Journal of Developing Drugs

Open Access

ISSN: 2329-6631

ISSN: 2329-6631

Research Article - (2016) Volume 5, Issue 2

The main aim of this investigation is to develop fast disintegrating oral films of Propranolol hydrochloride by using Pectin and synthetic polymers. The Propranolol HCl oro-dispersible films were formulated by using HPMC E15LV, HPMC regular, pectin, Carbopol, and PVA, as film forming polymers. The selected polymers were natural and synthetic water soluble polymers. Generally solvent casting method was used in the manufacture of the mouth dissolving films. The formula which incorporates pectin HPMC E15 LV 4:2 and pectin: Carbopol 3:2 ratios and also other varying ratio were used in the formulation of Oro-dispersible films. The quantity and type of plasticizer affected the formulation of films; Propranolol HCl has bitter taste so taste masking agents were used. Citric acid was used as a salivary stimulating agent. The prepared films were subjected to the analysis of various evaluation tests such as weight variation, tensile strength, thickness, surface pH, and drug content. The significant parameters such as disintegration and dissolution profiles also studied in detail since the product was prepared for fast dissolving in the oral cavity.

<Keywords: Oro dispersible; HPMC E15LV; Pectin

Hypertension is the chronic condition which is related to elevated arterial blood pressure. The condition also described as high blood pressure. In such conditions the heart has work harden its regular pattern to maintain the circulation. Hypertension is of two type’s primary or secondary hypertension. In the total hypertensive population 90–95% cases falls in the class of "primary hypertension" for which underlying medical cause is understandable [1]. The secondary hypertension affects 5-10% of the cases that affect the kidneys, arteries, heart and endocrine system. If the blood pressure is not controlled alternative therapeutic approaches can be used to bring back the issue to normal [2].

Oral medicated films can be described as a dosage form which dissolves rapidly in the water. The films can be prepared by the hydrocolloid or hydrophilic polymer. The hydrocolloids or a hydrophilic polymer makes the dosage form to dissolve rapidly in the oral cavity or when it is placed in the tongue. This kind of dosage form can be used for the local and systemic delivery of the drug [3]. Currently varieties of fast dissolving drug delivery systems are available for patient convenience. The fast dissolving dosage forms can be prepared by the regular technique such as direct compression, wet granulation, freeze drying and solvent casting [4]. These dosage forms can be prepared by using different super disintegrants and effervescent agents [5]. The mouth dissolving dosage forms are designed to dissolve with in the mouth within few seconds without using water or chewing [6]. Oral route of administration is still a dominant and widely accepted route by the physician as well as patients. The 50-70% of formulation in the market is dominated by oral dosage forms due to various known advantages [7]. The Mouth dissolving films are also described as the fast dissolving dosage form which dissolves as quickly as within 30 seconds in the oral cavity. The mouth dissolving films composed of the active ingredient, flavors and other ingredients then the drug was released as the film dissolves [8]. The fast dissolving dosage forms are very useful for pediatrics, geriatric and neurodegenerative disease patients to whom other type of dosing is unsuccessful.

Orally dispersible dosage forms are useful to the patients who is unable to swallow and suffering from nausea [9,10] The fast dissolving dosage forms or films delivers the drug in a faster rate which is readily absorbed under the tongue (Figure 1).

The diseases such as trigeminal neuralgia, Meier’s disease, diabetes, and addiction can be treated successfully by buccal drug delivery systems and the products also widely used by the patients and physician. The issues such as cold, flu and snoring and GIT disorders can be treated successfully by fast dissolving oral dosage forms [11].

The dosage form contains a thin, printable, low moisture non tacky film which is suitable for dosing, labeling and packing. The thickness and surface area of the typical film is ranged between 1-10 mil (1 mil=25 microns) and 1-25 cm respectively which is ideal for application and handling. This film when place in the tongue undergoes rapid hydration and softens immediately [12,13]. The wet tack property is offered by the muco adhesive polymers present in the system which secure the films with in the oral cavity. The flexibility and strength of the film may be modified during manufacturing by varying the polymers and ingredient concentrations. The flexibility and the strength of the prepared mouth dissolving films are determined by the following parameters such as tensile strength, elongation, young’s modulus, bending length and tear resistance [14]. The film having 2 mil thickness dissolves within 5-10 sec. The time required for dissolving not less than 80% of the film portion is called mouth dissolving time [15]. The drug is released from the dosage form upon disintegration and dissolution. The disintegration and dissolution times can be increased by increasing the thickness of the film. The disintegration dissolution time of the films can be altered by modifying the formula and choice of excipients [16].

Materials

Propranolol HCl-kindly gifted by Cipla Pvt Ltd, Mumbai pvt. Ltd. HPMC, HPMC E15LV, Carbopol 940, Pectin, Mannitol was received from Loba Chemie Pvt Ltd, Mumbai. PVA from Merck Specialties Pvt Ltd. Sodium Hydroxide and citric acid was received from Finar Chemicals, Ahmadabad. Glycine was received from Kemphasol, Mumbai. Tween-80 was received from SD Fine-Chem. Ltd. Mumbai.

Methods

FTIR study: The FTIR spectrums of the potato starch as well as prepared starch tartarate were recorded. The pellets were prepared by dispersing the drug in the dry potassium bromide under dry condition (Table 1).

| Ingredients (mg) | FPH-1 | FPH -2 | FPH -3 | FPH-4 | FPH-5 | FPH-6 | FPH-7 | FPH-8 | FPH-9 | FPH- 10 | FPH-11 | FPH-12 | FPH -13 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Propranolol | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Pectin | 50 | 30 | 70 | 40 | 20 | 40 | 40 | 70 | 30 | 60 | 30 | 70 | 40 |

| HPMCE15LV | 10 | 10 | 10 | 20 | 40 | - | - | - | - | - | - | - | - |

| HPMC | - | - | - | - | - | 20 | 40 | 10 | - | - | - | - | - |

| Corbopol | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 20 | 30 | 10 | 0 | 0 |

| Glycerin | qs | qs | qs | qs | qs | qs | qs | qs | qs | qs | qs | 0 | 0 |

| Mannitol | 15 | - | 15 | - | 15 | 20 | 0 | 0 | 20 | 0 | 10 | qs | qs |

| Citric acid | 16 | 18 | 20 | 15 | 10 | 10 | 20 | 20 | 10 | 20 | 15 | 20 | 0 |

| Water | qs | qs | qs | qs | qs | qs | qs | qs | qs | qs | qs | qs | qs |

Table 1: Formulation design of fast disintegrating oral films.

The spectra obtained with these two polymers were compared and the presence of additional peaks corresponding to the functional groups was noted. The propranolol HCl alone and with the physical mixtures of drug and excipients were also analyzed by FTIR using Perkin Elmer (USA), from 4000-400 between wave number (cm-1) and % transmittance. Samples were prepared in KBr discs (2 mg sample in 200 mg KBr) with hydrostatic press at force of 5 cm-2 and resolution was 4 cm-1. Experiments were duplicated to check the reproducibility. The major sharp and significant peaks of the drug and the drug with excipients were demonstrated in the respective Figure 2 and Table 2.

| Significant peak range cm-1 | Standard frequency in cm-1 | Significant peaks in Propranolol in cm-1 | Significant peaks in propranolol and HPMCE 15 LV in cm-1 | Significant peaks in propranolol and pectin in cm-1 | Propranolol and corbopol in cm-1 | Propranolol and PVA in cm-1 |

|---|---|---|---|---|---|---|

| 1600 -1450 | C=C aromatic | 1579.75 | 1597.11 | 1589.4 | 1577.82 | 1558.54 |

| 3150 -3020 | C-H aromatic | 3049.56 | 3057.23 | 3111.28 | 3053.42 | 3053.42 |

| 2960-2850 | C-H alkanes | 2947.33 | 2941.34 | 2943.47 | 2964.69 | 2945.4 |

| 3650-3580 | O-H alcohol | 3542.67 | 3562.64 | 3564.57 | 3628.22 | 3421.83 |

| 3310-3140 | N-H amines | 3282.53 | 3241.45 | 3284.88 | 3281.02 | 3282.95 |

| 1350-1260 | 0-Hsecondary | 1323.21 | 1323.21 | 1348.57 | 1321.28 | 1321.28 |

Table 2: FT-IR Spectra compatbility study of Propranolol HCl.

Differential scanning calorimetry study: The thermal characteristics of samples were studied by using a differential scanning calorimetry (DSC 60 Shimadzu). The behavior under heat was studied by heating the samples (2 mg) in an aluminum pan from 25°C to 350°C, at a rate of heating of 10°C min−1, under a flow of nitrogen of 10 cm3 min−1, using an empty pan as references.

General method of preparation of fast disintegrating films

Generally fast disintegrating films are prepared by various techniques such as hot melt extrusion, solid dispersion extrusion, rolling, semisolid casting, and solvent casting. The preferred manufacturing process for making this film was solvent casting method.

The solvent casting technique involves making a homogeneous mixture of drug and polymer including colorants and other excipients. Further the prepared homogenous mixture was poured in to the suitable device and allowed to remain undisturbed for 24 to 72 h until the complete evaporation of solvent and the development of easily peel able film from the device. The homogeneous mixture was developed by subjecting the solution in to high shear condition by using overhead stirrer at 1500 to 2000 RPM. The care should be taken to prepare the bubble free solution and this may affect the formation of film uniformity during casting. Previously water soluble polymer should be dissolved in the aqueous medium for at least 2 h for complete swelling to form a homogeneous solution or dispersion. The other ingredients also added in the high shear condition. This solution was degassed under vacuum and the resultant bubble free solution was poured in the glass mould which was kept in the oven for drying. The dried film was then peeled out and cut in desired shapes and sizes. The detailed formulation design was depicted in the Table 1.

Preparation of HPMC E15 LV fast disintegrating films

The film was formulated by solvent casting method. The polymer HPMC E 15LV was weighed (10 to 40 mg) and dissolved in water (7 ml) and it was kept undisturbed for 30 min for the completion of swelling behavior of the polymer. The 20 mg of drug was added to the polymer solution. The required amount of glycine and mannitol was dissolved in aqueous solvent (2 ml) and introduced in to the above solution. Finally tween-80 was introduced into the solution and was mixed by using magnetic stirrer. The final viscous solution obtained was degassed under vacuum move the air bubbles. The resultant bubble free solution was poured carefully on to glass mould, glass mould was kept for 24 h at 45° C in a hot air oven for drying, the film was removed with a care from the mould and preserved in an aluminum foil then stored in a desiccators.

Preparation of carbopol fast disintegrating films

The film was formulated by solvent casting by dissolving carbopol in water (7 ml) solution which was kept undisturbed for 30 min for the saturation of swelling behavior of the polymer. The drug (20 mg) was added to the polymer solution, followed by required amount of glycine, and mannitol was dissolved in 2 ml of aqueous solvent. The tween-80 was added to the above solution and the solution was mixed by using magnetic stirrer. The viscous solution was degassed under vacuum, the resultant bubble free solution was poured on to glass mould and kept for 24 h at 45°C in hot air oven for drying, the film was removed from the mould and preserved in an aluminum foil then stored in a desiccators.

Preparation of PVA fast disintegrating films

The film was formulated by solvent casting by taking poly vinyl alcohol and dissolved in water (7 ml) which was kept aside for 30 min for swelling the of polymer. The 20 mg of drug was introduced into the above polymer solution followed by the addition of required amount of glycine, and mannitol which was previously dissolved in 2 ml of aqueous solvent, tween 80 was added to the solution then the solution was mixed by using magnetic stirrer. The viscous solution formed was degassed under vacuum, the resultant bubble free solution was poured in to a glass mould and it was kept for 24 h at 45°C in a hot air oven for drying, the film was removed from the mould and preserved in an aluminum foil and stored in a dessicater.

Weight variation of the films

Films were prepared by casting method. Each of one square inch film was cut at three different places and weighed and weight variation was studied and corresponding results were presented in Table 3.

| Formulation-code | Wt variationma % Deviation | Thickness (mm) | Tensile Strength | Swelling index | Dissolution studies (sec) |

|---|---|---|---|---|---|

| FPH-1 | 46.45±0.12 | 243±023 | 1.50±0.042 | 4.13±0.05 | 84.92 |

| FPH-2 | 55.46±0.34 | 219±034 | 1.55±0.081 | 3.32±0.04 | 85.34 |

| FPH-3 | 45.32±0.14 | 230±033 | 1.26±0.01 | 3.37±0.02 | 83.42 |

| FPH-4 | 72.45±0.24 | 376±031 | 1.63±0.084 | 4.18±0.8 | 89.92 |

| FPH-5 | 70.23±0.21 | 313±056 | 1.03±0.02 | 4.16±0.1 | 88.98 |

| FPH-6 | 53.33±0.32 | 270±066 | 1.33±0.092 | 3.76±0.02 | 85.17 |

| FPH-7 | 69.35±0.14 | 206±028 | 1.43±0.032 | 4.10±0.08 | 86.12 |

| FPH-8 | 79.67±0.31 | 139±033 | 1.23±0.65 | 3.43±0.4 | 85.66 |

| FPH-9 | 60.12±0.41 | 392±013 | 1.67±0.023 | 4.21±0.03 | 90.44 |

| FPH-10 | 52.46±0.22 | 189±066 | 1.33±0.042 | 2.95±0.02 | 81.1.2 |

| FPH-11 | 56.64±0.51 | 285±069 | 1.26±0.034 | 3.36±0.2 | 88.44 |

| FPH-12 | 67.27±0.11 | 272±033 | 1.46±0.072 | 3.72±0.09 | 86.98 |

| FPH-13 | 68.53±0.23 | 269±043 | 1.34±0.100 | 4.15±0.04 | 80.34 |

| MKTD-1 | 62.45±021 | 330±56 | 1.60±0.068 | 4.17±0.9 | 86.54 |

Table 3: Evaluation of propranolol HCL fast disintegrating oral films.

Thickness measurement

Thickness of the films was determined by using a Dial thickness gauge (Mitutoyo Manufacturing Co. Ltd., Japan) at three random positions on the film and the mean thickness was calculated. Samples with air bubbles, films having mean thickness variation of greater than 5% were considered as exclusion criteria.

Tensile strength

Tensile strength is the point at which the film strips breaks when the maximum stress is applied. It is calculated by the following formula.

Tensile strength = Load at Failure × 100 Strip thickness × Strip Width

Percent elongation

Percentage elongation is the test on the strip capacity to retain its original size and shape upon the When stress is applied, a strip sample stretches and this is referred to as strain. Strain is basically the deformation of strip divided by original dimension of the sample. Optimum plasticizer content may prevent the deformation of the film.

% Elongation=Increase in length of strip × 100

Folding endurance

The folding endurance was measured manually. The strip of film was folded repeatedly at the same place until the film breaks. The number of times the film withstands without breaking gave the value of folding endurance (Table 4).

| Formulation-code | % Elongation | % content uniformity | Surface pH | Mouth Dissolving Time (sec) | Folding endurance |

|---|---|---|---|---|---|

| FPHS-1 | 19.88 | 85.32±2.5 | 6.58±002 | 68.66±0.1 | 199.3±0.02 |

| FPH-2 | 13.45 | 81.35±2.27 | 5.35±001 | 78±0.02 | 197.3±0.01 |

| FPH-3 | 18.33 | 89.54±5.32 | 5.13±007 | 67.66±0.11 | 200.1±0.04 |

| FPH-4 | 37.78 | 93.23±1.23 | 6.89±003 | 50±0.02 | 201.4±0.12 |

| FPH-5 | 26.89 | 86.34±2.34 | 7.08±001 | 66.33±0.6 | 198.2±0.04 |

| FPH-6 | 21.5 | 91.53±4.23 | 6.68±003 | 63.33±0.07 | 200.5±0.12 |

| FPH-7 | 19.78 | 82.65±2.45 | 6.74±0.5 | 58.66±0.04 | 197.3±0.31 |

| FPH-8 | 31.44 | 91.34±3.24 | 6.54±007 | 55.66±0.9 | 200.4±0.03 |

| FPH-9 | 17.6 | 85.22±2.24 | 6.75±003 | 84.33±0.03 | 198.6±0.10 |

| FPH-10 | 20.23 | 92.23±2.12 | 6.54±002 | 76.34±0.5 | 197.4±0.09 |

| FPH-11 | 21.66 | 92.24±2.34 | 6.81±008 | 86.23±0.03 | 199.2±0.03 |

| FPH-12 | 31.56 | 90.12±1.65 | 6.84±007 | 66.65±0.5 | 200.8±0.05 |

| FPH-13 | 25.12 | 92.11±1.4 | 6.39±003 | 70.43±0.03 | 198.3±0.06 |

| MKTD-1 | 31.58 | 92.54±2.13 | 6.86±008 | 60.23±0.9 | 200.3±0.09 |

Table 4: Quality control parameters of propranolol HCL fast disintegrating oral films.

In vitro disintegrating time

20 ml of pH 6.8 phosphate buffer was placed in a Petri plates. The film was placed on the surface of buffer. The time taken for the disintegration of the film was measured.

Mouth dissolving time (MDT)

The mouth dissolving time was determined by placing a film into a beaker containing 15 ml of 6.8 pH phosphate buffer. Time required by the film to completely dissolve without a hard residue was noted as a point of MDT.

Drug content uniformity

A fast-dissolving film (4 cm2) was placed in to graduated flask containing 100 ml of distilled water. The flask was shaken for 2 h in a mechanical shaker. The solution was filtered. The filtered solution was appropriately diluted with the distilled water and the absorbance value was measured at 243 nm using the placibo patch solution as a blank, and the drug content was calculated.

In vitro dissolution studies

In vitro dissolution studies for the all formulated films were carried out by using 50 ml glass beaker at 50 rpm in 20 ml of phosphate buffer pH 6.8 maintained 37 ± 05°C 5 ml. The aliquot was withdrawn at the specific time intervals, filtered through Whatmann filter paper and analyzed by spectrophotometer at 290 nm (Shimadzu 1800 spectroscopy) an equal volume of fresh medium was replaced in to dissolution medium after each sampling to maintain the constant volume throughout the process (Table 5).

| Formulations | Zero order | First order | ||

|---|---|---|---|---|

| R2 | K0(mg/hr) | R2 | K1(hr-1) | |

| F1 | 0.8045 | 8.033 | 0.804 | 2.261 |

| F2 | 0.8146 | 7.245 | 0.814 | 2.075 |

| F3 | 0.8126 | 7.68 | 0.812 | 2.146 |

| F4 | 0.87 | 7.413 | 0.87 | 2.241 |

| F5 | 0.705 | 6.093 | 0.705 | 2.099 |

| F6 | 0.807 | 7 | 0.949 | 2.185 |

| F7 | 0.768 | 6.891 | 0.957 | 2.281 |

| F8 | 0.784 | 6.854 | 0.982 | 2.261 |

| F9 | 0.86 | 7.4 | 0.956 | 2.282 |

| F10 | 0.758 | 6.423 | 0.976 | 2.247 |

| F11 | 0.717 | 6.403 | 0.993 | 2.254 |

| F12 | 0.836 | 7.824 | 0.901 | 2.1 |

| F13 | 0.863 | 7.13 | 0.982 | 2.924 |

Table 5: Drug release kinetics study of fast disintegrating oral films.

Kinetics of drug release

The in vitro dissolution profiles of all batches were fitted to Zero order, first order model to ascertain the kinetic modeling of drug release. Correlation coefficient (R2) values were calculated for linear curves obtained by the regression analysis of the above plot. Zeroorder kinetic model-Cumulative % drug released Vs time. First-order kinetic model-log cumulative % drug remaining Vs time was applied as the criteria for construction of regression line.

Surface pH

The film was placed in a petri dish. The film was moistened with 0.5 ml of distilled water drop by drop and kept aside for 30 sec. The pH was measured by bringing the electrode of the pH meter in contact with the surface of formulation and allowing equilibration for 1 min.

Swelling index

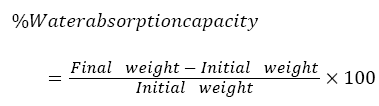

Swelling studies was conducted using 6.8 buffer solutions. Each film was weighed and placed in a pre-weighed plastic wire mesh. The mesh containing film was dipped into 20 ml medium in a plastic container. Increase in the weight of the film was determined at preset time interval until the constant weight was observed. The degree of swelling was calculated by using parameters.

Stability studies

Stability studies were carried out for a specific time period for up to the 3 months as per ICH guidelines. Long term testing 25° ± 2°C/60% RH ± 5% for 12 months. Accelerated testing 40° ± 2°C/75% RH ± 5% for 6 months for selected formulation at room temperature. Films were evaluated for assay, mouth disintegrating time and wetting time after three months.

Pre formulation studies for propranolol HCl

Thirteen formulations were prepared with different level addition of film forming polymers with different ratios of pectin, HPMC E15 LV, carbopol, poly vinyl alcohol and HPMC. The various pre formulation analyzes were carried out before executing formulation design. The solubility of the drug may be expressed in many ways. The US pharmacopoeia and national formularies list the solubility of solution in 1 gram of solute will dissolve one gram of drug was dispersed in the solvent such as water and methanol. The solubility study demonstrate 45-48 mg/ml with a slight heat and which complies with the referred value. The pH of the drug solution was tested by using pH meter 4% w/v solution of propranolol HCl was prepared by using methanol as a solvent and sonicated for 30 minutes the glass electrode of the pH meter was immersed in the prepared solution and the pH of the solution was recorded. The moisture content was determined by using sartorial moisture determining apparatus 5 gm of propranolol HCl was transferred to an aluminum plate and the moisture content was determined at 105°C and the moisture content was 8.85%. Melting point of the drug was determined by using melting point apparatus and the melting point was 163°C, which complies with the recommended values.

Differential scanning colorimetric (DSC) analysis

Thermo grams of the propranolol hydrochloride and the mixture of Propranolol HCl and other excipients were presented in Figures 3-8. A sharp endothermic peak of propranolol hydrochloride propranolol HCl was demonstrated at 164.23°C.

FT-IR Study

Drug polymer compatibility was studied by FTIR spectra of the Propranolol HCl compared with the mixture of drug with other excipients (Figures 1 and 2). As shown in figures Propranolol hydrochloride gives the peak in spectrum nearby 3282.53 cm-1 due to the presence of amine group. The peaks at 2947.33 cm-1 also observed due to the presence of alkane group. The peaks present in the drug, excipients physical mixture also demonstrated the peaks of propranolol hydrochloride near at 1597.11 cm-1, 1323.21 cm-1, 2943.47 cm-1 intact. The frequencies of functional groups of Propranolol HCl remained unaffected in physical mixture containing different polymers and other ingredients. Hence there was no interaction between the drug and excipients used in the study.

The onset of transition was started at 162.24°C. The thermo gram of propranolol hydrochloride and carbopol showed the endothermic peak at 163.72°C and the thermo gram of propranolol hydrochloride and PVA demonstrated the endothermic peak at 163.05°C. Thermo gram of propranolol hydrochloride and Pectin demonstrated the endothermic peak at 163.61°C. The endotherm of propranolol hydrochloride and HPMC E15LV demonstrated the peak at 163.29°C, which was observed to be the lesser peak value as compared to Propranolol HCl. The mixture of samples did not affect the Propranolol HCl nature and no major physico chemical changes happened to propranolol hydrochloride (Figure 9).

Post formulation study

The present invention relates to synthesis of novel polymers combination of pectin, and HPMC E15 LV and pectin:carbopol was used to design a fast dissolving oral films. More particularly, the present invention provides identification, characterization and evaluation of selected polymers. The study was carried to formulate and evaluate an oral dissolving dosage form containing propranolol HCl as an anti-hypertensive drug. Present study is an attempt to select the best possible combination of plasticizer and salivary stimulating agent to formulate oral dispersible films, which disintegrates within seconds in mouth, thereby reducing the time of onset of action. Mannitol was selected as sweetening agent, pectin, carbopol, HPMC, PVA, HPMC E15LV were selected as water soluble fast disintegrating polymers. Menthol as flavoring agent, tween-80, glycine and citric acid in all formulations in different concentrations. Solvent casting method was used to formulate the films. The post evaluation parameters such as mouth dissolving time, Weight variation, tensile strength, Dispersion time values were found to be within the limits. The present invention embodies in vitro drug release kinetics and stability studies of the prepared propranolol HCl orodispersible films. The present invention identifies two polymers they are pectin: HPMCE15LV being a best combination for a water soluble fast release drug delivery systems. The percentage Drug content of all the films was found to be between 81.23%- 95.4% of propranolol HCl, which was within the limit. From the data obtained it was observed from the formulation containing pectin 40 mg and HPMC E15 LV 20 mg in Formulation FPH4 and pectin 30 mg carbopol 20 mg in formulation FPH9 demonstrated the disintegration time 50 seconds, 44 seconds respectively (Table 6).

| Parameters | Immediately after preparation | After one month | After three months | |||

|---|---|---|---|---|---|---|

| Formulation code | FPH-4 | FPH-9 | FPH-4 | FPH-9 | FPH-4 | FPH-9 |

| Drug content (%) | 93.23 | 95.22 | 92.86 | 94.78 | 92.93 | 94.82 |

| Mouth dissolving time (Sec) | 50 | 44.33 | 52 | 46 | 53 | 47 |

| Dissolution time (sec) | 89.92 | 90.44 | 88.87 | 89.79 | 88.96 | 89.9 |

Table 6: Stability parameters of formulation F4 and F9 stored at Room Temperature.

The prepared films were found to be good without any major film manufacturing defects. The surface of the film was found to be smooth. There is no sign of picking, sticking, and cracking. The prepared films were evaluated for post evaluation parameters. Post evaluation parameters such as thickness, weight variation, surface pH, mouth dissolving time, and tensile strength were also studied by adopting suitable methods and values were represented in Tables 3, 4 and 6. Weight variation of the film was controlled within the limits by controlling the thickness of the film. The formulations (FPH3-FPH9) showed the tensile strength value at the minimum of 1.03 and to the maximum of 1.67 kg/cm². The folding endurance was maintained as low as 197 to the maximum of 201 and the values were found to be within the limit. Since the film was meant for oral administration it is subjected to mouth dissolving time test by placing the film on the tongue. Time required for to get dissolved in the mouth was measured by using a stopwatch. Mouth dissolving time of film was ranged between 44 secs up to 86 sec for the formulation FPH11 showed the highest time of 86 sec and formulation F9 demonstrated the lowest wetting time of 44 sec. The formulation FPH, FPH6 and FPH13 showed mouth dissolving time between 50-70 sec. Formulations FPH, FPH10 and FPH11 showed mouth dissolving time between 76-86 sec. Formulations FPH4 and FPH9, demonstrated least mouth dissolving time range of 44-86 sec.

The amount of the drug present in the formulations FPH, FPH9, was found to be within the limits. The in vitro drug release studies were accomplished for all the formulations in triplicate. The results in vitro drug release study was depicted in Figure 10. For the dissolution study 20 ml of 6.8 pH phosphate buffers was used. The samples from the dissolution was withdrawn at different time intervals and analyzed spectrophotometrically against the blank. The drug release profile of the formulation was analyzed. The formulations FPH4 were formulated with combination of two polymers pectin: HPMC E15 LV (4:2).

The formulation FPH9 was formulated with combination of two polymers pectin:carbopol (3:2). The Percentage drug release of FPH4 was 89.92% at the end of 7 min and FPH9 was 90.44% at the end of 7 min. These two formulations FPH4 and FPH 9 both satisfied all the films evaluation criteria for oro dispersible films (Figure 11).

Based on the above discussed parameter it was concluded that formulation of fast dissolving films of propranolol HCl was successfully developed and the optimized formulation of FPH-4 and FPH-9 results were comparable with that of marketed conventional films of verapamil. The formulations FPH, FPH, FPH6 and FPH10 released more than 88% of the drug within 7 minutes which were formulated by using different combination of pectin: HPMC; pectin: PVA; pectin: carbopol; pectin: HPMC E15 LV; with different ratios respectively. The dissolution kinetic studies of all the formulations were performed. Complete drug release was found from all the formulations after 12 minutes. The formulations followed zero order release. The correlation coefficient (r2) was 0.705- 0.870. The rate constant (k0) was in the range of 6.093-8.033. During the stability studies the formulations did not demonstrated any significant change in physical and chemical parameters of the films. The drug content did not alter by more than 1%. There was no significant Change in mouth dissolving time as well as dissolution time of the propranolol HCl even after three months hence the formulations were found to be stable.