International Journal of Advancements in Technology

Open Access

ISSN: 0976-4860

ISSN: 0976-4860

Research Article - (2017) Volume 8, Issue 3

In this study, the effect of Guar gum in three concentrations of 0.5, 0.75, and 1 gram per each kilogram of skim milk, containing 0.4% fat in producing Iranian white cheese was investigated. Control cheeses were prepared in two forms, that one of them was full fat cheese, made up from milk that containing 3.2% of fat and complete milk without Guar gum, and the other one was reduced fat cheese (containing 0.4%), without adding any gum. Results showed that chemical, textural, and rheological features of Iranian white cheese improved by increasing Guar gum's concentration up to 0.75 g. In present study, full fat control cheese had the least textural and rheological features extent of G′, G″, G*, σ and E that texture was soft and desirable. Produced cheese with 0.75 g of Guar gum was close to full fat control cheese. However, by increasing Guar gum's concentration to 1 g, these indices showed increment, and were close to reduced fat control cheese. Reduced fat control cheese had the most of G′, G″, G*, σ, and E indicating its hard texture and so undesirability. It can be concluded that Guar gum can be used as a fat replacer to decline energy-producing feature and its texture improvement as well.

<Keywords: Low fat cheese, Rheology, Texture, Guar gum, Iranian white cheese

Iranian white cheese, is the major part of Iranian breakfast, it is also used considerably. Meanwhile, many studies have been done to decrease fat in Iranian White Cheese; fat decline has bad effects such as texture hardness and its undesirability. Certainly, producing low fat cheese, having suitable texture features, can help in decreasing coronary heart diseases and improvement of social health. Scientific researches show that there is a relationship between much consumption of fat and various diseases. Nowadays, there are many attempts to decrease fat content of foodstuffs.

Studies show that whenever cheese fat content decrease, its humidity increases and protein plays much more role in cheese texture and structure. These events make alternations in sensory, functional, microbial, and chemical features of cheese. In micro structures of low fat cheese, protein makes major part of it [1]. Texture defects like rubberiest and hardness appear [2]. Since fat acts as a major lubricant in cheese texture and when it decreases much more protein part is there in volume unit for deformation, due to stress occurring during chewing. To improving reduced fat cheese taste and texture, the common methods are Modification of common technologies of cheese production, using fat replacers, and Choosing suitable starter culture [3,4].

Various studies have been done to improve cheese texture. Functional properties of modified starches of tapioca, and lecithin in low fat feta cheese have been surveyed [5]. Results showed that cheese produced with decreased fat, prepared with tapioca starch, had highest moisture and lowest protein and were harder, too. A mixture of starch and lecithin improved taste, texture, and general acceptance of low fat feta cheese and reduced fat cheese.

A combination of micro crystalized cellulose with carrageenan and dry milk without fat was used for making cheddar cheese with 11% of fat [6]. Cheese structure was softened by interference of interaction of casein – casein by carrageenan and micro crystalized cellulose particles, similarly plays fat globule role in clotted matrix.

The effect Xanthan gum on texture and rheological of Iranian white cheese was investigated by Ghanbari Shendi and his co-workers [7]. They reported that texture and rheological features of Iranian white cheese improved by using Xanthan gum.

The present study identified the effects of various concentrations of Guar gum as a fat replacer on rheological, textural properties and chemical features of Iranian white cheese after 60 days of ripening period in brine.

Treatments, cultures, rennet and Guar gum

To study the effects of Guar gum on Iranian white cheese, five treatments were prepared, that from now on they are recorded in this article in encoded way. All treatments were prepared three repeats: full fat control cheese produced with complete milk = FFC, Reduced fat control cheese or control cheese with decreased fat = RFC, reduced fat cheese with 0.5 g of Guar gum per each kilogram of producing milk (skim milk with 0.04% fat) = G1, reduced fat cheese with 0.75 g of Guar gum per each kilogram of producing milk (skim milk with 0.04% fat) = G2, reduced fat cheese with 1 g of Guar gum per each kilogram of producing milk (skim milk with 0.04% fat) = G3. Cheese batches were manufactured by 7 kg of standardized milk for each treatment. Consumed starter culture was FRC – 65, it was dairy culture of Hansen Co. Denmark. FRC – 65 included lactococcus lactis sub spp cremoris sub spp lactic, streptococcus thermophillus and lactobacillus delbrueckii sub spp bulgaricus. Chymosin derived by fermentation of Aspergillus niger Var. awamori (CHY – Max standard rennet, Hansen Dairy Co., Denmark), was used as a clotter with 0.025 concentration per one kilogram of milk. Consumed rennet was diluted 30 fold with cold water, and then added to each 7 kg batch of milk. Guar gum was a product from SIGMA-ALDRICH (Germany 1 kg). Guar gum did not used in producing full fat cheese as a control group, and reduced fat control was lack of gum and included 0.4% fat.

Cheese making procedure

Raw skim milk, including 0.4% of fat, was used for producing fat free cheese. At first 6 kg of milk from each treatment was pasteurized in a continuous way in 75°C for 15 s inside a pasteurizator. Rest of the milk (1 kg) was warmed to 35°C and different concentrations of Guar gum were solved in it by a mixer and then were pasteurized by continuous pasteurization in a similar way. Then both parts of the milk were mixed together [7] and were poured in to production vat (MKII, Armfeild Ltd., Ringwood, Hampshire, UK, model FT20). To mix these two parts uniformly and completely, it was let to stir the milk calmly for 20 min. During this time milk's temperature was 34°C, while 0.15 g of CaC for each kilogram of milk was added and starter culture with 0.04 g concentration was inoculated to each kilogram of milk and kept at this temperature for 55 min to have enough opportunity for starter's activity before the addition of rennet. Then the rennet, to the mentioned concentration, was added for 45 min to form clotting. The clotting’s next, were cut in to 1 cm cubes and kept release for 10 min, then with a gradual tone the cubes were stirred for 10 min to quicken cheese draining from them. After depletion of whey, the clotting’s were poured in to press especial molds and were pressed for 2.5 h. Press pressure was increased little by little during first 1.5 h and reached to 2.9 kpa, then it was kept until end of pressing.

In next stage, pressed clotting’s were cut into 6 cm × 6 cm × 4 cm pieces and were kept in 23-25°C for 2 h. Then they were put in airtight plastic containers and their surfaces were covered with 13% of brine. It should be mentioned that this brine, before application was pasteurized in 80°C for 10 min and after rapid cooling through passing a clean cloth, it was purified and adjusted to pH 4.45 by addition 99% Lactic Acid. Then the containers were potted and kept in 5-6°C until doing the related experiments. Full fat cheese was produced from milk including 3.2% of fat and in the same way as fat free cheese was produced, al bite without adding any gum. All experiments were done after 60 days of ripening period.

Chemical experiments

Milk and cheese samples’ pH was determined by digital pH meter (microprocessor pH meter model pH 537, WTW, weilheim, Germany). Cheese was analyzed for moisture content by vacuum oven (AOAC, 1997, method number 926.08). The fat content of milk and cheese samples was determined by the Gerber method and their total protein contents were determined by measuring total nitrogen using the kjeldahl method (AOAC, 1997, method number 920.123), and converting it to protein content by multiplying by 6.38 [7]. Total solid of milk were determined by drying 5 g of the sample at 100°C in an oven for at least 4 h. Milk features like protein content, fat, density, SNF and others were identified by milk analyzer machine (Eko Milk).

Measuring soluble nitrogen (SN) and nitrogen solved in three chloride acetic acid (NPN) was performed by Kochero and fox (1982) method [1]. Titrable acidity was measured on the basis of lactic acid (W/W) (A.O.A.C (1997)). All chemical measurements were repeated at least three times.

Rheological experiments

Uniaxial compression: Uniaxial compression, the simplest fundamental test, was done by the universal Experiment Machine HTE (Hounsfield test, UK S-Series Bench UTM model H 5k-S, Red hill, Equipment Ltd).

This machine was equipped with load cell of 500 N. To do the experiment, a flat piston with 49 mm diameter was connected to machine's forwarding front. Cheese pieces were cut into cylinders of 25 mm diameter and 10 mm height in 6°C. To prevent losing their moisture quickly, they were put in airtight containers and potted.

Cheese samples were selected from depth of at samples have temperature equal with room temperature, they were kept in room at least 4 hours before testing. The samples were pressed in uniaxial way with forwarding front speed of 50 to 57% of the sample's primary height in a munch. Rupture stress was calculated from dividing recorded force in rupture point of deformation cure into sample`s primary surface [8] and young (elastic) modulus as secant modulus in rupture point [8].

Dynamic rheological measurement: Small amplitude oscillatory shear measurements were performed with a Universal Dynamic spectrometer, Paar physica UDS 200 rheometer (physica Messtechnik GmbH, Stuttgart, Germany). The measuring geometry consisted of 2 parallel plates with a diameter of 25 mm and 1 mm gap size (sample thickness). Samples were cut at least 1cm deep into the cheese blocks at 6°C. These samples were immediately placed in small airtight plastic containers and equilibrated at room temperature (22 ± 1°C) for at least 4 h.

Excessive cheese was trimmed of carefully with a razor blade, and the sample allowed resting for 20 min on the rheometer to allow stresses induced during sample handling to relax. Frequency was set at 0.1 Hz and amplitude was varied between 0.1 to 10% resulting in a strain sweep test [1]. Calculated parameters were: G' (Storage modulus), G" (Loss modulus), G* (complex modulus), It is relationship between G' & G" [8]. In this study, these three parameters have been reported.

Color analysis

(L,a,b values) were determined by spectrophotmeter (Minolta, CM- 3600d, Japan). The maximum for L is 100, which would be a perfect reflecting diffuser. The minimum measuring for L would be zero, which would be black. The a and b have no specific numerical limits. Positive a is red and negative a is green. Positive b is yellow and negative b is blue.

Sensory evaluation: Cheese samples, encoded randomly, were evaluated by a group of acceptance sensory. Acceptance group's panels included 40 individuals in age range of 20-45, 25 males and 15 females. Before testing, they were asked to full fill a questionnaire including questions on sex, age, and times of consuming cheese (non-consuming in one month, less than one time in a month, 2-4 times in a month, 5-6 times in a month, and more than 6 times in a month). Those panels in which cheese consumption was 2-4 times in a month or less than that were put aside from data analysis.

Cheese in terms of appearance, texture, taste and general acceptance were evaluated according to hedonic scale of 5 scores (1 = the most undesirable, 5= the most desirable). Cheese pieces were cut into pieces with standard dimensions for biting (1 cm× 1 cm × 1.3 cm) and were put into airtight plastic containers for 2 hours before evaluation to reach heat balance of room. Panels used water to wash their mouth between samples treatments. Sensory evaluation was done after 60 days of ripening period.

Statistical analysis was performed by SPSS 17 (SPSS Inc.Chicago, IL) statistical software and using One-way Anova method. Differences among all groups were determined by Duncan test. All analyses were performed at least triplet.

Abbreviation

In present research these abbreviation words and codes were used for describing of treatments and results:

M: P Ratio of moisture to protein,

SN: Soluble nitrogen,

NPN=Non protein nitrogen,

TN: Total nitrogen

FFC: Full fat control cheese produced with complete milk that containing 3.2% fat without gum,

RFC: Reduced fat control cheese that was made up of skim milk, having 0.4% of fat without adding any gum,

G1: Reduced fat cheese with 0.5 gram Guar gum per each kilogram of producing milk (skim milk with 0.04% fat),

G2: Reduced fat cheese with 0.75 gram Guar gum per each kilogram of producing milk (skim milk with 0.04% fat),

G3: Reduced fat cheese with 1 gram Guar gum per each kilogram of producing milk (skim milk with 0.04% fat).

G′: Storage modulus

G″: Loss modulus

G*: Complex modulus

σ : Stress in rupture point

E: Elastic modulus or young modulus

Chemical combination and features

Chemical combination and features of milk, used to produce various treatments of milk and chemical features of produced cheese are shown in Tables 1-3.

| Milk type | |||

|---|---|---|---|

| Low fat | Full fat | ||

| Fat percent (%) | 0.40 b | 3.2 a | |

| Moisture (%) | 91.51 a | 89.2 b | |

| Protein (g) | 6.91 a | 6.15 b | |

| pH | 6.48 a | 6.50 a | |

Note: * Means, having different superscript, showed significant statistical difference (P<0.05) with one another

Table 1: Properties of consumed milk for producing cheese.

| Protein | Fat | Moisture | ||||

|---|---|---|---|---|---|---|

| M:P | Protein Recycling Percent | Fat Recycling Percent | (g) | (%) | (%) | Cheese Variety |

| 6.00 b | 1.82d | 4.33c | 11.23d | 13.86a | 67.43d | FFC |

| 5.12c | 1.97b | 11.25a | 13.61b | 4.50b | 69.65c | RFC |

| 6.10b | 1.71c | 1.25e | 11.83c | 0.50e | 72.20b | G1 |

| 7.83a | 1.38e | 2.25d | 9.54e | 0.90d | 74.73a | G2 |

| 3.65d | 2.63a | 7.20b | 18.20a | 2.88c | 66.45e | G3 |

Note: * Means, having different superscript, showed significant statistical difference (P<0.05) with one another

Table 2: Measured parameters in different treatments of cheese.

| NPN/TN | SN/TN | Acidity in basis of Lactic acid (%) | pH | Output (%) | Cheese Variety |

|---|---|---|---|---|---|

| 2.95e | 3.17e | 0.40d | 5.80a | 17.25c | FFC |

| 9.55a | 14.76c | 0.45b | 4.98c | 13.30e | RFC |

| 5.11c | 34.54b | 0.47ab | 5.50b | 15.32d | G1 |

| 5.85b | 36.88a | 0.49a | 4.89c | 17.42b | G2 |

| 4.12d | 11.21d | 0.34e | 5.49b | 18.12a | G3 |

Note: * Means, having different superscript, showed significant statistical difference (P<0.05) with one another

Table 3: Measured parameters in different treatment of cheese.

According to the Table 1 results, when fat content declines, moisture and protein of milk increasing considerably. But there was no difference in pH degrees of milks. This finding confirms other researchers.

Cheese with reduced fat had much more protein and moisture than full fat cheese. Difference between moisture rate of full fat and low fat cheese was probably due to difference in their proteins, so that high content of protein in cheese with reduced fat may be together with water absorption increase in protein matrix [7] and as a result lead to moisture increase in them. In casein matrix of cheese texture, fat and moisture perform as full fillers [4].

Whenever fat content decreases, moisture cannot be replaced with the same amount of lost fat; therefore, general volume of full filler decreases, declines moisture in ratio of moisture to protein. When Guar gum concentrates to G2 level, protein part per cent decreases, but when its concentration goes up to G3 level, the state is converted vice versa, i.e., protein part per cent increases, indicating less proteolysis, also ratio of moisture to protein in G3 decreases, too. This event may be related to especial structure of Guar gum that in high concentrations leads to bounding of water; also, it results in viscosity increases.

Therefore, ratio of moisture to protein, as an important factor in producing cheese, in cheese produced with Guar gum has been increased in level G1 and G2, but, by increasing to level G3, this rate is declined. By producing low fat cheese, as it was mentioned, ratio of moisture to protein declines; hence, cheese texture gets rough and undesirable [1]. This issue happens in G3 too. Therefore, to improve cheese texture features with decreased fat, the goal is to increase ratio of moisture to protein [7]. In this study, when Guar gum's concentration increased to level G2 (0.75 gr) and when moisture content increased and protein per cent declined, we got this goal.

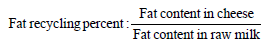

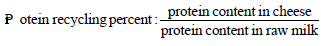

By increasing concentration of Guar gum in levels G1 and G2, the content of soluble nitrogen (SN) and non-protein nitrogen (NPN/ TN) increased, but, this value decreased in level G3 showing rigidity of cheese texture due to moisture decrease and ratio of moisture to protein, too. By increasing Guar gum's concentration, cheese fat contents showed increasing trend, this event was seen in levels G1 and G2, but a considerable increase in level G3 (1 gram Guar gum). Fat and protein recycling were affected dramatically from fat content. In this study, when fat content between full fat cheese and the one with reduced fat declines, fat recycling increased considerably.

Protein recycling per cent showed increase as well, but with a rate less that fat recycling. By increasing of Guar gum concentration, fat recycling per cent increased, but protein recycling per cent decreased up to level G3 and then in level G3 showed an increase. Fat content decrease caused pH decline and acidity increasing between two samples of full fat control cheese and reduced fat control cheese. When Guar gum concentrates to level G3, pH decline and acidity increasing were observed but in level G3, the opposite case is true. The main reason of pH decrease in level G1 and G2 is due to lipolysis and complete conversion of lactose into lactic acid. Decreasing fat content of milk leads to cheese producing output goes down very much. During cheese production, milk fat is trapped in casein field [4].

Although moisture is replaced with fat content in milk [1], Total output decline (one kilogram of cheese per one Kilogram of milk) in cheese production from low fat milk is unavoidable [7], since the extent of added moisture would not be equal with decreased fat amount [9,10].

Therefore, fat and casein of milk, as major compositions determining output, decrease. Among produced cheese with decreased fat, Guar gum's amounts addition, was made increase in cheese production output, as much more water remains in cheese because this gum likes to absorb water.

Rheological analysis

Uniaxial compression: Uniaxial compression parameters of cheese samples after ripening period are shown in Table 4. To understand texture features of cheese samples two parameters, stress in rupture point and young (elastic) modulus of cheese were evaluated. Stress in rupture point has direct relationship with cheese hardness [11], that is, the more stress in rupture point, the more hardness and vice versa. Elastic modulus or elasticity is for showing the relationship between stress and strain of foodstuffs [12], likewise stress in rupture point, the more elastic modulus, the more hardness, the cheese texture has. In this study, FFC had the least stress in rupture point and the least elastic modulus (E), showing its soft and desirable texture, while RFC had the most stress in rupture point and the most elastic modulus (E) or young modulus, indicating its hard and undesirable texture. When Guar gum’s concentration increases to level G2, elastic or young modulus and stress in rupture point decreased, then in level G3 it showed considerable increasing. This fact showed that its high concentrations made texture hard.

| E (kPa) | (kPa)σ | Cheese Variety |

|---|---|---|

| 15.03e | 8.12e | FFC |

| 177.02a | 58.39a | RFC |

| 75.31c | 37.04c | G1 |

| 55. 67d | 26.06d | G2 |

| 100.68b | 50.24b | G3 |

Note: * Means, having different superscript, showed significant statistical difference (P<0.05) with one another

Table 4: Means of uniaxial compression for Iranian white cheese treated by Guar gum (in basis of kPa).

Increasing gum’s concentration to level G2 and decreasing pH turn cacl into a solution. When calcium extent, connected to casein micelles, decreases, rejecting forces between caseins increase [1,7] and result in weakening structural bonds of cheese. This event can be a reason for stress decline in cheese rupture point and as a result in its softness until level G2. Guar gum’s concentration increasing until level G3, was made cheese hard texture, it was because of viscosity increase due to this gum’s performance in high concentration and increase of structural bonds.

Dynamic rheological measurement: Lower level of storage modulus (G'), like stress, has a relationship with Iranian white cheese hardness [7]. The more G', G", and G*, the more hardness and undesirability of texture (Table 5). Fat decrease in studied cheese, increased G', G", and G* considerably, surely due to moisture part share. Decreasing of moisture to protein ratio in reduced fat control cheese made the product be semisolid, but because of Guar gum concentration increase to level G2, G', G", and G* decreased and were near to full fat cheese, as a result of moisture content increase and cheese softness. However, G3 had high value of G', G", and G*, indicating G3 cheese texture’s hardness.

| G* | G" | G' | Cheese Variety |

|---|---|---|---|

| 30.73d | 10.65e | 28.28d | FFC |

| 308.79b | 112.25c | 285.70b | RFC |

| 290.15b | 137.08b | 257.02bc | G1 |

| 197.50c | 71.69d | 184.75c | G2 |

| 930. 07a | 269.25a | 892.11a | G2 |

Note: * Means, having different superscript, showed significant statistical difference (P<0.05) with one another

Table 5: Amounts of G' G" G*from rheometer machine (in basis of kPa).

It must be said that since the ratio of remained rennet to casein in cheese with high moisture content is much more than cheese with low moisture content [13], their softness is much too.

Color evaluation

In Table 6 results of color evaluation of different cheese treatments during ripening are shown. The scattering of light by any system is related to its heterogeneity at the molecular [7] and microstructural levels [1].

| L-Value | b-Value | Cheese variety |

|---|---|---|

| 21.84d | 2.05b | FFC |

| 22.57a | 1.51e | RFC |

| 22.12b | 1.77d | G1 |

| 21.85c | 1.85c | G2 |

| 20.84e | 2.14a | G3 |

Note: * Means, having different superscript, showed significant statistical difference (P<0.05) with one another

Table 6: Amounts of b-Value and L-Value in different treatments of cheese.

In a solid material such as cheese, light penetrates the superficial layers and is scattered mainly at the interfaces of milk fat globules [8], and the edges of whey pockets [1,7]. L–Value and b–Value were two criteria of color evaluation, indicating whiteness and yellowness of cheese respectively [14]. In a comparison made between full fat control cheese and reduced fat control cheese, it was cleared that full fat cheese had more yellowness and less whiteness.

In addition, when Guar gum concentrates, b–Value goes up and L-Value comes down; therefore, cheese treated with Guar gum have more yellowness and are similar to full fat control ones in terms of color.

The reason of this event is changes made in microstructure of cheese and as a result its density during ripening that lead to decrease of surface regions that distribute light. Perhaps protein’s hydration and as a result free water drops decline; also can decrease light distribution and cheese whiteness. Generally, when un-extractable serum amount is high and casein concentration, soluble in serum phase, goes up, L– Value of cheese declines.

Sensory evaluation: Table 7 shows results of sensory evaluation. We observed whatever we expected. Full fat cheese had the highest privileges in any terms. Fat content decline had strong effects on texture, taste, and general acceptance of Iranian white cheese. RFC had the least privileges in any terms. Among cheese treated with Guar gum, G2 had the highest privileges in terms of appearance. In terms of texture; also, G2 and in general acceptance view G1 had the most privileges. Softness and good whiteness let G2 to have highest privileges in appearance and texture view.

| General acceptance | Taste | Texture | Appearance | Cheese variety |

|---|---|---|---|---|

| 4.95a | 4.71a | 4.72a | 3.82a | FFC |

| 1.12e | 1.05d | 1.85c | 2.10d | RFC |

| 3.92b | 2.75b | 2.95b | 2.95bc | G1 |

| 3.19c | 2.11c | 3.51b | 3.28b | G2 |

| 2.22d | 1.31d | 2.02c | 2.37c | G3 |

Note: * Means, having different superscript, showed significant statistical difference (P<0.05) with one another

Table 7: Results of sensory evaluation.

This study showed that Guar gum can be used as fat replacer for decreasing of energy content of Iranian White Cheese, and improving of textural and rheological properties of it, up to 0.75 g per each kilogram of skim milk. Using Guar gum was helped to increase desirability of produced cheeses. It can be concluded that using fat replacer in certain amount, led to texture improve and digestibility of Iranian Low Fat White Cheese.

Nowadays, there are many attempts for decreasing of cheese fat content in the world, but most of them have many side effects on cheese texture and health problems. Using Guar gum can reduce fat content of Iranian White Cheese without side effects. It means that production of low fat cheese will decrease heart coronary diseases. So, results of this study can be used in dairy factories for health properties improving.