International Journal of Advancements in Technology

Open Access

ISSN: 0976-4860

ISSN: 0976-4860

Research Article - (2025)Volume 16, Issue 1

This study was designed to investigate the impacts of technological revolutions on supply chain evolution and revolution on industry performance and comparative advantage, in order to develop global collaboration and integration strategies. Using explanatory techniques, the evolution and revolution of a case study on the steel and basic metal industry supply chain within East Africa over the past decade, drawing on previous research work. Moreover, commoditization, globalization, the digital revolution, the turbulent world, and social media throughout society have been identified as drivers of supply chain evolution and revolutions. Due to these diving forces globally, the supply chain has evolved from traditional (uncoordinated, disparate, sub-optimal) to an integrated supply chain structurally. As a result of such evolution, the manufacturing industries' performances are highly impacted. While technologically, the supply chain changes from a manual supply chain (paper-based processes and documentation) to a digital (IT-supported and cloud-based) supply chain process. Moreover, globally, current digital supply networks integrate information from many different sources to drive production and distribution, potentially altering manufacturing’s competitive landscape within the firm. Even if, in the case of Ethiopian basic metal industry supply chain systems, they have been traditional, fragmental, non-integrated, and paper-based processes. Due to these, the regional basic metal industry performance in information and product delivery time, flexibility, product quality, resource utilization and competitiveness performance of the sectors have been weak and poor. As a result, the national and regional contribution of the sector has been newborn and underprivileged. Therefore, the strategies in this study reveal how to fill the gap found in the studies. The study was conducted primarily qualitatively, with descriptive analyses, and quantitatively, with data analyzed using fuzzy TOPSIS and SPSS. Finally, the conclusion and recommendation of the study were done.

Supply chain systems; Regional basic metals; Evolution and Revolution; Manufacturing performance

In the current economy supply chain systems used as a useful tool through encompasses the planning, production, distribution and management activities involved in sourcing, procurement, production, distribution conversion, and all logistics management activities of firms. Since, the supply chain system consists of main segments including suppliers, manufacturer, distributor, retailer, and customers. Though, in this supply chain systems firms integrate into business processes from supplier to end user through supply chain enablers providing products, services, and information that add value for customers and other stakeholders [1]. However, the primary purpose of any supply chain is to satisfy customer needs in the process of generating the profit for itself. Moreover, supply chain firms should be coordinate, collaborate and integrate among the member organization in various ways so as to fulfill mutual benefits. While, in negotiations and transactions between the members of supply chains, the tendency in the past has been to establish arm’s length relationships; however, significant changes have occurred over the years in the evolutionary process of supply chains, leading to a discernible shift from competition to collaboration [2]. Since, through effective and efficient supply chain integrations organization can get a competitive advantage on another and compete at global markets [3]. Though, the evolution of the emerging markets necessitates global firms to reorient their supply chains into global or network configurations to compete more effectively [4]. While a few research works have been conducted to the impacts of impact level of supply chain integration [5], the enablers of supply chain [6,7], supply chain integration strategies [8] supply chain firms studied as well. However, Up to now, there have been no efforts to conduct driver and the impacts of supply chain revolution were not properly studied. As well, the studies of how firms proceed from stage-to-stage, how supply chain driver interrelated on to each other as contractual relationships evolve dynamically are inadequate and a gap in the literature. Since this needed empirical findings that show how supply chain revolution advance in a firm and how supply chain driver’s impact on the current and future supply chain performances. Ultimately what extent and how supply chain evolution drivers interlink each other on supply chain Thus, using literature review, this study investigates how firms move through the various stages in supply chain systems and how firms how they can cooperate to ensure efficiency and equity in their contractual relationship is done. Though this study to fill the research gap represented by the lack of analysis on the business process specific factors, drivers which affect the evolution of supply chain relationships and the entire supply chain systems in the manufacturing by providing an integrated framework. Since, the ultimate goal of gap identification is to develop empirical investigation, so as to propose the concepts which need further study toward the improvement of supply chain firms. While, the driver and the impact of supply chain evolution for the current and future economic developments is examine. Therefore, this study is designed to investigate on the impacts of supply chain evolution and revolution to manufacturing industry performances and comparative advantage, so as to develop global collaboration and integration strategies.

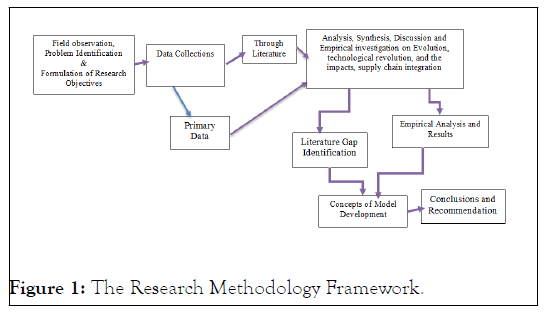

The study was conducted through field observation and literature review on research articles, books, magazines, manuals, company report and electronic-sources which are discuss related to supply chain evolution, the technological revolution in a supply chain systems, the impacts of supply chain evolution on the current businesses environments were assessed. The literature review study helps in finding gaps in previous researches on supply chain revolution impacts and the driving power potentials on firm supply chain systems. As well the gaps of the current research related to the given issues were studied, investigate and analysis in detail. Followed by the impacts of technological revolution in supply chain evolution and revolution to industry performances were empirically investigated. Finally, the conclusion and recommendation of the study were done.

Analysis tool and Research Methods

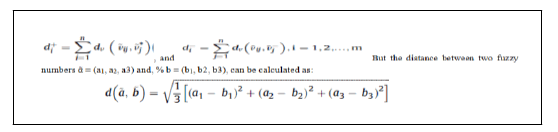

Mainly the study was mainly employed qualitatively through descriptive analyses, and quantitatively the data were analyzed and investigated using fuzzy TOPSIS and, SPSS analysis. Due to the popularity and simplicity in concept of the traditional TOPSIS, is often criticized for its inability to adequately handle the inherent uncertainty and imprecision associated with the mapping of the decision-maker’s perception to crisp values. Though initially the Fuzzy TOPSIS method was developed by Hwang and Yoon and widely used for estimate as far is a particular alternative near the ideal solution [9]. It provides to work on selected the alternative should have the shortest distance from the positive ideal solution and the farthest distance from a negative ideal solution [10]. In these methods the Fuzzy Positive Ideal Solution (FPIS), this represents a mission benefit and the Fuzzy Negative Ideal Solution (FNIS), lowering mission of business process. Mathematically Fuzzy TOPSIS concept follows the following concepts [9,11].

Step 1: Determination of Linguistic Terms, Membership Functions and the weighting of evaluation criteria investigate the linguistic variables for all criteria. Each linguistic variable is assigned a set of membership functions; determine weights of evaluation criteria and the ratings of alternatives are considered as linguistic terms. Suppose there are J possible alternatives called D={D1,D2,…, Dj}, which are to be evaluated against M criteria, C={C1,C2,…, Cm}. The criteria weights are denoted by wi (i =1, 2,…m). The performance ratings of each decision maker Dk (k =1,2,…, K) for each alternative Dj (j=1,2,…, n) with respect to criteria Ci (i=1, 2,…, m) are denoted by Rk = xijk (i =1, 2, …, m; j=1, 2, …, n; k=1, 2,…, K) with membership function μRk (x).s.

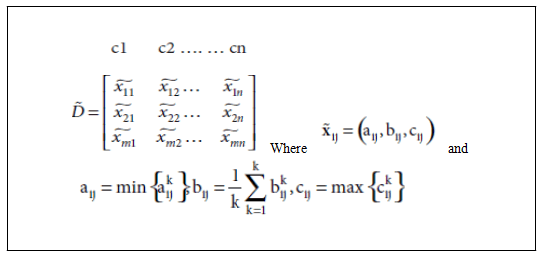

Step 2: Construct the fuzzy decision matrix. This matrix is directly associated with linguistic variables and the criteria alternatives. Assumed that the number of criteria is n and the count of projects is m, fuzzy decision matrix will be obtained with m rows and n columns as in the following matrix:

Where A1, A2... Am alternatives, the parameters of the process which must be ranked according to established criteria or indicators C1,C2,...,Cn, xij is the rating of alternative, Ai with respect to criterion Cj.

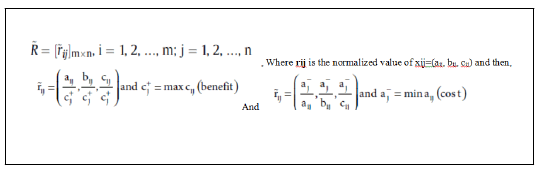

Step 3: Normalize the fuzzy decision matrix. The normalization of fuzzy decision matrix is accomplished using linear scale transformation. If the normalizing positive and maximum value, the factors are highly contributes at positive way and the reverse is true.

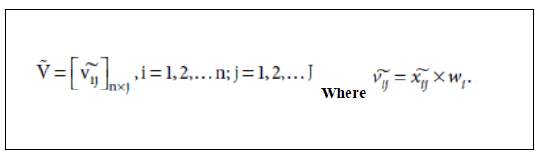

Step 4: Calculate the weighted normalized fuzzy decision matrix

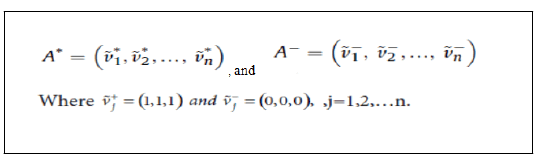

Step 5: Determine the fuzzy positive-ideal solution (FPIS A+) and fuzzy negative-ideal solution (FNIS A-). Value of ranges belongs to the closed interval [0, 1]. FPIS and FNIS are defined as triplet (1,1, and 1) or (0,0,0). Else the values determined by using the following formula:

Step 6: Calculate the distance of each alternative from FPIS and FNIS.

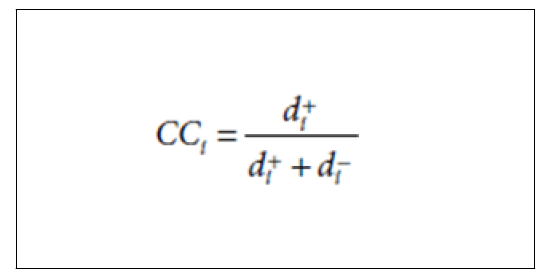

Step 7: Calculate the closeness coefficient to the ideal solution. The closeness coefficient CCi is defined to determine the ranking order of all alternatives. The index CCi indicates that the alternative is close to the FPIS (dj+) and far from the FNIS( dj−). The closeness coefficient to the ideal solution can be calculated as:

8. Ranking the Alternatives: The ranging order of all alternatives, the ranking of alternatives is carried out based on the calculated closeness coefficients.

The alternative with the highest coefficient represents the best alternative is close to FPIS and farthest from the FNIS.

Thus, this positive ideal solution is a solution that maximizes the benefit criteria and minimizes cost criteria, while the negative ideal solution maximizes the cost criteria and minimizes the benefit criteria Table 1 and Figure 1.

| Verbal Scale | Weak | Low impact | Moderately | Highly impact | Very Highly | Extremely High |

|---|---|---|---|---|---|---|

| Intensity of influence | 1 | 2 | 3 | 4 | 5 | 6 |

| Corresponding triangular fuzzy numbers | (1,2,3) | (2,2,3) | (3,4,5) | (4, 5,6) | (5, 5, 7) | (5, 6, 7) |

Table 1: Verbal scales for evaluation of on the influences of supply chain integration variables.

Figure 1: The Research Methodology Framework.

The evolution of supply chain

In the era of 1950s, manufacturing firms recognize the importance of logistics and physical distribution management as a part of the organizational function. In this era supply chain considered as to describe the logistic concepts in manufacturing firms. While, the idea of supply chain management can be traced to early beginning 1960s in with the quick response program and later to efficient consumer response of firms for the practice of physical distribution and logistics systems in fragmental position [12,13]. Although, supply chain management emphasizes and has clearly attracted increasing interest since the early 1980s. However, since1960s to 2000s, customer-supplier supply chain relationships, from individual to collaboration, computation to cooperation, from manual to computer-based systems have been undergoing enormous changes at a national and international level on manufacturing industries also seen [13]. While the study shows that, from the second half of 20th to the 21st first century the evolution of the supply system have recorded four main phases. Within this evolution and growth phase’s firms follow different supply chain theories, strategies, and practices. Thus from 1960s-1970s, the supply chain system was concerned with the phenomenon of economic development and with the process of structural change. As a result during these proceedings, the systems influenced by Perroux’s growth poles theory [13]. Since 1970s-1980s supply chain evolution exercise in the cost reduction principles through re-engineering, downsizing driven management concepts. While the 1980s, supply chain practices become one of the most popular concepts within management systems [12] and the firm business entity be driven by profit maximization and direct decision making were incorporated in resource allocation, production technique, pricing adjustments and quantity produced for decisions to maximize business profits. Thus in this era, business organizations inclined on the theory of firms. This also supported by [13] literature review analysis. Though, the theory of the firm was traditionally one branch of microeconomics and provides a supply of goods by profit-maximizing agents. While the production costs played a crucial role in the theory of firm’s principles. In the meantime, in the current globalization world, the evolution of supply chains have to change and emerged to meet the complex needs of human societies, to exploit natural resources and to enable humans to engage profitably in commerce and trade [14]. As a result in the early 1990s, the negative effects of the individual business environment were studied [9]. Since this time provides to improve firm performance, several collaborative initiatives were witnessed in the pursuit of enhancing the mutual benefits of the partners. Consequently, supply chain evolution process was, advanced from competition to collaboration and coordination of business systems between supply chain members [15]. In the late 1990s, the new trend and globalized business practice supply chain management have become increasingly apparent, over recent years, that deeper and wider collaboration way from a perspective of vertical integration and collaboration, to horizontal supply chain integration position [16,15,17]. Although the end of the 1990s, globalization, were dominated to customer-supplier relations in large, which can be the firms competitive. However, in this era, firms increase value addition and cost reduction through integration using enterprise resource planning seen.

As well, the evolution of supply chains were advance and shifts in strategically to lean and agile, whereas technologically supply chain changes from individual manual systems to IT- enabler inter-organizational systems Although the end of the 1990s, globalization, were dominated to customer-supplier relations in large, which can be the firms competitive. However, in this era, firms increase value addition and cost reduction through integration using enterprise resource planning seen. As well, the evolution of supply chains were advance and shifts in strategically to lean and agile, whereas technologically supply chain changes from individual manual systems to IT- enabler inter-organizational systems [18] Even though the advancement of supply chain systems was changed and increase gradually but it needs more emphasis focus on fit and alignment between progress in supply chain strategies and technological strategies that would potentially enable agility as well as trust and visibility within the supply network. Thus, the era of the 2000s till current and future generation supply chain management increase from computed systems to digital bussing process (that is internet use has skyrocketed supply chain systems, globally accessible supply chain, and supply chain performances begins, globalization and specialization combine together to give fast response to the customers) is developed. On the other side, the evolution of the supply chain was advanced and the substantive progress that can be made in achieving supply chain responsibility from the narrow economic, technical and legal requirements of the firms to accomplish social and environmental issues along with the traditional economic gains which the supply chain member seeks [19,20].

Supply chain revolutions

In the history of the supply chain the process, firms use supply chains in different ways at a different time. While the frame of the supply chain revolution has traced and passé the following phases. The revolution of logistical military operational solutions, transportation management systems, the logistics, and physical distribution, fragmental logistics process from 1940s-1960s were work and used. In this stage better focus was also placed on warehousing and materials handling process by the organizations. While early1980s (1970s-1980) ineffective the supply chain and the decisions were taken from a principally functional perspective. Since this period was the transformation process and planning and operation process done in an isolated manner. This is the tradition systems of supply chain and logistics. While, the transformation and supply chain incremental phase were (1980s-1990s) the benefits of aligning organizations, along with the associated business objectives [13] were happen. In this stage is the transition period for contemporary supply chain system and the negative effects of individual business underlined by corporate leaders. In addition, for executives and underlying business processes performance incentives, cost reduction through the technological application and the importance of IT base planning were developed [21]. This era is also, the era of specialization, companies improve their overall competence in the same way that outsourcing manufacturing and distribution has done and focused on their core competencies and assemble networks on best class domains specific partners to contribute the overall value chain and improve the overall performances of the systems. Following in 2000s own wards the era of globalization and specializations, the business process is done using digitalizing and internet based business process to facilitate ordering, production, logistics, planning, inspection and warehousing systems. Since individual business are participating and connecting their business process into the global economy directly, using digital platforms to participate, to learn how doing business, then doing business, develop competitive systems, formulate cooperation with firms and to attain profit economic benefits [22,6]. As well in this era business organizations implement ERP systems, cloud computing, and inert of thing in their supply chain systems.

The impacts of innovative technological adaptability on sustainable supply chain

Technologies involve the techno-economic workings of such artifacts, including costs, safety, and reliability. These features are crucial for understanding the feedback mechanisms between technological change and institutional change [23]. Technology consists technological trajectory and accumulation of knowledge. Since Technological trajectory refers to a single branch in the evolution of a technological design of a product/ service. As such, a technological trajectory is a set of technologies that consistently develop over time in certain direction [24]. However, innovation refers to a tradable application of an invention, as a result of invention integration into economic and social practice. Innovation is regarded, therefore, being a result of a process that starts with an idea genesis and continues with its materialization [25]. Thus the idea of the innovation process stresses that the flow of technology and information among people, organizations, regions, enterprises and institutions is key to an innovative process. These process consists the interaction between actors who are needed in order to turn an idea into a successful process, product or service in the marketplace. However, study [23] shows that, many innovation systems are characterized by some flaws that greatly hamper the development and diffusion of innovations. Since these flaws are often labeled as system failures or system problems. But Intelligent and evidence based innovation policy therefore evaluates how innovation systems are functioning, tries to create insight in the system problems and develops policies accordingly. Although an actors, institutions, networks and technology are the common and the basic building blocks or components of proper innovation systems [24]. Even if the Eastern Africa basic metal industries are infant stage of innovation, but they should use and adopt the building blocks of proper innovation system and procedures. Because Technological adaptability results for adapt the process or systems continuously its technological systems according to different changing conditions. Since elegant results are increasingly integrated in manufacturing and production process, involving a leading-edge-technology with an aim to preserve, yet enhance the environmental quality. In this circumstance technological adaptability plays a major role to improve the production sustainable attributes. Since technological adaptability could be impact supply chain sustainability with, accessibility, affordability, healthy production and performance of manufacturing industries Table 2.

| Events | First Stage | Second Stage | Third Stage | Fourth Stage |

|---|---|---|---|---|

| 1940s-1960s | 1970s-1980 | (1980s-1990s) | 2000s own wards | |

| Theory/principles(Evolutions) | The Logistics and Physical Distribution, Fragmentations | Functional perspective and tradition systems(Scale, Cost) | The incremental transformation and supply chain(Quality, Time) | Globalization and specializations |

| (Agility, Sustainability) | ||||

| Result of the events and SC revolutions | Logistical military operational solutions(1940s), transportation management systems(1950s), Joint logistics and Physical Distribution(1960s) | paradigm shift occur due to advent of personal computer(1960s-1970s) | The transition period for contemporary supply chain system and the negative effects of individual business underlined by corporate leaders. | The global business process done using digitalizing and internet based systems |

| Material Requirements Planning systems(1970s-1980s) | Enterprise Resource Planning (ERP)(1990s) | -innovative integration | ||

| -Flexible and ineffective the supply chain and the decisions were taken from principally functional perspective | Cost reduction through technological application and the importance of IT base planning were developed | Cooperation and long term relation | ||

| _Supplier oriented and competition rather than cooperation | -firm collaboration, value adding and cost minimization | -Innovativeness | ||

| -Cost reduction, business re-engineering process | -Delivery speed Delivery speed,& Flexibility | |||

| -Productivity Reliability | ||||

| Source: The author adopted from [13,15] | ||||

Table 2: The Evolution and Revolution Stages of Supply chain.

Technological revolution in the supply chain integration

Traditional supply chain

In supply chain systems, the traditional supply chains rely on a mix of electronic and paper-based processes and documentation [26]. Although, supply chains are traditionally linear, by way of a discrete progression of design, plan, source, make, and deliver. But in the current business environment, supply chains are transforming into dynamic, interconnected systems. This shift from linear, sequential supply chain operations to an interconnected, open system of supply operations could lay the foundation for how companies compete in the future. Since these digital supply networks integrate information from many different sources to drive production and distribution, potentially altering manufacturing’s competitive landscape.

Digital supply chains

Technological advancements such as increased computing power, penetration of broadband internet access or hand-held devices gave the impetus for digitalization [27]. However, due to changes in technology and customer expectations, companies which want to stay competitive increasingly need to digitize their production systems and services. Since digitalization provides to ubiquitous information availability is at the core of digital supply chains [22]. With the right organizational design and governance, they can enable superior collaboration and communication across digital platforms resulting in improved reliability, agility and effectiveness [26]. This performance difference will force organizations with traditional supply chains to adapt to the new digital realities or run the risk of falling behind the competition. A digital operating model is all about implementing digital capabilities along the organizational layers of governance, processes, data & performance management and IT. It allows for required levels of integration and standardization of processes. Since the digital supply chain provides to develop a digital strategy that embeds the right technologies for your business, understand and manage global supply-chain complexity and risks, optimize your global material, information, and financial flows and lead organizational change and SC transformation.

Hybrid supply chain systems

Today most organizations operate on hybrid supply chain models that combine paper-based and IT-supported processes.While, in the case of paper-based supply chain systems, provides information is only available locally, organizational design is largely based on local factories or branches serving local customers. Coordination and governance is based on local profit centers which optimize the performance of a region, country or branch and which often do not share information openly with other organizational units.

Profit-center heads often wield strong organizational power and hence applications are designed to support local processes or functional islands. These divergent local processes and IT applications lead to inconsistent and redundant data at the corporate level and create several inefficiencies.

What influences were considered on supply chain evolution and revolutions?

In the business process supply chain stems changes from fragmental to integrated, technological from manual to digitalized systems, so as to improve firm performance and mutual benefits. Since, commoditization, the digital revolution, social mediaization throughout society, globalization and the turbulent world are the main driving force for supply chain evolution and revolutions. While supply chains provides to transfer materials, products, information and money from suppliers and their suppliers to customers and their customers ,exactly, from digging raw materials out of the ground to the home of the final consumer [28]. However in figure above shows the main driving force for supply chain evolution includes commoditization, the digital revolution, social mediaization throughout society, globalization, the turbulent world and acceleration (or running faster to stay in the same place)Table 3.

| List of supply chain evolution and revolution drivers | Academic evidence and Resources |

|---|---|

| The digital revolution(iot, cloud computing) | [21,27,6, 29,30] |

| Globalization and opportunity of new markets and their effects | [31,32,33] |

| Social mediaization throughout society | [34,35,36,37,38] |

| The unstable world | [39,40], |

| Demand and supply uncertainties | [41] |

| Technology change technological uncertainty | [34,6] |

| Commoditization | [42,43], |

| Customer focuses business | [6,29,44,45] |

Table 3: The drivers of supply chain evolution and revolutions studied by numerous scholars.

The progress of supply chain management and supply chain integration changes in system wise have four major stage focus, single, arrow concepts traditional activities, multi-dimension traditional management systems, transformation mutual and computer-based systems to multi-dimensions, more improve enabling stages. While in technological scenario the supply chain evolution advancement improve through a year from simple, traditional, blocked and individual systems to develops multidimensional web-based controlling and management systems to make things within unlimited bounder's both globalized and specialization supply chain integration systems. Though each stogies on the supply chain technological revolution, evolutions and driver has the ability to directly affect the supply chain firm performance either positive or negatively. As a result the evolution and revolution of supply chain performances can be depend on the scenario of each driving forces. In the advancement of technologies digital supply chains transforming in all end-to-end business highly impacts for suitable production and distribution of the firm.

The ranking and fuzzy prioritization on in impacts of technological revolutions

While, based on the data collected from various expertise and qualitative inputs of supply chain integration ecosystem and the technological changes influences on supply chain performances were studied and investigated.

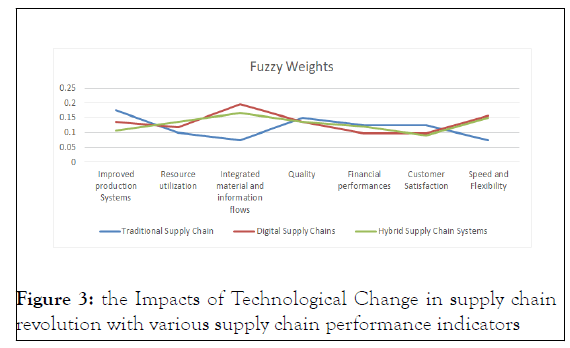

The impacts of traditional, digital and hybrid supply chain systems on the performance and competitiveness of manufacturing industries were studied and investigated. During fuzzy prioritization and ranking of supply chain ecosystems were done through various supply chain performance indicators including resource utilization, integrated material and information flows, improved product systems, financial performances, customer satisfaction, quality, speed and flexibility, and supply chain security.

Next creating weighted normalized fuzzy decision weight matrix in table (4) above, and the evaluation and investigation of the distance on each alternative to fuzzy positive ideal solution and fuzzy negative ideal solution for all variables were done. Thus, the distance of impacts of supply chain ecosystems and their influencing variables or alternatives to the positive and negative ideal solutions are given in (Table 4-5).Moreover from each distance, the closeness coefficient and the ranking of each supply chain ecosystem impacts on supply chain revolution and supply chain performances.

| Weights*[ Column Sum weight]-1 | Cumulative weight | (CCi)=(D-/(D-+D*) | ||||

|---|---|---|---|---|---|---|

| Ѽ1 | Ѽ2 | Ѽ3 | Rank | |||

| HSC | 0.4 | 0.452 | 0.446 | 0.432667 | 0.52 | 1 |

| DSC | 0.333 | 0.339 | 0.286 | 0.319333 | 0.528 | 2 |

| TSC | 0.263 | 0.21 | 0.268 | 0.247 | 0.537 | 3 |

Table 4: The Normalized fuzzy decision weights and closeness coefficient of (CCi) each decision variables.

| Various type of supply chain ecosystems | ||||||

|---|---|---|---|---|---|---|

| Supply chain performance indicators | Traditional supply chain | Digital supply chains | Hybrid supply chain systems | |||

| (CCi)=(D-/(D-+D*) | Normalized Cumulative weight | (CCi)=(D-/(D-+D*) | Normalized Cumulative weight | (CCi)=(D-/(D-+D*) | Normalized Cumulative weight | |

| Improved production Systems | 0.525 | 0.175 | 0.525 | 0.13725 | 0.525 | 0.10606 |

| Resource utilization | 0.545 | 0.1 | 0.529 | 0.11765 | 0.519 | 0.13636 |

| Integrated material and information flows | 0.563 | 0.075 | 0.517 | 0.19608 | 0.516 | 0.16667 |

| Quality | 0.529 | 0.15 | 0.525 | 0.13725 | 0.519 | 0.13636 |

| Financial performances | 0.536 | 0.125 | 0.536 | 0.09804 | 0.522 | 0.12121 |

| Customer Satisfaction | 0.536 | 0.125 | 0.536 | 0.09804 | 0.529 | 0.09091 |

| Speed and Flexibility | 0.563 | 0.075 | 0.522 | 0.15686 | 0.517 | 0.15152 |

| Supply Chain Security | 0.525 | 0.175 | 0.563 | 0.05882 | 0.529 | 0.09091 |

Table 5: The comparative analysis of supply chain ecosystems with various supply chain performance indicators.

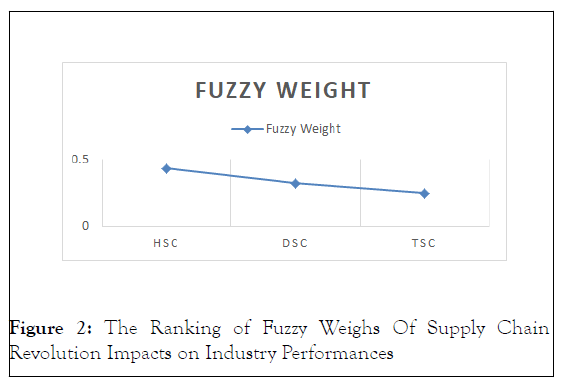

During the fuzzy TOPSIS analysis variables having lower closeness coefficient and higher fuzzy weights have higher impact on the performance and the success of the scenarios Figure 2 [46,9,10].

Figure 2: The Ranking of Fuzzy Weighs Of Supply Chain Revolution Impacts on Industry Performances

While, according to the normalized fuzzy decision weights and closeness coefficient of (CCi) each decision variables as shown in the (Table 6) above the hybrid (HSC), digital (DSC) and traditional supply chain systems (TSC) have highest positive impacts on manufacturing performance from the highest to the lowest respectively.

Likewise, the effects of traditional, digital and hybrid supply chain systems with various manufacturing industry performance indicators are investigated and studied in the following figure. While, improved production systems, resource utilization, integrated material and information flows, quality, financial performances, customer satisfaction, speed and flexibility, supply chain security are used as a performance inductors to the manufacturing industries Figure 3.

Figure 3: the Impacts of Technological Change in supply chain revolution with various supply chain performance indicators

The statistical analysis and results

Evaluation criteria’s on supply chain ecosystems

As shown in (Table 6-7) below the correlation analysis on supply chain integration performances with the traditional supply chain, digital and hybrid supply chain systems were determined and investigated. While, the hybrid supply chain systems (.246*), the digital supply chain (.226*), and the traditional supply chain (-.254*), correlations relation with supply chain performance within 0.05 and 0.01 significant levels. According to this investigations the hybrid, digital and traditional supply chain systems correlated with supply chain integration performances from the highest to the lowest respectively. Even though, traditional supply chain systems are negatively correlated with supply chain integration performances.

| Descriptive statistics | |||

|---|---|---|---|

| Mean | Std. Deviation | N | |

| Digital Supply Chain | 3.0625 | 0.9979145 | 16 |

| Improved product Systems | 3.5 | 0.5163978 | 16 |

| Resource utilization | 2.6875 | 0.75 | 16 |

| Integrated material and information flows | 1.5 | 0.5163978 | 16 |

| Quality | 2.875 | 0.7416198 | 16 |

| Financial performances | 3.03125 | 0.6944722 | 16 |

| Customer Satisfaction | 3.1875 | 0.5737305 | 16 |

| Speed and Flexibility | 2.78125 | 0.7520804 | 16 |

| Supply Chain Security | 2.65625 | 0.8107353 | 16 |

| Traditional Supply Chain | 2.5625 | 0.8920949 | 16 |

| Hybrid Supply Chain | 4.03125 | 0.7846177 | 16 |

Table 6: Descriptive Statistics.

| Correlations | |||||

|---|---|---|---|---|---|

| Supply chain ecosystems | SCP | TSC | DSC | HSC | |

| Supply Chain Integration Performances | Pearson Correlation | 1 | |||

| Sig. (2-tailed) | |||||

| Traditional Supply Chain | Pearson Correlation | -.254* | 1 | ||

| Sig. (2-tailed) | 0.018 | ||||

| Digital Supply Chain | Pearson Correlation | .226* | -.458** | 1 | |

| Sig. (2-tailed) | 0.035 | 0 | |||

| Hybrid Supply Chain Systems | Pearson Correlation | .246* | -.520** | .513** | 1 |

| Sig. (2-tailed) | 0.021 | 0 | 0 | ||

| *. Correlation is significant at the 0.05 level (2-tailed). | |||||

| **. Correlation is significant at the 0.01 level (2-tailed). | |||||

Table 7: The comparative analysis of supply chain ecosystems with supply chain performances.

Should be highly implemented a hybrid supply chain models that combine paper-based and IT-supported processes for the higher performance improvement and organizational success [26]. Conversely, a traditional and paper based supply chain ecosystems have a negative impact on the higher success and performance improvement of manufacturing industries and business organizations. Thu, manufacturing industries should be work for the implementation and practices of digital and hybrid supply chain systems in their own business process, to be competitive in the global markets Table 8.

| Correlations | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TSC | HSC | DSC | IPS | RU | IMIF | QU | FP | CS | SF | SCS | ||

| Traditional Supply Chain | Pearson Correlation | 1 | ||||||||||

| Sig. (2-tailed) | ||||||||||||

| Hybrid Supply Chain | Pearson Correlation | -0.265 | 1 | |||||||||

| Sig. (2-tailed) | 0.321 | |||||||||||

| Digital Supply Chain | Pearson Correlation | -0.342 | 0.423 | 1 | ||||||||

| Sig. (2-tailed) | 0.195 | 0.103 | ||||||||||

| Improved product Systems | Pearson Correlation | -.651** | 0.206 | 0.323 | 1 | |||||||

| Sig. (2-tailed) | 0.006 | 0.445 | 0.222 | |||||||||

| Resource utilization | Pearson Correlation | -0.268 | -0.124 | 0.251 | 0 | 1 | ||||||

| Sig. (2-tailed) | 0.316 | 0.648 | 0.349 | 1 | ||||||||

| Integrated material and information flows | Pearson Correlation | -.651** | 0.206 | 0.323 | 1.000** | 0 | 1 | |||||

| Sig. (2-tailed) | 0.006 | 0.445 | 0.222 | 0 | 1 | |||||||

| Quality | Pearson Correlation | -0.189 | 0.351 | 0.372 | 0.261 | 0.135 | 0.261 | 1 | ||||

| Sig. (2-tailed) | 0.483 | 0.183 | 0.156 | 0.329 | 0.619 | 0.329 | ||||||

| Financial performances | Pearson Correlation | 0.346 | 0.12 | 0.334 | 0.046 | 0.148 | 0.046 | 0.27 | 1 | |||

| Sig. (2-tailed) | 0.189 | 0.657 | 0.207 | 0.864 | 0.584 | 0.864 | 0.32 | |||||

| Customer Satisfaction | Pearson Correlation | -0.09 | -0.014 | 0.269 | 0.338 | 0.3 | 0.338 | 0.14 | .570* | 1 | ||

| Sig. (2-tailed) | 0.742 | 0.959 | 0.313 | 0.201 | 0.259 | 0.201 | 0.61 | 0.021 | ||||

| Speed and Flexibility | Pearson Correlation | -0.252 | .605* | 0.108 | .558* | -0.277 | .558* | 0.43 | 0.142 | -0.05 | 1 | |

| Sig. (2-tailed) | 0.347 | 0.013 | 0.69 | 0.025 | 0.299 | 0.025 | 0.1 | 0.601 | 0.85 | |||

| Supply Chain Security | Pearson Correlation | .608* | 0.123 | -0.219 | -.597* | -0.49 | -.597* | -0.24 | 0.139 | -0.14 | -0.022 | 1 |

| Sig. (2-tailed) | 0.013 | 0.65 | 0.415 | 0.015 | 0.054 | 0.015 | 0.37 | 0.608 | 0.61 | 0.935 | ||

| **. Correlation is significant at the 0.01 level (2-tailed). | ||||||||||||

| *. Correlation is significant at the 0.05 level (2-tailed). | ||||||||||||

Table 8: The bivariate correlation analysis of supply chain ecosystems with supply chain performances using various performance indicators.

Finally, both SPSS and the fuzzy TOPSIS empirical analysis were conducted to investigate the impacts of technological changes in the supply chain systems and the performance and global competitiveness of manufacturing industries. Both the statically correlation and the fuzzy weighting and factor the analysis was done to decide the condition of the given alternative and variables. While both the statically correlation and the fuzzy prioritization the result indicates that traditional supply chain, digital supply chain, hybrid supply chain systems have a positive impact on the performance and competitiveness of manufacturing industries from the lowest to the highest respect. As result industries that have hybrid supply chain systems have more advantages and competitive than firms having the digital and tradition systems [26,29].

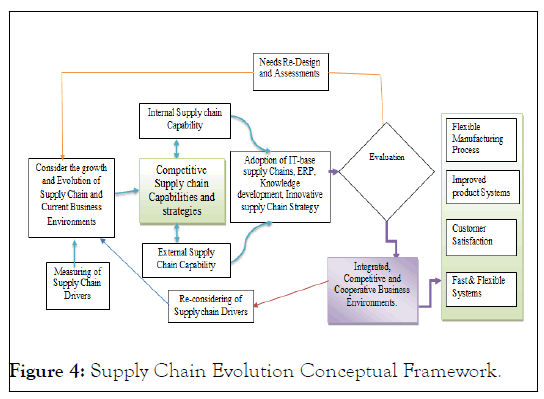

The development of supply chain evolution framework on firm performance

The proposed framework emphasizes on the competitive supply chain capabilities and strategies fit and alignment between internal supply chain and external supply chain capability. While an effective and efficient supply chain strategies would enable better alignment that potentially results in effective supply chain performance improvement and competitiveness of the firm. Though in the above model the knowledge integration and management is concerned with recognizing and managing all of an organizations intellectual assets to meet its business objectives. Since organizations are redesigning their internal structure and their external relationships, Knowledge development and creating knowledge networks to facilitate improved communication of data, information, and knowledge, while improving co-ordination, decision making, and planning in a supply chain firm [47]. While innovative supply chain strategy involves decisions that affect the long-term performance of an organization. Though innovative supply chain tools like ITbased systems helps to improve collaborative-supported work using different automation that includes computer-aided design/computer aided manufacturing (CAD/CAM) and CIM [47]. As well e-business technologies, and hence ultimately providing a fully integrated e-business process can integrate activities along the supply chain. Since this digital and e-business initiative is needed to fully utilize the capabilities of the internet technology in a specific business setting [48]. However this proposed supply chain revolution strategies provides to help clarify a strategic e-business vision and to seek new and digital supply chain paradigms to change and on new business opportunities. Furthermore this models provides to consist of multiple firms collaborating to leverage strategic positioning and to improve supply chain efficiency. Though this supply chain strategy is can be used as a channel and business organizational array based on acknowledged dependency, innovative flexible and collaborative within a supply chain firm. Since this strategies can be change the performances of manufacturing industries gradually rather than radically [49]. Though in the evaluation stage the contribution of the performance improvement system should be evaluated whether the companies are improve their competitive advantage, recover their performance and attain their expectation or not [50]. If the evaluation is in a good condition, the supply chain system approaches to overall organizational performance and business Success. Ultimately flexible, manufacturing process, improved product systems, customer satisfaction, fast & flexible logistics and distribution systems can be launce. Besides this conceptual model can also be modified through other studies in line with the issues and scenario of supply chain firm Figure 4 [51].

Figure 4: Supply Chain Evolution Conceptual Framework.

In order to improve supply chain integration performance of manufacturing industries, the characteristics, progress, and technological revolutions of supply chain integrations were investigated and studied. This study analyses the main issue, concepts and principal themes concerning the emergence and evolution of supply chains process in the business process. Supply chain process changes in system wise evolve from traditional (uncoordinated, disparate, sub-optimal) to an integrated supply chain structure. While technologically changes from manual supply chain (paper-based processes and documentation) to digital (IT-supported processes) supply chains. According to these empirical investigations, the evolution and revolution of supply chains have an impact on the performance and competitiveness of manufacturing industries. Accordingly, the main drivers of these supply chain evolution and revolutions include globalization, the digital revolution; commoditization, the turbulent world, and social mediaization throughout society are investigated. Although according to this investigation globally, in the current digital supply networks integrate information from many different sources to drive production and distribution, potentially altering manufacturing competitive landscape in the firm. Even though in the case of East African including Ethiopian basic metal industry supply chain systems have been traditional, fragmental, non-integrated and paper-based processes. As result, the performance in information and product delivery time flexibility, product quality, resource utilization and competitiveness performance of the sectors have been weak and poor. As a result, the national and regional contribution of the sector has been newborn and underprivileged. Likewise, these fragmental supply chain processes still continued in developing countries basic metal industries as it has been obtained from literature reviews discussed in this study. This fragmental supply chain system results in poor performance in information shearing nonflexible process, low product quality, poor resource utilization and weak competitiveness in a firm. Besides the drivers of supply chain evolution and revolutions are highly impact in traditional, digital and hybrid supply chain systems of manufacturing industries. Though without integrated supply chain systems, enhancing performance improvement and assuring global competitiveness is extremely complex to bring about fundamental change to sustainable economy sectors. Thus, the design and development of supply chain integrations models were done in this study. While the model considered the impacts of technological change supply chain revolutions and their impacts of various supply chain ecosystems on the performance and competitiveness of manufacturing industries were considered. Thus, implementing this conceptual model have a great impact on manufacturing firms.

Construct on the rich foundation of the research findings described and overall understanding acquired in this study, the authors present the concerns that a good point further research and anticipate that these issues may hold the potential in contributing towards the future research studies. The following may require attention from academics and researchers in the future and further work may be carried out. Commoditization, globalization, the digital revolution, the turbulent world, and social mediaization throughout society are investigated as the main drivers of supply chain evolution and revolution. But the impacts of each driver on supply chain evolution in various regions developing and developed are not studied so far. As well the relation with traditional, digital and hybrid supply chain relations on each driver also needs further investigations and studies for the solution development of sector performance improvements. As a result, the area needs further investigations. Given that academics and researchers may to explore more avenues for quality research both theoretically and empirically to spawn extra publications in the areas.

Citation: Damtew AW, Brihane E (2025) Impact of the Technological Revolution on the Supply Chain Integration Process Performance and Productivity (Case of Ethiopian Basic Metal Industries). Int J Adv Technol. 16:340

Received: 07-Jan-2025, Manuscript No. IJOAT-25-14025; Editor assigned: 09-Jan-2025, Pre QC No. IJOAT-25-14025 (PQ); Reviewed: 20-Jan-2025, QC No. IJOAT-25-14025; Revised: 28-Jan-2025, Manuscript No. IJOAT-25-14025 (R); Published: 10-Feb-2025 , DOI: 10.35248/0976-4860.25.16.340

Copyright: © 2025 Damtew AW, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.