Advances in dairy Research

Open Access

ISSN: 2329-888X

ISSN: 2329-888X

Research Article - (2016) Volume 4, Issue 4

Keywords: Calotropine; Cow milk, Composition, Sensorial profile

Several enzymes plant preparations are known for cheesemaking as cardosine from Cynara cardunculus, ficine from Ficus caricas , papain from Carica papaya , bromelain from Ananas comasus , and the calotropine from Calotropis procera [1-4]. The calotropine, a vegetable coagulating enzyme, is extracted from Calotropis procera of Asclepiadaceae family which is very widespread in the tropical and subtropical areas of Africa (Somalia, Egypt, Libya, the Algerian South, Morocco, Mauritania, Benin, Chad, Niger, Mali, Senegal, Togo) in Asia (India, Pakistan, Afghanistan, Iran, Saudi Arabia), in the center and in the South of America [5]. It is a well-known medicinal plant with leaves, roots and bark being exported as popular medicine to fight many human and animal diseases [6]. In the folk medicine of Algeria, Calotropis procera is used to treat respiratory diseases rheumatism and asthma [7,8]. Generally, in south African and Asian countries, latex of the plant is used as an antidysenteric, an expectorant, an antiinflammatory, and also for milk coagulation in cheese making [9,10].

Thus, the calotropine is a protease cysteine coagulant agent [11]. It is very known by its use in the preparation of traditional “Peulh” cheese also called «waragashi» or «wagashi» in most countries of West Africa, mainly in Benin. Calotropis procera is also met in the south of Algeria precisely in Béchar, where our plant study was brought from. This testifies on the Algerian plants biodiversification still ignored as coagulant agent’s sources. Therefore, these milk coagulating agents could contribute to the development of satisfactory quality protein dairy products which would replace proteins meat products relatively expensive. This cheese would have a moderate coast, since its preparation coast would depend mainly of the milk coast.

The work objectives are 1) extraction of the calotropine from the south of Algeria and its use in the fresh “Peulh type” cheese making 2) characterization of the fresh cheese “Peulh type”cheese on the chemical and sensory aspects. We remind that this study has not been approached yet by Algerian authors and we are interested in characterizing the cheese to show closely that it is possible to exploit this plant in Algeria to manufacture the traditional cheese “Peulh” while its origins are derived mainly from Benin.

Samples

Five liters of Fresh cow milk samples were purchased on days of experiment into sterilized containers from a private dairy “SAFILAIT” situated at Ain Smara, of Constantine city and transported immediately to the laboratory under cold storage.

Coagulant enzyme

The plant used is composed of leaves and stems of Calotropis procera proceeded from Béchar southern Algeria city, located 1500 km from Constantine (Figure 1). This plant is forwarded to the laboratory, 72 hours after collection.

Physicochemical composition

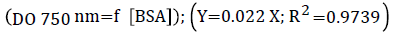

Chemical raw milk determinations were performed as described by AFNOR methods [12]: dry extract (NF V 04-207), lactic acidity, (NF V04-207), pH and density. The total proteins were quantified by Lowry's method [13], against a standard curve.

Typical diagram of « Peulh-type » cheese making

Cheese production was carried out generally, following methods described by O’Connor et al. [14,15]. Five liters of raw cow’s milk were filtred on gauze to eliminate rough fragments and then heated at 60°C for five minutes. Calotropis procera leaves (20 g/liter of milk) were triturated in a milk volume, then filtred trough gauze (Figure 2). The filtrate is added to whole milk (5 L) with increase of the heating temperature at 70°C for 10 minutes where the coagulation occurred and after followed by cooking the curd at 95°C for 4 minutes.

After the milk was fully coagulated, the whey-coagulum mixture was poured into a basket containing a cloth and sited in a test-tube to collect and to quantify the whey (Figure 2). The setup was left for the whey to filter through till it stopped dripping. The cloth was folded with the coagulum in it, tied and let out the remaining whey, to dry to a constant weight for approximately 3 hours. The cheese was then removed into a sterile container and stored in the fridge at 4°C overnight or analyzed immediately.

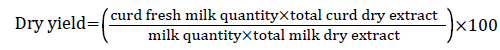

Cheese yield expression

To avoid water content errors, the cheese yield was estimated in relation to the dry matter by the use of the following expression as given by Michalski et al. [16]:

Evaluation’s method of cheese depth penetration

The vertical depth penetration of 25 g of cheese presented as a parallelepiped shape (4 cm×2 cm×1.5 cm) measured for 5 seconds by a specific semi-hard cheese plexiglass cone (inclination 30°C, weight 15 g, height 48 mm) using the penetrometer PNR 10, Petrotest, Symeonstr.2a.D-1000, Berlin.

Sensory analysis

Sensory evaluation was carried out to describeal with scoring test, the characteristics of the obtained cheese through tasting and visual observations according to Fallico et al. [17] and Bérodier et al. [18]. A panel of thirty three persons evaluated cheese texture, odour, aroma, flavour and taste persistence in mouth. 10 g of cheese covered and warmed at room temperature for one hour and then presented to examiners. All sesnsory characteristics were valued from 1 to 9 points on a point scale.

All analysis were repeated at least 3 times.

Milk and fresh Peulh-type cheese composition

The cow’s raw milk used for the cheese making presents the following chemical characteristics cited in Table 1.

| Characteristic | Mean ± SD |

|---|---|

| pH | 6.70 ± 0.10 |

| Lactic acidity (g/L) | 1.61 ± 0.13 |

| Total dry matter (g/100g) | 12.10 ± 0.25 |

| Proteins (mg/mL) | 32.10 ± 0.51. |

| Density (at 15°C) | 1.0273 ± 0.001 |

Table 1: Cow’s raw milk chemical characteristics.

The physicochemical characteristics of the raw milk used in cheese making are well inserted within the ranges given by different authors as reported by Veisseyre et al. [19-22], where the pH is from 6.6 to 6.8, lactic acid (g L-1), from 1.35 to 1.62, the total solids content from 11.5 to 13% and protein (mg mL-1) from 30 to 35.

According to Dossou et al. [23], raw milks used in the fresh cheese Peulh-type cheese making from three different Benin bovine races (Borgou, Lagunaire and Girolando) presented chemical characteristics as density (g cm-3) of 1, 03, a water content of 81% to 88%, a pH from 6.5 to 6.6, an acidity (% lactic acid) from 0.17 to 0.25% and proteins (dry basis) from 25.6 to 31.5.

Differences in the cattle breed, the type of diet and probably the climatic factors have created variations between values authors and those obtained. Nevertheless, the fresh milk used in cheese production meets the quality criteria relating to fresh milk, not acid, a dry extract and protein content suitable for obtaining a satisfactory cheese yield.

Fresh cheese Peulh-type chemical anlyses have provided the following results presented in Table 2. The results obtained of fresh cheese Peulh-type under experimental, meet the criteria of chemical intervals of some fresh cheese prepared in different countries, from different milk type and listed by different authors.

| Characteristic | Mean ± SD |

|---|---|

| pH | 6.28 ± 0.02 |

| Lactic acidity (g p.cent g) | 0.14 ± 0.10 |

| Total dry matter (g/100g) | 32.49 ± 0.16 |

| Proteins (g/100g) | 28.30 ± 0.09. |

| Yield | |

| (g/100g of fresh matter) | 17.69 ± 0.21 |

| (g/100g of dry matter) | 55.45 ± 0.13 |

Table 2: Yield and chemical composition of fresh cheese Peulh-type.

Indeed, the results of the fresh cheese Peulh-type chemical characteristics from three different bovine races (Borgou, and Lagunaire Girolando) obtained following the study of Kora (2005) cited by Dossou et al. [23], presented a water content (%) from 65 to 66, pH from 6.4 to 6.5, lactic acidity (%) from 0.14 to 0.17, a protein content (% dry basis) from 33.6 to 36.3 and a yield on wet basis (%) from 16 to 25.

According to Vierling [24], fresh cheeses have a solid content from 10 to 15%, Ramet [25] gives an amount ranging from 11.5 to 35%, while Veisseyre et al. [19,26] report that fresh cheese from cow's milk are always moist with a solid content of 20-40 %. However, Fox et al. [27], report water content greater than 40%. Other fresh cheeses are reported by O’Connor [14], where Ayib is a soft curd type cheese made in many parts of Ethiopia. The composition of Ayib which varies considerably from smallholder to smallholder is about 76% water, 14% protein. The expected yield of cheese depends on the composition of the milk and the final cheese but generally one kilogram of cheese will be obtained from about nine litres of buttermilk or skimmed milk. For « Peulh », or « wara » or « wagashi », or « Woagachi » cheese, the moisture content is about 65%. About one kilogram of this cheese will be obtained from about five litres of milk.

The fresh soft cheese list is not exhaustive, as well as cited by Fox et al. [27]. In Chad, Pont Belie cheese made from goats’ or sheep’s milk, in Dem.Rep.Congo, Mashanza cheese made from cows’ milk and in Ethiopia Mboreki Ya Iria cheese made from cows’ or goats’ milk which have chemical caracteristics similar to those of fresh cheese «Peulhtype ».

The nutritional importance of cheese arises from its high content of biologically valuable proteins. The protein content of different varieties of cheese varies between 20 and 35%. A 100 g portion of soft cheese will provide 30-40% of the daily protein requirements of an adult. Content (mg/l00 g) of fresh cheese contain calcium 90, phosphorus 190, sodium 30, potassium 120 and magnesium 9. As regards the sanitary quality of the fresh cheese Peulh-type, the germs are usually destroyed during cheese cooking at 100°C.

The whey recovered after spontaneous drainage has a pH and a lactic acidity correspond to a sweet whey where pH ≥ 5.6 and its dry matter consists among other serum proteins (min. 25% on dry basis) as Miller et al. [28] related (Table 3). These proteins can be increased by mechanical pressing which could contribute to the manufacture of some whey cheeses as Ricotta (Italy), Xynomyzithra Kritis (island of Crete, Greece), Manouri (Greece), Brunost, Getost, Mysost (Norway), Ziger (Germany), Karichee (Lebanon), Broccio (Corsica) in order to obtain satisfactory nutritional quality protein whey cheeses.

| Characteristic | Mean ± SD |

|---|---|

| pH | 5.90 ± 0.02 |

| Lactic acidity (g/L) | 6.80 ± 0.14 |

| Total dry matter (g/100g) | 6.40 ± 0.14 |

| Volume (mL) | 1727 ± 100 |

Table 3: Chemical composition of whey fresh cheese Peulh-type.

Indeed, Fox [29], repports that the casein of milk is incorporated into the cheese during cheese manufacture while most of the biologically valuable whey proteins pass into the whey. Thus, 75-80% of the total protein and about 95% of the casein are transferred from the milk to the fresh cheese. Therefore, in cheeses the content of whey protein in total cheese protein is 4-6%. Since the whey proteins are nutritionally superior to casein, which is somewhat deficient in sulphur amino acids, the biological value of the proteins in cheese is somewhat lower than that of the total milk protein, but is still higher than that of casein alone.

Cheese depth penetration

The mean penetration distance of the vertical cone on the fresh cheese Peulh-type surface is 5.08 ± 0.01 mm. This measure can be a valid indicator of the cheese consistency and therefore its firmness, denoting internal strength bounds in the product. Indeed, Lucey et al. [30], and Castillo et al. [31] reported that the whey draining method, the whey protein content and the curdling temperature influence the organization of the gel and consequently its firmness.

As well, McMahon et al. [32-38]; found that the textural properties of a clotting enzyme gel is mainly related to the high dry matter content expressed by proteins principally caseins, pH, and temperature. Also, it has been shown that water may act as a lubricant between caseins. The gel rigidity increases with its water decrease and probably with the electrostatic repulsion reduction. According to Fox [29], the cheese softening has been correlated with αsl-casein hydrolysis by residual rennet. This, results in reduced hydrophobic interactions between molecules, which can cause the protein network to weaken.

Sensorial characteristics

The mean sensory profiles (odour, taste and texture) of fresh cheese Peulh-type are presented in Figures 3 and 4. The texture of fresh cheese « Peulh type » (Figure 3) presented principally, an elastic texture (5.00 ± 0.18), followed by a softness (4.54 ± 0.15), a firmness (4.33 ± 0.14) and a spreadablity of 2.81 ± 0.15. These aspects could be a result of the calotropine acts on milk caseins and minerals at high temperature (over than 55°C) which confers a moderate compactness and an elastic stucture. As reported by Daviau et al. [30,39-42], the increase in the rate of caseins leads to increase in rigidity, elasticity and firmness of the lactic curd. Also, a high mineral (calcium and phosphorus) caseins rate leads to the establishment of a high number of interactions characterized by strong bonds which give to lactic curd fairly rigid structure.

For taste and odour aspects (Figure 4) the cheese provided dispersion in mouth (5.62 ± 0.18) and a persistance in mouth over than 15 seconds. This aspect is probably due to its texture which is in majority soft and smooth, principal characters of fresh cheese because of its minimum water content over than 60 % [19,26]. Likewise for lactic taste (3.54 ± 0.13) and lactic odour (3.24 ± 0.20), were most important in cheese than herbal odour (2.52 ± 0.08) and herbal taste (2.11 ± 0.11). During cheese making, the heat clotting temperature might relatively masked the herbal leaves odour and taste and might contrary developped lactic taste and lactic odour. However, pungent taste (2.12 ± 0.14) and clotty taste (1.80 ± 0.21) have a low perception intensity.

The traditional technique of peulh cheese making is well known in the West African region, but not in Algeria. The cheese making process that, essentially consists in a coagulation of raw milk by leaf extract of a tropical green plant (Calotropis procera ), gives a coagulum and then a fresh cheese after draining. This cheese could consequently improve food quality due to the interest that could present. Thus, its protein ratio, can make an interesting proportion needed for nutritional body human subsistence and its sensory aspects provides to the peulh cheese an appropriate aspect and consequently, an acceptable product. In the other hand, the peulh cheese, if made, in south Algeria could be a solution to save milk produced by farmers and might contribute to their revenue source after rural selling. This first study might contribute to the exploitation of the Calotropis procera plant and therefore valorization of its calotropine enzyme in cheese making, unrecognized and unappreciated in Algeria in spite of the plant abundance in the south of the country.

Dr. Ferial Aziza Benyahia-Krid she has provided the research design, participated in the research analysis and has draft and revised the paper.

Dr. Ouarda Aissaoui-Zitoun she has participated in the research analysis and in the paper redaction.

Dr. Halima Boughellout she has participated in the research analysis and has draft the paper.

Dr. Faiza Adoui she has participated in the research analysis and has draft the paper.

Mr. Cocou Rogatien Bakou has participated in the cheese manufacturing and in research analysis.

Mr. Dénis Wodo has participated in the cheese manufacturing and in research analysis.

Pr. Mohamed Nassereddine Zidoune he has provided the research design and revised the paper.