Journal of Pollution Effects & Control

Open Access

ISSN: 2375-4397

ISSN: 2375-4397

Research Article - (2015) Volume 3, Issue 2

An investigation was made to study the degree of toxicity of dyeing industry effluent on seed germination and early growth of Lady’s finger. Physico-chemical parameters of dyeing industry such as pH, Electrical Conductivitu, Total Solids, Total Dissolved Solids, Total hardness, Chloride, Sulphate, Dissolved oxygen, Biological Oxygen Demand, Chemical Oxygen Demand, Calcium, Sodium, and Potassium were analyzed of which electrical conductivity, total solids, total dissolved solids, sulphate, chemical oxygen demand were relatively high. Germination experiments were carried out in sterilized petri dishes containing 25, 50, 75 and 100% concentrations of untreated dyeing industry effluent. The germination percentage, growth parameters like plumule and radicle length, relative toxicity, percentage of phytotoxicity and tolerance index on the seed germination in response to dyeing effluent at various concentrations were also calculated. There was a gradual decrease in the percentage of seed germination and seedling growth with higher concentration of effluent. Relative toxicity and percentage of phytotoxicity was maximum at 100%. Growth parameter such as plumule and radicle length and tolerance index of seedlings was minimum at 100% and maximum at 25% of effluent concentration.

Keywords: Physico-chemical parameters; Dyeing industry effluent; Relative toxicity; Phytotoxicity; Tolerance index; Lady’s finger

Industrialization plays a major role for the economic development of any nation. This led to the tremendous industrial activity across the world. In spite of various positive aspects of industrialization, the foremost negative aspect is pollution. Today, it has become a matter of major concern in the deterioration of the environment. With the rapid growth of industries (sugar, paper, tannery, sago and dyeing industries) in the country, pollution of natural water by industrial waste water has increased tremendously. Industries discharge a variety of pollutants with chemical constituents of undesirable concentration which can deteriorate the surface and ground water resources. The waste water treatment system in Indian industries is recommended to be essentially installed to meet the waste water discharge norms, but presently only 10% of the waste water generated is treated and the rest of untreated water is discharged into nearby water bodies [1]. Effluents from industries are normally considered as the main industrial pollutants containing organic and inorganic compounds, acids, alkalies, suspended solids and other materials. But when untreated effluents are discharged in to the environment, it disrupts the ecological niches of living organisms. The disposal of wastewater is a major problem faced by municipalities, particularly in the case of large metropolitan areas, with limited space for land based treatment and disposal. On the other hand, wastewater is also a resource that can be applied for productive uses since wastewater contains nutrients that have the potential for use in agriculture. Thus, wastewater can be considered as both a resource and a problem. The use of industrial effluents for irrigation has emerged in the recent past as an important way of utilizing waste water, taking the advantage of the presence of considerable quantities of N, P, K and Ca along with other essential nutrients [2]. Effluent could be reused if concentration of all trace elements was found to be low and within guide lines for irrigation of agricultural crops [3]. Waste water and its nutrient content can be used extensively for irrigation and other ecosystem services. Its reuse can deliver positive benefits to the farming community [4]. Another benefit of reuse of effluent for irrigation is water conservation, due to water scarcity the industrial effluents are used as a source of irrigation for the crops but indiscriminate use of effluent ignoring the fact that untreated effluent may lead to disastrous effect on the growth and quality of the crops. Therefore, it is necessary to study the impact of these effluents on crop system before they are recommended for irrigation [5]. The present investigation has been carried out to study the degree of toxicity of dyeing industry effluent on seed germination and early growth of Lady’s finger.

The effluent samples were collected from dyeing industry located at Chinnalapatti, Dindigul district, Tamil Nadu in plastic containers (20 L). After collection, the effluent was immediately transported to the laboratory for analysis. Physico-chemical parameters such as pH, Electrical Conductivity, Total Solids, Total Dissolved Solids, Total hardness, Chloride, Sulphate, Dissolved oxygen, Biological Oxygen Demand, Chemical Oxygen Demand, Calcium, Sodium, and Potassium were analyzed as per the standard methods [6].

Petri dish experiment

The healthy and uniform seeds of Lady’s finger were selected and surface sterilized with 0.1% Hgcl2 and thoroughly washed with distilled water to avoid surface contamination. Germination experiments were carried out in sterilized petri dishes lined with double layer of Whatman filter paper 1. Twenty sterilized seeds were taken in petri dishes containing 25, 50, 75 and 100% concentrations of untreated dyeing industry effluent while tap water was taken as control and incubated at 26 ± 2°C for germination. Triplets of each concentration were maintained. The germination % was observed was recorded after 48 hrs. The growth parameters like plumule and radicle length were recorded after 7 days.

Relative toxicity (%R.T.) of industrial effluent on the seed germination and seedling growth of Lady’s finger were calculated to determine the degree of inhibition over control by using the following formula [7].

Relative Toxicity %={( x-y)/x} × 100

x = Germination percentage or seedling length in control at particular hour of incubation.

y = Germination percentage or seedling length in the presence of effluent at the same hour of incubation

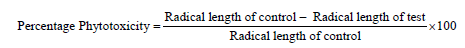

The percentage of Phytotoxicity was calculated using the formula [8].

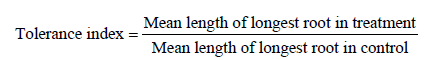

The tolerance index of seedlings was calculated by the formula [9].

The Physico-chemical parameters of dyeing industry effluent are discussed in Table 1. The pH value of the dyeing industry effluent was 7.3 that ranges within the permissible limit (6.5-8.5) prescribed by BIS. Similar results were observed by Nidhi Joshi and Ashwani Kumar [10] that the pH of textile effluent ranged from 7.6-7.9 whereas Mir Tariq Ahmad et al. [11] reported the pH of dye industry effluent ranged between 8.2 and 9.0. Electrical conductivity (EC) of effluent is a direct function of its total dissolved salts. Electrical Conductivity is an important physical parameter to measure the sodium hazard of water quality. The Electrical Conductivity found in the effluent (2,900 mS/ cm) was greater than that of the permissible limit of BIS (300 mS/cm) this may be due to the continuous discharge of the chemicals and salts used along with dyes in the industries. Saravanan et al. [12] reported that electrical conductivity of tannery industry effluent is above the accepted limits. The effluent recorded a Total Solids of 4301 mgl-1 beyond the standard value of BIS (1200 mgl-1). Garg and Kaushik [13] reported that the distillery effluent contained high values of total solids, Total dissolved solids (TDS) are due to soluble materials. TDS in the present study were recorded 3,745 mgl-1 that is beyond the standard value of BIS (1000 mgl-1) The experiments of Devarajan and Hameed Sulaiman [14] with untreated dye effluent observed that the total dissolved solids were not within the permissible limits for disposal into the inland surface water and unsuitable for land application. Chloride recorded in the effluent was 3158 mgl-1 that is above the permissible limit prescribed by BIS (600 mgl-1). The studies of Sajani Samuel and Muthukkaruppan [15] revealed that sugar mills effluent contained high amount of chloride. Sulphate in the present study was recorded 503 mgl-1 that is higher than the permissible limit prescribed by BIS (400 mgl-1). Prabhakar Pratap Singh et al. [16] reported that the fertilizer factory effluent contained considerable amount of sulphate. Biological oxygen demand in the present study was recorded 24.01 mgl-1 within the permissible limit prescribed by BIS (100 mgl-1). Smrithi et al. [17] recorded Biological Oxygen Demand of textile effluent was 19 mgl-1 and within the permissible limit prescribed by BIS. Chemical oxygen demand recorded in the effluent was 402 mgl-1 exceeded the permissible limit prescribed by BIS (350 mgl-1). Saravanan et al. [18] recorded that chemical oxygen demand of tannery industry effluent was above the accepted limits. Sodium recorded in the effluent was 12.33 mgl-1 while the recommended level set by BIS is 200 mgl-1. Potassium content recorded in the effluent was 0.21 mgl-1 found within the permissible limit of BIS (12 mgl-1). Medhi et al. [19] reported that potassium content in paper mill effluent was 11.7 mgl-1. Calcium in the present study was recorded 14.96 mg l-1 that falls within the permissible limit recommended by BIS (200 mgl-1). Baskaran et al. [20] reported that calcium content in sugar mill effluent was 91 mgl-1. There is 100% seed germination in the control after 48 hours whereas in effluent treatment, maximum germination percentage was in 25% concentration and decreases as the concentration increases. The promotion of seedling growth by lower concentration of effluent might be due to the presence of plant nutrient in the effluent. Suppression of germination at higher concentrations of effluent may be due to high levels of total dissolved solids which enhance the salinity and conductivity of the solute absorbed by the seeds before germination [21]. Relative toxicity percentage is given in Table 2. Minimum Relative toxicity percentage was with 25% concentration and maximum was recorded at 100% in 24 hrs. Similar trend was observed in 48 hrs. Textile effluent at different concentrations such as 0, 25, 50, 75 &100 % was treated to wheat (Triticum aestivum L). Minimum relative toxicity percentage was recorded in 25% concentration and increases gradually as the concentration increases. Textile effluent has more relative toxicity. The growth parameters such as plumule and radicle length (Figures 1 and 2) in 7 days showed reduction as the concentration of effluent increases. Maximum growth was recorded at 25% concentration and minimum at 100% concentration of dyeing effluent. Prabhakar Pratap Singh et al. [16] studied the effect of fertilizer factory effluent on seed germination, seedling growth and shoot and root length of gram (Cicer aeritenum) at different concentration of the effluent and time intervals and reported at 25% concentration of the effluent, growth promotion in terms of root and shoot length was recorded on 21 days. However, at higher concentrations of the effluent toxic effects were observed. As far as percentage of phytotoxicity of Lady’s finger treated with dyeing industry effluent is concerned, minimum phytotoxicity was observed at 25% concentration and maximum at 100% concentration. Control showed nil phytotoxicity (Figure 3). Maximum phytotoxicity was observed in untreated effluent of RI (Raghuvar India Ltd) for Vigna and in untreated effluent of SSI (Sri Seco Industries) for Cicer. Treated effluent of NEI (National Engineering Industries) and SSI (Sri Seco Industries) showed minimum phytotoxicity. Cicer was more sensitive towards effluent application as compared to Vigna [1]. Tolerance index (Figure 4) of seedlings was minimum at 100% of effluent concentration and maximum at 25% concentration. Control showed nil tolerance index. Tolerance index of seedlings were minimum in untreated effluent of RI (Raghuvar India Ltd) followed by NEI (National Engineering Industries) and SSI respectively. Maximum tolerance index was recorded in treated effluent of SSI followed by RI (Raghuvar India Ltd) and NEI (National Engineering Industries) [1].

| Parameters | Value |

| pH | 7.3 |

| Electrical conductivity (mS/cm) | 2,900 |

| Total Solids(mg/l) | 4301 |

| Total Dissolved Solids ” | 3745 |

| Chloride” | 3158 |

| Sulphate” | 0.322 |

| BOD” | 24.01 |

| COD” | 201 |

| Sodium” | 12.33 |

| Potassium” | 0.21 |

| Calcium” | 14.96 |

Table 1: Physico-chemical parameters of dyeing industry effluent.

| Different concentrations of dyeing effluent (%) | Relative toxicity % after 24 hours | Relative toxicity % after 48 hours |

| 25 | 13.6 | 8.2 |

| 50 | 19.4 | 14.4 |

| 75 | 25.8 | 18.6 |

| 100 | 29.5 | 22.5 |

Table 2: Relative Toxicity Percentage.

Based on the experimental observation it can be concluded that the physico-chemical parameters such as electrical conductivity, total solids, total dissolved solids, sulphate, chemical oxygen demand were relatively high in the dyeing industry effluent and also toxic to the plant, severely affected seed germination and seedling growth. There was a gradual decrease in the percentage of seed germination and seedling growth with higher concentration of effluent. The untreated dyeing industry effluent could possibly lead to soil deterioration and low productivity. In conclusion, dyeing industry effluent at various concentrations influences seed germination and seedling growth of Lady’s finger. However the effects vary from crop to crop because each plant species has its own tolerance of the different effluent concentrations.