Journal of Biomedical Engineering and Medical Devices

Open Access

ISSN: 2475-7586

ISSN: 2475-7586

Research Article - (2021)Volume 6, Issue 3

Premature infants in the Neonatal Intensive Care Unit (NICU) are at risk for hearing impairment, cognitive development abnormalities, and intraventricular hemorrhaging due to high noise levels. Nearly 400,000 infants are admitted into the NICU in the United States each year, and this number continues to increase. Up to 10% of these preterm infants are diagnosed with hearing impairment in comparison to only .1% for the general pediatric population. Noises from the CPAP machine and other life-sustaining devices along with external human noise in the NICU, sound levels average around 62 dB and can reach up to 120 dB. However, the American Academy of Pediatrics recommends noise levels should be lower than 45 dB. Existing incubators on the market do not address this noise issue. The designed solution is to create an adjustable foam insert that can be fitted to any incubator and used for sound absorption. The foam would line the edges of the incubator to reduce resonance and allow for neonatologists still to have full vision of the inside of the incubator. Additionally, the design contains a bottom piece that perfectly fits a Z-flow device so that the infants can be positioned for maximum health. This design was modeled in Solidworks, and various geometries were tested to improve the design’s effectiveness. Two foams were tested, and a statistical t-test was used to determine which foam had better noise reduction. In comparison to having no foam present in the chamber, the noise level was reduced by over 15 dB. The combination of this foam along with a multi-channel Active Noise Control system would significantly reduce noise levels to below the acceptable limit. This system would consist of one reference microphone that picks up noise, two error microphones to sense residual noise, and two loudspeakers to generate the “anti-noise” signal. Ultimately, this foam insert was found to reduce noise levels so that they are under the recommended limit given by the American Academy of Pediatrics.

Neonatal Intensive Care Unit; Neonatologist; Z-flow device; t-test; Anti-noise

Due to high noise levels in Neonatal Intensive Care Units, premature infants are at a high risk for hearing impairment, brain bleeds, and even cognitive development issues. In comparison to only .1% of babies that do not enter the NICU, approximately 10% of premature infants are diagnosed with hearing impairments [1].

The development of human hearing begins in fetal life. Intrauterine noises are unique and stimulate the growth of the central nervous system. These acoustic stimuli are very different from that outside of the uterus, which can be harmful. Similarly, the intrauterine environment is essential to the development of other organs and bodily processes. Before birth, infants should be able to breathe air, self-regulate body temperature, excrete waste, and fight off infections with a functioning immune system. For premature infants, many of these necessary functions are not developed, and as a result, they will be regulated in incubators in the NICU.

These incubators in the NICU measure vitals and maintain the optimum levels for proper development, such as temperature and humidity. One major issue with this environment is noise. Between ventilation, breathing equipment, and human activities, noise in the NICU can reach dangerous levels, which may cause auditory damage for these preterm infants [2]. The vast array of equipment to maintain the infants’ vitals such as CPAPs, ventilators, pulse oximeters, and different monitoring devices additionally cause harm to these infants.

In the uterus, the sound intensity rarely exceeds 30 dB; however, noise levels in the NICU can reach up to 120 dB and an average of 62 dB [1]. As a result, hearing impairment is diagnosed in 2-10% of preterm infants in comparison to only 1% for the general population [1]. Furthermore, high noise levels cause neuropathic changes in the central nervous system, which may cause regional brain volume reduction, white matter microstructure abnormalities, and abnormal cognitive development and language skills [1]. Additionally, these noises may alter homeostasis and increase the sympathetic autonomic nervous system. This part of the nervous system is the “fight or flight” response and results in many physiological reactions. Activation of the sympathetic nervous system causes adrenal hormone secretion, disturbances in circadian rhythm, and apnea. When experiencing apnea, an infant will temporarily stop breathing, which will cause blood oxygen levels to fall. The result, hypoxemia, causes many developmental issues. Another major problem that can result from hypoxemia is intraventricular hemorrhaging (IVH). Premature infants are at high risk for IVH because their blood vessels are not fully developed. Erratic blood pressure increases this risk. IVH can range from mild cases where no real harm is done to severe cases that can cause learning disabilities [3]. IVH occurs in approximately 30% of preterm infants.

There needs to be something done to protect these premature infants. The American Academy of Pediatrics recommends noise levels should be lower than 45 dB. However, nothing on the market meets this requirement, and no incubator by itself fully addresses this issue. MiniMuffs are one of the most common solutions currently being used. These noise-attenuating earmuffs are not sufficient enough. MiniMuffs reduce sound levels by 7 dB and are too large for preterm infants born months before their due date.

One more promising technology that has been designed is an Active Noise Control system. The noise in a NICU incubator is classified as broadband noise because it covers a broad range of frequencies [2]. These different frequencies come from nebulizers, humidifiers, pumps, doctors speaking, and other medical devices discussed earlier. The ANC system is used to cancel this highpower broadband noise by using destructive interference [2]. The ANC system works by creating an “anti-noise” signal to cancel out the primary noise. This concept is the same for noise-canceling headphones. They produce a wave with the same amplitude and the opposite phase so that the waves cancel each other out. The issue with this is that in a small 3-dimensional space such as an incubator, the sound is coming from more than one direction and plane. To account for this, a multi-channel ANC system is used. This system uses one reference microphone that picks up primary noise, two error microphones that sense residual noise, and two loudspeakers to generate anti-noise [4]. The loudspeakers are placed next to the infant’s head so that there is no constructive interference near the ears.

Although the multi-channel ANC system sounds very promising, it doesn’t work well for higher frequency noises, such as human speaking. It does, however, work very well for low-frequency noises such as those produced by the medical devices used to maintain the infant’s vitals and incubator environment. The team believes that by using a foam design to reduce high-frequency noise along with an Active Noise Control System to reduce low-frequency noise, the noise levels experienced in a NICU incubator will be significantly reduced to under the acceptable limits.

In this study, passive noise reduction was employed into an incubator to test an adjustable foam insert design. Two different foam materials were tested and compared at low and high frequencies. After determining the optimal foam material, different geometries were tested for the highest noise reduction level in an infant incubator.

Materials

The two foams tested were the Flat-Faced Melamine Foam manufactured by Acoustical Surfaces Inc. and the Sound Silencer ARPRO Foam manufactured by Acoustical Surfaces Inc. Two iPhone X’s were used for frequency production and noise level recording. The apps used were the “Sonic Tone Generator app created by Von Bruno and Decibel: dB sound level meter. A fish tank (23.5in x 11.5in x 15.75in) was used to replicate the incubator enclosure.

Design

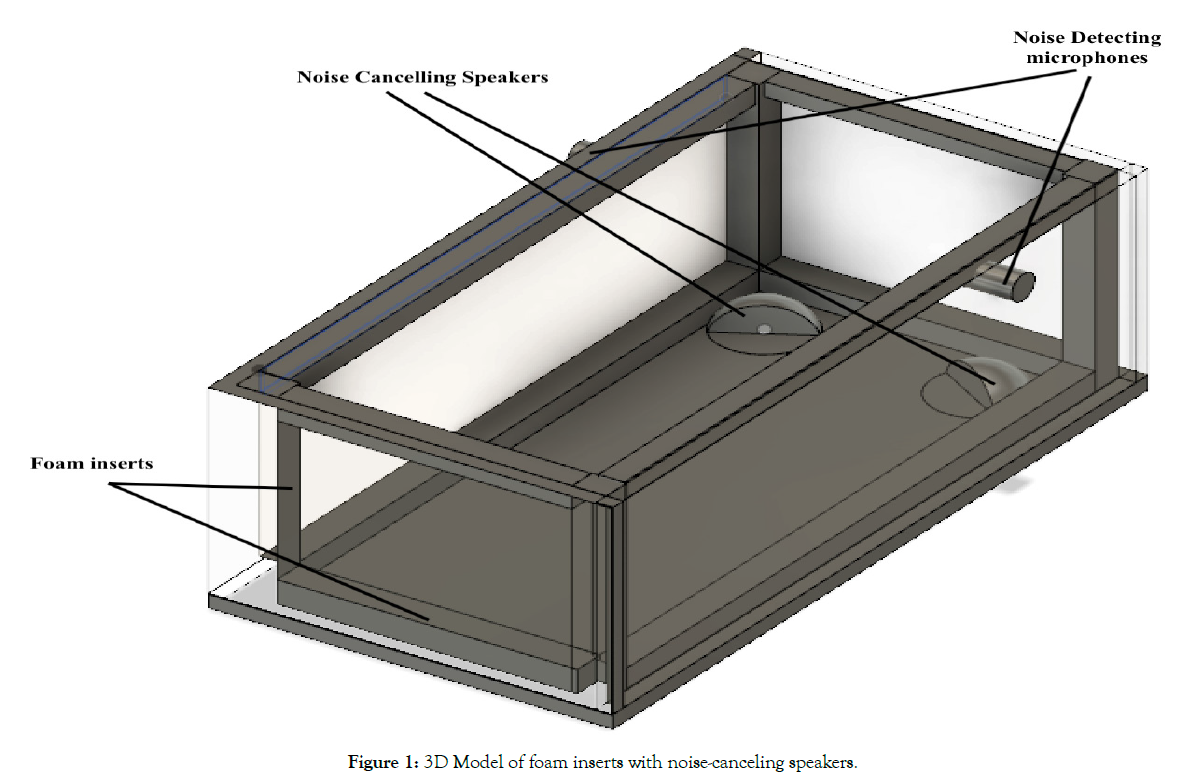

The premise behind the design was to develop an insert that can be utilized in various incubator brands. The design parameters included: adjustability to meet all incubator size demands, minimal materials that would interfere or obstruct view or equipment used, and noise reduction inside the incubator. In this particular study, the design was created with a base covered with foam that fit a Z-flow device. The Z-flow device is critical for positioning the infant which is essential for infant development. Additionally, the adjustable foam inserts lines at the edges of the incubator, as shown in Figure 1. This is important to avoid obstructing the view of physicians and nurses when monitoring the infant. Furthermore, the foam along the edges reduces resonance in the small contained space. The sound pressure is at a maximum when in a closed room at the edges [5]. Sound absorption works by trapping sound waves, and sound is absorbed best by porous materials with pockets of air, such as foam [6]. The other factors that determine the amount of sound absorption are the frequency and angle of incidence [6]. Foam is the most used and most effective sound absorber and, as a result, was chosen for this design.

Foam is effective for higher frequency noise, such as the human voice; ANC is better for low frequencies. Thus, the team created a design that would incorporate both of these. The ANC system would be a multichannel system with two loudspeakers placed on either side of the infant's head. The microphones would then be placed according to Figure 1 shown below. Our design was modeled in Solidworks, shown in Figure 1.

Figure 1: 3D Model of foam inserts with noise-canceling speakers.

Methods

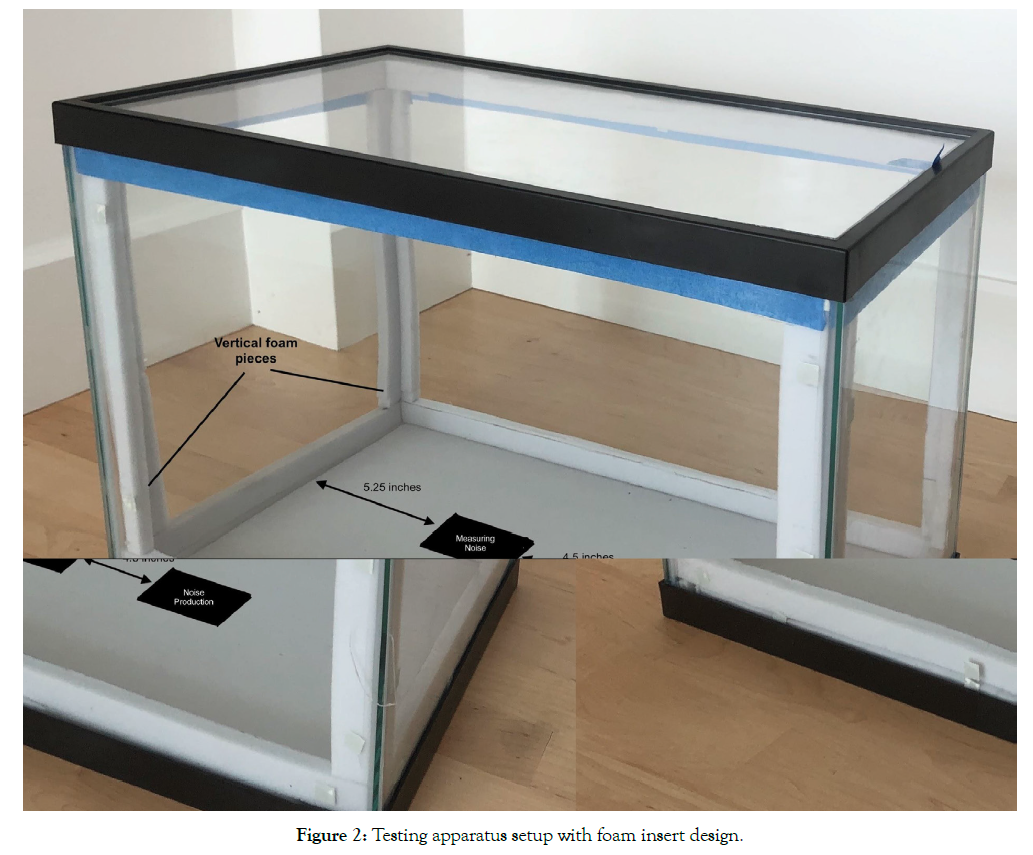

A fish tank was used to mimic the dimensions and environment of a NICU incubator. For the baseline testing, the sounds at high and low frequency were measured without any foam. Next, each foam material was placed in the tank to determine the performance of reducing noise. The type of foam that showed the greatest decrease in decibels was investigated further. The vertical foam pieces were replaced with two other geometries, all made from this type of foam, to determine whether another foam geometry could further decrease the noise level (Figure 2).

Figure 2: Testing apparatus setup with foam insert design.

Low-frequency test

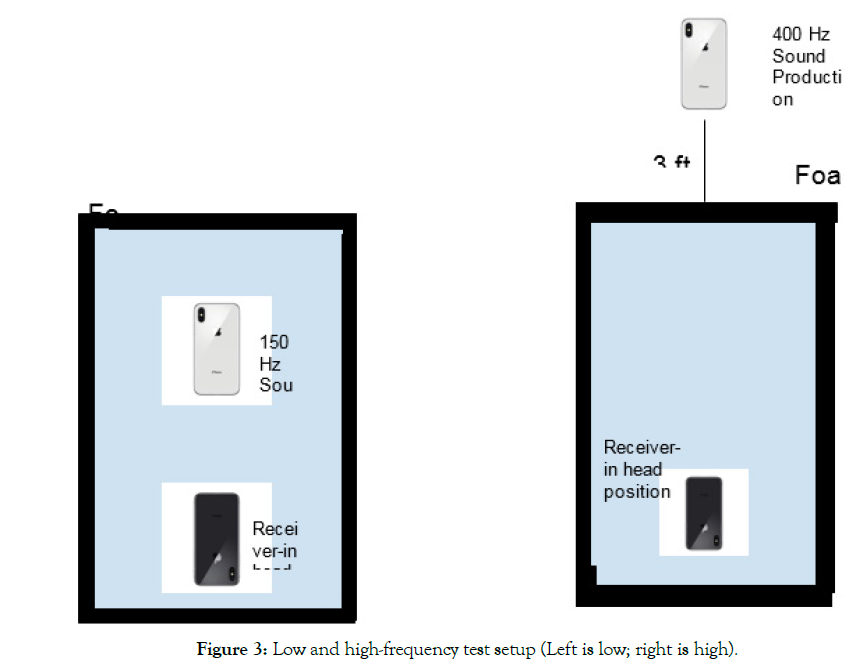

The noise source was placed inside the tank to play low-frequency audio at 150 Hz. This frequency replicates the noise produced inside a standard incubator from machines such as ventilators, infusion pumps, and other life-supporting devices [1]. The audio was played from a smartphone device, using the Sonic Tone Generator app. This sound producing phone was placed in the center of the incubator. The noise level inside the incubator was recorded using the “Decibel: dB sound level meter” phone application. This recording phone was placed in the position of the infant’s head in the incubator. First, without any type of sound-absorbing foam inserted in the incubator, the decibel levels inside the incubator were recorded while the low-frequency audio played. The same tests were repeated using the different foam inserts. The audio file was first played from the phone, pointing upwards, and the decibel levels were recorded. Four other noise-generating phone positions were tested, and noise levels were recorded. Each phone position was measured three times for each condition: without foam, with Melamine foam, and with ARPRO foam (Figure 3).

Figure 3: Low and high-frequency test setup (Left is low; right is high).

Geometry comparison test

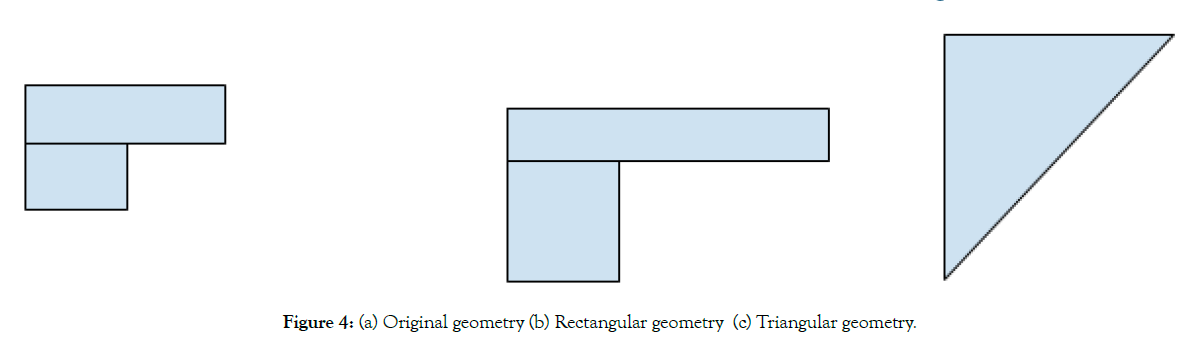

After determining which foam decreased the noise level in the incubator the most, the best foam geometry was determined. The different designs were similar except for the cross-section and size of the vertical foam pieces.

First, the phone position that showed the greatest decrease in noise level from the low and high-frequency test was determined. Thirty trials were conducted for this phone position using no foam and then again with the ARPRO foam.

The first modified cross-sectional geometry is similar to that used in the low and high-frequency test, except this alternate geometry uses foam inserts ½ inch longer. Thirty trials were done with this geometry using both the Test 1 and 2 setups (Figures 4a and 4b).

Figure 4: (a) Original geometry (b) Rectangular geometry (c) Triangular geometry.

Next, the triangular-shaped geometry is shown in Figure 4c, which created a smooth surface connecting the walls rather than a sharp 90-degree connection. The procedures from low and highfrequency tests were followed using both alternate foam geometries to compare resulting noise levels in the incubator. Thirty trials were performed with this geometry using both the low and highfrequency test setups. After collecting the data from all tests, t-tests were performed to determine which foam and geometry provided statistically significant decreases in noise level within the incubator. A p-value of .05 was used for determining significance, and 30 samples were used for each test.

The sound-absorbing foam inserts used in this experiment proved to decrease the sound level inside the enclosure significantly. The foam insert design is adjustable to fit multiple types of incubator brands. These foams were effective sound absorbers because they were able to trap sound in their porous cavities [6].

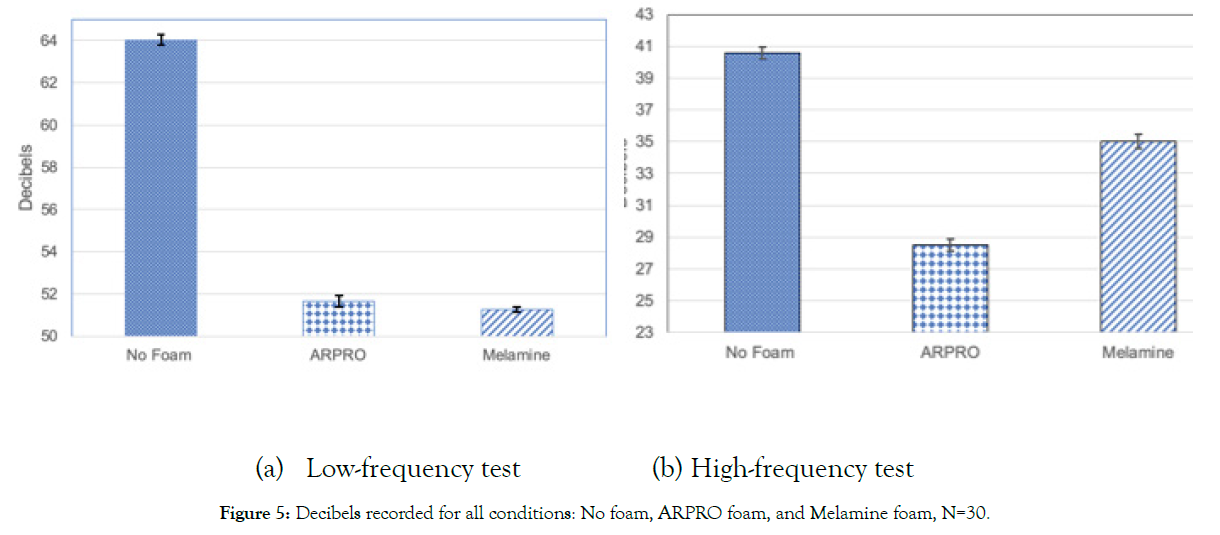

In the low-frequency sound tests, both the Melamine and ARPRO foam demonstrated equal amounts of sound absorption, as seen in Figures 5a and 5b. Compared to decibel recording inside the incubator without foam, both ARPRO and Melamine foam reduced noise levels by approximately 20%. In the high-frequency tests, ARPRO proved to reduce sound levels inside the incubator by about 29.7%, whereas Melamine provided a 13.7% decrease.

Figure 5: Decibels recorded for all conditions: No foam, ARPRO foam, and Melamine foam, N=30.

Both foams performed at about the same level during the lowfrequency tests. However, the ARPRO foam demonstrated a much higher sound reduction compared to the Melamine foam in the high-frequency test. The t-test shows that the ARPRO foam performs significantly better at high frequencies. The two tail P(T<=t) value was significantly lower than the p-value of .05. Thus, the ARPRO foam was selected for further investigation of geometry effects on noise reduction (Figure 6).

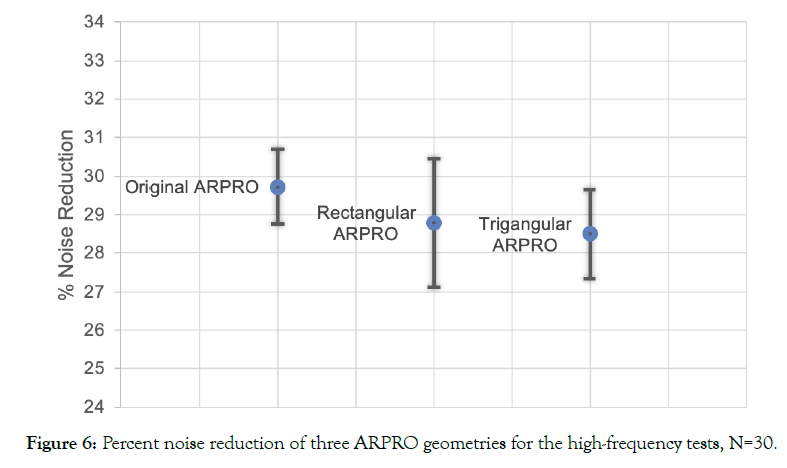

Figure 6: Percent noise reduction of three ARPRO geometries for the high-frequency tests, N=30.

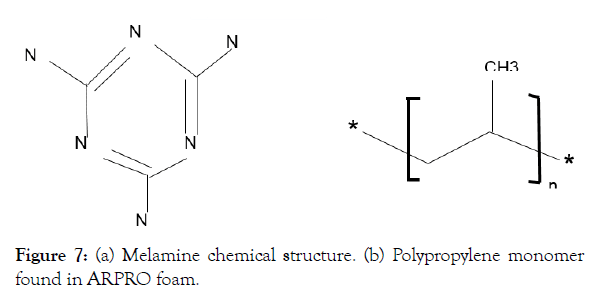

Between the two foams, the ARPRO Sound Silencer foam performed better than the Melamine foam. One significant difference between the two foams is density. The ARPRO foam has a density of approximately 44 kg/m^3, whereas the Melamine foam has a density of 9 kg/m^3. Although the team thought the lower density foam would perform better, what assists in the ARPRO sound absorption is its 30 percent porosity. By trapping the sound in its porous channels, the ARPRO foam is able to reduce the noise levels [6]. Melamine foam has a much higher porosity than 30%, but it may be too high to properly trap noise. Thus, the denser ARPRO foam through our testing demonstrated an optimal density and porosity. Furthermore, the material composition may play a role in the performance of sound absorption. The ARPRO foam is composed of polypropylene beads, and the Melamine foam is a formaldehyde-Melamine-sodium bisulfite copolymer. Thus, the ARPRO foam chemical composition is a more chainlike structure in comparison to a Melamine branched structure with aromatic components, as shown in Figures 7a and 7b.

Figure 7: (a) Melamine chemical structure. (b) Polypropylene monomer found in ARPRO foam.

After determining that the ARPRO foam performed better, different foam geometry tests were conducted to determine whether the noise level could be reduced by altering the shape and surface area of the ARPRO inserts. The different geometries chosen consider that the infant in the incubator must be completely visible and accessible at all times. The first alternate geometry used, the rectangular geometry, seen in Figure 4b, extends the original vertical foam pieces outward by another ½ inch, maintaining the 90-degree angle in the corners of the incubator. This design was based on the idea that increasing the surface area of the foam would help lower noise levels inside the incubator. The surface area of the original ARPRO foam inserts was about 96 in 2, whereas the surface area of the rectangular geometry was about 144 in 2, a 50% increase in surface area. The triangular ARPRO geometry (Figure 4c) used triangular corner inserts for the vertical pieces and had a surface area of about 68 in 2, about a 29% decrease in surface area compared to the original. This type of design was chosen to determine whether an uninterrupted, smooth connection to the incubator wall could reduce noise more than a 90-degree connection. In the low-frequency tests, neither of the alternate ARPRO foam geometries were able to further decrease the noise level inside the incubator compared to the original geometry. In the high-frequency tests, both of the alternate geometries showed less sound absorption compared to the original geometry. A t-test between the three different geometries indicated that only the percent noise reduction of the rectangular geometry is statistically significant. This could be caused by the way sound propagates around the edges of the incubator, but this is something that needs to be further investigated. Thus, the original geometry performed best, and the design was kept the same. This geometry had the lowest variability and the greatest percent reduction.

Ultimately, the ARPRO foam used in this design demonstrated that it effectively reduced the noise inside an incubator by over 20 decibels. A combination of the ARPRO foam and the multichannel ANC system integrated into this design should be considered to reduce the NICU average of 62dB to under 45dB, the recommended level. This will greatly help the field of neonatal care by protecting preterm infants from harmful noise that can cause hearing and cognitive impairments.

ANN The goal of this study was to develop an adjustable foam insert design to reduce sound levels inside the NICU incubator. In low-frequency tests, neither foam was able to bring the noise level down below 50dB. However, in the high-frequency tests, both foams reduced noise levels below 45dB. Although the foam inserts would ideally reduce the sound of high and low frequencies, other noise-canceling and or absorbing components could be added to the system. Machines in the NICU produce low-frequency hums, while the voices of nurses produce a high-frequency sound. The foam inserts were able to absorb the high-frequency sounds coming from outside the incubator, and an Active Noise Control system could be implemented to produce wavelengths that counter the low-frequency hum of the machines.

The ARPRO foam proved to absorb sound inside the NICU incubator better than the Melamine foam. Both foams performed equally well in the low-frequency tests. However, statistical tests proved ARPRO foam does absorb the sound of higher frequencies better than Melamine.

This design will greatly reduce the risk of detrimental effects on preterm infants due to high noise levels in the NICU. Currently, ten percent of the 400,000 infants that are admitted into the NICU each year develop hearing impairment, and some of those infants suffer from more dramatic complications such as intraventricular hemorrhaging. Nothing on the market properly addresses this problem, but our design has proven to be a great solution. With a minute amount of foam, the design has been able to reduce noise levels by approximately 20 decibels. Furthermore, the design is adjustable, does not obstruct the view for neonatologists, provides optimal accessibility, and can fit different incubator models. With the addition of noise reduction technology such as multi-channel Active Noise Control, this major issue can be solved. Noise reduction technology still needs to make progress due to the multidimensional nature of sound and the difficulty to produce antinoise in many dimensions, but this technology is very promising.

Citation: Makepeace S (2021) Noise-reducing Insert for NICU Incubator. J Biomed Eng & Med Dev. 6:152.

Received: 08-Feb-2021 Accepted: 12-Mar-2021 Published: 19-Mar-2021 , DOI: 10.35248/2475-7586.21.6.152

Copyright: © 2021 Makepeace S. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.