Journal of Ergonomics

Open Access

ISSN: 2165-7556

ISSN: 2165-7556

Research Article - (2020)Volume 10, Issue 1

Reportedly, 50 - 70% of current global labor force is exposed to poor working conditions. This study examined exposure and hazards of workers in a vegetable oil industry and the perceived health effects in Southwestern, Nigeria. A descriptive cross-sectional survey (including environmental monitoring) was employed to assess the workplace hazards and their perceived health effects on workers. The sampling covered 102 respondents across 15 departments within the industry. Data obtained were statistically analyzed using SPSS version 16. Common identified health and safety hazards were backache (17.6%), eye irritation (5.9%), breathing difficulty (6.9%), heat exhaustion (31.4%), bruises (2%), cuts and injuries (2%), and skin irritation (7.8%). Noise levels varied from section to section with the power plant recording the highest maximum mean noise level of 103.7dB though a lower mean noise level of 86.7dB was recorded for the office section. The noise level of 88.6dB was recorded at the boiler section; crushing floor had a noise level of 91.8dB at the work area while the office section had a lower noise level of 80.3dB. A noise level of 96.5dB was recorded at the Solvent Extraction Plant section; the office area had 78.2dB while agro laboratory and margarine section recorded 62.6dB and 73.3dB respectively. The study findings reveal that occupational health and safety in the workplace is inadequate with a wide range of hazards, physical, chemical, and ergonomic, which suggests implementation of stringent safety measures.

Noise level; Occupational; Safety; Working conditions; Respondent; Monitoring

Work is essential for life, development and personal fulfillment. Unfortunately, work activities such as food production, extraction of raw materials, manufacturing of goods, energy production etc. involve processes, operations and materials which can cause hazards which affect the health of workers [1]. Workplace hazards may be biological, chemical, physical, and psychosocial in nature. These hazards have resulted in a host of health impacts, ranging from catastrophic direct effects to chronic effects. While the identification of workplace hazards has often come from observations of adverse health outcomes among workers, unquestionably it is in the workplace that the impact of industrial exposures is best understood. In the past, the assessment of hazards in the workplace had been concentrated on agricultural workers, health-care workers and laboratory personnel, who are at considerable risk of adverse health effects [2].

Nigeria has a fast developing agricultural sector where variety of products are produced due to the favorable climatic conditions, good soils, government polices and the fact that over 70% of the entire land mass of the country is arable. Different oil-bearing seeds are produced in Nigeria. Due to the ban on importation of vegetable oil, the nation has witnessed a deficit supply. This calls for increase in local production of vegetable oil in Nigeria, thus leading to proliferation of vegetable oil production in companies across the country.

Several studies on occupational health hazards in developing countries like Nigeria have assessed the occupational injuries among occupational groups ranging from professionals (white collar) to manual workers (blue collar). The studies showed high prevalence of occupational injuries among blue-collar workers than their white collar counterparts. These blue collar occupation groups have been identified to include labourers, machine operators, drivers, and technicians who are found in the industry [3]. In Nigeria, workplace hazards and accidents have caused an average annual mortality rate of 1,249 per 100,000 workers in the past decade [4].

According to available literature, risk factors leading to injuries are present in every occupation with industrial and agricultural workers having the highest risks [5]. Governments in developing countries display apathy to occupational health and safety issues; different stakeholders (management, workers and government) do not appreciate the problems that can be solved or mitigated through occupational safety and health [1]. The available literature further identified risk factors leading to injuries which are present in every occupation with industrial and agricultural workers having the highest risks [4,5].

The job demands of most industries have been reported to be hazardous to the health and safety of workers. Although, some industries have evolved high-tech approaches to minimize workers’ exposure to heavy physical workloads, empirical evidence shows that workers in the developing countries still seem to be at high risk of occupational hazards [1,6]. The number of hours spent at workplace by either white or blue professionals, has resulted in several health issues such as cardiovascular disease, diabetes, hypertension, metabolic syndrome, obesity, subsequently high mortality rate thus, leading to a major health challenge in public [7-12]. Generation of noise by heavy machines in the companies has become a major menace to the workers. It is estimated that 16 to 24 percent proportion of workers world-wide is exposed to noise at moderately high (85-90 dB) and high (>90 dB) levels [13], and the relative risks of hearing loss at those exposure levels. The choice of these levels was based on the recommended exposure limits for occupational noise exposure around the world: 85 dB in most developed countries, and 90 dB in the U.S. and in many developing countries [14]. There is a seeming increase in advocacy on the right to health and safety at work as part of basic human rights. To further strengthen this, it is important to bring research into various production sectors to the fore as the findings will further enlighten the employers and employees on how to create a safe and conducive work environment.

Study area

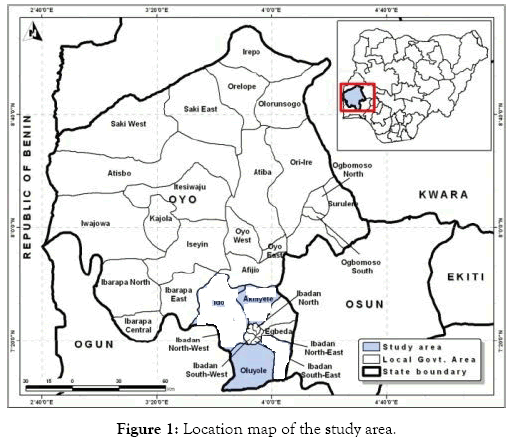

Ibadan, the capital of Oyo state (the largest city in southwest Nigeria) became a district council in 1961 and had the name Ibadan Municipal Government in 1989. Ibadan is 119 Km (74 miles) northeast of Lagos, 120 Km (75 miles) east of the Nigerian international border with Republic of Benin. The city has four rivers-Ona (North and West), Ogbere (East), Ogunpa (flows through the city) and Kudeti (Center of the city) - while Osun River and Asejire Lake are to the east of the city (Figure 1) [15,16]. The climate is tropical. When compared with winter, the summers have much more rainfall. The average annual temperature is 26.5°C in Ibadan. About 1311 mm of precipitation falls annually. Its wet season essentially spans the months of March through October while its dry season spans the month of November through February. It also experiences the extreme dry dusty wind that blows from Sahara towards the western coast of Africa, especially between November and March [17]. Ibadan is a prominent transit point between the coastal region and the areas in the hinterland of the country with 33 Local Government Areas (LGAs).

Figure 1: Location map of the study area.

Oluyole Local Government Area, which is the study area for this research, has its headquarters in the town of Idi Ayunre with an area of 629 km² and a population of 202,725 at the 2006 census. It shares boundaries with four LGs which are Ibadan South West; Ibadan South East; Ona Ara Local Government and Ido Local Government, all within Ibadan metropolis. It also shares boundaries with Ogun State through Obafemi, Owode, Odeda and Ijebu North.

Study site

Rom Oil Mill is a subsidiary of Flour Mills Nigeria Plc (FMN) that was incorporated on 29th September, 1960 as a private limited liability company with headquarters at Wharf Road, Apapa, Lagos. It was incorporated in Nigeria on 19 January 2006 by Mr. George Coumantaros, a Greek business man. The company is one of the leading manufacturers of a wide range of oil-based products in Nigeria under the Golden Penny Brand. Wheat milling is the financial backbone of our diversified company. FMN anchored flour milling in Nigeria that started in Apapa since 1962 with a crushing measure of 500 metric tonnes of wheat per day. At present, Apapa mill turns out a rated measure of over 8,000 metric tons per day making it one of the largest single site mills in the world. The FMN has been in existence for over five (5) decades. The company’s products include semovita, masavita, pasta, noodles, refined sugar, margarine, vegetable oils, and a range of snacks and breakfast cereals. The company started (and still continues) the production of a woven polythene sack brand, BAGCO, now popular in packaging of flour, cement, grains, salt, detergent, fertilizer, merchandise, farm harvests, shopping etc. The company also markets cement under the brand, “Burham Cement”. The industry uses locally sourced materials to develop and produce unique consumer products for the local markets. She also went into commercial venture in paramount handling of provincially fill out soybean, palm fruit, cassava, maize, and sugar cane; storage, aggregation and distribution of locally sourced grains and export commodities. The company also distributes seeds and fertilizers. The company is sited in Ibadan-Ijebu road, Alomaja, Oluyole Local Government, Ibadan, with an area mass of 986 km2.

Study design and population

The research was a descriptive cross sectional study involving a questionnaire survey, walkthrough survey with observations and Environmental/Occupational assessment. Participants were selected from the total population within the vegetable oil industry for the study. The population consisted of all the 15 sections within the factory. The sections are Refinery, Workshop, Boiler, Solvent Extraction Plant, Store, Warehouse, Power plant, Preparatory Section, Laboratory, HSE, Tank farm, Soya Silos, Margarine and Bottling, Crushing and Waste Water Treatment Plant with a total number of 102 workers from the two shift (Day and Night Shift).

Sampling procedures

The ROM oil industry: The company is one of the leading manufacturers of a wide range of oil-based products in Nigeria under the Golden Penny Brand. The company’s products include refined palm kernel oil, palm oil, soya oil, palm olefin, margarine and vegetable oil while the major by-product, Soya Bean Meal (SBM), is bagged for exportation.

Sections in the industry: The company is divided into 15 sections (Table 1) some of which are refinery, workshop, boiler, HSE, soya silos, margarine and bottling, crushing and waste water treatment plant. The company has two operational shifts (Day and Night).

Number of workers: One hundred and two (102) workers were evaluated from the 15 sections within the factory (Table 1). Participants were selected among workers who had worked for at least six (6) months in the company prior to the study, excluding interns and contractors. Two Research Assistants from the Health and Safety Department were employed for the data collection through questionnaire administration. Proper training on scientific research and ethics was given to them prior to the questionnaire administration.

| Total Number of Workers | Number of study Participants per shift | ||

|---|---|---|---|

| Day Shift | Night Shift | ||

| HSE | 3 | 2 | 1 |

| Crushing | 10 | 5 | 5 |

| Tank farm | 10 | 5 | 5 |

| Warehouse | 9 | 5 | 4 |

| Workshop | 7 | 4 | 3 |

| Laboratory | 5 | 3 | 2 |

| Waste water Treatment Plant | 3 | 2 | 1 |

| Solvent Extraction Plant | 8 | 4 | 4 |

| Store | 5 | 3 | 2 |

| Soya Silo | 4 | 2 | 2 |

| Power plant | 4 | 2 | 2 |

| Boiler | 2 | 1 | 1 |

| Bottling and Margarine | 18 | 9 | 9 |

| Preparatory Section | 8 | 4 | 4 |

| Refinery | 6 | 3 | 3 |

| Total | 102 | 54 | 48 |

Table 1: Sampling distribution according to shift sections.

Ethical approval: Ethical approval was taken from University of Ibadan/University College Hospital Joint Ethical Committee; letters were presented at the company before the research work was commenced.

Data collection method

Data was drawn from primary sources using a questionnaire and environmental assessment/monitoring device to measure noise level and temperature. Noise level is measured because the workers use machine that generates a loud noise that could affect them. Temperature is measured to assess the amount of heat being generated in the company and its impact on workers. The questionnaire was carefully designed with closed-ended items having available options for respondent to choose from.

The questionnaire sought information on the following sections:

Section A: Socio-demographic information of the participants;

Section B: Identification of inadequacies in health and safety measures;

Section C: Safety and health effects of worker’s exposure to workplace hazards; and

Section D: Identification of unsafe acts among workers.

Both interviewer and self-administered formats were used to obtain the data which covered all the sections per shift. The questionnaire was used to assess worker’s exposure to health and safety hazards in their workplace as well as compliance to safety standards.

Environmental monitoring

Environmental monitor meter Peak Tech 5035 (Figure 2) series was used to measure the following parameters: noise levels and ambient temperature of the work areas. The data collection was carried out on a daily basis for both day and night shift workers at two-time interval (Day-9 am, 2 pm) and (Night-9 pm, 2 am) in each of the sections.

Figure 2: Environmental Monitor Meter.

Noise/sound level meter

The environmental noise levels from the machines in the selected departments were measured using a factory-calibrated environmental monitor meter (Peak Tech 5035 series). The meter was taken to locations in the study sites and powered on. The Sound Level Mode (SLM) of the monitor was set at the slow response mode with a-weighting decibels (dB (A)) of the noise level displaying on the screen. The reading was taken for both day and night shift at two-time intervals (Day: 9 am, 2 pm and Night: 9 pm, 2 am) in each of the sections.

Temperature

The power/function/range of the environmental monitor was switched to “Temp” Position. The temperature probe was connected into the K-type thermocouple socket after which the end of the temperature sensor was positioned to the area or surface of the object to be measured. The display showed the corresponding temperature reading value (°C/°F) directly.

Data management and statistical analysis

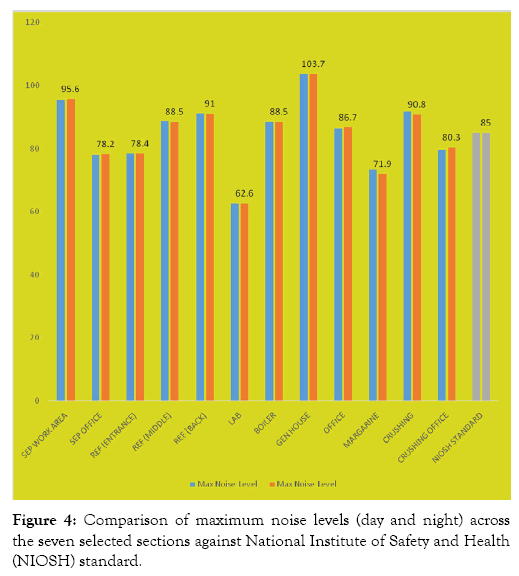

Data collected were analyzed using descriptive statistics of mean, standard deviation, frequency and percentages. The data analysis was carried out using SPSS software version 16 while data from environmental monitor were analyzed using Microsoft Excel version 16. The most appropriate exposure measurement for occupational noise is the A-weighted decibel, dB (A), usually averaged over an 8-hour working day. The maximum noise levels obtained across the seven selected sections were compared against the National Institute of Safety and Health (NIOSH) standard of 85 dB [18].

Socio-demographic characteristics of respondents

A total of 102 respondents took part in the research (Table 2). Almost all the respondents (97.1%) were males, while 2.9% were females. The respondents were grouped into three age brackets: 35.9% of the respondents fell into the age group 21-30 years, 47.4% of the respondents fell into the age group 31-40 years, while 16.7% of the respondents fell into the age group of above 40 years, the least represented group.

| Variable | Frequency (n=102) | Percentage% |

|---|---|---|

| Gender | ||

| Male | 99 | 97.1 |

| Female | 3 | 2.9 |

| Age Bracket (Years) | ||

| 21-30 | 28 | 35.9 |

| 31-40 | 37 | 47.4 |

| Above 40 | 13 | 16.7 |

| Level of education | ||

| Primary | 9 | 8.8 |

| Secondary | 27 | 26.5 |

| Tertiary | 66 | 64.7 |

| Marital Status | ||

| Single | 31 | 30.4 |

| Married | 71 | 69.6 |

| Working Experience (Years) | ||

| 1-5 years | 47 | 50.5 |

| 6-10 years | 28 | 30.1 |

| >10years | 18 | 19.4 |

Table 2: Socio-demographic characteristics of respondents.

Assessment of inadequacies in health and safety measures Seventy-one (69.6%) respondents claimed to be provided with Personal Protective Equipment (PPE) needed for their work while thirty-one (30.4%) respondents claimed they were not. Sixty-six (64.7%) claimed to have all the tools needed for their daily task while thirty-six (35.3%) claimed they did not the tools. Seventy (68.6%) respondents claimed to have gone through all trainings needed for their job while 32 (31.4%) claimed had not passed through the necessary training. A similar analysis was recorded for the conducive nature of their workplace.

Identification of unsafe acts among workers

Among the respondents, 13 (12.8%) engaged in horseplay at work while 99 (93.8%) did not. Six (6.2%) respondents claimed to enter restricted areas without permission while 91 (93.8%) respondents claimed they did not. Fifty (51%) respondents claimed to work while ill; forty-eight (49%) respondents claimed they did not. Eighteen (18.5%) respondents claimed to modify electrical appliances (cutting of plugs or cables) while seventy-nine (81.5%) respondents claimed they did not modify electrical appliances. Safety and health effects of workers’ exposure to work place hazards

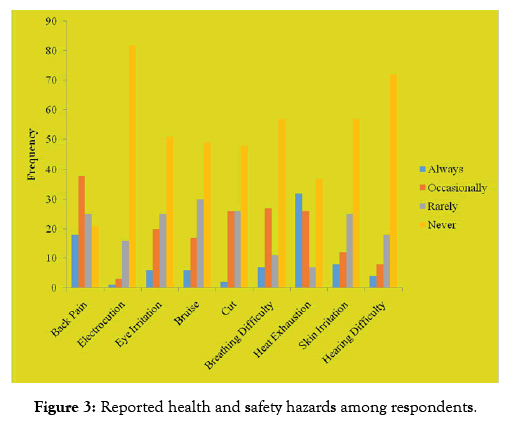

Various safety and health hazards were identified. Eighteen (17.6%) respondents claimed to experience back pain always, six (5.9%) respondents claimed to always experience eye irritation while seven (6.9%) respondents claimed to experience breathing difficulty. Thirty-two (31.4%) respondents reported heat exhaustion, two (2%) respondents claimed to always suffer cuts while at work, four (3.9%) respondents claimed to experience ear pain/hearing difficulty, while eight (7.8%) respondents claimed to always experience skin irritation (Figure 3).

Figure 3: Reported health and safety hazards among respondents.

Environmental monitoring

Two environmental parameters (Noise and Temperature) were monitored across 7 selected sections. These are Solvent Extraction Plant, Refinery, Laboratory, Boiler, Power Plant, Margarine and Crushing (Figure 2 and Table 3).

| DAY | NIGHT | |||||||

|---|---|---|---|---|---|---|---|---|

| LOCATION | Time Taken: 9 am and 2 pm | Time Taken: 9 pm and 2 am | ||||||

| Temperature Range (°C) | Mean Temperature | Temperature Range (°C) | Mean Temperature | |||||

| SEP | 29.6 | 29.8 | 30 | 29.8 | 29.2 | 29.6 | 29.8 | 29.5 |

| SEP Office | 28.1 | 28.5 | 28.7 | 28.4 | 28 | 28.3 | 28.6 | 28.3 |

| Refinery | 28.7 | 29.2 | 29.4 | 29.1 | 28.4 | 29.1 | 29.3 | 28.9 |

| Laboratory | 27.2 | 27.4 | 27.5 | 27.3 | 27.2 | 27.4 | 27.5 | 27.4 |

| Boiler | 29.1 | 30.2 | 30.4 | 29.9 | 29.4 | 30.4 | 30.5 | 30.1 |

| Generator house | 33.3 | 33.8 | 34.1 | 33.7 | 33.1 | 33.5 | 33.8 | 33.5 |

| Power plant (Office) | 27.2 | 27.6 | 27.9 | 27.6 | 27.2 | 27.4 | 27.6 | 27.4 |

| Margarine | 32.7 | 32.9 | 32.9 | 32.8 | 32.5 | 32.7 | 32.9 | 32.7 |

| Crushing | 34.4 | 34.6 | 35.2 | 34.7 | 33.2 | 33.9 | 34.3 | 33.8 |

| Crushing Office | 29.5 | 29.8 | 29.9 | 29.7 | 29.1 | 29.4 | 29.7 | 29.4 |

| SEP-Solvent Extraction Plant | ||||||||

Table 3: Temperature variations for day and night shift across seven selected sections.

Noise: The power plant area where the electricity generators are installed had the highest noise level of 103.7 dB; this exceeds the recommended exposure limit (85 dB). A lower noise level of 86.2 dB was recorded at the office section of the power plant. However this is still relatively hazardous as long term exposure to this level of noise impairs hearing [18]. The work area of the crushing section recorded a noise level of 91.8 dB during the day and a slightly lower value of 90.8 dB at night, while the office section recorded a noise level of 79.9 dB and a slightly higher value of 80.3 dB at night (Figure 4).

Figure 4: Comparison of maximum noise levels (day and night) across the seven selected sections against National Institute of Safety and Health (NIOSH) standard.

The noise level at the entrance of the refinery was 78.5 dB during the day and 78.4 dB at night, while at the entrance 88.7 dB was recorded during the day and 88.5 dB at night. At the back of the refinery, 91.2 dB was recorded during the day while 91.0 dB was recorded at night. The noise level at the back of the refinery exceeded the Recommended Exposure Limits (REL) though the noise level at the entrance of the refinery was within the recommended value.

Noise level measurement was done at the work area of the solvent extraction plant (78 dB during the day and 78.2 dB at night) and the main plant area (95.5 dB during the day and 95.6 dB at night). The noise level of 89.1 dB was recorded at the boiler section in the day and 88.4 dB at night, while that of margarine section (73.1 dB during the day and 71.8 dB at night). The laboratory recorded a much lower noise level of 62.9 dB during the day and 62.6 dB at night.

Temperature: The crushing floor area had the highest temperature (Table 3) for both day (34.7°C) and night shift (33.8°C); this was due to the heat produced by the palm kernel crushers as well as the poor ventilation in that work area. Other areas with high temperature were the power plant section with 33.7°C during the day and 33.5°C at night, and margarine section which recorded a temperature of 32.8°C during the day and 32.7°C at night. The temperature of the solvent extraction plant read 29.8°C during the day and 29.5°C at night. The laboratory had the lowest temperature of 27.3°C during the day and 27.4°C at night, while the power plant office section had 27.6°C during the day and 27.4°C at night. Solvent extraction plant, refinery and crushing section office had the temperature range of 28.9°C to 29.8°C. In all, the temperature differences between the day and night shifts were negligible. Though there are no regulations specifically addressing temperature, NIOSH recommends that employers provide the means for appropriate hydration and encourage their workers to hydrate themselves with potable water <15°C (59°F) made accessible in hot work areas [18]. During prolonged sweating lasting several hours, sports drinks containing balanced electrolytes should be taken. In addition, employers should implement a work/ rest schedule and provide a cool area [19].

The workers in the company were observed to have different ailments such as heat exhaustion, back pains, respiratory irritation, eye irritation, skin irritation, cuts and bruises on the workers. The most predominant unsafe act identified among the respondents was working while ill. Thus, occupational health and safety in the work place is inadequate since safety measures were not fully implemented.

It is therefore recommended that there should be more awareness on behavioral based safety to promote the safety culture among the workers. The safety health and environment messages can be displayed widely at conspicuous locations (mounted on the walls of the factory). The policies can be made known to all employees, contractors and contract employees by circulating the policies in both English and native language. Workers need to be educated on hazard identification and adhere strictly to safety control measures in place. There should be adequate provision of PPE for workers’ protection with the right education for proper use. Life jackets should be provided around the cooling towers and Waste Water Treatment section to prevent drowning in case of falls, while more 3 M-Respirators should be provided for workers in dusty sections to prevent respiratory issues.

Citation: Laniyan TA, Bobola EF, Sridhar MKC (2020) Occupational Hazard Assessment in a Vegetable Oil Producing Industry, Southwestern Nigeria. J Ergonomics 10:259. doi: 10.35248/2165-7556.20.10.259

Received: 21-Nov-2019 Accepted: 18-Feb-2020 Published: 25-Feb-2020 , DOI: 10.35248/2165-7556.20.10.259

Copyright: © 2020 Laniyan TA, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.