Journal of Geology & Geophysics

Open Access

ISSN: 2381-8719

ISSN: 2381-8719

Research - (2023)Volume 12, Issue 10

As oil production rates decline in the hydrocarbon fields and energy consumption increases, Enhanced Oil Recovery (EOR) methods are being used to recover the remaining oil after primary and secondary oil recovery methods, such as water flooding and gas injection, have been applied. Moreover, no field development project would be complete without numerical modelling of reservoir processes. In this study, factors affecting oil recovery are examined when simulating the alternate injection of water and gas WAG into a hydrocarbon reservoir. The simulation reveals that oil recovery increases with the horizontal permeability, but at permeability over 50 md, the effect of water alternating gas injection becomes insignificant. Additionally, a water-to-gas ratio WAG of 1:1 is the optimal injection value that yields maximum oil recovery.

Numerical simulation; Water alternating gas; Oil recovery factor; Enhanced oil recovery; Formation permeability

There is an average oil recovery factor of 35% around the world [1-4]. Consequently, one and a half times as much oil remains in the reservoir as was extracted. An increase in the oil Recovery Factor (RF) by 10% would bring, in the current situation, about 2 billion tons of additional oil.

Alternate injection of water and gas WAG is one of the EOR technologies. In recent years, this technology has received increasing interest as a method of additional oil recovery around the world [5-8]. A further advantage of the method is that gas produced in the field can be used as a displacing agent.

Alternate injection of water and gas in oil fields has shown an increase in oil recovery factor from 5% to 10% compared to conventional water or gas injection [9-12]. However, the application of this technology is constrained by the complexity of the intermittent injection process, as well as the difficulty of quantifying the expected performance before launching time- consuming and expensive technical studies [13-16].

This work aims to determine how reservoir parameters, reservoir fluid properties and the injection process itself affect the oil recovery factor. To determine this, numerical modelling of the reservoir will be used with constant and variable parameters that can affect the oil displacement process. Variable parameters will be lateral permeability, vertical permeability anisotropy, oil and gas density, water viscosity, water-to-gas injection ratio, and the duration of the alternate injection cycle.

Recovery factor and mechanism of Water Alternating Gas injection (WAG)

The overall oil Recovery Factor (RF) of any secondary or tertiary oil recovery method is a combination of three separate efficiency factors, which is defined through the following generalized expression [17-19]:

Where, Fod is the oil displacement factor, (0-1);

FLdc -Lateral displacement coverage factor, (0-1);

Fvdc -Vertical displacement coverage factor, (0-1).

The overall oil recovery factor depends on many factors, including fluid mobility, injection patterns, areal and vertical heterogeneities, gravity segregation, and volume of injected pore fluid. Due to an increase in both lateral and vertical sweep efficiency coupled with a decrease in residual oil saturation,

Water Alternating Gas injection (WAG) results in an additional oil recovery factor [20-23].

The mobility ratio is an essential factor that controls the volumetric displacement efficiency of a gas injection with favorable mobility less than one [24-27]. Reducing the mobility coefficient can be achieved by increasing the viscosity of the gas or reducing the relative permeability of the liquid. Water and gas can be injected alternately to reduce the mobility of the gas phase. It is important to adjust the amount of water and gas to achieve the best possible displacement efficiency. Too much water will result in poor microscopic displacement, and too much gas will result in poor vertical and possibly horizontal displacement coverage [28-31].

The increase in volume and evaporation of oil in the presence of oil and gas phases is one of the components of additional recovery in WAG. Gas injection improves oil recovery by swelling oil, decreasing gas-oil surface tension, decreasing oil viscosity and recovering light and intermediate hydrocarbons with immiscible displacement to fully miscible displacement. [32-35].

Input data to simulate the displacement process is shown in Table 1.

| Reservoir properties | Properties of fluids | ||

|---|---|---|---|

| Porosity, fraction | 0,17 | Model type | Black oil |

| Lateral permeability, md | 5 | Oil density, Kg/m3 | 820 |

| Vertical permeability, md | 0,5 | Oil compressibility, 1/MPa × 10-4 | 4,2 |

| Cell dimension XY, m | 100 | Oil formation factor, m3/m3 | 1,358 |

| Initial water saturation, fraction | 0,35 | Gas content of oil, m3/m3 | 125 |

| Irreducible oil saturation in water, fraction | 0,25 | Gas density, Kg/m3 | 0,9 |

| Initial pressure, MPa | 24 | Water viscocity, cP | 0,37 |

| Formation depth, m | 2370 | Water compressibility,1/MPa × 10-4 | 0,5 |

| Rock compressibility, 1/MPa × 10-4 | 0,6 | Water formation factor, m3/m3 | 1,014 |

Table 1: Input data for simulation.

Sensitivity to reservoir properties

Petroleum engineers have begun evaluating and implementing Enhanced Oil Recovery (EOR) technology due to decreasing production rates of petroleum reservoirs and increasing energy demand to recover the remaining oil after primary and secondary recovery procedures (i.e., waterflooding, gas injections, WAG) have been completed. Field recovery factors have been improved and production plateaus have been maintained using EOR technology. Since injection water stabilizes the displacing front by creating a more favorable mobility ratio, the WAG process provides better oil recovery compared to gas injection or waterflooding and sweeps the bottom part of the reservoir due to the higher density of water, injected gas provides better sweep by contacting un-swept zones.

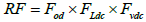

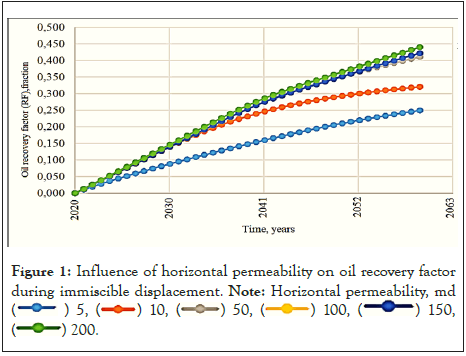

Numerous studies have shown that reservoir permeability is one of the main factors controlling WAG performance [36-39]. The performance of WAG is significantly affected by variations in reservoir permeability .The effect of vertical inhomogeneity was studied in [40-43], and it was found that the relationship between the permeability coefficient and the degree of oil recovery is inversely proportional. Because of the variations in depositional environments, most reservoirs are heterogeneous with random permeability variations, which have a significant impact on vertical sweeps of WAG displacement. Laboratory studies have shown that a lower value of (kv/kh) generally results in higher oil recovery in a heterogeneous reservoir due to dominant vertical permeability. The lateral permeability and vertical anisotropy of the formation were taken as variable parameters (Table 2).

| Variable | Minimum value | Maximum value |

|---|---|---|

| Horizontal permeability, md | 5 | 200 |

| Vertical permeability anisotropy kv/kh | 0,1 | 1 |

Table 2: Range of changes in formation permeability.

As a result of modelling the immiscible displacement of oil by gas and water, it turned out that with an increase in horizontal permeability, the final oil recovery factor also increases (Figure 1). However, under the same conditions, with permeability above 50 md, no significant additional oil production is observed.

Figure 1: Influence of horizontal permeability on oil recovery factor

during immiscible displacement.

Note: Horizontal permeability, md

( ) 5, (

) 5, ( ) 10, (

) 10, ( ) 50, (

) 50, ( ) 100, (

) 100, ( ) 150,

(

) 150,

( ) 200.

) 200.

The change in vertical permeability (Figure 2), did not lead to changes in incremental oil production. When alternating watergas injection is simulated, the Kv/Kh ratio plays a minor role.

Figure 2: Effect of vertical permeability anisotropy on oil recovery

factor under immiscible displacement.

Note: Vertical permeability

anisotropy, (Kv/Kh) ( ) Kv/Kh=0.1, (

) Kv/Kh=0.1, ( ) Kv/Kh=0.2, (

) Kv/Kh=0.2, ( )

Kv/Kh=0.4, (

)

Kv/Kh=0.4, ( ) Kv/Kh=0.6, (

) Kv/Kh=0.6, ( ) Kv/Kh=0.8, (

) Kv/Kh=0.8, ( )

Kv/Kh=1.

)

Kv/Kh=1.

Sensitivity to fluid properties

Several factors/parameters influence the success of a WAG injection process, including the reservoir petrophysical properties, fluid properties, and field scale considerations. According to literature studies, reservoir heterogeneity, relative permeability, hysteresis, and wettability have a major impact on WAG performance.

Based on a wide variety of reservoir conditions, different oil PVT inputs were taken. Below are the PVT variables and ranges used in this study (Table 3).

| Variable | Minimum value | Maximum value |

|---|---|---|

| Oil density, Kg/m3 | 700 | 900 |

| Gas density, Kg/m3 | 0,6 | 0,9 |

| Water viscosity, cP | 0,2 | 1,0 |

Table 3: Range of changes in properties of formation fluids.

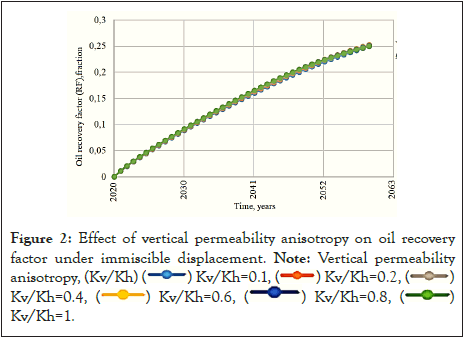

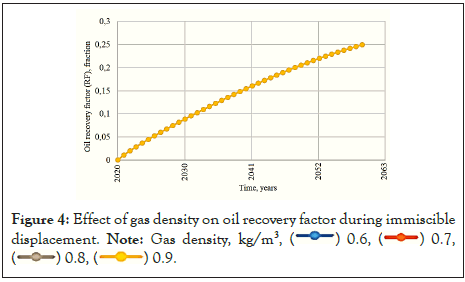

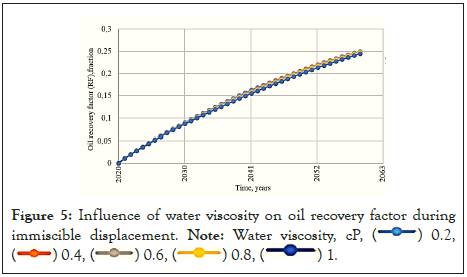

As a result of the simulation, no influence was found from changing the properties of formation fluids (Figures 3-5), only a slight increase in the oil recovery factor with a decrease in the viscosity of formation water.

Figure 3: Influence of oil density on oil recovery factor during

immiscible displacement.

Note: Oil density, kg/m3, ( ) 700,

(

) 700,

( ) 750, (

) 750, ( ) 800, (

) 800, ( ) 850, (

) 850, ( ) 900.

) 900.

Figure 4: Effect of gas density on oil recovery factor during immiscible displacement.

Note: Gas density, kg/m3, ( ) 0.6, (

) 0.6, ( ) 0.7, (

) 0.7, ( ) 0.8, (

) 0.8, ( ) 0.9.

) 0.9.

Figure 5: Influence of water viscosity on oil recovery factor during immiscible displacement.

Note: Water viscosity, cP, ( ) 0.2, (

) 0.2, ( ) 0.4, (

) 0.4, ( ) 0.6, (

) 0.6, ( ) 0.8, (

) 0.8, ( ) 1.

) 1.

Sensitivity to WAG parameters

The WAG process produces a mixture of gas and water that disappears after some time as it moves from the injector to the producer. Gravity separates this mixture due to large density contrasts, mobility ratios, and permeability variations between vertical and horizontal directions. In this mixture, the gas separates from the oil and goes to the top of the reservoir, while the water separates from the oil and goes to the bottom.

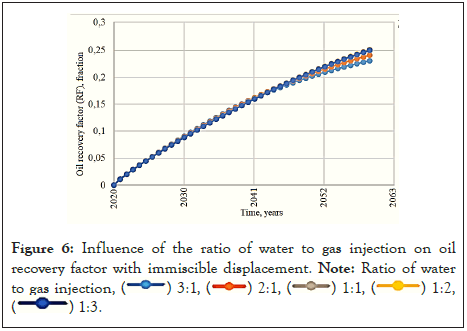

The size of the slug with alternate injection of water and gas is one of the most important design parameters for this EOR. The ratio of the water slug to the gas slug, as one of the injection parameters, strongly affects the displacement mechanism throughout the entire process. A comparison of WAG injection results with different slug sizes shows that short gas and water slugs perform better than large cycle injections in terms of efficiency and recovery performance [44-47].

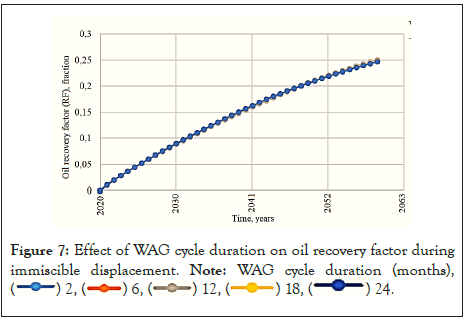

Another important parameter is the duration of the alternate injection cycle, which also affects the entire waterflooding process. It is also important to consider the Cycle Length (CL) of the WAG flooding process, which is another important parameter. Practically, it was found to be one of the critical factors affecting WAG process design, and this was specifically noted in the heterogeneous reservoirs, where cycle length during miscible WAG flooding was found to be a critical factor [48-51].

However, in numerical simulations, only the water-to-gas injection ratio parameter had an effect. Nevertheless, it is most effective when agents are injected 1:1. A further increase in the proportion of injected gas does not lead to an increase in oil recovery. The calculation results are shown in Figures 6 and 7. Variable parameters are given in Table 4.

Figure 6: Influence of the ratio of water to gas injection on oil

recovery factor with immiscible displacement.

Note: Ratio of water

to gas injection, ( ) 3:1, (

) 3:1, ( ) 2:1, (

) 2:1, ( ) 1:1, (

) 1:1, ( ) 1:2, (

) 1:2, ( ) 1:3.

) 1:3.

Figure 7: Effect of WAG cycle duration on oil recovery factor during immiscible displacement.

Note: WAG cycle duration (months), ( ) 2, (

) 2, ( ) 6, (

) 6, ( ) 12, (

) 12, ( ) 18, (

) 18, ( ) 24.

) 24.

| Variable | Minimum value | Maximum value |

|---|---|---|

| Water-Gas ratio | 3:1 | 1:3 |

| Cycle duration, months | 2 | 24 |

Table 4: Range of changes in variable injection parameters.

In tertiary oil recovery, the Water Alternating Gas injection process (WAG) is used to enhance displaced oil recovery from residual oil that cannot be recovered during primary and secondary recovery.

According to the results of numerical modeling of the process of alternate injection of water and gas and the determination of the parameters influencing this process, it was revealed that with an increase in horizontal permeability, oil recovery also increases, but with an increase in permeability above 50 md, the effect of water alternating gas injection is insignificant. Numerical simulation using the black oil model showed that fluid properties had no effect on oil production, except that the oil recovery factor slightly increased with a decreased formation water viscosity.

In addition, the optimal injection value that gives maximum recovery of oil is a water-to-gas WAG ratio of 1:1.

Authors are highly thankful to IWASRI and Ministry of Water Resources for providing funds for the study.

There is no conflict of interest.

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Citation: Alexander G, Sudad AO, Viktor S (2023) Numerical Simulation of Water Alternating Gas Injections (WAG) into Hydrocarbon Reservoirs: Factors Influencing Oil Recovery. J Geol Geophys. 12:1147.

Received: 24-Sep-2023, Manuscript No. JGG-23-27151; Editor assigned: 26-Sep-2023, Pre QC No. JGG-23-27151 (PQ); Reviewed: 10-Oct-2023, QC No. JGG-23-27151; Revised: 17-Oct-2023, Manuscript No. JGG-23-27151 (R); Published: 25-Oct-2023 , DOI: 10.35248/2381-8719.23.12.1147

Copyright: © 2023 Alexander G, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.