakanay rope makers in performing the last process-finishing process. The illustration showed that the worker was making the process just sitting on a chair but with no back support. People commonly adopt bad sitting postures in unsupported sitting settings without a backrest or desk, which increases the risk of musculoskeletal problems. In the study of Jung, et al., the result suggested that sitting in a slumped position for an extended period of time causes lower back pain independent of muscular exhaustion [14].

Figure 6: Posture of finishing process.

The following tables presented the score of the different tools used for assessing the working posture of the lampakanay workers in each process with their current method.

Table 4 showed the mean score of each process. In REBA, an overall process mostly scores 10, a very high risk on the body parts of the worker. Thus, the Lampakanay rope maker must take measures to protect their selves against MSD. In general, multiple factors contribute to a high-risk REBA score, some of these causes include the worker's body postures, which include the neck, trunk, wrist, upper arm, and lower arm, in not ergonomic position as long as the task is completed [15]. As a result, a redesign of rope making equipment that is suitable for the worker's anthropometric measurement must be done for the worker's posture and productivity to increase.

| Process | Mean score | Risk level | Action level |

|---|---|---|---|

| Cleaning | 10.97 | High | Change soon |

| Stringing | 5.77 | Medium | Change necessary |

| Coiling | 10.43 | High | Change soon |

| Finishing | 10.47 | High | Change soon |

Table 4: Rapid entire body assessment mean score.

| Process | Mean score | Risk level |

|---|---|---|

| Cleaning | 6.37 | Moderate discomfort |

| Stringing | 6.61 | Moderate discomfort |

| Coiling | 6.5 | Moderate discomfort |

| Finishing | 6.33 | Moderate discomfort |

Table 5: Cornell musculoskeletal discomfort questionnaire mean score.

Table 5 showed the mean score for CMDQ. The current methodology that the rope maker follows showed that most of their body parts are exposed to medium and high risk when doing the processes. As for the mean score for CMDQ, it is showed that in all of the processes, workers experienced moderate discomfort. The process which got the highest score is the stringing process with 6.61, followed with coiling which has 6.50, cleaning with 6.37 and the finishing which had 6.33.

Table 6 showed the mean score of the posture of Lampakanay rope makers for every processes according to the ovako working analysis system with their current method. It showed that the postures for all of the processes contributed some harmful effects on their musculoskeletal system and that it needed to implement corrective actions in the near future [16].

| Process | Mean score | Description | Interpretation |

|---|---|---|---|

| Cleaning | 2.3 | Posture with some harmful effects on the musculoskeletal system. | Corrective actions required in the near future. |

| Stringing | 1.8 | Posture with some harmful effects on the musculoskeletal system. | Corrective actions required in the near future. |

| Coiling | 1.87 | Posture with some harmful effects on the musculoskeletal system. | Corrective actions required in the near future. |

| Finishing | 1.93 | Posture with some harmful effects on the musculoskeletal system. | Corrective actions required in the near future. |

Table 6: Ovako working analysis system mean score.

With all of the results from the tools used, it was found out that the current method used by the workers in all of the process were harmful to their musculoskeletal system. Thus, the researchers suggested some outputs to help minimize the risk of having work-related musculoskeletal disorders. Using REBA, CMDQ, and OWAS, the researchers evaluated the scores of worker’s postures in each process for every output.

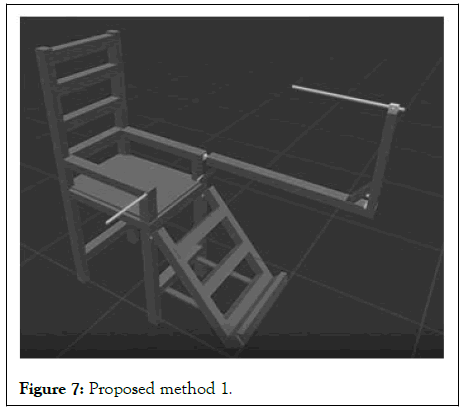

Proposed method 1

Figure 7 showed the illustration of the first method presented by the researcher. According to van Niekerk, chairs that reduce undue strain on the muscles of the body may help to prevent musculoskeletal pain and discomfort. Generally, the most usually proposed intervention is the ability to change the seat height and seat pan depth to fit the body measurements of the user. In the study again of van Niekerk, et al. he asserted that a chair should match the user's body measurements and assist the user in often shifting sitting postures, rather than supporting one optimal position. Thus, the researchers proposed a chair which is adjustable in height as well as the foot rest in order for the workers to choose on what they are most comfortable. The proposed method would also give back support to the workers in order to minimize back pains [17].

Figure 7: Proposed method 1.

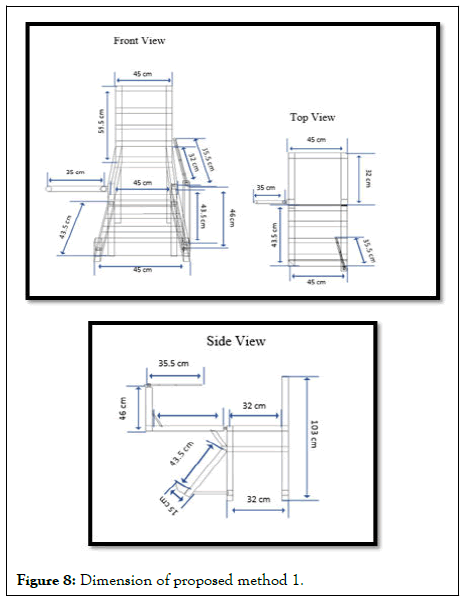

Figure 8 showed the measurements of every part of the proposed method 1 according to its top, side and front view. The following tables presented the score of the different tools used for assessing the working posture of the lampakanay workers in each process for the first proposed output:

Figure 8: Dimension of proposed method 1.

Table 7 showed the REBA mean score of cleaning is 4.40, stringing is 5.00, coiling is 4.60 and the finishing is 4.70. The four processes were in between the score of 4 to 7 score which means medium risk, further investigation, and change soon. Comparing the first proposed method and the current method, the results were lowered down from high risk to medium risk. In general, multiple factors contributed to a medium REBA score. Some of these causes include the worker's body postures, which include the neck, trunk, wrist, upper arm, and lower arm, in an un-ergonomic position as long as the task is completed. As a result, a redesign of rope making equipment that is suitable for the worker's anthropometric measurements must be done for the worker's posture and productivity to increase [18].

| Process | Mean score | Risk level | Action level |

|---|---|---|---|

| Cleaning | 4.4 | Medium | Change necessary |

| Stringing | 5 | Medium | Change necessary |

| Coiling | 4.6 | Medium | Change necessary |

| Finishing | 4.7 | Medium | Change necessary |

Table 7: Rapid entire body assessment mean score.

Table 8 showed the mean score of CMDQ as for the proposed method 1. In all of the processes, workers experienced moderate discomfort. However, comparing the scores to the current method, the mean scores for proposed 1 are lowered. The process which got the highest score is the stringinsg process with 3.41, followed with cleaning which has 3.39, coiling with 3.34 and the finishing which has 3.28.

| Process | Mean score | Risk level |

|---|---|---|

| Cleaning | 3.39 | Moderate discomfort |

| Stringing | 3.41 | Moderate discomfort |

| Coiling | 3.34 | Moderate discomfort |

| Finishing | 3.28 | Moderate discomfort |

Table 8: Cornell musculoskeletal discomfort questionnaire mean score.

Table 9 showed the mean score of the posture of Lampakanay rope makers for every process in terms of ovako working analysis system for the proposed method 1. It showed that there was an improvement from the current method. For the proposed method 1, cleaning and finishing process had a mean score of 1.47 and coiling process which all indicated that the posture of workers while performing the process were normal and had no harmful effects in their musculuskeltal systems. Meanwhile, stringing process got a score of 1.57 which indicated that the posture of the workers had some harmful effects on their musculoskeletal system and it needed corrective actions in the near future. All in all, the results suggested that the proposed method is better than the current method, however, still needed further improvements [19].

| Process | Mean score | Description | Action level |

|---|---|---|---|

| Cleaning | 1.47 | Normal and natural postures with no harmful effect on musculoskeletal disorder. | No action required. |

| Stringing | 1.57 | Posture with some harmful effects on the musculoskeletal system. | Corrective actions required in the near future. |

| Coiling | 1.4 | Normal and natural postures with no harmful effect on musculoskeletal disorder. | No action required. |

| Finishing | 1.47 | Normal and natural postures with no harmful effect on musculoskeletal disorder. | No action required. |

Table 9: Ovako working analysis system mean score.

Proposed method 2

Figure 9 showed the illustration of the second proposed output presented by the researcher. In this proposed method, the researchers decided to have the chair detachable from the platform in order for the workers to choose the desired working position. This aimed to help workers minimize work-related musculoskeletal disorders. In the study of Ma, et al. it has been proved that using a sit-stand desk decreases sitting time and improves workplace health and productivity.

Figure 9: Proposed method 2.

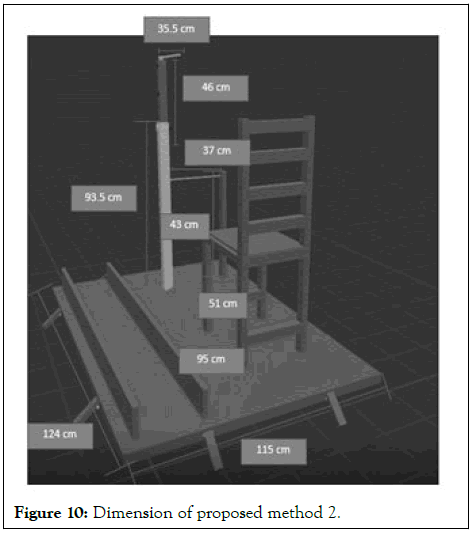

Figure 10 showed the measurements of the proposed method 2. The following tables presented the score of the different tools used for assessing the working posture of the lampakanay workers in each process for the second proposed method.

Figure 10: Dimension of proposed method 2.

Table 10 showed the final REBA mean score of cleaning is 4.40, stringing is 4.60, coiling is 4.60 and the finishing is 4.67. The four processes were in between the score of 4 to 7 score which means medium risk, further investigation, and change soon. Comparing the second proposed method and the current method, the results were lowered down from high risk to medium risk. In general, multiple factors contribute to a medium REBA score. Some of these causes include the worker's body postures, which include the neck, trunk, wrist, upper arm, and lower arm, in an un-ergonomic position as long as the task is completed. As a result, a redesign of rope making equipment that are suitable for the worker's anthropometric measurements must be done for the worker's posture and productivity to increase [20].

| Process | Mean score | Risk level | Action level |

|---|---|---|---|

| Cleaning | 4.4 | Medium | Change necessary |

| Stringing | 4.6 | Medium | Change necessary |

| Coiling | 4.6 | Medium | Change necessary |

| Finishing | 4.67 | Medium | Change necessary |

Table 10: Rapid entire body assessment mean score.

Table 11 showed the mean score of CMDQ as for the proposed method 2. In all of the processes, workers experienced moderate discomfort. However, comparing the scores to the current method, the mean scores for proposed method 2 are lowered.

The process which got the highest score is the cleaning process with 3.20, followed with stringing which has 3.18, coiling with 3.16 and the finishing which has 3.11.

| Process | Mean score | Risk level |

|---|---|---|

| Cleaning | 3.2 | Moderate discomfort |

| Stringing | 3.18 | Moderate discomfort |

| Coiling | 3.16 | Moderate discomfort |

| Finishing | 3.11 | Moderate discomfort |

Table 11: Cornell musculoskeletal discomfort questionnaire mean score.

Table 12 showed the mean score results of the posture of Lampakanay rope makers for every process in terms of Ovako working analysis system for the second proposed method. It showed that there was an improvement from the current method. In second proposed method, the workers’ postures for all of the processes were normal and had no any harmful effects on musculoskeletal system. Thus, it prevented the risk of having work-related musculoskeletal disorders.

| Process | Mean score | Description | Action level |

|---|---|---|---|

| Cleaning | 1.4 | Normal and natural postures with no harmful effect on musculoskeletal system. | No action required. |

| Stringing | 1.47 | Normal and natural postures with no harmful effect on musculoskeletal system. | No action required. |

| Coiling | 1.27 | Normal and natural postures with no harmful effect on musculoskeletal system. | No action required. |

| Finishing | 1.33 | Normal and natural postures with no harmful effect on musculoskeletal system. | No action required. |

Table 12: Ovako working analysis system mean score.

Table 13 showed the comparison between the current method and the two proposed methods in terms of the posture’s mean score in each process using the different tools. As for REBA, it is showed that the posture’s mean score in most of the processes for the current method belonged to high risk which is harmful to the worker’s musculoskeletal system, while, both proposed methods 1 and 2 belonged to the level of medium risks. In CDMQ, all of the processes for current method and both of two proposed methods resulted to moderate discomfort. However, there were several factors that affected the results regarding the proposed methods such as that the workers were not used to using the new implemented methods. However, for the OWAS, all of the posture of workers in all processes in current method depicted to have some effects to musculoskeletal system, while, the worker’s posture for all process in proposed method 1 were normal except for stringing which had some effects to musculoskeletal system. On the other hand, for OWAS mean score for proposed method 2, all of the postures for all process were normal and not harmful.

| Method | Process | Mean score | ||

|---|---|---|---|---|

| REBA | CMDQ | OWAS | ||

| Current method | Cleaning | 10.97 | 6.37 | 2.3 |

| Stringing | 5.77 | 6.61 | 1.8 | |

| Coiling | 10.43 | 6.5 | 1.87 | |

| Finishing | 10.47 | 6.33 | 1.93 | |

| Proposed method 1 | Cleaning | 4.4 | 3.39 | 1.47 |

| Stringing | 5 | 3.41 | 1.57 | |

| Coiling | 4.6 | 3.34 | 1.4 | |

| Finishing | 4.7 | 3.28 | 1.47 | |

| Proposed method 2 | Cleaning | 4.4 | 3.2 | 1.4 |

| Stringing | 4.6 | 3.18 | 1.47 | |

| Coiling | 4.6 | 3.16 | 1.27 | |

| Finishing | 4.67 | 3.11 | 1.33 | |

Table 13: Comparison of current and two proposed methods.

Table 14 showed statistical comparison of the current method that the Lampakanay makers are using and the proposed methods for every process in terms rapid entire body assessments mean score. It showed that for the current and proposed method 1, all of the score for every process had 0.00000 except only for stringing which had 0.000682.

As for the current and proposed method 2, all of the process as well had 0.000000 p-values except for stringing process which had 0.000008. Nonetheless, there is a significant difference between proposed methods and current method for all of its processes.

| Process | p-value | Alpha (α) | Decision | Interpretation | |

|---|---|---|---|---|---|

| Current method vs. proposed method 1 | Cleaning | 0 | 0.05 | Reject the null hypothesis | There is a significant difference |

| Stringing | 0.000682 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Coiling | 0 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Finishing | 0 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Current method vs. proposed method 2 | Cleaning | 0 | 0.05 | Reject the null hypothesis | There is a significant difference |

| Stringing | 0.000008 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Coiling | 0 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Finishing | 0 | 0.05 | Reject the null hypothesis | There is a significant difference |

Table 14: Statistical comparison between the current method and the two proposed methods in terms of rapid entire body assessment mean score for every process.

Table 15 entailed the differentiation of the proposed method 1 and proposed method 2 with the current method of making the Lampakanay ropes. It could be seen that both of the proposed methods have a 0.0000 p-value for every process which is less than the alpha 0.05. Hence, all of the null hypotheses are rejected and that for all of the process, there is a significant difference between current method and the two proposed methods.

| Process | p-value | Alpha (α) | Decision | Interpretation | |

|---|---|---|---|---|---|

| Current method vs. proposed method 1 | Cleaning | 0 | 0.05 | Reject the null hypothesis | There is a significant difference |

| Stringing | 0 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Coiling | 0 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Finishing | 0 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Current method vs. proposed method 2 | Cleaning | 0 | 0.05 | Reject the null hypothesis | There is a significant difference |

| Stringing | 0 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Coiling | 0 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Finishing | 0 | 0.05 | Reject the null hypothesis | There is a significant difference |

Table 15: Statistical comparison between the current method and the two proposed methods in terms of cornell musculoskeletal discomfort questionnaire score for every process.

Table 16 showed statistical comparison of the current method that the Lampakanay makers are using and the proposed methods for every process in terms of Ovako working analysis system mean score. It showed that there is a significant difference between current method and proposed method 1 for all of the processes expect only for stringing which has a 0.128689 p-value, thus there is no significant difference between proposed 1 and the current method. Meanwhile, the proposed method 2 depicts that the posture’s mean score for all of the processes are lower that the alpha, 0.05, thus, there is a significant difference between current method and proposed method 2.

| Process | p-value | Alpha (α) | Decision | Interpretation | |

|---|---|---|---|---|---|

| Current method vs. proposed method 1 | Cleaning | 0.000044 | 0.05 | Reject the null hypothesis | There is a significant difference |

| Stringing | 0.128689 | 0.05 | Accept the null hypothesis | There is no significant difference | |

| Coiling | 0.000335 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Finishing | 0.000335 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Current method vs. proposed method 2 | Cleaning | 0.000003 | 0.05 | Reject the null hypothesis | There is a significant difference |

| Stringing | 0.009853 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Coiling | 0.000011 | 0.05 | Reject the null hypothesis | There is a significant difference | |

| Finishing | 0.000003 | 0.05 | Reject the null hypothesis | There is a significant difference |

Table 16: Statistical comparison between the current method and the two proposed methods in terms of the mean score for Ovako working analysis system for every process.

Table 17 showed the comparison of the two proposed methods in terms of the posture’s mean score in each processes using the different tools. As for REBAS, it could be shown that the postures’ mean score in all process for both proposed methods 1 and 2 belonged to the level of medium risks. In CDMQ, all of the processes for the two methods have moderate discomfort.

And for the OWAS, the worker’s posture for all process in proposed method 1 were normal except for stringing which has some effects to musculoskeletal system. On the other hand, for OWAS mean score for proposed method 2, all of the postures for all process were normal and not harmful.

| Process | Mean score | |||

|---|---|---|---|---|

| REBA | CMDQ | OWAS | ||

| Proposed method 1 | Cleaning | 4.4 | 3.39 | 1.47 |

| Stringing | 5 | 3.41 | 1.57 | |

| Coiling | 4.6 | 3.34 | 1.4 | |

| Finishing | 4.7 | 3.28 | 1.47 | |

| Proposed method 2 | Cleaning | 4.4 | 3.2 | 1.4 |

| Stringing | 4.6 | 3.18 | 1.47 | |

| Coiling | 4.6 | 3.16 | 1.27 | |

| Finishing | 4.67 | 3.11 | 1.33 | |

Table 17: Comparison of the two proposed methods.

Table 18 showed the ranking of the proposed methods in each process in terms of the mean score. It is showed that proposed method 2 has the lowers scores among the two, thus, it is ranked first. This result suggested that the proposed output 2 have provided a greater improvement to the posture of the workers and minimized the risk to work-related musculoskeletal disorders.

| Process | Mean score | |||

|---|---|---|---|---|

| REBA | CMDQ | OWAS | ||

| Proposed method 1 | Cleaning | - | 2nd | 2nd |

| Stringing | 2nd | 2nd | 2nd | |

| Coiling | - | 2nd | 2nd | |

| Finishing | 2nd | 2nd | 2nd | |

| Proposed method 2 | Cleaning | - | 1st | 1st |

| Stringing | 1st | 1st | 1st | |

| Coiling | - | 1st | 1st | |

| Finishing | 1st | 1st | 1st | |

Table 18: Ranking of the two proposed methods.

Based on the findings, the researchers concluded that the current method used by the lampakanay rope makers contributed high risk to workers musculoskeletal system. Hence, the researchers proposed new methods. The first method proposed by the researcher depicted improvement in their working posture for some processes, however, it still needed further development to achieve greater results. On the other hand, the second proposed method was found out to be best used by lampakanay rope makers. It depicted an improvement in their posture in all of the process and lowered work-related musculoskeletal discomfort.

Based on the results of the data gathered, presented, and interpreted, the researchers found out that the posture of the workers in performing each process in making lampakanay using the current method contributed a high risk to their musculoskeletal system. The results of the REBA suggested that all of the processes presented medium to high risks to the worker’s musculoskeletal system. As for CMDQ, the results found out that workers experience moderate discomfort in performing all of the process in making lampakanay ropes. Lastly, for OWAS, the results showed that the postures of the rope makers have some harmful effects on their musculoskeletal system. Thus, it needed corrective actions. With these, the researchers proposed methods to help prevent these risks. Upon testing the proposed methods, it has found out there is a significant difference between both proposed methods and the current method. In addition, the second method have more lowered results in all of the tools used in evaluating and is ranked as the first among the two.

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Citation: Sarenas DJA, Habierto AP, Emia MAT, Suaybaguio DGL, Simbajon EAMS (2024) Ergonomic Assessment of Lampakanay Rope Makers in Lapu-Lapu City. J Ergonomics. 14:395.

Received: 18-Jun-2023, Manuscript No. JER-23-25190; Editor assigned: 20-Jun-2023, Pre QC No. JER-23-25190 (PQ); Reviewed: 04-Jul-2023, QC No. JER-23-25190; Revised: 28-Jun-2024, Manuscript No. JER-23-25190 (R); Published: 04-Jul-2024 , DOI: 10.35248/2165-7556.24.14.395

Copyright: © 2024 Sarenas DJA, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.