Journal of Thermodynamics & Catalysis

Open Access

ISSN: 2157-7544

+44 1300 500008

ISSN: 2157-7544

+44 1300 500008

Research Article - (2017) Volume 8, Issue 1

The effect of external resistance on voltage, current, power, power density and current density is investigated in a microbial fuel cells using cowdung is investigated. This involves use of varying resistance resistors. The fuel cells were operated under anaerobic condition for 9 days. PVC pipe was used to make a salt bridge using lamp wicks and potassium chloride. The obtained results indicated that the maximum voltage was on day 7 with 0.153 V across 33 kΩ resistor. The power was in the range of 0.000001 to 0.01 mW, current density was in the 0.1 to 23.29 mA/m2 range while the power density was in 7.5 × 10-7 to 3.1036 mW/m2 range.

Keywords: Microbial fuel cells; External resistors; Power; Power density

Moon et al. [1] defines Microbial fuel cells (MFCs) as electrochemical bioreactors which converts chemical energy to electricity through biocatalysis of microbes. In a MFC, organic matter is oxidized at an anode by biological process where microorganisms deliver the electrons to the anodic electrode. These electrons flow through an external load and are released at the cathode where they are consumed to reduce an oxidant agent, usually oxygen. This biological system has the potential to oxidize a large variety of organic compounds producing at the same time electricity [2,3]. In literature the electricity generation using MFCs has been studied using pure organic compounds, such as acetate, butyrate, and glucose, sewage sludge and petroleum hydrocarbon [4-9]. The main advantage of electrogenic microorganisms is their ability to oxidize wastes with simultaneous energy generation [7].

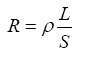

The electrical resistance of an object is a measure of its opposition to the passage of a steady electric current. For a uniform material of electrical resistivity ρ (Ωm) surface S (m2) and distance L (m) it is given by the following equation:

(1)

(1)

Typical values of the electrical resistivity ρ for common materials at 20°C range from 1.59 × 10-8 Ω m for silver to 7.5 × 1017 Ω m for quartz and even more for engineered materials like polytetrafluoroethylene (PTFE). A Fuel Cell is not meant to have an electric current passing through it but to produce one. Its electrical resistance is not defined. Nevertheless internal resistance is a concept that helps to model the electrical consequences of the processes happening inside it.

Internal resistance of an MFC

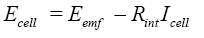

When a cell delivers a current, the measured voltage output is lower than when there is no current delivered. This is because when electrons flow, they have to face the resistivity of the materials composing the fuel cell. The internal resistance of an MFC can be distributed into anodic resistance, cathodic resistance, and electrolyte (including the membrane if present) resistance [10,11]. In an MFC system, where electrochemical reactions are under proton diffusion control we will see that the electrolyte resistance can be assimilated to the Warburg impedance [12]. since it requires a current to be observed, the internal resistance of a battery cannot be measured using a conventional ohmmeter. Other ways have to be used to determine it. According to

(2)

(2)

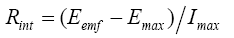

The slope of the linear section of the polarization curve represents the internal resistance of an MFC. MFC generates its maximum power (Pmax, W) when Rint=Rext [13], where Rint can be determined as:

(3)

(3)

Where Emax (V) and Imax (A) are the cell voltage and current that give the maximum power.

At the same time, following Ohm’s law

(4)

(4)

Hence, when Rint=Rext,

(5)

(5)

A schematic representation of MFC is shown in Figure 1.

A double chamber MFC was fabricated using inexpensive materials. They include 16.3 cm to 15.3 cm diameter and 7.4 cm to 9.4 cm long plastic containers, PVC pipes, adhesive glue, scissors, wicks, driller, masking tape and pipes joiners. The following materials were also used copper wires, graphite rod electrodes, 1 Ω-33 kΩ resistors, and digital multi-meters. The substrate used in this work is fresh cow dung with sucrose as bacteria food.

MFC construction

Two 1.2 L containers were prepared as an anode chamber and a cathode chamber. Two small holes were made in the caps of the bottles as to insert wire through. One end of the copper wire was attached to 5.7 cm long and 0.7 cm diameter graphite rod electrodes. The anode chamber was filled with the substrate (0.1 kg of cow dung mixed with 1 L of water) while the cathode chamber was filled with plain water of 1 L. Other two ends of wires were attached to digital multimeter for open circuit voltages and different 1 to 33 kΩ resistors.

Salt bridge

Salt bridge was prepared using 1.5 liter of 1M KCl solution and lamp wicks. The wicks were boiled in the KCl solution for 10 minutes after which it was kept in the freezer at -4°C for solidification. The solidified salt bridge was passed through PVC pipes and attached to the chambers using araldite adhesive which makes them leak proof.

Circuit assembly

The assembly of the H-shaped MFC was done as shown in Figure 2.

Figure 2: Set-up of H-shaped microbial fuel cells.

Experimental variations

To characterize voltage, current, power, current and power density across different resistors, 600 ml of cow-dung was added to the anodic chamber and 25 ml of sugar solution added via a pipette. 1 Ω, 1 kΩ, 2 kΩ, 3.3 kΩ, 5.1 kΩ, 10 kΩ, 15 kΩ, 20 kΩ, 33 kΩ resistors were attached to the terminals from cathodic and anodic chamber. The amount of voltage and current from the cells were recorded daily for 9 days across the attached resistors.

Data collection and observation

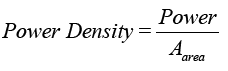

The generated voltage and current was recorded from the digital multimeter at an interval of 24 hour for 9 days. The corresponding power, current density and power density was calculated by using formula

(6)

(6)

(7)

(7)

(8)

(8)

Some resistance must be overcome if MFC technology is to be used in highly powered devices. In the current study resistors of varying resistances were used. The current and voltage across these resistors were monitored using a digital voltmeter. The obtained results are shown in Figure 3. From the graph, the maximum voltage was on day 7 with 0.153 V across 33 kΩ resistor. The power was in the range of 0.000001 to 0.01 mW, current density was in the 0.1 to 23.29 mA/m2 range while the power density was in 0.1 to 3.26 mW/m2 range. They were all dependent on the resistors resistance as shown in Figure 4. The high values across 33 kΩ are attributed to the high amount of work to be done to overcome the high resistance.

Previous studies by Menicucci et al. [14] using 6 to 0.125 KΩ revealed that, the cell voltage decreases when external resistance decreases. This is explained by the limitations imposed on the electrode reaction kinetics, on mass transfer, and on charge-transfer processes at the current-limiting electrode. In another study, Ghangrekar and Shinde [15] observed that cell voltage increased with an increase in external resistance from 0 to 4,000 Ω; the maximum voltage of 358 mV was observed at an external resistance of 4,000 Ω. Later on, Rismani- Yazdi et al. [16] obtained similar cathode potentials at different external resistances. However, anode potential varied under different external resistance employed. MFCs with lower external resistances resulted in higher anode potentials. This was also observed in the study of Song et al. [17] carried out using a sediment microbial fuel cell (SMFC).

High electron transfer from the anodic to the cathodic chamber leads to high current. In this study, when the external resistance was increased from 1 kΩ to 15 kΩ, the current decreased from 0.0024 mA to 0.0020 mA in day 6. Similar trends were observed for other days as shown in Figure 3. This is in agreement with previous studies [16-20].

A stepwise descent in external resistance have been observed to improve current generation over a given time. For instance, Aelterman et al. [21] observed that decreasing the resistance from 50 to 10.5 Ω resulted in significant upward trend of current generation. They observed that operating a MFC at lower resistances, the mass transfer or kinetic limitations during polarization lowered resulted in less steep descent of current density. Similar to previous studies, Zhang et al. [22] observed that a conventional MFC with a lower external resistance showed a higher current generation after start-up. The study further observed that when operating at high external resistance that almost mimics an open circuit, microorganisms were unable to transfer their electrons to such an unfavorable electron acceptor. In this situation, the high external resistance restricts the current that is able to flow from anode to cathode, and this may affect which microorganisms are able to colonize the anode [23,24]. In the study of Ghangrekar and Shinde [15], it was demonstrated that when external resistance is very high, the current was brought to minimum and nearly constant value. Moreover, in this case, the limiting factor is the external resistance, and the current production is almost independent of another factor, such as the distance between the electrodes and surface of the anode.

The power resulting from use of 1 Ω for day 1 to 9 was in the range of 1.02 × 10-9 mW to 2.0 × 10-5 mW. Increasing the external resistance from 1 kΩ to 33 kΩ translated to power increment of 4.5 × 10-6 mW to 1.386 × 10-3 mW in day 1 as shown in Figures 3 and 5. Similar trend was witnessed in the other days. Earlier studies on influence of external resistance by Gonza´lez et al. [25] indicates that decreasing the external resistance from 2.7 kΩ to 2.2 kΩ result in power decrease from 1.69 × 10-3 mW to 1.27 × 10-3 mW. It was observed in this study that the power generated increased from 0.00002 mW to 0.003131 mW when the external resistance was varied from 1 Ω to 33 k Ω on day 6. A clear illustration of the observation is shown in Figure 5.

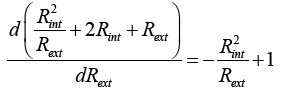

The potential of the cell adjusts to the external resistance. The maximum power transfer theorem states that maximum power is drawn when the external resistance (Rext) of electric power source equals internal resistance of power sources. This means that the power generated by MFC is highly dependent on the current.

(9)

(9)

And hence,

(10)

(10)

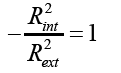

P is maximum when the denominator is minimum. Differentiating the denominator with respect to Rext,

(11)

(11)

For maximum or minimum, the first derivative is zero, so

Therefore, the power is maximum when Rext=Rint.

If external resistance is higher or lower than internal resistance, generated power will decrease. Many research have be carried out to investigate the applicability of maximum power transfer theorem [26-32]. Figure 4 shows the power density and the current density obtained in this work. It is clear from the figure that increasing the external resistance from 1 Ω to 33 kΩ resulted in power density increase of 23.2757 mW m-2 in day 6 with similar trend observed for the other days. The power density increases from day 1 through to 6 and then decreases. Similar observations were made by Lyon et al. [28], who observed that at an internal resistance of 300 Ω, high power production was obtained with an external resistance of 470 Ω, followed by 1,000 Ω, 100 Ω, 10 KΩ, and finally 10 Ω. External resistance of 10 Ω produced the weakest power production as the resistance was too low compared to the internal resistance (300 Ω). In other studies, Ren et al. [28], showed that higher power density values were observed when external resistances were changed from high to low (from 5,000 to 10 Ω) compared to low to high (from 10 to 5,000 Ω). In the study of Zhang et al. [22], the power obtained after start-up increased from 1.96 to 6.05 mW when external resistance increased from 10 to 50 Ω. Then, when external resistance increased from 50 to 1,000 Ω, the power decreased to 0.64 mW.

The theorem is not always true as observed by Ref. [17,33]. Song et al. [17] observed that power density increased with the increase in external resistance and the highest power density of 3.15 mW/m-2 was obtained at an external resistance of 1,000 Ω. However, the internal resistance varied between 132 and 214 Ω. This fluctuation could be explained because internal resistance is not a system constant and depends on the external resistance applied to the MFC. In the study of Lee et al. [33], MFC with highest external resistance had better power densities. In the current study, the same trend was also observed in some cases. For example, the highest power densities were recorded for 33 kΩ external resistor which ranged from 0.1142 to 3.103 mW/ m2. Figure 6 shows the relationship between the power density and the current density across different resistors. As shown Figure 6, the power density increases with increase in current density for the first 6 days, reaching maximum at day 6 or 7 then decrease to day 9. Similar trend was observed by Zhang [33] in 2011.

The external resistance directly influences on anode potential and current, and they influence on other variables in a MFC, such as microbial diversity, biofilm morphology, power generated, coulombic efficiency, and MFC stability among other variables. In this way, the selection of the optimal external resistance in order to get the best performance in the MFC is very important.