Advances in Automobile Engineering

Open Access

ISSN: 2167-7670

ISSN: 2167-7670

Research Article - (2016) Volume 5, Issue 2

In this study, static and fatigue analysis of three different electrical bikes’ rim which are coupled with electrical hub motor was investigated. Loading conditions were applied on rim in order to simulate driving forces that exert on road conditions. Analysis results of three rims were compared with each other. According to results, sharp edges increase von-Mises stresses and decrease fatigue safety factor due to stress concentration on the corners. Also, it was observed that contact area of spokes to flange affects the total deformation and von-Mises stress distribution. Three dimensional models of the rims were designed with the aid of CATIA V5 and their computational analyses were carried out with ANSYS WORKBENCH software program.

<Keywords: Rim; Modelling; FEM; Electrical bike

Nowadays, electric vehicles are becoming more and more important due to financial and energy crisis in all over the world. Electric bike which is a bicycle with an integrated electric motor, is one of the most popular electric vehicle in many countries [1,2]. In Asia, there has been a large increase in sales of e-bikes and in Europe even more due to its advantages of high efficiency, almost zero emissions, low initial, running and maintenance cost. [1-4].

Tyres are the only part of a vehicle which directly contact with the road surface [5]. Rim, skeleton of the tyre, must be light and provide enough strength to transmit vehicle power. In this study, static and fatigue analysis of three different electrical bikes’ rim which are coupled with electrical hub motor was compared and investigated by using finite element method. Over the years, scientists are researching on various rim designs. They are trying to find best material composition and best mechanical design of the rim which provide requirements above. There have been many studies about various types of rims under different load conditions.

Most of the studies are carried out with the aid of finite element method since the methodology saves cost and time and it is able to solve problems with complicated geometry shape [6].

Adigio and Nangi used finite element method to simulate the radial test and Akdogan et al. studied on cornering fatigue test of a vehicle rim [7,8]. Topaç et al. investigated the fatigue failure that occurs on the air ventilation holes of a heavy commercial vehicle steel rim [9]. Stearns et al., studied on finite element technique for analyzing stress and displacement distribution in an aluminum alloy rim [10].

Three different rims which has 406.4 mm (R16) outer diameter and made of aluminium alloy were compared by finite element methods in order to comprehend their behaviour on road conditions. The rims named as Rim A, Rim B and Rim C were illustrated in Figure 1.

Firstly, three-dimensional models of the rims were prepared with CATIA V5 software program (Figure 2). The exact models were designed as 3D model. And then, few simplifications on the models were performed to overcome complexities during meshing operation.

The prepared models were exported to ANSYS Workbench software program for stress analyses. Default mechanical properties of aluminium alloy material according to software program was performed and mechanical properties of material that used in this study were shown in Table 1. More than 3.5 million nodes and 2.3 million elements were used for each of the rim model (Figure 2). Mechanical properties of the rims were given in Table 1. For meshing operation, proximity and curvature size function with 1.40 growth rate were used (Figure 3). Analyses were carried out in Çukurova University Automotive Engineering Laboratories with the aid of workstation, which has 2 processors (24 cores) and 32 GB RAM.

| Material | Young’s Modulus (GPa) |

Poisson’s Ratio (V) | Yield Strength (MPa) |

|---|---|---|---|

| General aluminium alloy. Fatigue properties come from MIL-HDBK-5H, page 3-277. | 71 | 0.33 | 280 |

Table 1: Mechanical properties of the rims.

On road, electric bike is exposed to various loads; however it is difficult to consider all possibilities. Common forces that exerts on an electric bike were considered as;

• Tyre pressure that was applied on the rim from outside of the circumference as 0.2344 MPa,

• Radial load which was applied as pressure and distributed according to cosine function along to 900 portion of the bead seat in order to simulate the total weight of electric bike.

• 43.5 rad/s rotational velocity to the models. The models were fixed from the hub where axle mounted inside it.

The models were run for the applied boundary and loading conditions. Von-Mises stresses and total deformations of the rims were illustrated in Figures 4- 6. Maximum von-Mises stress found as 16.74 MPa, 4.34 MPa and 5.5 MPa and maximum total deformation found as 0.0026 mm, 0.0019 mm and 0.002 mm respectively. In Figures 4a - 6a, stresses over 4 MPa were shown in red colour.

Static tests showed that the highest stresses were occurred at sharp edges and spoke to flange connections. It must be pointed out that the stress increased with the decrement of spoke-flange connection section area.

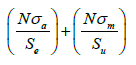

The other step of the simulation was fatigue analysis. In this analysis, stress life analysis type preferred due to high fatigue cycle (>105). The mean stress σm on the true fatigue strength Se should had been corrected by Modified Goodman and Gerber approaches, since the loading characteristic fluctuated as σm > 0. Gerber approach is preferable by many researches for ductile materials [9,11]. The formula of Gerber Fatigue Theory is shown in Equation 1.

(1)

(1)

N: safety factor for fatigue life in loading cycle,

Se: endurance limit

Su: for ultimate tensile strength of the material.

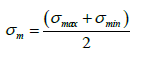

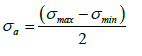

Mean stress σm and alternating stress σa are defined in Equation 2 and Equation 3, respectively;

(2)

(2)

(3)

(3)

Von-Mises stresses obtained from analyses were utilized in fatigue life calculations. The result of fatigue analyses showed that all rims can withstand more than 106 cycles. Minimum safety factor was found to be 4.5 on the sharp corners. Fatigue analysis results as safety factor was shown in Figure 7.

From the static and fatigue analyses tests, the following results were summarized;

• Von-Mises stresses were primarily affected by sharp corners, due to the stress concentration on edges.

• Von-Mises stress can be decreased by increasing flange to spoke cross section areas.

• The rims which were investigated in this study can withstand 106 cycles.

• All tests results revealed that the rims are extremely safe (except on sharp corners), they may be re-designed in order to cost and weight reduction.