Journal of Agricultural Science and Food Research

Open Access

ISSN: 2593-9173

ISSN: 2593-9173

Research Article - (2017) Volume 8, Issue 4

This study was undertaken to scrutinize the influence of bacterial wilt diseases, growing environment and blanching on potato chips quality on five released potato cultivars grown at Humbo Tabala experimental fields in 2016 Ethiopian cropping seasons. The cultivars were planted in a Randomized Complete Block Design with three replicates. The effect of growing environment on selected agronomic parameters including stem number, plant height, dry matter content, specific gravity, yield and other yield components were studied. Maximum (9.13) and minimum (1.67) stem numbers as produced by Variety 5 and Variety 4. The lowest was produced by cultivar Variety 4 (248.7 g/hill).

The highest specific gravity (1.110) and dry matter content (27.33%) was produced by Variety 5, while the lowest specific gravity (1.078) and dry matter content (20.33%) produced by Variety 2. All cultivars produced specific gravity and dry matter content greater than 1.07 and 20%, which is in the acceptable range for chips processing. In the blanching treatment, sliced potatoes were blanched at 90°C for 5 minutes. Both blanched and Unblanched slices were fried at 175°C for 5 minutes using vegetable oil. The quality of chips was evaluated in terms of sensory (sourness, bitterness, sweetness, crispiness, flavor, overall acceptability) and instrumental (texture and color) quality attributes.

The sweetness of potato chips was significantly influenced by the interaction effect of bacterial wilt diseases, growing environment and blanching. The interaction effect of variety and growing environment significantly influenced bitterness, crispiness, overall acceptability and texture of potato chips whereas, all sensory attributes were significantly influenced by blanching. All cultivar has got better overall acceptability rated between “like moderately to very much”. The most acceptable cultivars were Variety 4 and Variety 5 (like very much) while cultivars Variety 1 and Variety 2 were rated between "like slightly" to moderately" respectively.

<Keywords: Humbo tebela; Cultivars; Variety; Chips processing; Chips quality; Bacterial wilt diseases; Growing environment; Solanum tuberosum L.

Worldwide, potato is the third most important food crop in terms of consumption after rice and wheat [1]. Potato cultivation is exceeding 18.6 million hectares of land in more than 157 countries in the world with an estimated annual production of 330 million tons [2]. It is a crop of world’s major economic importance and number one nongrain food commodity [3]. In Ethiopia, it is the crop which ranks fifth in money value and contributes in poverty alleviation both as a source of income generation and employment creation [4]. Despite its importance, the potato is affected by lack of the clean seeds, improper pest and disease management, a disorganized marketing chain and lack of clear policies on packaging [5]. Potato processing quality is characterized by high dry matter; low sugar and phenol content. The informal system leads to the use of poor quality seeds and often accelerates the spread of seed-borne diseases such as bacterial wilt [6].

Bacterial wilt has affected 77% of potato production [7]. Because of the high prevalence of this disease, a strict rotation programme is required in the production of the crop; few farmers can rotate for the recommended one and a half years due to land scarcity [5]. Control of bacterial wilt on potatoes is difficult and no single control method has been found to be totally effective [8]. Ethiopia is endowed with suitable climatic and edaphic conditions for quality potato production with an altitude of 1800-2500 m a.s.l and an annual rainfall of more than 600 mm, which is suitable for potato production [9]. However, the national average yield is approximately 10.5 tons ha-1, which is very low compared to the world average of 16.4 tons/ha [10].

If tubers with the dry matter content is too low, the quality if French fries was too soft or too wet and will need more heat to fry to evaporate the water. The production of lighter color chips acceptable to the market often requires some pretreatment of the sliced potatoes in the processing plants [11]. Prior to drying most food products are usually subjected to one form of pretreatments, among which blanching is one of the most important techniques [12].

Potato growers interested in producing raw stock for chip processing, so they should consider the varieties best suited for the industry and growing conditions. The primary aim of the study was evaluating the Effect of Bacterial wilt disease, Blanching and Growing environment on potato varieties (Solanum tuberosum L.) and processing quality of potato chips.

Study area

The study was conducted at Humbo Tabala located in the Southern Ethiopia Wolaita zone with latitude of 09°26'N, longitude 041°46'E, altitude 2025 m, and vertisol soil type.

Experimental setup

For this study five regionally released potato varieties tubers were planted at each location in a Randomized Complete Block Design (RCBD) with three replications. The land was prepared, and wellsprouted tubers of each cultivar were planted in three rows and ten hills per row at spacing of 75 cm and 30 cm between rows and plants. A plot within a replication was arranged continuously and end plots were bordered by two rows of potato plants.

Pre-harvest data collection

The average number of main stems produced per hill was taken from five randomly selected plants from each plot and the height of plant was measured from the ground level to the tip of the plant at full maturity. The days to physiological maturity was recorded when the haulms (vines) of 50% of the plant population per plot have turned yellowish or showed senescence and an average of 24 hills tuber number was recorded.

Postharvest data collection

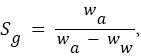

The following formula was used to calculate specific gravity of potato tubers,

Where: Sg=Specific gravity, Wa=Weight in air (g), Ww =Weight in water (g) [13].

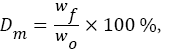

Dry matter content (%): Clean and unpeeled tubers were chopped, and 200 g chopped samples was dried in oven at 70°C for 72 hours to a constant weight. This was calculated as,

Where: Dm=dry matter (%), Wf=weight of sample after drying (g), and Wo=initial weight of sample (g).

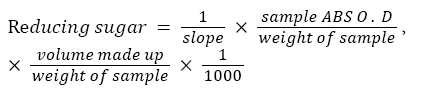

Sugar analysis: The juice used to determine the pH to evaluate the reducing sugars. 10 ml of the juice was added to 15 ml of 80% ethanol, mixed and heated in boiling water bath for 40 minutes. After extraction, 1 ml saturated Pb(CH3COO)2.3H2O and 1 ml Na2HPO4 was added and the content was mixed by gentle shaking and filtered. An aliquot was diluted to 25 ml with 1 ml copper reagent in a test tube and heated for 20 minutes in a boiling water bath and cooled by adding tap water. Arsenomolybdate color reagent (1 ml) was added to the cooled content made up to 10 ml with distilled water and left for 10 min to allow color development, after that absorbance was determined by a spectrophotometer (Jenway, model 6100) at 540 nm. The reducing sugar was calculated using formula:

Where: slope=0.00148, ABS=absorbance of sample and O.D=optical density.

Quality evaluation of potato chips (Texture and color measurement)

Potato chips texture was determined using hardness tester (Kiya Seisakusho. Ltd. Takyo, Japan). Chips color was measured using a standard color chart having scale ranging from grade 1 to 5 (1=the lightest color (white to cream), 2=light tan, 3=dark tan, 4=brown and 5=dark brown, (Munsell Color Company, USDA 1988) chip color between grade 1 and 3 is commercially acceptable [14].

Data analysis

Analysis of variance (ANOVA) was carried out using MSTAT-C statistical software packages (MSTAT-C, 1991). Means were compared using least significant differences (LSD). In analyzing the sensory data, the 5-point scale and the 9-point hedonic scales was used and the numerical values for each sample was tabulated and analyzed by ANOVA to determine whether significance differences in mean degree of scoring points exist among the samples or not.

Average stem number

The effects of growing environment on main stem number of potato varieties were compared (Table 1). The average main stem number per hill was significantly (p<0.01) influenced by interaction of the variety and growing environment. The highest and lowest number of stem number per hill was 9.13 and 1.67 by Variety 5 and Variety 4, respectively. This result coincides with Berga and Caesar, who reported increase in stem number because of either planting large tuber size or more tuber number per unit area [15]. In this case tubers with many main stems and tubers with single branched main stems have produced similar yields. In this study, average stem numbers were positively correlated with total tuber yield (r=0.33), though not significant.

| Cultivars | Stem number per hill | Plant height (cm) |

Days to physiological maturity | |

|---|---|---|---|---|

| Variety 1 Variety 2 Variety 3 Variety 4 Variety 5 |

3.47cde 2.80de 4.67c 1.67e 9.13a |

65.73a 63.47a 51.87b 52.00b 48.20bc |

81.33h 81.00h 99.00e 99.67e 110.33b |

|

| Level of significance | ** | * | * | |

| CV (%) | 19.40 | 8.36 | 1.33 |

Means followed by the same letter within a column are not significantly different at the prescribed level of probability. *=significant at 5% and **=significant at 1%.

Table 1: The interaction effect of cultivars on stem number per hill, plant height (cm), and days to physiological maturity of potato.

Plant height

The interaction of cultivars and growing environment significantly (p<0.05) influenced the average plant height during the growing seasons (Table 1). The highest plant height was recorded for cultivar Variety 3 (68.27 cm) and the shortest was recorded for cultivar Variety 4 (40.40 cm). So, we can conclude that, it is highly influenced by environmental factors like nutrient status of the soil, available moisture and intercepted radiation. Girma observed positive and significant correlation between plant height and total tuber yield (r=0.89**) [16]. Nonetheless, Gopal also reported no significant association between plant height and tuber yield. In this study, there was a positive correlation value (r=0.34) between plant height and total tuber yield but not significant [17]. This result shows a little existence of association between plant height and total tuber yield.

Days to 50% flowering was significantly (p<0.01) affected by the growing environments and cultivars (Table 2). The interaction effect of cultivars and growing environment did not significantly (p<0.05) influence days to 50% flowering. Variety 1 and Variety 2 flowered earlier at 50 days while, Variety 5 flowered lately at 63 days after planting. Differential flowering of the tested cultivars may be due to their inherent character. On the other hand, days to physiological maturity was significantly (p<0.05) influenced by cultivar and growing environment interaction (Table 1).

| Treatments | Days to 50% flowering |

|---|---|

| Cultivars | |

| Variety 1 Variety 2 Variety 3 Variety 4 Variety 5 |

50.67d 50.33d 56.11c 59.44b 62.78a |

| Level of significance | ** |

| CV (%) | 3.30 |

Table 2: The effect of cultivar on days to 50% flowering. **=significant at 1% probability level.

Similar results were reported by Asmamaw, that early flowering and physiological maturity [18]. The days to flowering and days to physiological maturity shows significant correlation (r=0.96**), though the correlation is found having medium association (Table 2).

The number of tubers produced was significantly influenced by the interaction between a cultivar and growing environment (Table 3). The highest marketable tuber number was recorded from cultivar Variety 3 while the least was obtained from Variety 4. Variety 3 produced the highest (8.33) and Variety 4 the least (1.33) unmarketable tuber number. Total tuber number of Variety 4 initiated the least (4.0). This indicates that number of tubers initiated by a cultivar influenced by the growing conditions. Tekalign and Hammes observed a considerable variation in tuber number among four cultivars indicating that there was difference in the number of tubers initiated during development [19]. There was weak and positive correlation (r=0.23) between total tuber number and total tuber of yield while positive and high significant correlation value (r=0.73**) was obtained between marketable tuber number and total tuber yield. This indicates that both tuber number and size increment are responsible for yield improvement which is in line with Yibekal [20].

| Cultivars | Tuber number per hill | |||

|---|---|---|---|---|

| Marketable | Unmarketable | Total | ||

| Variety 1 Varity 2 Variety 3 Variety 4 Variety 5 |

6.68cde 7.33b-e 8.33a-d 2.67f 6.33de |

2.67ef 2.00ef 6.33ab 1.33f 3.33def |

9.35e 9.33e 14.66c 4.00g 9.67c |

|

| Level of significance | ** | * | * | |

| CV (%) | 16.26 | 31.88 | 18.28 | |

Means followed by the same letter within a column are not significantly different at the prescribed level of probability. *, ** means significant at 5% and 1%, respectively.

Table 3: The interaction effect of cultivars on marketable, unmarketable and total tuber number per hill of potato.

Tuber yield

The effects of cultivar and growing conditions on marketable, unmarketable and total tuber yield are presented in Table 4. Variety 4 produced the least (5.33 g hill-1). The highest total tuber yield was produced by Variety 2. This showed that yield and yield components are influenced by the growing environments. Yield per unit area is the product of components of several yields contributing characters which are highly influenced by environment.

| Treatment | Cultivars | Tuber yield (g hill-1) | ||

|---|---|---|---|---|

| Marketable | UnmarketableTotal | |||

| Bacterial wilt disease | Variety 1 Variety 2 Variety 3 Variety 4 Variety 5 |

533.30bc 553.30b 466.70bc 243.30de 463.30bc |

16.67g 13.33g 75.33b 5.33h 39.00ef |

550.00bcd 566.63bcd 542.03bcd 248.63f 502.30cd |

| Level of significance | ** | * | ** | |

| CV (%) | 16.29 | 36.95 | 15.10 | |

Means followed by the same letter within a column are not significantly different at the prescribed level of probability. *, **=significant at 5% and 1%, respectively.

Table 4: Marketable, unmarketable and total tuber yield (g hill-1) of potato as influenced by bacterial wilt disease and cultivar interaction.

Effect of cultivar, growing condition and blanching on sensory attributes

Sourness: The growing environment, cultivars and their interaction did not significantly (p<0.05) influence the sourness of the chips (Table 5). The maximum and minimum sourness rates were 1.64 and 1.48 for cultivar Variety 2 and Variety 4, consecutively. The sourness rates for all cultivars lie between 1.48 to 1. 64 where =not sour and 2=less sour. This may be due to the presence of very low or absence of sourness taste in the potato chips when fried after harvesting. Gebramedhin et al. also reported that after harvesting chips from most of the cultivars were very much liked by the panelists while during the storage period there was a progressive loss of taste of chips [21]. Sourness of the chips was negatively and significantly (r=−0.52*) correlated with overall acceptability of the chips indicating the reverse relationships of sourness and overall acceptability. The mean sourness rates for chips made after being blanched and unblanched were 1.44 and 1.68, respectively (Table 5). Blanching reduced the sourness of the chips which could be due to its leaching effect of reducing sugar and other chemicals which may be responsible to induce sourness in chips.

| Treatment | Sourness | Bitterness |

|---|---|---|

| Unblanched Blanched |

1.68a 1.44b |

1.61a 1.36b |

| Level of significance | ** | ** |

| CV (%) | 14.08 | 14.48 |

Means followed by the same letter within a column are not significantly different at 1% of probability level. **=significant at 1% level of significance.

Table 5: The effect of blanching on sourness and bitterness of potato chips.

Bitterness: The interaction of cultivars and growing environment significantly (p<0.05) influenced bitterness of potato chips as presented in Table 5. The maximum and minimum bitterness rate was found to be 1.52 and 1.28 for Variety 2 and Variety 1 cultivars, respectively. This difference resulted due to tubers growing in different environmental conditions. All the cultivars were rated in the range of 1 to 2 where 1 and 2 refers to not bitter and less bitter rates, respectively. This may indicate that at harvest bitterness of potato chips are very low as compared to potatoes which were stored before processing. Asmamaw et al. showed that the loss in taste of chips during the storage may be due to the increase in the concentration of glykoalkaloids level of tubers [18]. The observed bitterness of the chips was negatively (r= −0.21) correlated with the overall acceptability of the chips, though not significant. This indicated the reverse relationship between the two parameters.

Bitterness of potato chips was significantly (p<0.01) influenced by blanching (Table 5). In all cases blanched samples get better score by the panels. The blanched and unblanched tubers resulted in chips having bitterness rate of 1.36 and 1.61, respectively (1=not bitter and 2=less bitter). This result showed that blanching leached out some chemical in addition to reducing sugar.

Sweetness: The interaction effect of location, cultivar and blanching significantly (p<0.05) influenced the sweetness of potato chips (Table 6). In general, blanching appeared to result higher sweetness of chips as compared to ones made from unblanched potato slices. The maximum rate for sweetness was found 3.07 for chips made from blanched potato slices of variety 5 cultivars whereas the minimum was 2.60 for unblanched potato slices of Variety 2 and Variety 3 cultivars (1=not sweet and 5=very sweet). Sweetness of potato chips was positively and strongly correlated with flavor (r=0.80**) and overall acceptability (r=0.74**) of potato chips. This is may be due to the positive and high significant correlation value of sweetness and dry matter content of the tuber (Table 6) that means tubers with high dry matter content always produces acceptable potato chips quality.

| Cultivar | Unblanching | Blanching | |

|---|---|---|---|

| Variety 1 Variety 2 Variety 3 Variety 4 Variety 5 |

2.87g-j 2.60j 2.60j 2.73ij 3.07e-j |

3.13d-i 3.07e-j 2.80hij 3.73ab 3.27b-h |

|

| Level of significance | * | * | |

| CV (%) | 9.19 | ||

Means followed by the same letter within a column are not significantly different at 5% of probability level. *=significant at 5% level of significance.

Table 6: The interaction effect of cultivars and blanching on sweetness of potato chips.

Crispiness: The interaction of cultivars and growing environment significantly (p<0.01) influenced the crispiness of potato chips (Table 7). Variety 3 produced moderately crispy chips (4.08) while variety 2 produced crispy (3.57) chips according to 1 to 5 scales (1=not crispy and 5=very crispy). This is strongly linked to the difference in tuber dry matter content of the cultivars. The result indicated that the dry matter content of cultivars influences the crispiness of the chips. Lisinska and Leszynski established that crispy texture is associated with the dry matter content of raw potato tubers, chips obtained from potatoes rich in dry matter (above 25%) can exhibit hard textures, whereas crispiness of chips made from potatoes with low dry matter are characterized by greasy and sticky textures [22]. Kita reported that percentage of dry matter in potatoes for crisp production should be 20-25% and that of starch should be more than 15% [23]. Crispiness was positively and significantly associated with dry matter content (r=0.54*) and specific gravity (r=0.54*) indicating that tubers with high dry matter content and specific gravity produce crispy potato chips.

| Cultivar | Bitterness | Crispiness | Over all acceptability | Texture(N) | |

|---|---|---|---|---|---|

| Variety 1 Variety 2 Variety 3 Variety 4 Variety 5 |

1.28d 1.52bcd 1.45bcd 1.45bcd 1.33cd |

3.67cd 3.80a-d 4.08a-d 3.55de 3.92a-d |

7.27ef 7.33def 7.30ef 7.55b-e 7.85a-d |

10.20a 8.37a-f 7.19def 7.65b-f 7.44c-f |

|

| Level of significance | * | ** | ** | * | |

| CV (%) | 14.48 | 9.76 | 4.68 | 15.99 |

Means followed by the same letter within a column are not significantly different at the prescribed level of probability. **, *=significant at 1% and 5% level of significance, respectively.

Table 7: The interaction effect of cultivars on bitterness, crispiness, overall acceptability and texture of potato chips.

It was reported that the crispy structure of potato chips is the result of changes at the cellular and sub-cellular levels in the outer most layers of the product Taiwo et al. [24]. During pre-treatment, change occurred in the cell membranes, which play a key role in the change that occurred within the tissue during further processing. Krokida et al. studied the effect of various pretreatments on textural properties of fried potatoes where blanching was reported to reduce oil absorption by gelatinization of the surface starch while air dehydration led to reduce oil absorption (Table 8) [11].

| Blanching | Crispiness | |

|---|---|---|

| Unblanched Blanched |

3.35b 4.25a |

|

| Level of significance | ** | |

| CV (%) | 9.76 | |

Means followed by the same letter within a column are not significantly different at 1% of probability level. **=significant at 1% level of significance.

Table 8: The interaction effect of blanching and location on crispiness of potato chips.

Flavor: The growing environment did not significantly (p<0.05) influence the flavor of potato chips while the cultivars significantly influence it (Table 9). The highest flavor score was given for Variety 4 (7.67) while the minimum was for cultivar Variety 2 (7.12). According to the panelists, the flavor score of all of the cultivars lies between 7 and 8 indicating that the flavor of the cultivars is between liked moderately to very much. This could be due to their dry matter content which is in between 20.33 to 27.33% which fulfill the criteria for chip processing and the vegetable oil used. In this study, flavor of the chips was positively and significantly correlated with dry matter content (r=0.72**) and specific gravity (r=0.73**) of the tubers. This implies that potatoes with high dry matter content and specific gravity produces acceptable flavor of potato chips. Smith reported that chips possess flavors inherent in the raw potato as changed by high temperature for a short time [25].

| Treatments | Sourness | Flavor | Color |

|---|---|---|---|

| Cultivars | |||

| Variety 1 Variety 2 Variety 3 Variety 4 Variety 5 |

1.59a 1.64a 1.57a 1.48a 1.52a |

7.36bc 7.12c 7.18c 7.67a 7.51ab |

1.28ab 1.61a 1.61a 1.39ab 1.17b |

| Level of significance | Ns | ** | * |

| CV (%) | 14.08 | 4.52 | 36.88 |

Means followed by the same letter within a column are not significantly different at the prescribed level of probability. **, *, ns=significant at 1% and 5% and non-significant, respectively.

Table 9: The effect of cultivars and location of sourness, flavor and color of potato chips.

Luis E has established that flavor is one of the important quality factors of potato chips and affected mainly by the type of oil used to fry chips, flavor compounds inherent in the raw potatoes, and added flavoring. Flavor was significantly influenced by blanching (Table 10) [26]. Flavor of blanched chips scored 7.56 (liked very much) while unblanched chips 7.17 (liked moderately) indicating blanching improves the flavor of the chips.

| Treatment | Flavor | Over all acceptability | Texture | Color |

|---|---|---|---|---|

| Unblanched Blanched |

7.18b 7.57a |

7.28b 7.72a |

10.42a 5.89b |

1.20b 1.62a |

| Level of significance | ** | ** | ** | ** |

| CV (%) | 4.52 | 6.68 | 15.99 | 36.88 |

Means followed by the same letter within a column are not significantly different at 1% of probability level. **=significant at 1% level of significance.

Table 10: The effect of blanching on sensory attributes of flavor, overall acceptability, texture and color of potato chips.

Overall acceptability: The overall acceptability of potato chips was high significantly (p<0.01) influenced by the interaction of cultivars and growing environment (Table 7). The highest acceptability scores were given for variety 5 (7.85) and the least were scores (7.27) variety 1. Similar to the crispiness, the acceptances of the potato chips were related with the specific gravity and dry matter content where cultivars having high specific gravity and dry matter content obtained higher acceptance score than those with less dry matter and specific gravity.

There was a positive and strong correlation between overall acceptability and specific gravity (r=0.93**) and dry matter content (r=0.92 **) of potato tubers indicating that the high dry matter and specific gravity of potato tubers are essential for quality chips processing. It is necessary or desirable for processed potato products to have an attractive color, acceptable texture and good flavor. The overall acceptability of potato chips was positively and significantly correlated with sweetness (r=0.74**), crispiness (r=0.48*) and flavor (r=0. 80**) of potato chips. This indicated that there is strong association between these parameters. Potato product quality and acceptability are related to color and texture [27]. Yost et al. indicated that color is the first attribute of a food product that immediately convey a positive or a negative connection of overall quality [28,29]. Color also influences a consumer’s perception of flavor, taste, and the intent to purchase a food product.

The overall acceptability of chips was significantly (p<0.01) influenced by blanching as presented in Table 10. Better scores were given for blanched chips. Blanched chips scored 7.7 (like very much) while the unblanched once 7.1 (like moderately).

Color: Growing environment as well as cultivar significantly influenced potato chips color while the interaction did not (Table 10). The color of all cultivars ranges between 1 and 2 where 1 is light color and 2 is light tan which is commercially acceptable. This may be due to their lower reducing sugar content (below 0.051) which is suitable to produce commercially acceptable chips color. In the same way, regardless of the cultivar, the color range for the three locations lies between 1 (light color) to 2 (light tan) indicating that the color is within the acceptable range. In this study, the very low reducing sugar content and relatively higher pH value of potato makes the cultivars lighter and light tan in chips color which is commercially acceptable.

The study was conducted to investigate the influence of cultivars, growing environment and blanching on the chip making potential of potato varieties. Five released potato cultivars namely Variety 1, Variety 2, Variety 3, Variety 4 and Variety 5 were grown in 2016 at Humbo Tabala Southern part of Ethiopia. The varieties were planted in a Randomized Complete Block Design with three replications. The effect of genotype and growing environment on selected agronomic parameters including stem number, plant height, specific gravity, dry matter content and yield were studied. The interaction between growing environment and cultivars influenced stem number/hill and plant height. Maximum (9.13) and minimum (1.67) stem number was produced by cultivar Variety 5 and Variety 4, respectively.

All cultivars dry matter content of greater or equal to 20.33% is acceptable for chip making. Cultivar Variety 5 produced high (27.33%) dry matter content while cultivar Variety 2 produced low (20.33%) dry matter content, although it was grown at the same growing environment. All cultivars relatively maintained better dry matter content which is greater than 21.6%. A strong positive correlation (0.997**) was observed between specific gravity and dry matter content.

The analysis of variance showed significant difference in pH between cultivars during harvesting. The pH value for all of the cultivars was between 6.18 and 6.37. Very low reducing sugar content was obtained from all of the cultivars ranging from 0.036 to 0.051 g 100 g-1 of fresh weight. For chips making peeled potatoes were sliced to 2.0 mm thickness, washed and surface-dried. In the blanching treatment, sliced potatoes were blanched at 90C for 5 minutes. Both blanched and unblanched slices were fired at 175C for 5 minutes using vegetable oil. The quality of chips was evaluated in terms of sensory (sourness, bitterness, sweetness, crispiness, flavor, overall acceptability) and instrumental (texture) and based on a color chart (color) quality attributes. Sourness and bitterness of potato chips were significantly influenced by blanching. In all of the cases blanched samples have got better score by the panelists. Color of potato chips was significantly influenced by blanching. Unblanched chips are relatively lighter (1.2) in color while blanched chips are in between light color and light tan (1.62). In both cases, the color of chips ranged between 1 and 2 (1=light color and 2=light tan). The interaction effect of growing environment and cultivars significantly influenced the texture of potato chips. Maximum force (10.20 N) was recorded for cultivar Variety 1.

The absence of potato processing plants in the country limits the utilization of produced potatoes restricted to be used only for traditional foods. Moreover, there is no differential payment in the market for potato cultivars with high dry matter content developed and officially released for processing purpose. Therefore, the potato improvement program should give due attention to the processing quality of potatoes while developing new cultivars. In addition to this, environment-genotype interaction must be considered in varietal development and pre-frying treatments for production of high quality potato products. The study indicated that the cultivars considered could potentially be used for chips making. However, a comprehensive study under wide frying and blanching conditions would be necessary to optimize the best operating conditions.