Advances in Automobile Engineering

Open Access

ISSN: 2167-7670

ISSN: 2167-7670

Research Article - (2022)Volume 11, Issue 1

In the pace of automobiles, machines energy requirement is increasing every-day to operate these automobiles and machines. Although there a number of electricity generation sources available but still the researchers, scientists and engineers keep searching new, cost effective and automatic electricity and energy generating sources. In this research paper one such technique for the generation of electricity has been proposed where the electricity has been produced using the piezoelectric fixed on the inner side of door underneath the sealer material lining of the door which also provides cushion to the door while closing the door. Piezoelectric has been fixed in cushion rubber pads on the inner side of the door of the four wheelers. The electricity produces when the door is slammed because due to the shutting of the door the piezoelectric underneath gets pressed and electricity produces with voltage ranging from 0-100 V depending upon the size, surface area exposing to the force applied, shape and the applied force on/off the piezoelectric which are available in ring, plate, cylindrical, disc shapes and in this paper only plate, cylindrical and the disc shape has been used. The electricity generated will charge the battery of the vehicle in comparatively less time as compared to the normal charging of the vehicle or this energy can be used for other applications in the vehicle. This research may also help to charge the extra batteries installed in the vehicle to meet the energy demand of the vehicle for various appliances.

Automobile; Battery; Cushion; Cylindrical; Electricity; Piezoelectric; Sealer; Voltage

Piezo is used to describe material which, due to the piezoelectric effect, accumulates the burden. The addition of the applied stress means that piezo materials like crystals to earthenware create a voltage. But in the case of inverse effect, when the same materials are applied voltage their shape gets changed either by lengthening or by shortening in response to the applied voltage. The voltage, force and the movements produced by the piezo materials are small and usually require enlargement [1]. For example, by merely changing the thickness of the piezoelectric, these materials can be used in many far reaching applications. These are usually preferred in many applications due to their ability to get tailored to fulfill the specific requirements. Currently, PZT materials are the most abundantly used materials because they offer greater sensitivity and higher operating temperatures than the other ceramics.

The term “piezoelectricity” has been derived from two words which means from press and amber means a source of electricity or it can be assumed that the transfer to latent pressures and temperatures applies to the production of electricity. So an electric charge, like ceramics, crystals but some biological materials, including DNA, bone and even some proteins, may be created in the solid material if mechanical pressure is applied. Via pressure or thermal energy otherwise known as piezoelectricity the effect is therefore that the form of electricity emitted. In 1880, when the samples were electrically polarized, the Pierre brothers observed a rare activity of some crystalline minerals. Voltages of reverse polarity with proportion to the force used were created by tension or compression. The form of the applied energy can be knocking, squeezing, tapping or may be some other type which pressurizes the material but don’t make it to fail. So, the force should be applied with utmost car.

Applications

It will overall be utilized for a degree of uses like inkjet printing and the conspicuous evidence and development of sound. For instance, it very well may be utilized in the general cells to change the energy of an individual's voice into the electrical signs that are gotten by other telephone and changed into interpretable sounds. It's additionally utilized for the time of electronic rehash, high voltage age, driving ultrasonic spouts, microbalances and the ultrafine concentrating of optical gatherings. As this improvement can be utilized for specific applications, it's all things considered utilized across the entirety of the undertakings and areas. In spite of the great level mobile phones and the contraptions, it moreover gives keyless area gadgets, airbag sensors, recognizable cautions, for example, smoke alerts fish and patient screens and importance locaters. The retrogressive piezo influence is utilized in the commencement applications, for example, in engines, gadgets that decisively control organizing and in making the sonic and the ultrasonic signs. In the twentieth century metal oxide-based piezoelectric stoneware and other man-made materials empowered producers to utilize the piezoelectric impact and the inverse piezo influence in a noteworthy package of the new applications. The piezoelectric materials everything considered are incredible, falsely torpid and are likewise usually productive to make. Stoneware made from the implications of lead zirconate/lead titanate have more delicate and have high working temperature, relative with the ceramics making of different pieces, and "PZT" materials are exhaustively utilized piezoelectric pottery creation.

Piezo ceramic elements

A standard piezoelectric potter consists of perovsky lenses, which together consists of a small metal ion, normally titanium or circconium, composed of a grid of larger divalent metal ions, commonly plum or barium and O2-ions [2]. Fine PZT powders are mixed in exact proportions with metal oxides of modules for the production of a dielectric material to become normal powder. The piezo powder is combined with an organic agent and moved into structural elements of the required kind (discs, rods, plates, etc.). The atoms are heated until the transducer powder particles sinter and until a finely crystalline form meets the material after a certain period of time and temperature. The elements are then cooled, molded or cut to determine the appropriate surface, adding electrodes.

What can piezoelectric ceramics do?

Mechanically compressive or tensioned, a polar piezoelectric ceramic element may modify the momentum to generate voltage. The Polarization Voltage is squeezed in a polarization or tension direction, perpendicular to the polarization direction [3]. The voltage signal is an anti-polarizing, voltage signal due to a course of voltage or contraction perpendicular to polarization direction. These steps are generator measures-the ceramic component converts mechanical energy compression or vibration into electrical energy. That is used in power sensors, fuel-igniting devices, and solid-state batteries. The compression values of a piezoelectric ceramic part and the strain induced by stress are linearly proportional to the material stress. The voltage applied and the tension induced also is applicable. The unit is lengthened and its diameter is decreased in the direction of poling voltage when a tension of the same polarity is added to a ceramic element with the tension of the poling element. If a polarity tension opposite the poling voltage is used, the part will become shorter and broader [4]. The element lengthens or shortens cyclically on frequency of the applied voltage when an alternating voltage is applied. This involves motor motionelectricity is transformed into mechanical energy. The theory is adjusted for piezoelectric motors, sound or ultrasound generators.

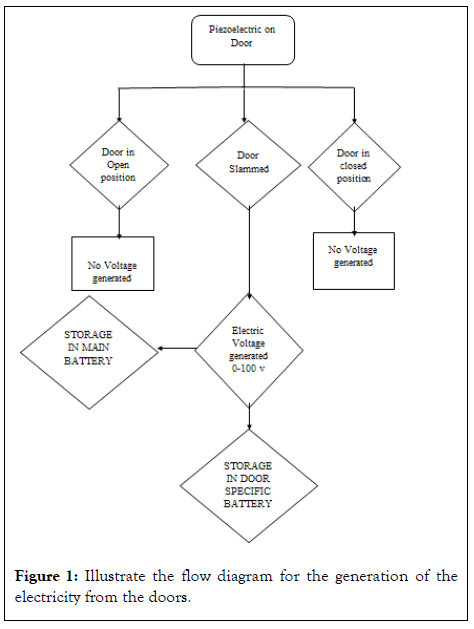

A Daniels in their research paper proposed a new type of piezoelectric energy harvesting device known as the piezoelectric flex transducer (PFT) [5]. For the design and analysis of the PFT, Finite Element Model consists of a piezoelectric element sandwiched between sub-state layers and metal end caps, which are able to expand the axial force of the piezo-electrical element. This PFT can carry higher forces based on the principle of the cymbal transducer. The PFT provided a maximum power of 2.5 mW when 760 N is applied with a speed of 3.1 mi/h. Such a piezoelectric can be useful in the present research paper to withstand the large forces generated during the slamming of the door and also the force gets amplified so it can lead to generation of large amount of voltage or current which can stored in the main battery of the vehicle or some specific batteries. Henry A Sodano in their research paper proposed the use of piezoelectric as an alternative source of energy and they also studied that the energy produced by these piezoelectric is small enough to directly power some devices so their energy produced must be stored in batteries so that when accumulated sufficiently can be reused. They also tested three different piezoelectric for their rate of charging the battery [6]. Monolithic piezo ceramic substance, the Fast Pack (QP) and macro fibre compounds are lead-zirconated-titanate (PZT) (MFC). From these three piezoelectric they found that PZT was the fastest charging piezoelectric among the three. So, this piezo can be suitable for the application in this present research paper. Shu and Lien in their research, they analyzed the power output for piezoelectric energy harvesting systems. The research was mainly concentrated on the AC-DC power generation for a rectified piezoelectric device [7]. An analytical expression is obtained under the constant state conditions for the AC-DC power output. It has been inferred, therefore, that the harvested capacity is conditioned by the input vibration properties, such as frequency and acceleration, motor mass, electrical load, natural frequency, mechanically damping and also the electromechanical device coefficient. For the comparison of the relative output and efficiency of the systems, a power normalization programme was developed. This study can be helpful for the calculation of exact theoretical value of voltage or current output from the piezoelectric (Figure 1).

Figure 1: Illustrate the flow diagram for the generation of the electricity from the doors.

Research Questions:

What are piezoelectric? How does it produce electricity?

What is the use of the electricity produced with the piezoelectric in door of the vehicles?

Where this electrical energy produced can be stored?

Sampling

The production of the electricity depends upon the shape, shape of the piezoelectric and it also depends upon how the piezoelectric has been placed or fixed to the door of vehicle due to which the surface area of the piezoelectric exposing to the force applied varies and the force applied on the piezoelectric also. Suppose for the best placement of the piezoelectric on the door of the piezoelectric is on the inner side where the door slams with the panel of body of the vehicle because the area that comes under the force is the rubber lining on the inner side of the door. Secondly piezoelectric can also be placed on the rubber pad on the lower side of the door which also provide cushion to the door [8]. Depending upon the shape, size, force applied and the surface area of the piezoelectric exposed various calculation can be performed and best shape and size can be chosen. Generally, disc and cylindrical shapes are chosen and the force applied in on thickness wise or the in the radial direction.

Instrumentation

Piezoelectric of Disc, cylinder and plate shape to generate the voltage with the application of the pressure on them.

Wiring to establish the connection between the piezoelectric and the battery of the vehicle.

Storage unit/battery to store the generated charge.

Design

Thus from the above calculations it can be inferred that the maximum value of static voltage is for the ring shape piezoelectric for almost similar dimensions. It is also beneficial to use ring shape piezoelectric because multiple piezoelectric can be placed with decreasing diameter one inside the bigger one so that more amount of current can be obtained in a given space. For a single door suppose there are 20 piezoelectric installed, then the voltage will add up if the connections are in series and the current will add up if the connections are in parallel. For the 5 door vehicle like car the generated electricity will be in good amount to charge the battery. Ring shape is preferred as per the calculation wise because ring shape produces more voltage than other shapes but depending upon the space and shape of the door available shape of the piezoelectric can changed so as to fit properly on the door and thus the amount of voltage will vary according to the real situation. Calculations mainly vary with kind of shape installed on the door and the direction of the application of force on the piezoelectric which can be in radial, tensile or thickness wise. So, in real situation actual value may differ from the calculated one depending upon some other factors that may have not been considered while calculating the value of the voltage produced [9,10].

Although there are a number of sources available for the generation of electricity in a vehicle but the set up required is voluminous and costly and also requires energy to operate to charge the battery like alternator which is operated by the belt attached with engine pulley. Alternator in itself is very costly component but this setup requires one-time arrangement, design and investment. Door opening, closing is a usual activity that happens in the vehicle to step-in or step-out. For each step-in and step-out everybody will feel strange that there is generation of electricity which is getting stored for the usage in operating the appliances. This energy generated if stored in the main battery unit of the vehicle can be used for the other appliances wherever is required or if the specific batteries are installed for the doors then can be used for the door operation purposes. This research will certainly help to reduce the energy load on the main battery unit and the reduced consumption form the main battery can be utilized for operating other devices installed in vehicles.

Citation: Parashar K, Kumar A, Deshwal D (2022) Generation of Electricity from the Doors of the Vehicles. Adv Automob Eng. 11: 179.

Received: 30-Dec-2021, Manuscript No. aae-22-45899; Editor assigned: 03-Jan-2022, Pre QC No. aae-22-45899 (PQ); Reviewed: 17-Jan-2022, QC No. aae-22-45899; Revised: 21-Jan-2022, Manuscript No. aae-22-45899 (R); Published: 28-Jan-2022 , DOI: 10.35248/2167-7670.1000179

Copyright: © 2022 Parashar K, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.