Journal of Nutrition & Food Sciences

Open Access

ISSN: 2155-9600

ISSN: 2155-9600

Research Article - (2023)Volume 13, Issue 1

The paper deals with the issue of solving the problem of drying of berries in the humid subtropical region of Gvara- Khutsubani vine and orchard nursery and in particular, introduced blue blueberry. As a result of experimental studies and review methods of drying, biologically active compounds and antioxidant activity change, in the humid subtropical zone, the blueberry drying in ZEFIRO-MAX dryer is preferred. Experiments were being carried out in the experimental vine and orchard nursery of Gvara-Khutsubani. Using modern drying aggregate ZEFIRO-MAX, and HACCP methods we have chosen the level of maturity of the fruit, and constant control of biologically active substances during processing was available. During the blueberry drying process in the ZEFIRO-MAX dryer (45°C-55°C), we obtained the drying parameters that fully meet the standard characteristics of the dryer.

Blue blueberries; Drying; Blanching; Dry substance; Drying machine

Blueberries are evergreen and deciduous plant with a semi-frutex or frutex berred culture. Worldwide blueberry varieties are: Patriot, Duke, Elizabeth, Early blue, Legas, Chandler, Chanticleer have been successfully cultivated in the Black Sea coastal areas of western Georgia, in areas with pre-existing tea plantations [1]. Blueberry crops grow on all types of soils, but give maximum yield is given on acidic soils. They are less demanding towards light and moisture and are distinguished by superficial root system and frost resistance. Breeding of its seedlings is propagated in laboratory conditions by cell culture (in a test tube) (Figure 1).

Figure 1: Worldwide blueberry varieties in the black sea coastal areas of western Georgia.

Blueberry fruit contains sugars (glucose, fructose), catechins, pectins, tanning substances, apple, and lemon, dairy acids, flavonoids, ascorbic acid, B, D vitamins and other useful compounds. The fruit is sour sweet. It is eaten raw. When the product is canned, its enzymes and microorganisms, which are the basis of biochemical and microbiological transformations, are inactivated, thereby eliminating or minimizing these processes and increasing storage capacity.

Drying berries aims to preserve the natural properties of raw material as much as possible; taste, flavor, color, vitamins and more. After the addition of water, the recovery of the product should proceed rapidly and fully. Dried fruits should be well swollen with water and after melting the berries should have their original appearance [2]. Optimum conditions for drying should be provided for berry drying; drying method, regime, heat source, dryer construction. The drying process of the berries should be carried out in continuous action machines using automated process management and control.

The research material was berries and, in particular, introduced blue blueberry in Gvara-Khutsubani vine and orchard nursery in the humid subtropical region of Georgia. Where we ensured the most problematic issues of drying through optimum methods. Optimal regimes of processing and drying blueberry fruit were also applied. Physico-chemical research methods were also used for the study:

• Determination of dry substance-by refractometer in juice-ISO 2173-2013.

• Determination of water and dry substance-by standard, thermo gravimetric method ISO 6557-1. The method is based on the fact that each moisture-containing material we place under a certain pressure (atmospheric or low) and temperature (100°C-105°C) loses moisture.

• Determination of titratable acidity (total acidity)-by the standard, potentiometric titration method, ISO 750-2013. The method is based on potentiometric titration with a standard solution of natrium alkaline up to pH-8,1.

Quantitative determination of anthocyanins by spectral methodaccording to Europharmacopoeia (Ph Eur 1602): Extraction of 1.00 g sample was carried out with methanol at low temperature (-200°C). After extraction, the volume of the extract is reduced to 100 ml. After 50 times dilution of the sample taken from total volume with 0.1% hydrochloric acid methanol, the optical density to the visible light filter (528 nm) is determined’. The obtained results were calculated on cyanidin-3-glucoside.

The content of anthocyanins is calculated by the formula:

X=A × 5000/718 × m (2.1.1)

where X-Anthocyanin content; 718-Cyanidin-3-glucoside adsorption at 528 nm, adsorption of A-research sample at 528 nm; m-mass of the sample taken for extraction.

• Determination of sugar-ISO 6557-1-84

• Determination of ash-ISO 750-2013

The studies have shown that the production of high quality products requires the drying process of blueberry processing plants in accordance with HACCP methods. A 4-person team was created at the study site to describe the product, introduce it into production, use the highly efficient HACCP method of berry processing monitoring, and develop the following block diagram of the berry processing process:

• Download the berries through the bunker

• Sorting berries by size

• Washing berries

• Blanching berries

• Transport system for berries

• Drying berries

• Wrapping line and storage for berries

A block scheme was tested on site, all possible hazard analyzes were conducted, monitoring measures were identified, critical control points were identified and monitoring was established for each control point, corrective measures were named, verification procedures were established.

Blue blueberry is a perishable product, but its drying allows us to obtain highly concentrated and easily prepared food.

Evaporation from the berries results in an increase in the dry matter content, resulting in a highly concentrated product whose nutritional value and calorie content increase by 5-10 times. The vitality conditions of microorganisms are restricted, and therefore the dry product acquires long term storage capacity under normal conditions [3]. The permissible moisture content of a dry canned product depends on its chemical composition. The higher the acidity of the products, the content of essential oils and other conservation factors are, the higher the permissible moisture content. Our research was carried out on the Italian drying machine “ZEFIRO-MAX”, purchased and installed by the ENPARD program in the Gvara-Khutsubani vine and orchard nursery, which enables us to produce high quality dry fruits of blueberries and other products. This unit is a solar dryer, the solar energy absorber grid is located at the top of the dryer, and it is effective even during low sunlight. At 25°C air temperature we can provide 35°C-40°C in the unit. The blueberries are placed in the dryer on stainless steel nets. Drying takes place on 45°C-55°C. Dried fruits are packed in polyethylene bags. 1 kg of dried fruit will be accepted from 7 kilogram of blueberries with a residual moisture content of 18%-20%. The drying process depends on climatic conditions. For proper drying, the outdoor air temperature should be not less than 22°C, drying temperature -41°C-55°C, drying time is 6-7 days. Drying is carried out in a Heliosystem type dryer with ZEFIRO-MAX.

Technological process of drying

From the available areas, we have selected the optimal technological regimes of fruit processing. The main purpose of drying is to maintain quality and reduce losses between harvest and consumption. Although different types of blueberries were planted on the cover areas, we used common samples of these species for drying. The raw materials obtained are sorted, washed and stored in the Heliosystem unit "ZEFIRO-MAX" without any alternative energy source.

At the initial stage of drying, the free moisture was evaporated from the raw material first, and then the evaporation of the bound moisture began, which are chemical, physico-chemical and physico-mechanical depending on the strength of the bonding material. Increasing the temperature of hot air the rate of evaporation of moisture increased, but the use of high temperature limited the quality of berries due to its negative effect. The higher the speed of air movement, the faster the drying process. Hot air at the same time served as a function of heat transfer, moisture absorber and moisturizer at the same time. According to these instructions, the whole batch of raw materials was sorted via inspection and calibration.

The blueberries were dried according to the following technological scheme: Raw materials and technological equipment were used to meet the drinking water requirements.

The raw material was washed in an aqueous tank 2-3 times and delayed for 5-10 minutes to rinse. The panels were positioned at the top of the dryer to absorb solar energy; the average weight of berries in the dryer is 500 kg. Drying was performed at 45°C-55°C in a Heliosystem type dryer.

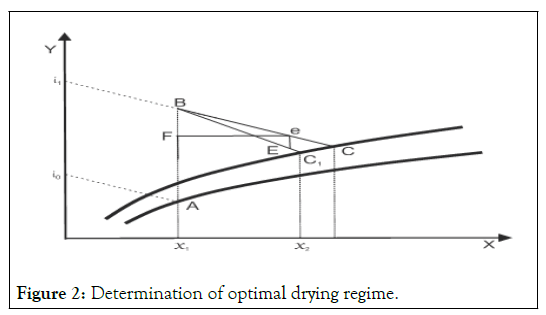

The characteristic air parameters during drying can be calculated by different methods. In our case, the I-d diagram was used presented in Figure 2.

Figure 2: Determination of optimal drying regime.

On Figure 2 the abscess axis shows the moisture content dg/kg in dry air, the thermal content I (kcal/kg air)-on the ordinate axis. In the process of evaporation of moisture from the surface the temperature of the surface layers does not exceed the evaporation temperature. In this case, we increase the evaporation rate only by increasing the ambient air temperature.

It does not adversely affect the quality of raw materials. To illustrate the drying process, we drew a point A on the diagram I-d corresponding to the state of warm air coming from the panels at the top of the dryer [4-7]. The heating process is shown on the diagram by AB line.

The point B corresponds to the parameters of the air at the moment of its entry into the dryer. If the heat supply increases, then the process goes on the BC1 line, and if it decreases on the BC line. In order to draw the line of the drying process, take any point on the line, draw a vertical on it and on it we get the magnitude of the heat coming in above the point on the scale [8-10]. At B we draw a line that characterizes the actual drying process. After choosing any of the air parameters on this line at C1 point, we get the value of other parameters of the air coming out of the dryer. On the diagram the temperatures of the air humidity and wet thermometer, drying potential and more can be specified. The diagram provides a statistical overview of the drying machine or the optimal mode of drying of raw materials.

The content of biologically active substances obtained from raw materials and dried products is given in Table 1.

| Raw materials and products | Moist % | Acidity by potentiometric titration method % | Ash % | Total nitrogen % (NX6.25) | Pectinic substances % | Anthocyanins in m/kg | ||

|---|---|---|---|---|---|---|---|---|

| General | Soluble pectin | Protopectin | ||||||

| Blueberry-crude | 83.8 | 1.3 | 0.234 | 0.560 | 0.29 | 0.20 | 0.09 | 400 mg/kg |

| Blueberry-dried | 18.4 | 1.2 | 0.201 | 0.551 | 0.21 | 0.19 | 0.08 | 430 mg/kg |

Table 1: Content of some biologically active substances in raw and dried blueberries.

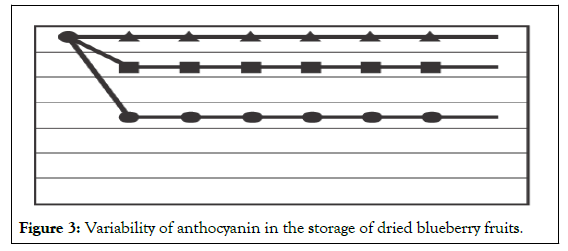

The content of anthocyanins in blueberry fruits was also studied. Figure 3 shows the time period on the abscess axis (June, July, August) when the blueberries are dried. The ordinate axis shows the content of anthocyanins when drying the fruit.

Within 8 months of receiving the dried fruit products, monthly controls determined that they did not change as organoleptic indices: Color, taste and aroma, they also retain the content of anthocyanin as much as possible.

Figure 3: Variability of anthocyanin in the storage of dried blueberry fruits.

The optimum period for sampling blueberries was determined by the technical maturity which fully coincides with the consumer maturity period. Samples taken from the territory of Gvara and Tsetskhlauri were dried at the zefira-max device. Optimal regimes of drying have been established. Eight months after the shock freezing of blueberry fruits on a monthly basis, it was established that organoleptic parameters did not change, such as color, taste and aroma, as well as the quantitative and qualitative composition of the fruits do not change. The obtained studies provide the basis for the start of industrial processing in humid subtropics of western Georgia.

Citation: Gaprindashvili I, Asanidze N, Ardemenashvili T (2023) Investigation of Technological Parameters of Drying Blue Blueberries Introduced in Gvara-Khutsubani Vine and Orchard Nursery. J Nutr Food Sci. 13:893.

Received: 08-Oct-2019, Manuscript No. JNFS-19-2440; Editor assigned: 11-Oct-2019, Pre QC No. JNFS-19-2440(PQ); Reviewed: 25-Oct-2019, QC No. JNFS-19-2440; Revised: 02-Jan-2023, Manuscript No. JNFS-19-2440(R); Published: 30-Jan-2023 , DOI: 10.35248/2155-9600.22.13.893

Copyright: © 2023 Gaprindashvili I, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.