Research - (2020)Volume 6, Issue 1

Fatty Acid Methyl Ester Analysis of Olive Oil Degraded by Candida parapsilosis

Popoola Bukola Margaret1* and Onilude Anthony Abiodun2Abstract

Fatty acids are the major components of lipids; and the physical, chemical and physiological properties of a lipid class depend primarily on its fatty acid composition. Gas chromatography method can be used for the identification of microbiological degraded fatty acids in vegetable oils as methyl ester. The use of GC for FAME Quantification determination with flame ionization detectors has been effectively used for some time. It is highly sensitive, high accuracy and high reproducibility. It has advantages over Mass Spectrometry (MS) when analyzing n-6 and n-3 fatty acid metabolism as it is able to distinguish between structurally similar fatty acids as it uses retention time for labeling as opposed to atomic mass. MS is able to identify fatty acids within a sample but unable to distinguish double bond positions in stereoisomers and therefore unable to tell certain fatty acids apart.

Although GC/MS and other technical methods have been developed to quantitate C8-C26 chain-length FAs, the GC analysis of FAs with FID remains the most frequently used method (Jumat et al., 2006).

This study monitored the breakdown of olive oil by the lipase of Candida parapsilosis which was grown in two different mineral salt medium, one consisting of (g/L) of KH2PO4, 7.584; K2HPO4-, 0.80; MgSO4 .7H2O, 0.80; CaCl2, 0.16; (NH4)2NO3, 0.80; FeSO4¬, 0.16; and olive oil 2%, PH maintained at 7.0. The second one is also a modification of the first medium consisting (g/L) of KH2PO4, 7.584; K2¬HPO4¬, 0.80; MnSO4.4H2O,0.80; NaCl, 0.16; (NH4)2NO3, 0.80; Fe2(SO4)3, 0.08; and olive oil, 2%, pH maintained at 7.0 was studied over 25 days. The fatty acid profiles of the oils and methyl esters were determined by chromatography analyzer. The olive oil was analyzed for the fatty acids commonly present in it which are Myristic, Palmitic, Stearic, Oleic, Linoleic, Linolenic, Behenic and Lignoceric, having specific carbon number and their values in approximate percentage C14:0 (0.4), C16:0 (14.0), C18:0 (5.5), C18:1 (76.4), C18:2 (3.4), C18:3 (0.1), C22:0 (0.1) and C24:0 (0.1) respectively. Of all the fatty acid, oleic acid percentage is high in olive oil containing considerable amount of 76.4%.

The lipase of Candida parapsilosis reduced the fatty acid by 6.7% after 20 days in the media used. Hence the lipase from Candida parapsilosis had potential for degradation of fatty waste, a potential microbial isolate to be used for bioremediation processes.

Keywords

Fatty acid; Candida parapsilosis; Degraded; Olive oil Bioremediation

Introduction

The olive oil industry generates large amounts of olive mill wastes (OMWs) as by-products that are harmful to the environment. Due to high organic load and the elevated salt and poly-phenols content, olive mill wastes are significant sources of environmental pollution. About 30 million tons of OMWs per year are produced in the world. Thus, more research is needed on the development of new bioremediation technologies and strategies of OMWs, as well as the volarisation by microbial biotechnology.

A number of different microorganisms and processes have been tested to treat OMW [1]. Biological processes investigated for OMW treatment are aerobic and anaerobic [2-4]. Yeasts of the genus Geotrichum [1-6], Candida [2-7], Yarrowia [7], Moulds [1] White-rot fungi [1] have also been investigated in studies of OMW biodegradation.

Fatty acids are almost entirely straight chain aliphatic carboxylic acids. The broadest definition includes all chain lengths, but most natural fatty acids are C4 to C22, with C18 most common. Naturally occurring fatty acids share a common biosynthesis.Over 1000 fatty acids are known, but twenty (20) or less are encountered in significant amounts in the oils and fats of commercial importance (www.scribd.com).

The analysis of fatty acids (FAs) is very common in olive oil industry and is usually done by gas chromatography. Due to their polar nature and their high boiling points, they generally show poor peak shapes and bad reproducibility. To avoid these problems, most methods use derivatization reactions to convert fats to fatty acid methyl esters (FAMEs), which are easier to separate and exhibit better peak shapes.

The objective of this study was to use G.C analysis of fatty acids to monitor changes in the composition of olive oil degraded by Candida parapsilosis.

Materials and Methods

Degradation of the olive oil in the laboratory by the test organisms

This study was carried out using a modified method of Gogoi et al. and a method of Popoola et al. [8], where two forms of the Mineral Salt Medium was tested. 100 ml each of the two Mineral Salt Medium was dispensed into several 250 ml Erlenmeyer flasks. These medium in several flasks were autoclaved at 121°C for 15 minutes and allowed to cool. To each of the flasks was added 2 ml of olive oil sterilized through membrane pore filtration, as the sole carbon source. Candida parapsilosis grown in potato dextrose broth overnight was used in pure cultures to inoculate the flasks. Non-inoculated medium kept under the same condition served as control. The flasks were duplicated and were inoculated at room temperature on an orbital shaker Stuart SSLI at 180 rpm for 25 days. Two media are used for comparative sake, in order to ascertain the best growth nutrients in the media for the breakdown of the oil by the organism.

Monitoring the degradation pattern in the laboratory has shown that within 25 days lipase produced during fermentation could breakdown olive oil, which from this study had initial composition of oleic acid to be 76%. It has been reported that olive oil is the richest in monoenes fatty acids (Kolayli et al., 2011). It has unique double bonds the commonest of which are of the n-9 series, as oleic acid, probably the most common fatty acid (olive oil has a high content of this acid, about 60%-70% (Al-Darbi et al., 2005). Report also shows that oleic acid (C18:1), a mono-unsaturated omega 9 fatty acid makes up 55% to 83% olive oil (Oliveoilsource, 1998). Deferne and Pate [9] found olive oil to contain saturated stearic 16%, oleic acid 76% and monounsaturated linoleic 8%.

Olive oil contains more oleic acid and less linoleic and linolenic acids than other vegetable oils, as also noted in this study, that is, more mono-unsaturated (a single double bond) than polyunsaturated (more than one double bond) fatty acids. This renders olive oil more resistant to oxidation because generally, the greater the number of double bonds in the fatty acid, the more unstable and easily broken down by heat, light, and other factors oil will be (Oliveoilsource, 1998). This infers that if olive oil could still be biodegradable as observed in this work, other vegetable oil (like palm oil pollution in Malaysia which could be very challenging) could as well be easily broken.

These findings can be explained through an understanding of the effect of oil structure and composition on the degradation processes. The structure of a fatty acid molecule is characterized by the length of the carbon chain (number of carbon atoms), the number of double bonds and also the exact position of these double bonds, define and determine the biological reactivity of the fatty acid molecule and even of the lipid containing those fatty acids (Shanks, 2014).

Hence in areas of need like Malaysia, where there is huge contamination of palm oil and the effluents in the environment, this technique of degradation could be employed for the clean-up of the polluted sites that would have had adverse effects on the environment, even from the economic point of view.

From each of the culture media residual oil after degradation by the organism was extracted using n–hexane. This procedure involves pouring the content of the flasks into a separating funnel after which 100 ml n–hexane was added. After vigorous shaking and re-extracting of the aqueous phase, it was discarded while the organic phase was allowed to evaporate to a constant weight in a Petri dish, which was subsequently analyzed by gas chromatography.

Fatty acid methyl ester analysis

This was carried out by modified AOAC 965.49 and AOAC 996.06 official methods. 50 mg of the oil sample was saponified (esterified) for five minutes at 95°C with 3.4 ml of the 0.5 M KOH in dry methanol, which was then neutralized by using 0.7 M HCL, 3 ml of the 14% boron tri fluoride in methanol was added. This mixture was heated for five minutes at temperature 90°C to achieve complete methylation process. The Fatty Acid Methyl Ester were thrice extracted from the mixture with redistilled n – hexane and subsequently concentrated to 1 ml for gas chromatography analysis and 1 μl was injected into the injection port of GC. The Fatty Acid Methyl Esters were separated using HP 6890 Gas chromatography analyzer powered by HP chemstation Rev A O 9.01 (1296) software and equipped with a flame Ionization Detector (FID) and HP INNOwax column (30 mm x 0.25 cm x 0.2 μm film thickness). The carrier gas nitrogen and the oven initial temperature was at 60°C. The first ramping was at 120°C/ min for 20 minutes and maintained for 2 minutes. The second was at 15°C/mm for 3 minutes and maintained for 8 minutes. The detector temperature was 32°C, while hydrogen and compressed air pressures were 22 and 35 psi respectively. The carrier gas sweeps the concentrated content through the column; the various components of the content were separated as they progress along the column and reach the end of the column at different times. A detector was used to monitor the outlet stream from the column; thus, the time at which each component reaches the outlet and the amount of that component were determined.

Results and Discussion

Monitoring the degradation pattern in the laboratory has shown that within 25 days lipase produced during fermentation could breakdown olive oil, which from this study had initial composition of oleic acid to be 76% (Table 1), while Table 2 shows that of the oleic acid only.

| Degradation period (days)/medium/ percentage composition | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| S/N | Fatty acid | 5 | 10 | 15 | 20 | 25 | |||||

| 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | 1 | 2 | ||

| 1 | FGN1 | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a |

| 2 | FGN2 | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a |

| 3 | FGN3 | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a |

| 4 | F001 | 0.0820 h | 0.0815 i | 0.1090 g | 0.0721 j | 0.0900 f | 0.1564 e | 0.3822d | 0.4040 c | 0.5658 b | 0.6020 a |

| 5 | F002 | 10.1880 j | 10.2901 i | 11.7739 g | 11.1909 h | 13.7205e | 13.4261f | 15.7671c | 15.2642d | 16.3746a | 16.0694b |

| 6 | F003 | 0.0941a | 0.0937 b | 0.0674 c | 0.0443d | 0.0304g | 0.0421 e | 0.0211 h | 0.0323 f | 0.0000 i | 0.0000 i |

| 7 | FCS1 | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a |

| 8 | FCS2 | 4.5799j | 4.5545i | 5.5983 g | 5.1792 h | 6.2702 e | 6.0156 f | 7.6284d | 7.8235 c | 8.2155b | 8.4980 a |

| 9 | FCS3 | 74.873 a | 74.4584b | 72.5577 d | 73.3139 c | 71.0757f | 71.4433e | 69.2278j | 69.4455i | 70.0411h | 70.0905g |

| 10 | FCS4 | 9.0634c | 9.5437a | 8.8472d | 9.4090 b | 8.25074e | 8.1514f | 6.040h | 6.0909g | 4.0864j | 4.1804i |

| 11 | FSF1 | 0.8426 a | 0.7033 b | 0.6762 c | 0.5457d | 0.4394h | 0.4714e | 0.4528g | 0.4674f | 0.3047i | 0.2074j |

| 12 | FSF2 | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a | 0.0000 a |

| 13 | FSF3 | 0.0731 d | 0.0727 a | 0.0978 c | 0.0646 b | 0.0000 e | 0.0000 e | 0.0000 e | 0.0000 e | 0.0000 e | 0.0000 e |

| 14 | FP01 | 0.0553gj | 0.0547h | 0.0735f | 0.0436j | 0.0333i | 0.0794e | 0.1517a | 0.1490 b | 0.1302d | 0.1415c |

| 15 | FP02 | 0.0296c | 0.0292d | 0.0405b | 0.0272e | 0.0186f | 0.0429 a | 0.0000 g | 0.0000 g | 0.0000 g | 0.0000 g |

| 16 | Lignoceric | 0.1187g | 0.1182h | 0.1584f | 0.1046i | 0.0715j | 0.1711e | 0.3285a | 0.3231b | 0.2816c | 0.2108d |

Table 1: Percentage composition of released fatty acid degraded by Candida parapsilosis (CP) (from culture medium 1and 2) over 25 days.

| S/N | Sample nature | Percentage oleic acid |

|---|---|---|

| 11 | 1C5 | 74.8731 |

| 12 | 1C10 | 72.5577 |

| 13 | 1C15 | 71.0757 |

| 14 | 1C20 | 69.2278 |

| 15 | 1C25 | 70.0411 |

| 16 | 2C5 | 74.4537 |

| 17 | 2C10 | 73.3139 |

| 18 | 2C15 | 71.4433 |

| 19 | 2C20 | 69.4455 |

| 20 | 2C25 | 70.0905 |

Table 2: Percentage of oleic acid released from residual oil by Candida parapsilosis.

The structure of a fatty acid molecule that is characterized by the length of the carbon chain (number of carbon atoms), the number of double bonds and also the exact position of these double bonds, define and determine the biological reactivity of the fatty acid molecule and even of the lipid containing those fatty acids (http://www.tdx.cat).

Deferne and Pate [9] find olive oil contains saturated stearic 16%, oleic acid 76% and mono-unsaturated linoleic 8%. Report also shows that oleic acid (C18:1), a mono-unsaturated omega 9 fatty acid makes up 55 to 83% olive oil (www.oliveoilsource.com).

The residual oils tested were degraded by Candida parapsilosis grown in the two mineral salt medium over 25 days (Table 2), and the percentage composition of the released components of the fatty acid are also indicated

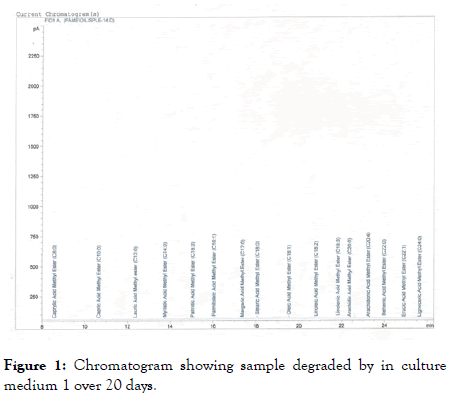

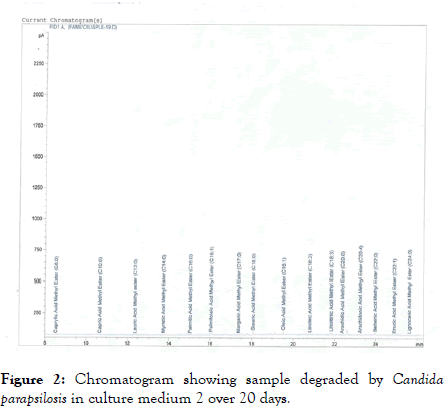

Using medium 1, Candida parapsilosis reduce percentage oleic acid from 76% to 69.2278% on the 20th day (Figure 1). However, on the 25th day, it came up to 70.0411% as shown in Table 2. In the case of fermentation by Candida parapsilosis using medium 2, day 20 marked a reduction in oleic acid composition to 69.4455%. Increase in oleic acid percentage composition occurred on 25th day of fermentation by Candida parapsilosis, as shown in Table 2. The first chromatogram shows analysis of the olive oil sample degraded by Candida parapsilosis on the 20th day using medium 1, while the second shows analysis of the sample degraded by the same organism on the 20th day using medium 2 (Figure 2).

Figure 1. Chromatogram showing sample degraded by in culture medium 1 over 20 days.

Figure 2. Chromatogram showing sample degraded by Candida parapsilosis in culture medium 2 over 20 days.

During the experimental period of 25 days, the contents of all individual fatty acids in all the media treated with Candida parapsilosis underwent both increases and decreases in their percentage composition. This result suggests that this substrate were not consumed by microorganisms at the same rate. These are in agreement with Kangala and Krystyna [10], who find different utilisation rates of fatty acids by activated sludge microorganisms. Novak and Kraus [11] also found that the utilisation rate of fatty acid by activated sludge microorganisms is different and depends on the length and degree of unsaturation of their carbon chains. Results of Dignac et al. [12] also showed increases in contents of fatty acids (Palmitoleic, Stearic, Linoleic, Linolenic, Linoleic, Arachidic, Behenic and Lignoceric) in wastewater effluents after 24 hr of a biological treatment process using activated sludge. Pereira et al. [13] report the appearance of palmitic acid in wastewater after a biological treatment process. Because palmitic acid was absent from the wastewater at the beginning of the process, they conclude that it is a by – product of biodegradation of oleic acid initially added to the wastewater.

Kamariah et al. [14] noted when mycelium – bound lipases of Aspergillus sp. were used to catalyse the hydrolysis of coconut oil, palm olein, olive oil and flaxseed oil. In most cases, relative percentage of monounsaturated fatty acid (C18.1) in non – hydrolysed fractions of oils increased after 12 days of hydrolysis.

Many other researchers have reported that fatty acids accumulate in biological wastewater treatment systems [14-19]. Therefore, since biodegradation and biosynthesis of fatty acids occur inside microbial cells, the observed increases in contents of fatty acids show that they were released into the wastewater as microbial by – product. At the same time, decreases in their content shows that fatty acids were subsequently consumed by the organisms as substrates.

Conclusion

However, as observed in this work olive oil was actually biodegraded in the laboratory. This infers that if olive oil could still be biodegradable despite the fact that it is more resistant to oxidation because it has more mono-unsaturated fatty acids, other vegetable oils could as well be easily broken down as they contain less oleic acid.

Hence, monitoring the result of degradation patterns of the vegetable oil using fatty acid methyl ester analysis, by Candida parapsilosis, proves that this microorganism (Candida parapsilosis) could become potential candidates in the development of microbial bioaugmentation products for the treatment of vegetable oil mill effluents and soils, particularly in polluted areas and sites.

References

- McNamara CJ, Anastasiou CC, O’Flaherty V, Mitchell R. Bioremediation of olive mill wastewater. Internat Biodeterioration Biodegradation, 2008;61: 127-134.

- Ben Sassi A, Ouazzani N, Walker GM, Ibnsouda S, El Mzibri M, Boussaid A. Detoxification of olive mill wastewaters by Moroccan yeast isolates. Biodegradation. 2008 ;19 3:337-346.

- Amaral C, Lucas MS, Coutinho J, Crespί AL, do Rosário Anjos M. Microbiological and physicochemical characterization of olive mill wastewaters from a continuous olive mill in north eastern portugal. Bioresour Technol. 2008;99 15:7215-7223.

- Peixoto F, Martins F, Amaral C, Gomez-Laranjo J, Almeida J, Palmeira CM. Evaluation of olive oil mill wastewater toxicity on the mitochondrial bioenergetics after treatment with Candida oleophila. Ecotoxicol Environ Saf. 2008;70 2:266-275.

- Asses N, Ayed L, Bouallagui H, Sayadi S, Hamdi M. Biodegradation of different molecular-mass phenols derived from olive mill wastewater by Geotrichum candidum. Internat Biodeterioration Biodegradation. 2009;63 4:407-413.

- A’yed L, Assas N, Sayadi S, Hamdi M. Involvement of lignin peroxidase in the decolourization of black olive mill wastewaters by Geotrichum candidum. Lett Appl Microbiol. 2005;40 1:7-11.

- Gonҫalves C, Lopes M, Ferreira JP, Belo I. Biological treatment of olive mill wastewater by non-conventional yeasts. Bioresource Technol. 2009; 100: 3759-3763..

- Popoola BM, Onilude AA, Olateru CT. Fatty acid methyl analysis of olive oil degraded by Pseudomonas fluorescens. J Adv Microbiol. 2017;2 2: 1-7.

- Deferne JD, Pate DW. Hemp Seed Oil: A source oil, a source of valuable essential Fatty acid. J Internat Hemp Association.1996;3 1: 1-7.

- Kangala B, Krystyna M. Characterization of the Fate of lipids in activated sludge. J Environ Sci. 2008; 20: 536-542.

- Novak JT, Kraus DI. Degradation of long chain Fatty acids by activated sludge. Water Res. 1973; 7: 843-851.

- Dignac MF, Ginestet P, Rybacki D, Bruchet A, Urbrain V. Fate of wastewater organic pollution during activated sludge treatment: Nature of residual organic matter. Water Resources. 2000; 34: 4185-4194.

- Pereira MA, Pires OC, Mota M, Alves MM. Anaerobic degradation of oleic acid by suspended and granular sludge: Identification of Palmitic acid as a key intermediate. Water Sci Technol. 2002; 45 10:139-144.

- Kamariah L, Nurul Huda H, Azlina MD, Rosmawati O, Hasanah MG, Lai OM, et al. Substrate specificity of lipase from four species of Aspergillus towards hydrolysis of homo acid triacylglycerols and vegetable oils in non-aqueous system. J Tropical Agricul Food Sci. 2006; 34 1: 103-109.

- Beccari M, Majone M, Torrisi L. Two-reactor system with partial phase separation for anaerobic treatment of olive oil mill effluents. Water Sci Technol. 1998; 38: 53-60.

- Salminen E, Rintala J, Lokshina LY, Vavilin VA. Anaerobic batch degradation of solid poultry slaughter waste. Water Sci Technol. 2000;41 3:33-41.

- Kunau WH, Dommes V, Schulz H. β-oxidation of fatty acids in mitochondria, peroxisomes, and bacteria: A century of continued progress: Prog Lipid Res. 1995;344:267-342.

- Lalman JA, Bagley DM. Anaerobic degradation and methanogenic inhibitory effects of oleic and stearic acids. Water Res. 2001; 35: 2975-2983.

- Chtourou M, Ammar E, Nasri M, Medhioub K. Isolation of a yeast Trichosporon cutaneum, able to use low molecular weight phenolic compounds: application to olive mill wastewater treatment. J Chemis Technol Biotechnol. 2004; 79 8:869 – 878.

Author Info

Popoola Bukola Margaret1* and Onilude Anthony Abiodun22Department of Microbiology, University of Ibadan, Ibadan, Nigeria

Citation: Popoola BM, Abiodun OA (2020) Fatty Acid Methyl Ester Analysis of Olive Oil Degraded by Candida parapsilosis. Appli Microbiol Open Access 6:168. Doi: 10.35248/2471-9315.20.6.168

Received: 23-Jan-2020 Accepted: 07-Feb-2020 Published: 13-Feb-2020 , DOI: 10.35248/2471-9315.20.6.168

Copyright: �© 2020 Popoola BM, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.