International Journal of Advancements in Technology

Open Access

ISSN: 0976-4860

ISSN: 0976-4860

Research Article - (2016) Volume 7, Issue 4

Laminated composites are widely used in engineering and structural applications. In present work failure analysis of cantilever beam made up of boron-epoxy laminated composite has been analyzed. Finite element software ANSYS has been used to perform failure analysis. Maximum stress and Tsai-Wu failure theories are implemented to predict failure index for different lamination schemes. Unidirectional and angle ply laminates has been analyzed for different fiber orientation angles. From results it is found that angle ply laminates exhibits higher failure strength compare to unidirectional laminates. Cantilever beam with fibers orientated along the direction of loading shows maximum failure strength whereas unidirectional and angle ply laminates with 45Ë fiber orientation shows minimum strength.

<Keywords: FEA; Laminated composites; Cantilever beam; ANSYS

Laminated composites are made up by stacking various layers of unidirectional lamina at different angles to provide required stiffness and strength in particular direction. Each lamina is made up of unidirectional fibers arranged in a matrix. Laminated composites have high strength to weight ratio, high corrosion resistance and high directional stiffness and strength due to these reasons widely used in automobile industries, space applications, sports goods and marine applications.

Composites are widely used in form of thin plate structures in various engineering applications. Thin walled composite beam such as cantilever beam subjected to transverse loads are generally used structures. Cutouts are provided in composite structures to fulfill design requirements. Hence study of thin walled composite beam with and without cutouts is required. Various researchers have studied effect of cut-outs on laminated composite plates and structures. Al Qablan et al. [1-5] studied effect of size of circular cut-outs, location of cut-out on buckling behavior of laminated composite plate. Kaltahci et al. [6] studied effect of fiber orientation on stress concentration around the hole. Hu and Lin [7-10] studied effect of fiber orientation on buckling of symmetric laminates with circular cut-outs. Talib et al. [11] studied effect of cut-outs on laminated composite plates under compressive and tensile loading. In present work cantilever beam made up of boron epoxy laminates with (θ°/θ°/θ°/θ°)s and (θ°/-θ°/θ°/-θ°)s lamination schemes have been analyzed.

To predict the behavior of laminated composites various analytical theories have been developed.

Strains in laminate can be written as:

Where,

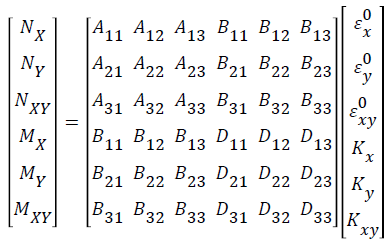

are the mid-plane strains of the laminate and

are the mid-plane strains of the laminate and  are the curvatures,

are the curvatures,

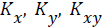

Relation between Force and Moments in laminate are given by:

Where,

[A] is extensional stiffness matrix, in which in-plane forces are related to in-plane strains.

[D] is bending stiffness matrix, in which the resulting bending moments are related to the laminate curvatures.

[B] is coupling matrix which couples the force and moment terms to the mid-plane strains and mid-plane curvatures.

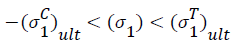

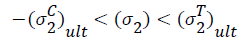

Maximum stress failure theory: This theory is based on maximum stress theory of Rankine and maximum shear stress theory of Tresca. According to this theory failure occurs when any one of stress in material axis exceeded the failure value of stress.

Lamina is considered to be failed if any one of the following conditions violates

Tsai-Wu failure theory: This interactive failure theory is based on strain energy theory for isotropic materials.

Tsai-Wu failure theory when applied to a lamina states that, a lamina is considered to be safe if:

Finite element procedure for analysis of laminates

Failure analysis of boron-epoxy laminates is performed using finite element software ANSYS. A rectangular plate of 100501 mm3 is modeled in ANSYS. Thickness of each layer is taken as 0.125mm and 8 layers of boron-epoxy are used to make laminate (Figure 1). Unidirectional (θ˚/θ˚/θ˚/θ˚) s and angle ply (θ˚/-θ˚/ θ˚/-θ˚)s laminates are studied in present investigation. Fiber orientation angle θ˚ is varied from 0˚ to 90˚. 4 node element SHELL181 is used to mesh geometry. After meshing boundary conditions are applied. All degrees of freedoms are constrained at left end of beam to fix left end of beam and point load of 1N is applied at right end of beam. Failure properties of boron-epoxy lamina are entered to calculate failure index of laminates (Tables 1-3).

| EX(GPa) | EY(GPa) | vxy | Gxy(GPa) | Xt(MPa) | Xc(MPa) | Yt(MPa) | Yc(MPa) | S(MPa) |

| 204 | 185 | 0.23 | 5.59 | 1260 | 2500 | 61 | 202 | 67 |

Table 1: Elastic and strength properties for boron/epoxy lamina.

| Failure Criteria | First Ply Failure Load(N) | Error % | ||

|---|---|---|---|---|

| Theoretical | ANSYS | Experimental | ||

| Max. stress | 229.11 | 225.63 | 253.6 | 11.02 |

| Tsai-Wu | 238.6 | 274.3 | 8.16 | |

Table 2: Comparison of ANSYS results with experimental data [2] for (02°/902°)s laminate

| Failure Criteria | First Ply Failure Load(N) | Error % | ||

|---|---|---|---|---|

| Theoretical | ANSYS | Experimental | ||

| Max. stress | 290.12 | 281.77 | 317.74 | 11.32 |

| Tsai-Wu | 304.13 | 301.7 | 5.04 | |

Table 3: Comparison of ANSYS results with experimental data [2] for (0°/90°/0°/90°)s laminate.

Figures 1 and 2 shows stresses in y-direction in 0° and 90° layers of cross ply laminate. Layer with 90° fiber orientation are subjected to higher stresses compare to layer at 0° fiber orientation. Most of the portion of layers having fiber orientation 90° is subjected to compressive stresses since loading is along the direction of fibers.

Figure 3 shows stress distribution in unidirectional and cross ply laminates. For unidirectional laminate stress distribution in all layers is uniform whereas for cross ply laminates layers at 0° fiber orientation and layers at 90° fiber orientation have different stresses. Layer having fiber orientation 90° are subjected to higher stresses compare to 0° c layers.

Failure analysis of laminated composite cantilever beam having circular cutout have been performed in present investigation. Unidirectional and angle ply laminates are used to model cantilever beam. Fiber orientation is varied from 0° to 90° with 15° step length. Figure 4 and Figure 5 shows plot between failure index and fiber orientation angle for cantilever beam made up of unidirectional and angle ply laminates. Maximum stress and Tsai-Wu failure criteria are used to predict failure index.

Values of failure index for unidirectional laminates are greater than angle ply laminates for most of the fiber orientations. Since failure index is inversely proportional failure strength hence it can be concluded that angle ply laminates have higher failure strength compare to uniaxial laminates. Effect of fiber orientations is only significant up to 45°. Beyond 45° fiber orientations there is no significant difference in failure strength of unidirectional and angle ply laminates. From present investigation it can be concluded that unidirectional laminates with 90° fiber orientation have highest failure strength compare to all other configurations whereas unidirectional and cross ply laminates with 45° fiber orientation have minimum failure strength (Tables 4 and 5).

| Failure Criteria | Failure Index | ||||||

| q=0° | q=15° | q=30° | q=45° | q=60° | q=75° | q=90° | |

| Max. Stress | 0.005134 | 0.007054 | 0.009899 | 0.009927 | 0.007521 | 0.00375 | 0.002018 |

| Tsai-Wu | 0.00547 | 0.006837 | 0.008302 | 0.008727 | 0.007533 | 0.004743 | 0.00248 |

Table 4: Failure index of composite beam for (θ°/θ°/θ°/θ°)s laminate.

| Failure Criteria | Failure Index | ||||||

| q=0° | q=15° | q=30° | q=45° | q=60° | q=75° | q=90° | |

| Max. Stress | 0.005134 | 0.005302 | 0.007 | 0.00997 | 0.00716 | 0.004218 | 0.002018 |

| Tsai-Wu | 0.00547 | 0.005332 | 0.006573 | 0.009601 | 0.008776 | 0.004325 | 0.00248 |

Table 5: Failure index of composite beam for (θ°/-θ°/ θ°/-θ°)s laminate.

In present investigation failure analysis of cantilever beam made up of boron epoxy laminated composite material has been analyzed. Beam is subjected to point load in downward direction. From results it is found that angle ply laminates are stronger than unidirectional laminates. Unidirectional and angle ply laminates with 45° fiber orientation exhibits minimum failure strength. (45°/-45°/45°/-45°)s laminate is weakest among all other configurations whereas (90°/90°/90°/90°)s is strongest one. Tsai-Wu failure theory predicts lower values of failure loads compare to maximum stress theory.