Advances in dairy Research

Open Access

ISSN: 2329-888X

ISSN: 2329-888X

Research Article - (2020)Volume 8, Issue 2

The consumption of raw cow’s milk and its derivatives is common in Ethiopia, which is not safe from consumer health point of view as it may lead to the transmission of various diseases. The milk handling practices and different constraints that affect milk quality in different production systems were identified to take corrective measures. The data were collected from 212 respondents randomly selected respondents. Descriptive statistics was employed to summarize raw milk handling practice, hygienic quality of equipment. Pair-wise ranking technique was used to identify and prioritize the major milk quality related constraints. The result of the study revealed that, the milking methods of dairy farmers was hand milking with milking frequency of twice (90.1%) and once (9.9%) a day. On the other hand, only 28.3% of households were found practicing cleaning of the milking barn. There was statistically significant difference between milk producers who wash their hands before milking (85.8%) than that of milk producers who do not wash (14.2%) their hand before milking. Besides, this study revealed that, only 36%, and 23.1% of dairy producers washed udder and teat in urban and peri-urban production systems, respectively. Majority (85.9%) of milk producers weren’t practicing drying udder and teats after washing whereas, only 14.1% milk producers were practicing to dry udder and teats with individual towel (4.7%) and common towel (9.4%). Significant number of milk producers (47.8%) and (68.8%) used gourds as milk storage equipment in peri-urban and rural area, respectively while plastic container was dominant (84%) in urban production system. In this study, it was observed that lack of potable water as a major bottle neck that hampered milk quality (index=0.167), followed by lack of knowledge (index=0.153), poor hygienic condition (index=0.116) and absence of quality based payment system (index=0.11). Generally the hygienic practice during milk production in the study area was poor and milk handling practices were also vulnerable for contamination. Moreover, traditional milking container (Kell) and storage utensils (Kabo) were dominantly used in the area.

Handling practice; Raw milk; Constraint; Focus Group Discussion

Fat-Protein Ratio (FPR) as an indicator for lactation dairy cows

The most widely used farm animal for milk production in Ethiopia is cow [1]. Cows contribute to about 94.58% of the total annual milk produced at national level [2]. Similarly, in and around Bahir Dar City goat and camel milk is not used for human consumption [3]. In Ethiopia, there is no standard hygienic condition followed by producers, transporter and processor during milk production. More recent study conducted in and around Asosa town showed that, there is no standard hygienic condition followed by producers during milk production which may cause for contamination and affect milk quality [4].

Since, the handling practice and production system is traditional, the cow’s milk in Ethiopia is mostly contaminated with external sources which are bacteria and categorized as poor quality, and this is mainly due to less attention for hygiene [5]. Handling practices of raw cow's milk produced and marketed in Shashemene town was traditional [6]. The quality of milk consumed by children is poor and affected by different factors such as udder hygiene, cleanness of hands and utensils [7]. On the other hand the consumption of raw milk and its derivatives is common in Ethiopia, which is not safe from consumer health point of view as it may lead to the transmission of various diseases. Therefore, availability of hygienic quality milk and milk products is necessary in all production systems to ensure good health condition of the consumers, reduce the amount of milk products imported and to compete in international market. Any improvement in the handling and quality of milk could contribute to the insurance of public health safety while at the same time having positive economic consequences [8].

Study design and sampling techniques

The study involved a questionnaire-based cross-sectional survey aimed at assessing the handling practice of raw milk produced and sold in and around Bahir Dar city and the constraints of clean milk production in the study area.After selection of study units and households, questionnaire was administered. Sampling frame included milk producers/farmers from urban, peri-urban and rural production systems. The kebeles from each production system were selected purposively based on their milk production potential, availability of milk during the time of sample collection and availability of cooperatives. After that, random sampling was used to find the respondents at household level in the selected Kebeles.

In order to determine the sample size from each area the following formula was used.

Where, n = sample size,

N = population size,

e = Margin of error

The level of precision is the range in which the true value of the population is estimated to be; it is expressed in percentage points (± 5) [9]. A total of 212 dairy producer households (25, 91 and 96 from urban, peri-urban and rural areas, respectively) were selected and interviewed according to a short semistructured questionnaire to establish facts.

Method of data collection

Both primary and secondary data sources were used in this study. Questionnaire survey was conducted on different aspects of raw milk handling practices and major constraints of clean milk production. Focus group discussion and key informant interview were used to investigate qualitative data’s, to supply interpretations of the participants' results and for generating additional information for a study on a wide scale.

Methods of data management and statistical analysis

The data collected through the survey was analyzed using simple descriptive statistics (i.e., means and percentage) with the help of Statistical Package for Social Sciences (SPSS, version 20) software. Descriptive statistics was employed to summarize raw milk handling practice, hygienic quality of equipment. Pair-wise ranking technique was used to identify and prioritize the major milk quality related constraints. A rank score was also calculated for each variable to screen the major constraints perceived by milk producers. Rank index formula was employed to put the order of importance of constraints for clean milk production in the study area [10].

The Rank Index was calculated as follows:

Rank Index= Sum of (3 × number of household ranked first + 2 × Number of household ranked second + 1 × Number of households ranked third) for individual constraints divided by sum for overall constraints

Demographic characteristics of households

The household size, age group, sex and education level in and around Bahir Dar city are shown in Table 1. In this study, there was statistically significance difference in family size among production systems. The average family size per household observed indicated that 5.2, 5.76 and 6.28 in urban, peri-urban and rural production systems, respectively with the overall mean of 5.93 ± 1.88. This value is higher to comparable with figures reported in west Shewa zone (5.73 persons per household [11]. Regarding to the age group, majority of the respondents (58.5%) in the study area were within the middle age (36-55 years) which is important to perform any farming tasks effectively.

| Household characteristics | Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Â Production systems | Overall (N=212) | ||||||

|---|---|---|---|---|---|---|---|---|

| Urban (N=25) | Peri-urban  (N=91) | Rural (N=96) | ||||||

| Family size per household (Mean+SD) | 5.2± 1.6 | 5.76 ±Â 1.92 | 6.28 ±Â 1.64 | 5.93 ±Â 1.88 | ||||

| Age group | N | (%) | N | (%) | N | (%) | N | Â (%) |

| 18-35 years | 7 | 28 | 18 | 19.8 | 17 | 17.7 | 42 | 19.8 |

| 36-55 years | 13 | 52 | 59 | 64.8 | 52 | 54.2 | 124 | 58.5 |

| > 55 years | 5 | 20 | 14 | 15.4 | 27 | 28.1 | 46 | 21.7 |

| Sex (%) | ||||||||

| Male | 19 | 76 | 75 | 82.4 | 84 | 87.5 | 178 | 84 |

| Female | 6 | 24 | 16 | 17.6 | 12 | 12.5 | 34 | 16 |

| Education level | ||||||||

| Can't read and write | 3 | 12 | 21 | 23.1 | 27 | 28.1 | 51 | 24.1 |

| Read and write | 6 | 24 | 24 | 26.4 | 34 | 35.4 | 64 | 30.2 |

| Grade 1-4 | 3 | 12 | 14 | 15.4 | 11 | 11.5 | 28 | 13.2 |

| Grade 5-8 | 6 | 24 | 20 | 22 | 20 | 20.8 | 46 | 21.7 |

| Grade 9-12 | 4 | 16 | 9 | 9.9 | 3 | 3.1 | 16 | 7.5 |

| Above grade 12 | 3 | 12 | 3 | 3.3 | 1 | 1 | 7 | 3.3 |

Table 1: Household characteristics of the respondents in and around Bahir Dar city.

Majority of households in the study area were male headed (84%) whereas the proportion of female headed households was only 16% of the interviewed respondents. Despite the fact that, women have indigenous knowledge about milk production and handling practices, they are not encouraged to involve dairy production activities in and around Bahir Dar.

The highest proportions of the respondents were educated from elementary to higher education which accounts 45.7% while the remaining 54.3% were not educated. Particularly in the rural area 63.5% of the respondents were not educated hence; it is challenging to introduce new improvement interventions and technologies regarding to clean milk production.

Milking practices

All dairy cows in the study area were milking by hand, with the milking frequency of twice (90.1%) and once (9.9%) a day. This finding is in agreement with reported figures, that all smallholder farmers in peri-urban areas in Burkina Faso practiced hand milking [12]. Almost all dairy producers don’t have milking barn. As a result, dairy farmers in the study area were milked their cows in undesignated poorly maintained barn which predisposing milk to contamination and spoilage. Milking in open area may allow contaminants entry in to the milk and can be cause for high spoilage rate [13]. The milking area must minimize the risk of contamination from any source, including dust, flies, birds or other animals [14].

The practice of cleaning milking area was significantly different among production systems. The survey result showed that, only 28.3% of households were cleaning the milking area. Contrary to this, 48.9% of respondents clean the milking area on daily basis in Bench Maji Zone [15]. About 85.8% of milk producers wash their hand before milking while the remaining 14.2% don’t wash their hands (Table 2). A statistically significant difference in hand washing was observed among production systems. Comparable result was reported in Bahir Dar Zuria and Mecha district washed there hand before milking [3]. Even though the highest proportion of households wash their hands, only 35.6% implement hand drying. This result is not in line with the figure reported in Borana pastoral community were drying their hands with own cloth [16].

| Hygiene of cow and milker’s | Production systems | Overall (N=212) | ||||||

|---|---|---|---|---|---|---|---|---|

| Urban (N=25) | Peri-urban (N=91) | Rural (N=96) | ||||||

| N | % | N | % | N | % | N | % | |

| Hand washing practices | ||||||||

| Normal water | 9 | 36.4 | 38 | 48.3 | 77 | 100 | 128 | 70.2 |

| Warm water | 8 | 31.8 | 13 | 16.1 | 19 | 10.6 | ||

| Normal water and soap | 6 | 22.7 | 23 | 28.7 | 28 | 15.2 | ||

| Warm water and soap | 2 | 9.1 | 6 | 6.9 | 7 | 4 | ||

| Udder washing practices | ||||||||

| Normal water | 12 | 52.9 | 17 | 75.4 | 12 | 100 | 41 | 70.7 |

| Warm water | 3 | 11.8 | 3 | 13 | 6 | 10.3 | ||

| Normal water and soap | 5 | 23.5 | 2 | 7.2 | 7 | 12.1 | ||

| Warm water and soap | 3 | 11.8 | 1 | 4.3 | 4 | 6.9 | ||

| Milking cloth | ||||||||

| Clean outer garment | 1 | 4 | 1 | 1.1 | 2 | 0.9 | ||

| Own daily cloth | 21 | 84 | 86 | 94.5 | 96 | 100 | 203 | 95.8 |

| Unclean outer garment | 3 | 12 | 4 | 4.4 | 7 | 3.3 | ||

| Presences of permanent milker | ||||||||

| Yes | 14 | 56 | 20 | 22 | 10 | 10.4 | 44 | 20.8 |

| No | 11 | 44 | 71 | 78 | 86 | 89.6 | 168 | 79.2 |

Table 2: Milking practice, hygienic condition and frequency of milking for dairy cow in and around Bahir Dar city.

Our current study showed that, only 14.1% of respondents were washing udder and teat before milking in the three production systems which was higher in urban area (36%) followed by periurban (23.1%). However, no udder and teat washing practice in rural area (Table 2). This finding is similar with other result, that 37% and 21% of the respondents washed the udder before milking in urban and peri-urban areas of Dangela town, respectively [17]. Contrary to the current study, indicated there was no any udder washing practice in Ezha district of the Gurage zone [18].

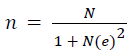

Based on the result of this study, majority 85.9% of households weren’t practicing drying udder and teats before and after milking whereas 14.1% milk producers were drying udder and teats with individual towel (4.7%) and common towel (9.4%) (Table 3). The towel used in the area wasn’t clean and it may have numerous microorganisms those contribute a lot for milk contamination (Figure 1).

| Hygiene of cow and milker’s | Production systems | Overall (N=212) | ||||||

|---|---|---|---|---|---|---|---|---|

| Urban (N=25) | Peri-urban (N=91) | Rural (N=96) | ||||||

| N | % | N | % | N | % | N | % | |

| Hand washing practices | ||||||||

| Normal water | 9 | 36.4 | 38 | 48.3 | 77 | 100 | 128 | 70.2 |

| Warm water | 8 | 31.8 | 13 | 16.1 | 19 | 10.6 | ||

| Normal water and soap | 6 | 22.7 | 23 | 28.7 | 28 | 15.2 | ||

| Warm water and soap | 2 | 9.1 | 6 | 6.9 | 7 | 4 | ||

| Udder washing practices | ||||||||

| Normal water | 12 | 52.9 | 17 | 75.4 | 12 | 100 | 41 | 70.7 |

| Warm water | 3 | 11.8 | 3 | 13 | 6 | 10.3 | ||

| Normal water and soap | 5 | 23.5 | 2 | 7.2 | 7 | 12.1 | ||

| Warm water and soap | 3 | 11.8 | 1 | 4.3 | 4 | 6.9 | ||

| Milking cloth | ||||||||

| Clean outer garment | 1 | 4 | 1 | 1.1 | 2 | 0.9 | ||

| Own daily cloth | 21 | 84 | 86 | 94.5 | 96 | 100 | 203 | 95.8 |

| Unclean outer garment | 3 | 12 | 4 | 4.4 | 7 | 3.3 | ||

| Presences of permanent milker | ||||||||

| Yes | 14 | 56 | 20 | 22 | 10 | 10.4 | 44 | 20.8 |

| No | 11 | 44 | 71 | 78 | 86 | 89.6 | 168 | 79.2 |

Table 3: Hand and udder washing practices of dairy cows in and around Bahir Dar city.

Figure 1: Towels used for drying udder and teat in the study area.

About 26% and 28% of respondents in Bishoftu used individual and common towel, respectively [19]. Milking in dry condition significantly reduces bacterial count. It is because no surplus water remains in the surface of the udder to drip into the milk and due to less chance of leaching dirt and bacteria from udder, teats and hands into milk [20].

This study revealed that, udder and hand washing practices were different by production systems. In the study area, 80.8% of households used only water (normal and warm) followed by normal and warm water with soap (19.2%) for hand washing purpose. About 70.7% and 10.3% of milk producers in the study area were washed the udder by using normal water and warm water, respectively. Clean milking cloth is required to minimize the possibility of contamination. Almost all of the households (95.8%) don’t have any milking cloth rather they used owns daily cloth. Only 3.3% and 0.9% of them had unclean and clean outer garment milking cloth, respectively.

Milk handling practices

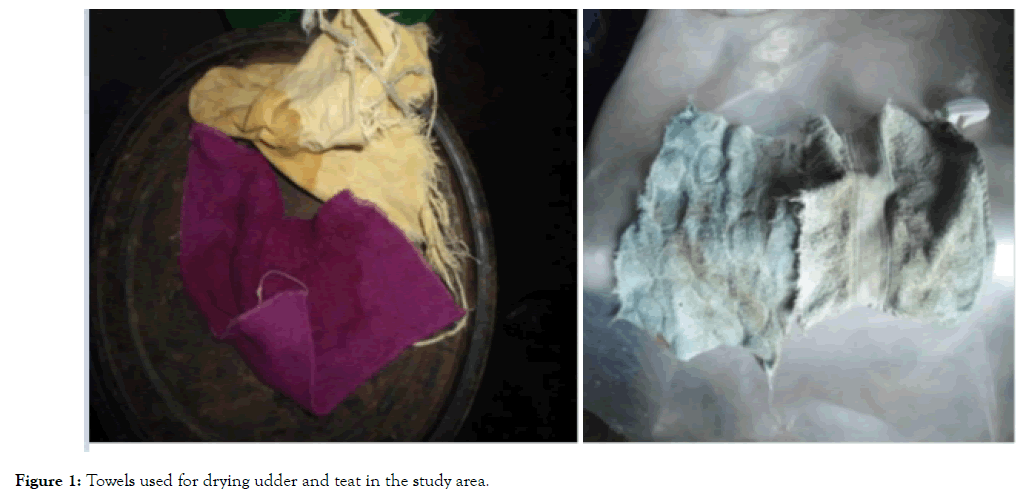

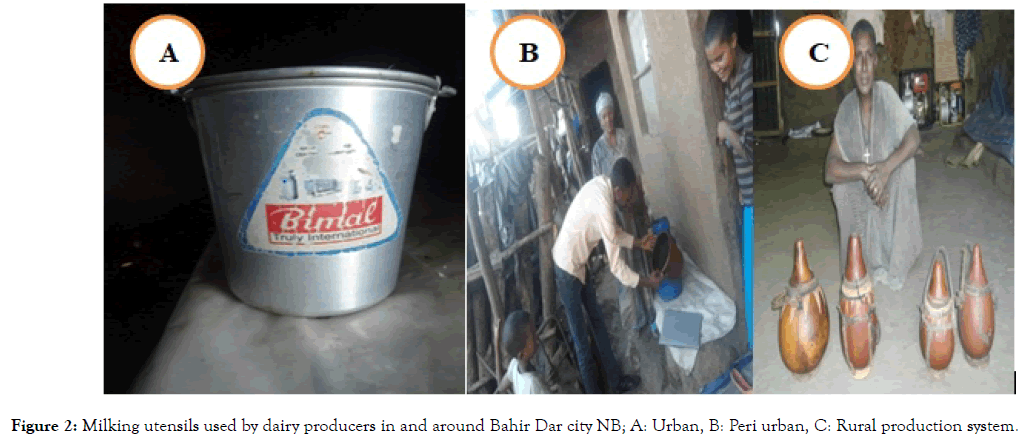

Different types of utensils were used for milking in and around Bahir Dar City. Most farmers (54.2%) used Gourds which are made of traditionally called Kell (Geryera). The highest (82.1%) and (34.1%) of dairy producers were using Kell in rural and periurban area, respectively (Figures 2 and 3). Traditional milking equipment was dominant in the rural area. As some respondent said in FGD, using gourds (kell) for milking is their culture and they don’t need to change it. About 48% in urban and 51.6% of dairy producers in peri-urban production system used plastic container for milking (Table 4). This finding is lower than other reports, the majority (84.62%) of milk producers and sellers used plastic buckets for milking and collection [6].

| Milk handling utensils | Production systems | Overall N=212 | ||||||

|---|---|---|---|---|---|---|---|---|

| Urban (N=25) | Peri-urban (N=91) | Rural (N=96) | ||||||

| N | % | N | % | N | % | N | % | |

| Milking utensils | ||||||||

| Clay pot | - | 1 | 1.1 | 2 | 2.1 | 3 | 1.4 | |

| Stainless steel can | 4 | 16 | 10 | 11 | - | 14 | 6.6 | |

| Plastic container | 12 | 48 | 47 | 51.6 | 15 | 15.6 | 74 | 34.9 |

| Metal bucket | 4 | 16 | 2 | 2.2 | - | 6 | 2.8 | |

| Gourd (Geryera) | 5 | 20 | 31 | 34.1 | 79 | 82.3 | 115 | 54.2 |

| Milk storage utensils | ||||||||

| Gourd (Kabo) | 1 | 4 | 43 | 47.8 | 65 | 68.8 | 109 | 51.5 |

| Plastic container | 21 | 84 | 30 | 33.3 | 14 | 14.6 | 65 | 30.8 |

| Stainless steel can | 3 | 12 | 2 | 2.2 | - | 5 | 2.4 | |

| Clay pot | - | 16 | 17.58 | 16 | 16.7 | 32 | 15.1 | |

Table 4: Milking and milk storage utensils used in and around Bahir Dar city.

Figure 2: Milking utensils used by dairy producers in and around Bahir Dar city NB; A: Urban, B: Peri urban, C: Rural production system.

Figure 3: Types of milk storage equipment in the study area; (NB) A: Urban, B: Peri urban, C: Rural production system

Even though stainless steel can is mostly preferred for milk handling [21], in this study, only 6.6% of dairy producers used stainless steel can which was donated by GOs and NGOs, but they are not able to buy this equipment since it has highest price and inaccessible. The use of plastic and traditional containers can be a potential source for the contamination of milk by bacteria, because this allows the multiplication of bacteria on milk contact surfaces during the interval between milking.

About 51.5% of total respondents with the majority (68.8%) in rural areas were using gourd (Kabo) for storage (Table 4). On the other hand, 84% in urban and 33.3% in peri-urban areas were using plastic container. This is in line with other findings [22]. Stainless steel can was used by only 2.4% milk producers in the study area. It was observed in urban and peri-urban areas where some nongovernmental organization provide milking and storage materials for selected dairy producers.

Hygienic practices of milking and milk storage utensils

In this study, smoking and washing of milking utensils were normal practices. Almost all (92.9%) of respondents performed both washing and smoking as cleaning methods. The rest 7.1% of dairy producers were cleaning their utensils only by washing that was common in urban areas this might be because of some cooperatives and consumers don’t like the aroma and flavor of smoked milk (Table 5). In addition, the small pieces of plant materials may be left on the milk that makes it unattractive for consumers. Similarly, in the rural lowland system of Metema, nearly all the producers clean milking and milk storage utensils by smoking [23]. Since smoking is the most common methods of cleaning utensils and milk preservation [24].

| Hygienic practice of milking and milk storage utensils | Production systems | Overall N=212 | ||||||

|---|---|---|---|---|---|---|---|---|

| Urban (N=25) | Peri-urban (N=91) | Rural (N=96) | ||||||

| N | % | N | % | N | % | N | % | |

| Cleaning methods | ||||||||

| Only washing | 4 | 16 | 9 | 9.9 | 2 | 2.1 | 15 | 7.1 |

| Both washing and smoking | 21 | 84 | 82 | 80.1 | 94 | 97.9 | 197 | 92.9 |

| Reason for smoking | ||||||||

| Good flavor and aroma | 11 | 52.4 | 45 | 54.9 | 70 | 74.5 | 126 | 64 |

| Increase shelf life | 5 | 23.8 | 32 | 39.1 | 19 | 20.2 | 56 | 28.4 |

| Facilitate fermentation | 2 | 9.5 | 4 | 4.8 | 5 | 5.3 | 11 | 5.6 |

| Inhibit Bacterial growth | 3 | 14.3 | 1 | 1.2 | 4 | 2 | ||

| Sources of water for cleaning | ||||||||

| Well | 1 | 4 | 26 | 28.6 | 38 | 39.6 | 65 | 30.7 |

| River | 49 | 53.8 | 46 | 47.9 | 95 | 44.8 | ||

| Tape water | 24 | 96 | 16 | 17.6 | 12 | 12.5 | 52 | 24.5 |

Table 5: Hygienic practice of milking and milk storage utensils in and around Bahir Dar city.

Smoking of milking utensils had its own purpose in the study area. According to the result, except few households in urban, almost all of milk producers in peri-urban and rural areas practiced smoking of milking and milk storage utensils to add good flavor and aroma (64%), to increase the shelf life (28.4%), facilitate fermentation (5.6%), and to inhibit bacterial growth (2%). The study indicates that, the highest proportion of dairy producers in all production systems smoked milking and milk storage utensils by using loca lly available plants in order to produce milk with good flavor and aroma, since such types of flavored milk is highly liked by many milk consumers. In line with this result the major reasons outlined by the households for smoking of dairy product equipment are to improve the taste and/or flavor of the milk products and to increase the shelf life [25].

Types of plants used for smoking

Majority of the respondents reported that, the most common plant species used for smoking milk vessels in the study area was Abalo (Terminalia brownii) (63.5% ) followed by Woyira (Olea Africana) (10.2%) and the other smoking plant species were occasionally used. Zegudem (9.1%) and Teji (5.6%) were also used for smoking milking and storage equipment (Table 6). Contrary to this finding, a study revealed that, the plant species used for smoking milk vessels in selected areas of Eastern Gojjam was Cheba (Acacia spp) [26]. Majority of the respondents (83.2%) in the study area were used the steam parts of plants for smoking. This is might be due to the type of plant species used, Abalo has more steam part than woyira. As the respondent reported, using steam part is preferable than leaves and it is suitable to prevent the residual effect of small plant pieces in the milk, hence it can be remaining attractive with good flavor and aroma (Table 6).

| Â Â Â Â Â Â Production systems | Overall (N=212) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Urban (N=25) | Peri-urban (N=91) | Rural (N=96) | |||||||

| Vernacular name (Amharic) | Scientific name | N | % | N | % | N | % | N | % |

| Abalo | Terminalia brownie | 13 | 62 | 59 | 72 | 53 | 56.5 | 125 | 63.5 |

| Zegudem | Unidentified | 11 | 13.4 | 7 | 7.6 | 18 | 9.1 | ||

| Woyira | Olea Africana | 2 | 9.5 | 4 | 4.9 | 14 | 15 | 20 | 10.2 |

| Cheba | Acacia spp | 6 | 28.5 | 2 | 2.4 | 3 | 3.3 | 11 | 5.6 |

| Wanza | Unidentified | 2 | 2.4 | 2 | 2.2 | 4 | 2 | ||

| Tegi | Unidentified | 4 | 4.9 | 7 | 7.6 | 11 | 5.6 | ||

| Gufa | Unidentified | 3 | 3.3 | 3 | 1.5 | ||||

| Dengel | Unidentified | 5 | 5.5 | 5 | 2.5 | ||||

| Plant parts used | |||||||||

| Leaves | 1 | 1.2 | 7 | 7.4 | 8 | 4.1 | |||

| Steam | 19 | 90.5 | 72 | 87.8 | 73 | 77.7 | 164 | 83.2 | |

| Both | 2 | 9.5 | 9 | 11 | 14 | 14.9 | 25 | 12.7 | |

Table 6: Plants used for smoking of milk handling utensils in and around Bahir Dar city.

Cooling and transportation system of raw cow’s milk

In this study, milk producers used different techniques to preserve raw milk without clotting, such as traditional method and refrigeration. Out of the total respondents 47.2% were using cooling system. The current result is found to be higher than the finding (28%) reported in Uganda [27]. According to this study, 76% in urban, 52.7% in peri-urban and 34.3% of the total households in rural production system were practicing cooling of raw cow’s milk until the milk is consumed, sold or distributed to consumers and when there is surplus milk production especially during fasting period. The research finding is in agreement with other findings, 18% of dairy farmers in Hawassa and Yirgalem areas were cooling their milk by Putting in cooler place [28].

Traditional cooling method is dominant in the study area. This might be due to unavailability of electric power, lack of awareness and technical skills. In the rural area 34.37% of the interviewed households were using a traditional cooling system by putting within sand, cold water bath or in a small underground pit. The result is consistent with reported figures, traditional cooling was practiced by about 4.8% of the periurban producers in Dawa Chefa district [24].

About half (52.8%) of the respondents in the study area weren’t using any cooling system however, simply stored the milk at room temperature or a relatively cold place with in their home which prevents rapid fermentation rate (Table 7). Regarding to transportation, some milk producers were using vehicles for milk transportation while the majority of them were simply transporting by manpower. The vehicles were not appropriate for raw milk transportation because its lacks cooling facilities. The bacterial load of milk increases during transportation and if the transportation equipment is not appropriate, the bacterial counts increase and causing spoilage before milk reaches its destination or consumers [8].

| Cooling system of raw milk | Production systems | Overall (N=212) | ||||||

|---|---|---|---|---|---|---|---|---|

| Urban (N=25) | Peri-urban (N=91) | Rural (N=96) | ||||||

| N | % | N | % | N | % | N | % | |

| Use of cooling system | ||||||||

| Yes | 19 | 76 | 48 | 52.7 | 33 | 34.3 | 100 | 47.2 |

| No | 6 | 24 | 43 | 47.3 | 63 | 65.7 | 112 | 52.8 |

| Types of cooling system | ||||||||

| Refrigerator | 12 | 48 | 13 | 14.28 | 25 | 11.8 | ||

| Traditional cooling (Cold water bath) | 7 | 28 | 35 | 38.46 | 33 | 34.37 | 75 | 35.37 |

Table 7: Cooling system practiced by dairy producers in and around Bahir Dar city.

Udder and teat management

In this study, 65.6% of respondents checked the presence of udder and teat problems before milking. In proportion almost all milk producers in the urban (92%) inspect their cows udder followed by peri-urban area (73.6%). The highest udder and teat problem was found in rural production system (68.8%) whereas only 52.7% in peri-urban areas (Table 8). The reasons for high occurrence might be due to poor hygienic practice and housing system. Similar research finding were reported, a number of microbial agents are responsible in causing udder and teat problem in livestock with presence of multitude of predisposing factors which include: animal, environmental and pathogen risk factors [29].

| Udder management practices | Production systems | Overall (N=212) | ||||||

|---|---|---|---|---|---|---|---|---|

| Urban (N=25) | Peri-urban (N=91) | Rural (N=96) | ||||||

| N | % | N | % | N | % | N | % | |

| Udder health checking before milking | ||||||||

| Yes | 23 | 92 | 67 | 73.6 | 49 | 51 | 139 | 65.6 |

| No | 2 | 8 | 24 | 26.4 | 47 | 49 | 73 | 34.4 |

| Occurrence of udder problem | ||||||||

| Yes | 10 | 40 | 48 | 52.7 | 66 | 68.8 | 124 | 58.5 |

| No | 15 | 60 | 43 | 47.3 | 30 | 31.2 | 88 | 41.5 |

| Corrective measures taken | ||||||||

| Treatment in clinic | 22 | 88 | 66 | 72.5 | 40 | 41.6 | 128 | 60.4 |

| Local treatment by bassline, butter | 3 | 12 | 24 | 26.3 | 56 | 58.4 | 83 | 39 |

| Culling | 1 | 1.2 | 1 | 0.6 | ||||

| Last milking of udder infected cows | ||||||||

| Yes | 15 | 60 | 56 | 61.5 | 34 | 35.4 | 105 | 49.5 |

| No | 10 | 40 | 35 | 38.5 | 62 | 64.6 | 107 | 50.5 |

| Time of culling when | ||||||||

| 1 teat disappeared | 6 | 24 | 20 | 22 | 4 | 4.2 | 30 | 14.1 |

| 2 teat disappeared | 12 | 48 | 28 | 30.7 | 26 | 27 | 66 | 31.1 |

| 3 teat disappeared | 6 | 24 | 19 | 20.8 | 26 | 27 | 51 | 24 |

| All teat disappeared | 1 | 4 | 20 | 22 | 23 | 24 | 44 | 20.8 |

| No culling at all | 4 | 4.5 | 17 | 17.8 | 21 | 10 | ||

| N= number of respondents | ||||||||

Table 8: Udder management practice and corrective measures taken in and around Bahir Dar city.

Concerning the remedial action for udder problems, provision of treatment with in animal clinic was a common corrective measure taken in urban (88%), peri-urban (72.5%) and rural (42.1%) production systems. On the other hand, in the rural area traditional medicine like butter, basline and local plant species (Astenager) were used to treat especially visible wounds. Similar result showed that, specific plants were used for the treatment of udder health problems [30]. Only 1.2% of milk producers in peri-urban area were implementing culling for those animals suffering from udder and teat health problem.

Unless the cows with udder health problem are milked last, it can be transmitted to healthy cows, however, only less than half (49.5%) of dairy producers were practicing last milking of infected cows in the study area.

Amongst many reasons of culling, the disappearance of one or more teats due to udder health problem is the major reason reported by households in the study area. The culling practice of dairy farmers in the study area showed that, about 31.1%, 24%, 20.8%, and 14.1% of the total interviewed households were culling their cows when 2, 3, 4 and 1 teats are disappeared, respectively. However, 10% of respondents weren’t practicing culling even if all teats of cow are nonfunctional. Since controlling production costs and maximizing income is a priority for dairy farmers. So the culling of unproductive cow from the herd through either sale or slaughter is important.

Major constraints of clean milk production

In this study, dairy keepers have encountered with a number of difficulties and constraints that are hindering with the success of desired milk production. Of which lack of clean water, lack of knowledge, poor hygienic condition and absence of quality based payment system were the major constraints of clean milk production in and around Bahir Dar city. After having identified the major problems facing the dairy activities, farmers were requested to list their priority in order of importance. In adequate and unclean water access for both human and animals was identified as a primary constraint (index=0.167) in the study area. It was serious especially in the peri urban area (index=0.3) followed by rural framers (Table 9). This might be because of the availability of water sources from wells in the rural area which is preferable than river water in terms of quality that found in periurban areas. Similarly, lack of clean water was found to be problem in Bure district and Gondar town, respectively [31].

| Constraints of clean milk production | Production systems | Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Urban  Rank | Peri-urban    Rank | Rural Rank | ||||||||||||

| 1 | 2 | 3 | Index | 1 | 2 | 3 | Index | 1 | 2 | 3 | Index | Rank | Index | |

| Lack of clean water | - | - | - | - | 50 | 2 | 6 | 0.3 | 6 | 9 | 11 | 0.08 | 1st | 0.167 |

| Lack of knowledge | 4 | 2 | 1 | 0.11 | 7 | 16 | 9 | 0.12 | 25 | 16 | 9 | 0.2 | 2nd | 0.153 |

| Poor hygienic condition | 4 | 1 | 3 | 0.11 | 2 | 3 | 8 | 0.036 | 23 | 15 | 13 | 0.193 | 3rd | 0.116 |

| Absence of quality based payment system | 9 | 4 | 1 | 0.23 | 11 | 15 | 17 | 0.14 | 4 | 7 | 4 | 0.05 | 4th | 0.11 |

| Lack of adequate capital | 6 | 4 | 4 | 0.19 | 7 | 14 | 9 | 0.1 | 1 | 3 | 3 | 0.021 | 5th | 0.078 |

| Marketing problem | 1 | 2 | 2 | 0.058 | 2 | 7 | 3 | 0.04 | 6 | 8 | 9 | 0.074 | 6th | 0.058 |

| Improper handling and transportation | - | 4 | 5 | 0.083 | 1 | 8 | 11 | 0.054 | 1 | 7 | 10 | 0.047 | 7th | 0.055 |

| Unhygienic barn | - | 1 | 1 | 0.019 | - | 3 | 5 | 0.02 | 7 | 12 | 12 | 0.098 | 7th | 0.055 |

| Absence of cooling facilities | 1 | - | - | 0.01 | - | 6 | 5 | 0.03 | 9 | 8 | 8 | 0.088 | 7th | 0.055 |

| Lack of smoking plants | - | 2 | 1 | 0.032 | 9 | 3 | 6 | 0.054 | - | 2 | 3 | 0.012 | 8th | 0.04 |

| Lack of hygienic storage container | - | - | 2 | 0.012 | 2 | 7 | - | 0.036 | 4 | 6 | 4 | 0.048 | 9th | 0.039 |

| Unclean milking utensil | - | 2 | 3 | 0.064 | - | 2 | 7 | 0.02 | 9 | 4 | 6 | 0.07 | 10th | 0.038 |

| Udder health problem | 1 | 3 | 1 | 0.064 | 2 | 3 | 6 | 0.032 | 1 | - | 4 | 0.012 | 11th | 0.027 |

Table 9: Major constraints of clean milk production in and around Bahir Dar city.

Comparably, limited awareness on hygienic handling, shortage of capital, lack of clean water, and poor type of barn were the major constraints of milk quality in the central highlands of Ethiopia [32]. The result is in agreement with the report of other authors, lack of clean water for cleaning purpose, limited knowledge on the hygienic handling of milk and milk products and unimproved milk processing materials were main constraints in the Ezha district of the Gurage [18].

The major problem found in urban area was the absence of quality based payment or marketing system (ranked 1st with index= 0.23). Similar to the other parts of the country raw milk is distributed through the informal and formal marketing systems. The majority of the respondents in and around Bair Dar city (particularly urban and peri-urban) sale the raw cow’s milk in order to generate cash income. This might be due to the presence of milk marketing place, production objective and high demand. In the three production systems, raw milk is distributed from producers to consumers through the traditional means; however, there was no any quality based marketing systems. According to the observation, all types of milk found in the market had similar price without considering its quality or standard. Surprisingly, farmers who produce quality milk products may become out of the market competition, if poor quality milk is widely available at market with lower price. This is an indication for designing quality based milk marketing (payment) system should be considered. However, cooperatives were trying to fix price for milk collection based on organoleptic and physical qualities of milk. Comparable result was reported in other research findings [33,34].

Moreover, lack of technical knowledge and poor hygiene were also reported by urban dairy produces as a challenge. Unlike other districts, there are no organizational structures and extension services in the urban kebeles of Bahir Dar city hence, producers couldn’t get different technical trainings and extension services regarding to clean milk production. Nevertheless, in the rural production system lack of knowledge (1st), poor hygienic condition (2nd) and shortage of clean water (3rd) were the main obstacles for clean milk production in decreasing order of importance. This finding is in line with other reported figures, limited awareness on hygienic handling of milk and milk products, lack of clean water for sanitation purpose and poor condition of barn or milking area were the major milk quality related constraints.

The hygienic practice during milk production in the study area was poor and milk handling practices were also vulnerable for contamination. Milking procedures like cleaning milking area, hand washing and drying, udder washing and drying before milking were highly performed by urban dairy producers followed by peri-urban. Yet, in the rural production system most of the procedures were not implemented proper hygienic practices except hand washing before milking. Normal water was commonly used for both udder and hand cleaning purpose which might contribute for high microbial contamination and quality deterioration. In general the hygienic condition through the entire milk production process is far away from the scientific principles and standards.

Traditional milking container (Kell) and storage utensils (Kabo) were dominantly used in the rural production system. On the other hand, in urban and peri-urban areas plastic container was used for raw milk handling purpose. Smoking and washing milking and storage utensils were normal practices in and around Bahir Dar city in order to produce milk with good flavor and aroma. Abalo (Terminalia brownie) was the most common plant species used to smoke milk handling utensils. Clean milk production in the area was affected by a number of factors, of which absence of quality based payment system and lack of clean water were the primary constraints of clean milk production in urban and peri-urban production systems, respectively. However, lack of knowledge was a serious problem in rural production system.

Based on these findings the following are recommended:

Milk handling practice and hygienic condition was poor especially in rural area, so training regarding to hygienic quality of milk shall be provided and stainless steel milking and milk storage utensils shall be accessible for all milk producers with optimum price.

Clean water has to be provided in the study area particularly in rural and peri-urban production systems to improve milk quality and prevent public health hazard.

There should be quality based payment system (price) in order to create strong competition among producers. Hence, the quality of raw cow’s milk produced in the area can be improved.

The corresponding author collected different primary and secondary data used for this study. There was full participation of all authors in data analysis, drafted the manuscript and contributed on improving the manuscript towards its completion. All authors read and approved the final manuscript.

We thank the different government offices, agriculture experts and development agent for their cooperation during data collection and throughout the entire work. We thank also Woldia University for financial support.

The authors declare that they have no competing interests.

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Not applicable.

This work was supported by the Woldia University.

Citation: Yeserah B, Tassew T, Mazengia H (2020) Handling Practices of Raw Cow’s Milk and Major Constraints of Clean Milk Production in and around Bahir Dar City, Ethiopia. J Adv Dairy Res 8: 234. doi: 10.35248/2329-888X.20.8.1.234

Received: 28-Feb-2020 Accepted: 12-Mar-2020 Published: 19-Mar-2020 , DOI: 10.35248/2329-888X.20.8.234

Copyright: © 2020 Yeserah B, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.