Journal of Ergonomics

Open Access

ISSN: 2165-7556

ISSN: 2165-7556

Research Article - (2021)Volume 11, Issue 3

Rice is the most important cereal food crop of India. The total production of rice is estimated at record 116.42 million tones and has area of 43.79 million hectares under rice cultivation. Rice is the basic food crop and being a tropical plant, it flourishes comfortably in hot and humid climate. Manual hand transplanting consumes a lot of energy and time and full of fatigue, but the poor socio-economic condition of the farmers does not allow them to adopt power operated transplanter. Transplanting operation by different research centers have been developed as tworow and three-row paddy transplanter. Keeping this in view fifteen female subjects were selected in the age group 18-45 years. The HR work, HR rest, Oxygen Consumption Rate (OCR), Relative Cost of Work Load (RCWL) and Energy Expenditure Rate (EER) were reduced from 130.8 beats/min to 127.7 beats/min, 70.6 beats/min to 70.2 beats/min, 1.02 l/min to 0.9 l/min, 59.6 percent to 57.8 percent and 21.3 to 20.7 from three-row transplanter to tworow transplanter. All these planters have their own limitations and restrictions. Hence, the present study was undertaken to evaluate the transplanters which will be helpful for the farmers to select the suitable transplanter. The transplanters were evaluated in terms of planting parameters like missing hills, floating hills and buried hills. The field capacity, planting efficiency and field efficiency were also measured to recommend a suitable machine. Threerow manual rice transplanter was found to be better in performance on the basis of total unproductive hills (6.9%), planting efficiency (93%), and field efficiency (72%). The draft requirement for two-row and three-row manual rice transplanter was found to be 7.2 kg and 8.2 kg respectively. The cost of operation for two-row and three-row manual rice transplanter was found to be Rs 7300/ha and Rs 9250/ha respectively.

Transplanter; Working heart rate; Oxygen consumption rate; Missing hill; Buried hill

Rice is the basic food crop and being a tropical plant, it flourishes comfortably in hot and humid climate. Rice is mainly grown in rain fed areas that receive heavy annual rainfall. That is why it is fundamentally a Kharif crop. It demands temperature of around 25 degree Celsius and above and rainfall of more than 100 cm. Rice is the staple food of eastern and southern parts of India. For the year 2018-2019 area under rice cultivation in eastern India is about 19.88 million hectares with 45.43 million tons of production (Source: Directorate of Economics and Statistics 2018-19). Rice is a semi-aquatic plant which grows in a variety of soils provided water is available. Mainly, there are two methods of planting rice viz. direct seeding and transplanting. In direct seeding, the seeds are sown (either by row seeding or broadcasting of germinated or ungerminated seeds) in the field under dry or wet condition at the beginning of rainy season [1]. This method of seeding requires minimum labor and well suited for upland farms. However, it suffers from few limitations i.e., the rate of germination of all seeds is not uniform, heavy rain extricate the seeds from the soil, seeds are vulnerable to birds. Due to these inherent demerits of direct seeding, transplanting method is preferred. In transplanting process, seedlings are raised in nursery at least a month before planting. These seedlings are then planted manually or mechanically in the puddled soil [2]. Puddling is achieved by repeated intensive tillage under ponded-water conditions, which helps in reducing water losses through percolation and controlling weeds by water stagnation in rice fields. The mechanical transplanters are available in the market which uses mat type of nursery for transplanting, but for raising mat type of nursery it requires a lot of skill and management in comparison to the traditional root wash type of nursery. In paddy cultivation transplanting is very drudgeries operation in overall paddy cultivation processes and 22.3% of total time is spent in this operation [3]. Generally, it is found that the production increases 10%-12% in transplanting from direct sowing. Therefore, the study is conducted to compare the ergonomically field evaluation of different manual transplanters i.e., two-row manual rice transplanter (root wash type) (Figures 1 and 2) and three-row manual rice transplanter (mat type) (Figure 3) with traditional hand transplanting [4].

Figure 1: Traditional method of rice transplanting.

Figure 2: Two-row manual rice transplanter (root wash type).

Figure 3: Three-row manual rice transplanter.

Selection of subjects

For this ergonomical evaluation 15 subjects were selected thosehave experience of transplanting. The selected fifteen subjectswere in the age group of 18-45 years as at this age maximumstrength can be utilized, they cover the 5th to 95th physicalcharacteristics of total female population shown in Table 1 [5].

| Physical and physiological parameters | Range | Mean | Std. Deviation |

|---|---|---|---|

| Age, years | 15-45 | 31.1 | 8.06 |

| Weight, kg | 45-59 | 51.7 | 4.91 |

| Height, cm | 142.1-163 | 152.3 | 7.61 |

| HR rest, beats/min | 65-76 | 70.3 | 3.17 |

| HR max, beats/min | 176-200 | 188.2 | 7.27 |

| VO2 rest, l/min | 0.16-0.24 | 0.19 | 0.02 |

| VO2 max, l/min | 1.56-1.81 | 1.71 | 0.08 |

| BSA, m2 | 1.37-1.69 | 1.52 | 0.12 |

| BMI, kg/m2 | 20.5-23.25 | 22.32 | 0.82 |

| Blood Lactate Accumulation (mm/l of blood) |

0.9-1.3 | 1.2 | 0.08 |

| Experience, years | 3-25 | - | - |

Table 1: Physiological parameters of selected subjects (N=15).

Calibration of subjects

The selected subjects are calibrated in laboratory beforeconducting the test. To get the maximum heart rate, maximumoxygen consumption, heart rate at rest the subjects wereundergone treadmill test. The average value of fifteen subjectswas taken as representing value for working duration. The heartrate was measured by Polar heart rate monitor and oxygenuptake was measured by K4b2. The Energy Expenditure wascalculated by the formula [6]:

EER (kJ/min) = OCR (l/min) × 20.88

The detail of specifications of two-row manual rice transplanter(root wash type) and three-row manual rice transplanter (mattype) are placed in Table 2.

| SL. No. | Parameter | Two-row manual rice transplanter (root wash type) | Three-row manual rice transplanter (mat type) |

|---|---|---|---|

| 1 | Type of machine | Manual | Manual |

| 2 | Type of nursery used | Root washed | Mat type |

| 3 | Type of steering | Manual | Manual |

| 4 | Overall dimensions L × W × H (cm) | 164 × 50 × 94 | 600 × 600 × 940 |

| 5 | Planting mechanism | Four bar mechanism | Fixed fork |

| 6 | Row spacing (cm) | 25 | 24 |

| 7 | Hill to hill distance(cm) | 25 | Adjustable |

Table 2: Technical specifications of different transplanters.

Statistical analysis

One way ANOVA test assuming unequal variances was performed among the female rice cultivators to find out whether there is any significant difference in ergonomical parameters of female workers shown in Table 4 for the chosen level of significance (P<0.001). Statistical analysis was performed using the statistical package IBM-SPSS statistics (Version=20) [7,8].

Physical and physiological characteristics of female subjects

The mean heart rate of subjects at rest is found in the range 65 to 75 whereas the mean value was 70.3 and the corresponding oxygen consumption was 0.19 l/min. The maximum oxygen consumption of female subjects was found to be 1.71 l/min and lies in the range 1.55-1.80. The mean body mass index was found to be 22.3 kg/m2 and body surface area was 1.52 m2 which shows that the workers were of normal health [8].

Comparative ergonomical evaluation of traditional method of transplanting, two-row manual rice transplanting (root wash type) and three-row manual transplanting (mat type)

The ergonomical parameters of the female subjects changed according to the type of transplanting procedure from rest value after 30 minutes of work. These values were given in the Table 3.

| SL. No | Parameter | Traditional method of transplanting | Two-row manual rice transplanter (root wash type) | Three-row manual rice transplanter (mat type) |

|---|---|---|---|---|

| 1 | HR rest (beats/min) | 70.3 | 70.2 | 70.6 |

| 2 | HR work (beats/min) | 113.4 | 127.7 | 130.8 |

| 3 | Work pulse (beats/min) | 43.0 | 57.5 | 60.2 |

| 4 | VO2 rest (l/min) | 0.19 | 0.20 | 0.20 |

| 5 | VO2 work (l/min) | 0.75 | 0.9 | 1.02 |

| 6 | EER, kJ/min | 15.3 | 20.7 | 21.3 |

| 7 | RCWL (% of VO2 max) | 33.4 | 57.8 | 59.6 |

| 8 | Area coverage, ha/day | 0.054 | 0.096 | 0.108 |

| 9 | Man days/ha | 17 | 16.6 | 11.3 |

| 10 | Continuous operating time, min | 12 | 24 | 27 |

Table 3: Variation of ergonomical parameters.

Heart rate

The working heart rate (HR work) of the subjects when the paddy transplanting was performed with conventional method ranged from 110.5 to 122.6 beats/min with a mean value of 116.3 ± 3.61 beats/min.

The corresponding values with two-row and three-row transplanter were 123.78 to 156.45 and 136.37 ± 10.88 beats/min and 126.42 to 163.3 and 142.4 ± 10.56 respectively.

This showed a significant (P<0.001) increase of mean HR work by 17.1% and 22.3% for two and three-row rice transplanters. The mean work pulse (HR) with manual transplanting was observed to be 63.93 ± 3.16 beats/min but reduced to 54.16 ± 5.74 and 54.8 ± 4.89 beats/min with two-row and three-row mechanized method. Work pulse of 40 beats/min is the allowable limit for sustained working [9].

Oxygen Consumption Rate (OCR)

OCR was found to be 0.42 ± 0.13, 0.6 ± 0.12 and 1.28 ± 0.35l/ min, respectively for manual, two-row and three-row mechanized method of paddy transplanting.

ANOVA test showed a significant decrease (42.8%) in OCR with two-row root wash type transplanting compare to manual transplanting (P<0.001). In the reported that an OCR of 0.63 l/min and HR of 105 beats/min for women were considered acceptable for sustained work of 8 hours with intermittent rests [10].

Energy Expenditure Rate (EER)

EER with manual transplanting was observed to be 17.8 ± 1.59 kJ/min whereas with two-row and three-row transplanter it slightly increased to 18.68 ± 1.72 and 20.15 ± 1.96 kJ/min.

Overall Discomfort Rating (ODR)

ODR was 8.4 ± 1.43, 4.62 ± 1.46 and 4 ± 1.11 with manual, tworow and three-row mechanical method respectively. ODR decreased significantly (P<0.001) with paddy transplanter (Table 4).

| Parameters | Traditional method of transplanting | Two-row manual rice transplanter (root wash type) | Three-row manual rice transplanter (mat type) | F-value | P -value | |||

|---|---|---|---|---|---|---|---|---|

| Range | Mean ± S.D. | Range | Mean ± S.D. | Range | Mean ± S.D. | |||

| HR work (beats/min) | 110.5-122.6 | 116.3 ± 3.61 | 123.7-156.4 | 136.37 ± 10.88 | 126.4-163.3 | 142.4 ± 10.56 | 34.35 | <0.001 |

| Work pulse (beats/min) | 59.8-70.8 | 63.93 ± 3.16 | 46.3-64.6 | 54.16 ± 5.74 | 48.3-63.4 | 54.8 ± 4.89 | 19.93 | <0.001 |

| VO2 work (l/min) | 0.69-1.1 | 0.42 ± 0.13 | 0.45-0.9 | 0.6 ± 0.12 | 0.85-2.01 | 1.28 ± 0.35 | 27.06 | <0.001 |

| EER, kJ/min | 15.3-20.54 | 17.8 ± 1.6 | 16.4-21.3 | 18.68 ± 1.72 | 17.2-22.7 | 20.15 ± 1.96 | 6.49 | 0.003 |

| ODR | 6.5-10 | 8.4 ± 1.43 | 3-6.6 | 4.62 ± 1.4 | 2.5-5.5 | 4 ± 1.11 | 15.62 | <0.001 |

| Field Capacity (ha/day) | 0.003-0.009 | 0.007 ± 0.002 | 0.013-0.016 | 0.015 ± 0.013 | 0.015-0.018 | 0.016 ± 0.013 | 36.38 | <0.001 |

| Man days/ha | 17-19 | 17.8 ± 0.8 | 15.5-18 | 16.7 ± 0.9 | 11.3-14.2 | 12.2 ± 1.2 | 45.90 | <0.001 |

Table 4: Comparison of different parameters with different transplanting methods.

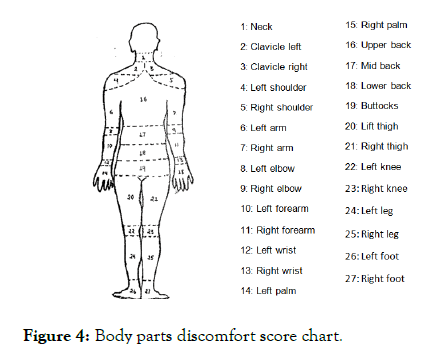

The body parts with maximum discomfort as expressed by the operators were right upper leg, lower back, right lower leg, right foot, right upper arm and right in the descending order. The body parts discomfort was mainly due to the effort to maintain a static and bending posture while manual transplanting [11].

Self-reported pain/Discomfort

Workers were asked few questions about perceived pain/ discomfort, which lasted, for at least 24 hours. Majority of the respondents were feeling pain and discomfort in different body parts (Figure 4) (Tables 5 and 6).

| S. No. | Body parts | Traditional method of transplanting | Two-row manual rice transplanter (root wash type) | Three-row manual rice transplanter (mat type) |

|---|---|---|---|---|

| 1 | Neck | 11(68) | 32(20) | 2(15) |

| 2 | Right shoulder | 6(36) | 12(80) | 7(45) |

| 3 | Right wrist | 8(52) | 12(80) | 8(50) |

| 4 | Lower back | 12(76) | 7(45) | 4(25) |

| 5 | Buttocks | 4(24) | 6(40) | 11(72) |

| 6 | Upper arm | 5(28) | 8(50) | 8(50) |

| 7 | Thighs | 7(44) | 7(45) | 7(45) |

| 8 | Hips | 7(44) | 9(60) | 6(40) |

| 9 | Feet | 7(48) | 8(50) | 9(60) |

Table 5: Discomfort in different body parts of the subjects during different transplanting methods.

| Traditional method of transplanting | Two-row manual rice transplanter (root wash type) | Three-row manual rice transplanter (mat type) |

|---|---|---|

|

|

|

Table 6: Body parts feeling discomfort during different transplanting methods.

Figure 4: Body parts discomfort score chart.

68 percent female who were involved in manual transplanting had pain and discomfort in neck. 45 per cent female respondents who were involved in manual uprooting were suffering from neck pain.

In shoulders cent per cent respondents reported discomforted during manual transplanting and uprooting [12].

Total three-fourth of the total respondents reported pain in elbows during manual transplanting and majority (85 per cent) respondents were suffering from elbow pain.

About majority of workers feeling pain and discomfort in buttocks, right wrist, hip and feet in two-row manual rice transplanter (root wash type) and three-row manual rice transplanter (mat type), it is due to continuous movement of right palm for cranking operation and due to backward movement while operating the machines [13].

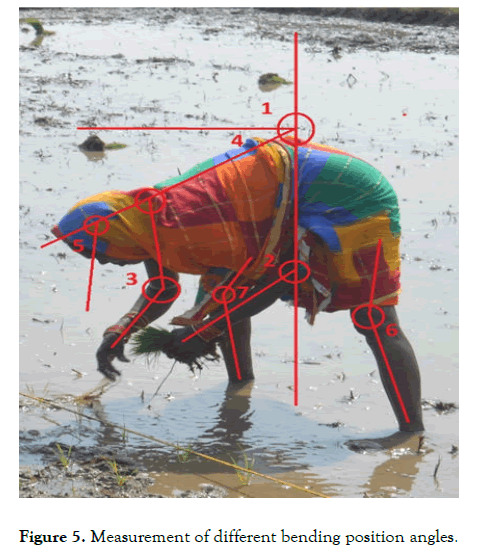

Body parts discomfort score chart is shown in Figure 4 and measurement of different bending position angles shown in Figure 5 and results obtained are shown in Table 7.

Figure 5: Measurement of different bending position angles.

| Angle in degrees | Subject 1 | Subject 2 | Subject 3 |

|---|---|---|---|

| Waist angle with vertical line (1) | 110 | 105 | 115 |

| Left elbow (2) | 105 | 100 | 103 |

| Right elbow (3) | 170 | 172 | 175 |

| Waist angle with horizontal line (4) | 20 | 15 | 25 |

| Eye (5) | 60 | 55 | 57 |

| Left knee (6) | 120 | 118 | 115 |

| Right knee (7) | 120 | 115 | 116 |

Table 7: Different bending position angles (in degrees) during traditional rice transplanting.

Comparative field evaluation of different transplanters

The results obtained from the present study have been summarized in Table 8.

| SL. No. | Parameter | Traditional method of transplanting | Two-row manual rice transplanter (root wash type) | Three-row manual rice transplanter (mat type) |

|---|---|---|---|---|

| 1 | Number of seedlings/hill | 2-3 | 2-3 | 2-4 |

| 2 | Hill to hill distance, mm | Adjustable | 25 | Adjustable |

| 3 | Number of hills/m2 | 26-28 | 24 | 30-35 |

| 4 | Missing hills, % | - | 2.08 | 4.58 |

| 5 | Floating hills, % | - | 1.47 | 1.54 |

| 6 | Buried hills, % | - | 1.53 | 0.89 |

| 7 | Total unproductive hills, % | - | 5.08 | 6.89 |

| 8 | Planting efficiency, % | - | 91.96 | 93 |

| 9 | Draft, kg | - | 7.3 | 8.2 |

| 10 | Field capacity, ha/h | 0.009 | 0.016 | 0.018 |

| 11 | Field efficiency, % | - | 75 | 72 |

| 12 | Cost of operation (Rs/ha) | 15000 | 7300 | 9250 |

Table 8: Comparative field evaluation of different transplanters.

The ergonomical analysis of different paddy transplanting methods revealed that the physiological response reduced in two-row paddy transplanter from that of three-row and manual paddy transplanter. The HR work, HR rest, OCR, RCWL and EER were reduced from 130.8 beats/min to 127.7 beats/min, 70.6 beats/min to 70.2 beats/min, 1.02 l/min to 0.9 l/min, 59.6% to 57.8% and 21.3 to 20.7 from three-row transplanter to two-row transplanter. Missing hills may be primarily due to the entanglement of roots, non-uniformity of seedling in the mat and buckling of mats. Maximum missing hills permissible is 8%.

It was found minimum for two-row manual transplanter (2.08%) followed by three-row manual transplanter (4.58%). Floating hills may have occurred due to poor anchorage of seedlings in the soil. Maximum floating hills permissible is 3%. It was found to be minimum in case of two-row manual transplanter (1.47%) followed by three-row transplanter (1.54%). Buried hill occurred due to the flow of the soil along with the transplanter due to higher float sinkage. Buried hills was found minimum in case of three-row manual transplanter (0.89%) and maximum in case of two-row transplanter (1.53%). Planting efficiency was 91.96% and 93% for two-row and three-row manual transplanter respectively. The draft requirement for tow-row and three-row manual transplanter was found to be 7.2 kg and 8.2 kg respectively. The cost of operation for tow-row and three-row manual transplanter was found to be Rs 7300/ha and Rs 9250/ha. The field capacity and field efficiency were found to be as follows for two-row manual transplanter (0.45 ha/h, 75%) and for three-row manual transplanter (0.016 ha/h, 72%) respectively. It can be concluded that manual uprooting and transplanting is more physically demanding activity as compared to mechanical transplanting activity. Most of the times workers adopted standing, bending and sitting posture for performing manual rice transplanting. Thus, it can be concluded that through mechanization, the level of MSDs can be reduced or minimized.

Citation: © 2021 Inthiyaz M, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Received: 30-Apr-2021 Accepted: 14-May-2021 Published: 21-May-2021 , DOI: 10.35248/2165-7556.21.11.282

Copyright: Inthiyaz M, Mishra J, Mohanty SK, Pradhan PL, Behera D (2021) Ergonomics of Manual Transplanting Operations with Female Workers in Eastern India. J Ergonomics.11:282.