Journal of Nutrition & Food Sciences

Open Access

ISSN: 2155-9600

ISSN: 2155-9600

Review Article - (2023)Volume 13, Issue 2

Palm oil has several exceptional nutritional qualities and physical properties. It contains no trans-fats, which makes its cholesterol content 1/3 of that in cocoa butter. It is rich in nutrients and antioxidants, such as beta-carotene, carotenoids, glycerolipids, phospholipids, phytosterols, squalene, tocopherol, tocotrienols, triacylglycerols, ubiquinones, vitamins A, D and E, and it keeps the confections free from adhering to teeth and dentures. The escalating price and increasing scarcity of cocoa butter in the market and the substantial drop in the supply of the other lauric acid based fat, the coconut oil, make palm oil the prime substitute to cocoa butter in the confectionary industry. However, more target-based technical research in this regard should be done for palm oil to be competitive with similar products that are already dominating the market. The uniformity of composition of the genuine cocoa butter and the non-uniformity of the same in all other hard butters is a challenge to be addressed in the future for palm oil-based confectionery fats. Apart from technical research, the palm oil producers should also work on societal and marketing aspects of promoting palm oil based hard butter at the international level to be a market leader in the field.

Palm oil; Confectionary fats; Cocoa butter; Hard butter; Lauric acid

Elaeis guineensis or widely known as oil palm has its roots in the soils of Africa. Before the 1980’s, there was not much demand for oil palm products. After much research and consumer awareness, palm oil extracted from the oil palm was rapidly popularized as a dietary fat worldwide and became one of the largest selling edible oils in the market. Malaysia, being one of the major producers and exporters of palm oil, exports the edible oil over 90 countries to be used in the food industry. A major contributor to the food industry from the oil palm tree comes from the palm oil extracted from oil palm fruit bunch. Palm oil has been used as a food product for over 5000 years, given the fact that this substance has been found in an old tomb in Egypt among other grave components [1].

Conventionally, palm oil is being used as a medium to fry food, due to its stability at high temperatures. Palm oil is resistant to oxidation, polymerization and foaming. The smoke point of palm oil is considerably high which is at 230°C and the oil has stronger resistance towards thermoxidation in comparison to other vegetable oil. After much research done on the characteristics and properties of the palm oil, it has now made its way towards other consumable industries. Non-conventional usage of the palm oil as edible materials can be categorized into: Confectionary fat; emulsifiers; stabilizers and supplements. Extracted palm oil that contains low free fatty acids, low moisture content, low impurities and good bleach ability can be considered as high quality oil. Often, this high quality extracted palm oil will make its way to the food industry whereas the low quality palm oil will be distributed to other non-food related industry. A comprehensive review of palm oil in the food industry has been done in. The paper was mostly focussed on conventional edible materials, their refining processes, nutrients from palm oil as well as the conventional usage of palm oil; the frying capability. However, the paper does not cover nonconventional edible products derived from oil palm components, despite several researches have been done during the last few years on such commodities. Have done a comprehensive review on the cocoa butter fats based on their varieties, extraction methods, composition, and characteristics. They have also addressed the possibilities of replacing cocoa butter with few possible alternatives. However, the discussion is basically focussed on the properties of cocoa butter itself.

The present study addresses this shortfall in the available literature, in the recent past, with the aim of figuring out the aspects of concern for oil palm product industry in upgrading their products and meets the future challenges in the highly competitive market. The analysis specifically focusses on the replacement of cocoa butter by palm oil based hard alternatives as the former is becoming increasingly scarce due to various geographic, climatic, economic and societal factors [2].

Palm oil as a non-conventional edible material

Two distinct oil products could be derived from the oil palm fruit bunch; the Crude Palm Oil (CPO), extracted from the mesocarp or the flesh of the palm fruit and the Palm Kernel Oil (PKO), extracted from the endocarp of the palm fruit. Palm oil has a unique composition of saturated and unsaturated fatty acids. The composition of these two fatty acids is well balanced as can be viewed in Table 1.

| Saturated fatty acid | Unsaturated fatty acid |

|---|---|

| Palmitic acid (44%) | Oleic acid (40%) |

| Stearic acid (5%) | Linoleic acid (10%) |

| Alpha-linolenic acid (0.4%) |

Table 1: Composition of fatty acids in palm oil.

Generally, palm oil can be classified into two parts: Palm olein (80%) and palm stearin (20%). Palm olein, liquid oil, is commonly used as frying and cooking oil. In the recent years several non-edible applications of palm olein has been developed in various engineering spheres such as mechanical lubrication and transformer coolant. Super olein which is the double fractioned palm olein is being used in mayonnaise and salad dressing. On the other hand, palm stearin which has the physical of solid fat is being used for food applications that require high solid fat content such as shortening, margarine and vanaspati. Palm stearin is also helpful in providing the solid fat functionality without the use of hydrogenation.

In preserving and increasing the shelf life of food products, some food manufacturers use hydrogenation process which adds hydrogen atoms to the product. The outcome of this process is the production of trans-fats. Trans-fat increases bad cholesterol in the body when the food is consumed and ultimately leads to heart diseases. It is worth mentioning that palm oil is derived without involving any genetic modification, thus, it contains no trans-fat [3].

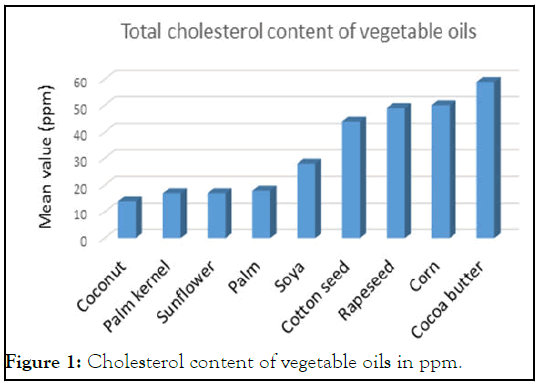

Regarding the total cholesterol content, in comparison to animal fat, palm oil and other vegetable oil have negligible cholesterol content. The cholesterol content of vegetable oils is depicted in Figure 1 for which the sources of data are gashaw. It is interesting to note that palm oil (18 ppm) is comparable with the much expensive sunflower oil (17 ppm), in terms of the mean value whereas the former is much better in the range (13-19 ppm) compared with that of later (8-44 ppm). This range depends on the refining process of the respective oil.

Furthermore, the total cholesterol content of palm oil is 60% and 35% of soya oil and corn oil which have much larger market share at present. The cholesterol content of dairy and meatbased oils are much higher than that of all vegetable oils; eg. beef tallow: 800-1400 ppm, dairy butter: 2200-4100 ppm and animal lard: 3000-4000 ppm. The above data clearly shows that health and cost concerns will soon make many types of animal and vegetable oils being replaced by palm oil, in the food manufacturing industry.

Figure 1: Cholesterol content of vegetable oils in ppm.

Palm oil contains many nutrients, antioxidants, and other health benefits such as, but not limited to: beta-carotene, carotenoids, glycerolipids, phospholipids, phytosterols, squalene, tocopherol, tocotrienols, triacylglycerols, ubiquinones, vitamins A, D and E. However, more market-oriented research in this regard should be done in order to be competitive with similar products that are already dominating the market.

Confectionery fats

Oils and fat collected by different origins are main components for producing many confectioneries. For centuries, coco-butter has been considered as the major ingredient for this purpose. In the near future, a sharp increase in demand for coco-butter is anticipated as the global production of chocolate and chocolatesort items is increasing day by day. In this backdrop, the possibility of using palm oil as a coco-butter replacer has drawn the attention of many researchers that work in the oil palm industry. Another reason for the open-ended research horizons for palm oil fats to replace cocoa butter in chocolate and ice cream parlour applications is the ever-increasing cocoa butter cost. Furthermore, Figure 1 shows that coco-butter is three times cholesterol rich compared to palm oil. This will be an important social-psyche triggering factor that should be highlighted in the marketing materials that promotes palm oil-based products [4].

The ability of palm oil in providing many desirable characteristics for the products in the confectionary industry will play a key role in replacing coco-butter at global level. In this regard all lauric oils (palm kernel and coconut) are good contenders as Coca Butter Equivalents (CBE) in the market. However, due to the drastic reduction in exports of high-grade coconut products from countries such as Sri Lanka, Philippines and Tanzania due to various factors in the recent past pave the way to the sharp increment of coconut oil price at the international market. This situation favours palm oil to be the prime replacement for coco-butter.

The search for crude biomaterials and processing techniques that may be utilized in extracting fat from attributes like cocobutter, continues. Three of the most discussed materials in this regard are Lauric Coco-Butters Substitutes (Lauric CBS), Nonlauric Coco-Butters Substitutes (Non-lauric CBS) and Coco- Butters Equivalents and Extenders (CBE). This classification may further be subdivided to uncover a detailed assortment of hard butter. Out of the range of potential materials, lauric and palm oils have a clear edge over the other potential materials to be the best vegetable oil bases for the production of cocoa butter. The substitution of coco-butter with fat, known as hard butter, are extracted conventionally using solvent and supercritical fluid, however in the present context production either by blending or modifying the natural oils is quite popular. However, one critical comment against the cocoa butter alternatives is their wide content variation of the constituents such as fatty acid, triacylglycerol, tocopherol, tocotrienol and sterene. Genuine cocoa butter has a much narrower range of compositional variation with respect to such constituents. Such non-uniformity of constituents significantly restricts the substitution of the alternatives in quality chocolate production. This is an important aspect to be addressed by the palm oil based cocoa butter alternative producers in the future.

Hard butter is appropriate as an assortment of many confectionary applications, apart from chocolate. The fat-derived from lauric acids such as palm oils could give a boost up to some dying industries due to cocoa butter price hike. Hard butter could also maintain good consumption quality due to the favourable range of melting point and now it is being widely used in granolas bars. Additionally, hard butter in taffies and caramels plays an important role in keeping the confections free from adhering to teeth and dentures. The hard butter industry needs strong backing for this claim from the dental research sector with comparative evidence with regard to other alternatives.

Coatings made from fats of other sources rather than the cocobutters are referred as confectionery coating or compound coating. These coating materials can be produced from the cocobutter blend and could be replaced by hard butter at fat stage. Alternatively, the ingredients extracted from cocoa butter could be added with hard butter as an aggregate. Hard butter is also utilized as a part of the formulation of non-chocolate coatings, accessible in many flavours and colours normally referred as paste coating. These coating and pastels are used regularly in confections, baked products; the coating is likewise shaped or stored in chips or “cookies” manufacturing. As we can see from the current trends, in the view of future potentials and growing demand for coating materials of bread-like consumable products, some serious efforts should be made to prepare and formulate palm oil based hard butter with advanced physical and functional parameters to make it well suited to replace genuine cocoa butter [5].

Production and characteristics of hard butter and substitutes

The fat phase of hard butter has a high influence on coating characteristics as compared with all other ingredients. The function of coating fats is to produce a matrix continuous in nature to hold all other components. It also contributes colours, aroma, and flavours required for pleasant consumption. The fats-matrix should be hard and dry in touching at normal temperature and it must not show any stickiness or greasy touch. On the other hand, in the consumption stage, the fats-matrix must be capable of melting at normal body temperature. Slow melting of coating fats will deteriorate the taste and produce a wax-like material which gives an unpleasant taste and contact feeling.

Coco-butters are considered as hard fats at normal temperature as shown in Solid Fats Index (SFI) in Table 2 below. Whereas, coco-butters carry narrow range of melting points, they melt just at less than the body temperature; normally near 34°C. Additionally, it is unaffected by oxidation process. Thus, cocoa butter gives an excellent eating quality, crumbliness or snap to chocolate at normal temperature and extended shelf life. Properly tempered, chocolate exhibit and retain the best gloss. Hard butter, produced from palm oil is also expected to carry similar thermal properties, to be competitive with cocoa butter [6].

| Variables | Non-lauric CBS | Lauric CBS | ||||||

|---|---|---|---|---|---|---|---|---|

| Solid fat index | Cocoa butter | Hydrogenated | Fractionated | Inter-esterified | Fractionated | |||

| 10.0°C | 76 | 60 | 70 | 66 | 68 | 70 | 72 | 77 |

| 21.1°C | 73 | 48 | 60 | 54 | 55 | 58 | 70 | 75 |

| 26.7°C | 62 | 39 | 54 | 38 | 42 | 46 | 54 | 68 |

| 33.3°C | 10 | 18 | 24 | 8 | 14 | 20 | 2 | 11 |

| 37.8°C | 0 | 4 | 3 | 0 | 3 | 8 | 0 | - |

| Wiley melting point | 34°C | 39°C | 38°C | 35°C | 39°C | 43°C | 34°C | 36°C |

Table 2: Quantitative comparison of cocoa butter to lauric and non-lauric CBS.

Many documents have been published about hard butter grading and grouping models covering various aspects. Whereas all these models have been developed on a satisfactory method of reasoning, sometimes, the application of the right model for a given case could be confusing for the oil chemist, covering producer or even an inquisitive coating consumer. The quantification of the essential unsaturated fats; palmitic, oleic and stearic; required to be present in a cocoa butter substituent is presented in Table 3. These fatty acids may be mixed to form more than 95% of the unsaturated fats that are included in coco-butters. This unique property of unsaturated fat exhibits the required cocoa butter qualities.

Triglyceride groups of coco-butters constitutes about 74% of symmetrical triglycerides with unsaturated fatty acid contributing to the rest. The mono-oleo desaturates are transcendently Palmitic-Oleo-Palmitic (POP), Palmitic-Oleo- Stearic (POS) and Stearic-Oleo-Stearic (SOS). It is a fact that if vegetable fats have similar levels of triglycerides (as in cocoa butter), they could be utilized to replace coco-butters. The CBE hard butter is the outcome of these rationale approaches.

Palms, shea, kokum, illipe and allanblackia are recognized to have a greater level of required triglycerides. As it is depicted in Table 3, oil palm is POP rich (about 26%) and have lower POP measures (about 3%). Adjusting the oil palm in twofold fractions will give a Palm-Mid Fraction (PMF) that has high POS and POP levels. Typically, palm-mid fractions contain unwanted triglycerides like POO, PPP and PPO. All these undesired triglycerides holding with palm-mid fractions at higher concentrations cast an unfavourable influence on the melting of hard fat fraction and CBE nature. During the production of palm-mid fractions attempts should be made to minimize these unwanted triglycerides.

During manufacturing of coco-butters equivalents, the palm-mid fractions rich with POP mixed in POS and SOS rich vegetable fats. Usually, shea and illipe are being utilized bases for POP and SOS. Table 3 presents the POS and SOS normal oils substances. Illipe shows large amounts of disaturated symmetrical triglyceride mono-oleos which may be mixed in different segments with no adulteration. On the other hand, Shea provides a POS and SOS fraction rich source. By proper mixing of all the distinctive bases, conceivably be delivered a coco-butter equivalent which is capable of mixing with coco-butter in any proportion for compound coating productions [7].

| Fat raw material | Typical fatty acid content (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| C12:0 | C14:0 | C16:0 | C18:0 | C18:1 | C18:2 | C18:3 | C20:0 | |

| Cocoa butter | Trace | Trace | 25 | 35 | 35 | 3 | Trace | 1 |

| Illipe butter | - | 2 | 20 | 42 | 36 | 4 | Trace | - |

| Palm oil | Trace | 1 | 44 | 4 | 45 | 10 | 1 | Trace |

| Palm kernel oil | 48 | 16 | 8 | 2 | 15 | 3 | Trace | Trace |

| Sal fat | - | - | 5 | 44 | 40 | 2 | - | 4 |

| Shea butter | Trace | Trace | 4 | 41 | 47 | 5 | Trace | Trace |

| Kokum butter | - | Trace | 2 | 57 | 40 | 1 | - | - |

| Mango seed fat | Trace | Trace | 8 | 38 | 45 | 7 | 1 | 2 |

| Typical triacyl glyceride content (%) | ||||||||

| POP | POS | SOS | ||||||

| Cocoa butter | 16 | 37 | 26 | |||||

| Illipe butter | 7 | 35 | 45 | |||||

| Palm oil | 26 | 3 | - | |||||

| Palm kernel oil | Trace | - | - | |||||

| Sal fat | 1 | 11 | 42 | |||||

| Shea butter | Trace | 6 | 42 | |||||

| Kokum butter | Trace | 5 | 72 | |||||

| Mango seed fat | 5 | 13 | 42 | |||||

Table 3: Cocoa butter compared to alternative fats.

Typically, sweet and dark chocolates can be produced by mixing 32% chocolate liquor, 14.6% coco-butter, 53% sugar and 0.4%lecithin. These chocolate liquors are around 52% cocobutter and 48% cocoa solids. In this manner, aggregate of coating fat content would be around 31.2% (14.6% coco-butter and 16.6%chocolates liquor.) The genuine coco-butter can be utilized to supplant the 14.6% coco-butter during production.

The coco-butter extenders are produced similarly with the components same as coco-butter equivalents. But in this case, the extenders may not be at similar high levels as in cocobutter. Thus, a high number of palm-mid fractions can be used to produce coco-butter extenders. Being readily available and more economical in nature the oil pal is more viable for this purpose compared with shea and illipe. Thus, palm oil paves the way to produce significantly low-cost butter extender. The cocobutter extenders might be utilized at 5% greater levels in a coating that can be still named as chocolates in Ireland, UK Japan, and Denmark. Countries of European economic community such as France, West Germany, Italy, Luxembourg, Holland and Belgium have found the proportion characterizing a synthetic structure restriction for coco-butter extenders if this embrace can permit up-to 5% CBE in items as "chocolates".

It has been observed that, the chocolate producers in the US are reluctant to grasp an adjustment in present chocolate norms of character. However, the high price of cocoa butter for coating may prompt such reluctant countries too, to adopt cost effective substitutes in the near future. The information depicted in Table 4 may clearly explain that there are several equivalents that may easily replace the use of cocoa butter the chocolate and coating industry. Non-lauric coco-butters are developed mostly using hydrogenated non-lauric oil sources. In the US, the oil sources are prevalently cottonseed oil and soybean oil. However, lightly hydrogenated oil palm is utilized as a part of hard butter (at a low percentage) in hydrogenated cottonseed and soybean oils. Such Non-lauric hard butter could be divided into two types; non-lauric hydrogenated CBS Non-lauric fractioned and hydrogenated CBS.

Hydrogenated non-lauric coco-butter substitutes do not meet the functional and physical properties of coco-butter, satisfactorily. From Table 2 it is clear that non-lauric CBS show lower hard fats at room-like temperatures in contrast with coco-butters. This is a fact on which the palm oil producers should capitalize in promoting palm-oil based hard butter.

At the point when a hydrogenated non-lauric CBS is utilized as a part of a compound covering as a complete replacement of coco-butter coatings exhibits poor flavour in the mouth. Furthermore, other than poor eating quality, such hard butter coatings also produce low taste snap due to light solid form that these materials possesses at normal temperature. Hydrogenated non-lauric coco-butters substitutes show low coefficients of withdrawal bringing about the poor form of discharge, thus they can display an inclination towards getting stuck in the process lines [8].

These hard butters have some affirmative properties as well. They have reasonable gloss and antioxidant characteristics that make them suitable for long-term storage. It is advantageous to use a compound cover produced with hydrogenated non-lauric CBS as it doesn't require a hardening step of chocolate, thus it keeps the end gloss un-effected. These fats display a minimal propensity to experience polymorphic changes in precious crystalline structure. Therefore, these coatings have a tendency to hold a satisfactory physical shape if presented to temperatures change that can bring about the hard butter exhibit melting and recrystallization. Chocolates and various chocolate mixes once are subjected to fat liquefaction and recrystallization may create noticeable surface contortions, known as bloom. Zhao and James show that the differing bloom appearance could be observed on chocolate surface at cycling temperatures. This is a fact that has not been investigated with respect to CBS based chocolates. Another appealing factor for using hydrogenated non-lauric CBSs is the ease of processing. However, palm oil based hard butter could also compete closely with these nonlauric CBS, with respect to the processing convenience.

Non-lauric CBS, when hydrogenated, are considered as a lowquality coco-butters option. They may be improved by adjusting the hydrogenation of non-lauric oil by a fraction. As it is depicted in Table 2 a common fractionated non-lauric CBS displays enhanced hard fat substance at normal temperatures and much narrow range of melting points compared to that is shown by non-lauric CBS, manufactured using solely hydrogenation. By processing the hydrogenated oil sources combined with fractioning hard fats, the hard butter products exhibit indexed changes which are responsible for affecting a peripheral decrease in Wiley’ melting points (Table 2).

The improved hard fat is somewhat due to the availability of long chains in palm oil as a source of non-lauric oils, same as in cocoa butter. As it is depicted in Table 2, fractioned non-lauric coco-butters or coco-butters and butter fat substitutes are up-to 25% cocoa butter as compound covering. This reality proposes that eating quality change can be accomplished by introducing a constrained measure of chocolate liquors in compound coatings. Such a covering contrasts positively to a covering defined and a hydrogenated non-lauric CBS. The compounds coating produced by fractioning of non-lauric CBS are commonly utilized in makings of fine quality baked produces also sometimes, higher mass confections and also for manufacturing the cookie droppings [9].

Factors that favour the adoption of red palm oil in confectionery industry

Refined palm oil, known as red palm oil, is the functional-food is intensively filtered and concentrated to contain a high amount of vitamin A, vitamin E, tocotrienols, carotenes, and other antioxidants to make it into a super antioxidant food. Thus, hard butter made from red palm oil, although it is costlier than using normal palm oil due to the addition cost of processing, could be a much better alternative to cocoa butter itself, with respect to the nutritional values [10].

Red palm oil is easily characterized by the distinctive dark red colour. The colour comes from carotenes such as beta-carotene and lycopene that gives tomatoes and carrots their red and orange colour. Red palm oil is one of the richest dietary sources of Beta-carotene (β-carotene), containing 500 ppm total carotene with high bioavailability; the Retinol Equivalent (RE) value of 0.3 g/g. Other sources of carotenoids that can be found are in crude vegetable oil, but they are generally much lower, usually less than 100 ppm. It is estimated that its retional is equivalent to 15 times of carrots and 300 times that of tomatoes. Red palm oil is mainly used to prevent malnutrition and vitamin deficiency disease in impoverished countries and region. In addition to that, the high content of benefits in red palm oil is also the most economical oil to produce compared to another source of oil such as sunflower oil coconut oil (Table 4) [11].

| Properties | Chocolate | Cocoa butter equivalent | Cocoa butter extender | Hydrog. non-lauric CBS | Fraction. non-lauric CBS | Inter-esterified lauric CBS | Fraction lauric CBS |

|---|---|---|---|---|---|---|---|

| Flow release | Very good | Very good | Very good | Poor | Good | Good | Very good |

| Mouth feel | Very good | Very good | Very good | Poor | Fair | Good | Very good |

| Texture snap | Very good | Very good | Very good | Poor | Fair | Good | Very good |

| Mold/belt release | Very good | Very good | Very good | Poor | Good | Good | Very good |

| Gloss | Very good | Very good | Very good | Fair | Good | Good | Good |

| Oxidative stability | Very good | Good | Good | Good | Good | Very good | Very good |

| Temper/ | Temper | Temper | Temper | Non-temper | Non-temper | Both | Both |

| Non-temper | |||||||

| Cocoa butter compatibility | - | Complete | Very high | Limited | 25% max. | 6% max. | 6% max. |

| Relative cost | - | Very expensive | Expensive | Very cheap | Moderate | cheap | Moderate |

Table 4: Qualitative comparison of properties of coatings made with cocoa butter alternatives.

Typically, Malaysian crude palm oil contains 500-700 ppm of carotenoids of which 37% is α-carotene and 50% is β-carotene whereas other species of palm oil such as E. oleifera Melanococca (M) from South America was reported to contain up to 4000 ppm of carotenoid. The pro-vitamin A content of crude palm oil is considered as the world’s richest natural plant source as it is estimated to be of 15times that of carrots and 300 times of tomatoes [12].

The use of red palm oil as a source of Vitamin A was first thought of in 1937 by aykroyd and wrigth at the nutrition research laboratory, coonoor. Laboratory and clinical studies were performed with crude palm oil from then Malaya. They found that 0.5 ml-2.0 ml of crude red palm oil cured the characteristic eye lesion of vitamin A deficiency in rabbits. The test was then further tested in humans with one group of patients receiving the emulsion containing 1.1 g of red palm oil daily against another group of patients that are given an emulsion of 1.5 g of cod liver oil as a control. Both emulsions supplied the subject with over 500 IU of Vitamin A. They concluded that the red palm oil gave comparable result to cod liver oil; it’s better than cod liver oil in the event of juvenile or infantile diarrhoea and ultimately that red palm oil was an effective substitute for cod liver oil in the routine treatment of keratomalacia. In the same year, arykroyd and Wright, 1937 suggest that all common oil and fats in the market should somehow be enriched with red palm oil to improve the nutritional content of the oil hence solves the Vitamin A deficiency problem in India [13].

Since then, various strategies and technologies were developed to incorporate red palm oil the human diet as crude palm oil has a strong unpleasant smell and taste. In the 1990’s, deodorized and deacidified crude red palm oil by the regional research laboratories, India and a highly refined edible grade red palm oil by Palm Oil Research Institute of Malaysia (PORIM) was developed to combat vitamin A deficiencies. Vitamin E that is present in red palm oil is tocotrienol, tocotrienol and tocotrienol. Tocopherols and tocotrienols are lipid soluble natural antioxidants and they protect the oil from oxidation by retarding the oxidation of polyunsaturated acids. Furthermore, it also provides synergistic protection against auto and photo oxidation of unsaturated. The high vitamin E and tocotrienol content function as a ‘chain breaker’ during lipid peroxidation in cell membranes and various lipid particles [14].

A study was conducted to investigate the use of tocotrienol-rich Vitamin E in treating patients with peripheral vascular disease. Patients given 300 mg tocotrienol-rich vitamin E for 12 weeks recorded an average 46% improved treadmill walking distance compared to 21.7% of 300 mg aspirin and 24.4% placebo. This finding suggests that pure tocotrienols could be used in treating atherosclerosis. The author suggests that tocopherol and tocotrienols function by capturing and destroying damaging oxy free radicals that play a role in cellular ageing, atherosclerosis and cancer. This is in line with other previous research conducted [15].

Ubiquinones or ubiquinone-10 or also known as Coenzyme Q10 (CoQ10) are a minor group of components found in crude palm oil. It is found in minor quantities of around 18-25 ppm in red palm oil. Although Ubiquinone is at a low concentration, it is an important component as it was found to boost the immune system, relieve angina, protect against heart disease and reduce high blood pressure of humans. The quinol form of this substance is a potent antioxidant that is 10 times more effective than vitamin E. thus making it as a very important component of determining red palm oil as a health supplement [16].

The above characteristics of red palm oil evidently justify that CBE made of it could easily outweigh the cocoa butter itself in applying as a confectionery fat, especially in the chocolate industry. At present, the cost of red palm oil (in comparison with cocoa butter) at the entrance stage of the confectionery process has not been evaluated quantitatively, however one may guess that it may be comparable with that of cocoa butter. Cocoa butter has its own cost constrains due to the rarity of the raw material, whereas, the red palm oil has the additional refining cost tagged to it at the confectionery process entrance. As the demand increases from the industry for high quality confectionery fats cocoa butter will face a distinct disadvantage of not having solutions for supply constraints, whereas the processing cost of red palm oil could be reduced as the quantity of supply is increased and the technology of processing is improved. This is an encouraging news for the palm oil industry, however, unless the producers keep their products and technology abreast of the modern trends, they may face tough challenges in the future at the global market where a fierce completion is taking place for the product promotion [17].

Apart from being a frying medium, palm oil has also made its way into various food industries in the recent years. Confectionary fats, emulsifier, stabilizer, and supplement are examples of non-conventional usage of palm oil as an edible biomaterial. In the confectionery industry, due to the increasing cost of cocoa butter, palm oil could be treated as one of the best suited substitutes. Palm oil can be processed to be classified as cocoa-butter equivalent, and a lauric cocoa butter substitute, which will be significantly cost-effective compared to genuine cocoa butter. The red palm oil, an extra-refined palm oil that contains higher nutrient value compared to normal palm oil, could be used to make superior hard butters with respect to nutritional value. The red palm oil contains higher amounts of vitamins, carotenes and anti-oxidants.

Furthermore, palm oil contains only 1/3 of the cholesterol that is present in an equal mass of cocoa butter. Health benefits from palm oil include anti-ageing effects, reducing blood pressure; prevent heart disease and also possible cancer treatment. Thus, replacement of cocoa butter by palm oil based hard butter will definitely have advantages with respect to the nutrients.

Despite many advantages as a hard butter that can replace cocoa butter in many confectionaries, still there is a tendency in the confectionary sector, especially among the chocolate producers in USA, to stick to the traditional cocoa butter. In order to break this practice, there are several technical challenges to be overcome by the palm oil based hard butter producers in the near future. If cocoa butter could not be completely replaced by the alternatives, up to 100% satisfaction of the producer, then food technocrats should develop methods to replace at least a part of the cocoa butter in the content with substitutes. It is equally important to focus on the marketing aspects of the product at global scale, in parallel with the technical advancements.

The authors would like to thank the faculty of engineering, universitiy Putra Malaysia, and the faculty of engineering and the built environment, university of the Witwatersrand, South Africa for placing excellent facilities to conduct this study. Thanks are also due to the information provided and guidance provided by the members of the Malaysian palm oil Association.

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Citation: Asghar MT, Johari AM, Saiah HRM, Choy JMS, Khoon NE, Gomes C, et al. (2023) Palm Oil Based Confectionery Fats: A Comparison with Cocoa Butter and Other Hard Butters. J Nutr Food Sci. 13:015.

Received: 19-Aug-2019, Manuscript No. JNFS-19-1345; Editor assigned: 22-Aug-2019, Pre QC No. JNFS-19-1345 (PQ); Reviewed: 05-Sep-2019, QC No. JNFS-19-1345; Revised: 17-Apr-2023, Manuscript No. JNFS-19-1345 (R); Published: 15-May-2023 , DOI: 10.35248/2155-9600.23.13.015

Copyright: © 2023 Asghar MT, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.