Journal of Nutrition & Food Sciences

Open Access

ISSN: 2155-9600

ISSN: 2155-9600

Research Article - (2018) Volume 8, Issue 4

Keywords: Extrudates; In vitro digestibility; Functionality; Potatocereal combination; Acceptability

In developing countries like India, people are traditionally reliant on cereals and are generally unacquainted of the nutritional profile of potatoes (Solanum tuberosum L). Potatoes are tubers belonging to the family “Solanaceae” [1,2] and considered as comfort food being reasonably rich in phytonutrients like flavonoids, carotenoids and caffeic acid. Worldwide potato is the fourth chief crop in production after maize, wheat and rice [3-5]. Furthermore, potato is a nourishing food and is considered as high-potential food security crop because of its ability to provide high yield with good quality product per unit area than other major cereal crops like maize [6]. Despite their nutritional and health values, the presence of high moisture content, high carbohydrate content (starch) makes its more prone to sustained metabolism and microbial attack during harvesting and storage which generally limits their use and consumption [7]. Under the existing circumstances, processing of the bulky perishable potatoes into various processed products like snacks etc. is a viable option which can help to extend the storage life, solve the storage problem [8] and ensure remunerative prices to the farmers as well.

Extrusion cooking of cereals is a very important process in food industry, since it includes a wide range of products such as snack-foods, baby-foods, breakfast cereals and pasta [9]. Extrusion cooking is a process whereby raw feed material is exposed to controlled conditions of high temperature, pressure, shear and moisture. Potato being a starch rich product is a versatile ingredient for extrusion technology because of starch structure and size. Many researchers have studied the extrusion behaviour of potato starch and potato flours [10-14]. Incorporating potato into extruded products improves the nutritional profile of snacks, while increasing utilization of potato. Moreover, use of cereal grains and potato as the major raw materials in extruded snack foods had found to increase the product specific volume and textural characteristics of snack foods [11,15,16] which subsequently determine consumer acceptance. Thus the present study was carried out to explore the possibility of utilizing potato for development of non-gluten based cereal-potato extrudates and to assess the nutritional, functional characteristics, in vitro digestibility and consumer acceptability of prepared extrudates.

Raw material

Rice flour, maize flour and potato mash were used for preparation of extruded snacks. Raw material was procured from the local market near Punjab Agricultural University, Ludhiana. Maize, rice and potato was fed to Cyclotec mill to produce flour, sifted to pass through a 60- mesh sieve (BIS) which corresponds to the particle size of 250 μm.

Extrusion

Extrusion was carried out on a co-rotating intermeshing twin screw extruder model BCH (Clextral, Firminy, France). The barrel diameter was 2.5 mm and its length to diameter ratio (L/D) was 16:1, respectively. Temperature of first, second, third and fourth zone was maintained at 30, 50, 90 and 150°C, respectively throughout the experiment. The extruder was run by power motor of 8.5 kW with speeds variable from 0 to 682 rpm. The extruder was equipped with a torque display, which indicates percent of torque relative to the current drawn by the motor.

Expansion ratio

The ratio of diameter of extrudate and the diameter of die (6 mm) was used to express the expansion ratio of product [17]. The diameter of extruded product was determined as the mean of 10 random measurements made with a vernier caliper. The extrudate expansion ratio was calculated by following formula.

Expansion ratio = Extrudate diameter (mm)

Water absorption and solubility index

Water absorption Index (WAI) and water solubility index (WSI) were determined according to the method suggested by [18].

Color

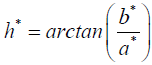

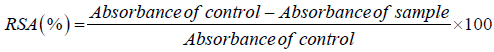

The color of extruded snacks was measured using a color meter, CR-300 (Minolta Camera Co. Ltd., Japan). Three random sample readings were taken on the levelled surface of several aligned raw pasta. Results are expressed in the L*a*b* space as L* (brightness; 0 = black, 100 = white), a* (-a*= greenness,+a*= redness) and b* (-b*= blueness, +b* =yellowness) values (CIE, 1986). The value of hue angle (h*) and chroma (C) for each sample was calculated using the following equations.

Hardness

Textural quality of the extruded snacks was examined by using a TA-XT2i Texture Analyzer. The compression probe (75 mm diameter, aluminium cylinder) was applied to measure the compression force required for samples breakage which indicates hardness. Hardness of extruded snacks was expressed in Newton [19].

Overall acceptability

All product samples were coded and assessed for degree of liking or disliking on a 9-point hedonic scale, using descriptive categories ranging from like extremely, through neither like nor dislike, to dislike extremely [20]. The samples were presented randomly in identical petri dishes and the panellists were asked to check the appropriate category on the scale. Products were judged for sensory attributes (flavour, mouthfeel/texture, appearance, and color).

Bioactive composition

Total phenolic content (TPC): Extraction was made according to the method proposed by Sharma and Gujral (2010) with slight modifications. Finely ground samples (1 g) were extracted twice with acidified methanol:water (80:20 v/v) solution acidified with 0.1% HCl, for 2 h and centrifuged. Total phenolic contents in the extracts were estimated using Folin-Ciocalteu reagent [21]. In brief, the reaction mixture contained equal volumes of extract and aqueous methanol and 5 mL freshly diluted (1:10) Folin-Ciocalteu reagent. After 4 min, 4 ml sodium bicarbonate was added. The contents were shaken and incubated for 2 h at 25°C. The absorbance at 725 nm was measured using Spectronic-200 and used to calculate the phenolic contents considering gallic acid for standard. The total phenolic contents were stated as mg Gallic Acid Equivalent (GAE)/100 g dry weight.

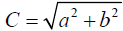

Antioxidant activity: Antioxidant activity was measured using the method of Brand-Williams et al. [22]. 1,1-Diphenyl-2-picrylhydrazyl (DPPH) radical scavenging capacities of extracts were estimated by the reduction of the reaction color between DPPH solution and sample extracts. Freshly prepared DPPH solution (0.2 mM) was mixed with sample extracts. The mixture was kept in dark for 30 min and absorbance was recorded at 515 nm using Spectronic-20. Control was made without sample and measured absorbance at t=0. The results were presented as per cent radical scavenging activity (RSA) calculated by following formula.

Total flavonoid content: The total flavonoid content was estimated with Aluminium chloride colorimetric method of Woisky and Salatino (1998) [23]. Two ml of the extract was mixed with 100 μl of 10 per cent AlCl3, 100 μl of 1 mol per litre potassium acetate and 2.8 ml water and allowed to incubate for 30 min at room temperature. Thereafter, the absorbance of the reaction mixture was subsequently measured at 415 nm.

In vitro starch digestibility

In vitro starch digestibility (SD) of pasta was determined according to the method of Onyango et al. [24]. In vitro starch digestibility of starch was determined by estimating the quantity of maltose formed by the dinitrosalicylic acid method. 100 mg finely ground sample was dispersed in phosphate buffer pH 6.9 and incubated with 100 mg α-amylase at 37°C in a total volume of 20 ml buffer. The rate of enzymatic hydrolysis of starch was determined by estimating the amount of maltose released upto a period of 2 h. After the filtration, 2 ml of dinitrosalicylic acid was added to tube (containing 1 ml filterate) to arrest the reaction, boiled for 5 min, cooled and made volume to 50 ml. Absorbance was read at 540 nm, standard curve of maltose was used to calculate mg of maltose released corresponding to absorbance of sample.

In vitro protein digestibility

In vitro protein digestibility was analysed by Akeson and Stahmann method [25]. Two step proteolysis was carried out at 37°C; firstly 2 hours incubation of protein with pepsin followed by pancreatin for 2 hours. Toluene was added to obtain aseptic conditions. The samples were then centrifuged at high speed and filtered through Whatman No. 44 filter paper. Macrokjeldal method was used to analyse the N content. The digestibility coefficient was calculated by subtracting the residual protein from initial protein on the basis of 100 g of sample.

Expansion ratio

Expansion ratio measures the degree of puffing undergone by the product as it exits the extruder. Expansion ratio is one of the important physical properties of the extrudates and it varies greatly with variations in feed composition and extrusion processing variables. A porous, expanded, sponge-like structure is developed inside extrudates due to many minor steam bubbles produced by rapid release of pressure after exiting the die [26].

Figure 1 displays the expansion ratio of various extrudates and control (100% cereal). Significant variation was observed for expansion ratio of extrudates from potato-rice (3.45-4.00), potato-maize (2.18 to 3.26) and rice+maize in combination with potato (2.84 to 3.22). Higher expansion ratio was obtained for potato-rice extrudates. The heat developed during extrusion can increase the temperature of the moisture above the boiling point so that when the extrudates exits from the die, a part of the moisture would quickly flash off as steam and results in an expanded structure with larger pores and low density.

Water Absorption Index and Water Solubility Index

Water absorption index (WAI) of extrudates measures the amount of water held by the starch after its dispersion in excess water. It is related to the degree of starch damage due to the starch gelatinization and fragmentation during high temperature and shear extrusion cooking [27]. The WAI of potato-rice, potato-maize and flour in combination with potato lied from 1.35 to 2.11 g/g; 3.05 to 4.38 g/g and 6.12 to 8.73 g/g, respectively (Table 1). Water acts as a plasticizer in the starch extrusion and cause a decline in degradation resulting in products with a higher capacity of water absorption. Among various cereal-potato extrudates, potato-maize based extrudates exhibited higher WAI of 4.38 g/g. Moreover, it was observed from Table 1 that in case of potato-rice extrudates, incorporation of potato upto 20% evinced a positive co-relation with water absorption index.

| Samples (Cereals:potato) |

Functional properties | Color characteristics | |||||

|---|---|---|---|---|---|---|---|

| Water absorption ratio | Water solubility index | L* | a* | b* | Hue Angle (°) |

Chroma | |

| Rice:Potato (90:10) | 1.80 ± 0.09h | 26.15 ± 0.15f | 69.33 ± 1.21ef | 2.87 ± 0.10c | 19.50 ± 0.46f | 81.65 ± 1.01e | 19.71 ± 0.49f |

| Rice:Potato (80:20) | 2.11 ± 0.05g | 26.63 ± 0.10f | 70.90 ± 1.01cd | 3.67 ± 0.50b | 21.43 ± 0.12e | 80.29 ± 0.76f | 21.74 ± 0.11e |

| Rice:Potato (70:30) | 1.35 ± 0.00i | 38.36 ± 0.09c | 73.97 ± 0.99a | 3.93 ± 0.15a | 23.83 ± 0.15c | 80.63 ± 0.60f | 24.16 ± 0.16b |

| Maize:Potato (90:10) | 4.38 ± 0.11a | 38.13 ± 0.01c | 73.77 ± 1.00a | 0.17 ± 0.12h | 22.40 ± 0.20d | 89.57 ± 0.89a | 22.40 ± 0.20d |

| Maize:Potato (80:20) | 4.26 ± 0.08b | 40.02 ± 0.98b | 70.73 ± 0.56cd | 2.60 ± 0.76d | 26.70 ± 0.30a | 84.44 ± 0.34c | 26.83 ± 0.30a |

| Maize:Potato (70:30) | 3.05 ± 0.01e | 51.78 ± 1.01a | 67.50 ± 0.11fg | 2.83 ± 1.01c | 24.30 ± 0.20b | 83.35 ± 1.01d | 24.46 ± 0.19b |

| Rice:Maize:Potato (45:45:10) | 3.91 ± 0.03c | 30.41 ± 1.34e | 68.90 ± 0.90f | 1.77 ± 0.43f | 23.30 ± 0.44c | 85.67 ± 1.11b | 23.37 ± 0.44c |

| Rice:Maize:Potato (40:40:20) | 3.29 ± 0.09d | 36.14 ± 1.21d | 72.60 ± 1.00ab | 1.67 ± 0.21g | 21.90 ± 0.10e | 85.65 ± 0.10b | 21.96 ± 0.09e |

| Rice:Maize:Potato (35:35:30) | 2.70 ± 0.10f | 50.45 ± 0.67a | 71.43 ± 1.21bc | 2.13 ± 0.34e | 22.70 ± 0.44d | 84.63 ± 0.21c | 22.80 ± 0.44d |

Table 1: Effect of various blends on functional properties and color characteristics of potato - cereal extrudates.

The water solubility index of extrudates measures the amount of soluble components released from starch after extrusion. It is considered as an indicator of degradation of internal structural components [28]. The results of water solubility index of cereal-potato extrudates is elucidated in the Table 2. The WSI of potato-rice, potato-maize and flour in combination with potato varied from 26.15 to 38.36 g/g; 38.13 to 51.78 g/g and 30.41 to 50.45 g/g, respectively (Table 1). A lower value of water solubility index was observed for cereal-potato extrudates produced at 10 and 20% potato level. Moreover, the extrudates produced using rice as ingredient depicted decreased water solubility index then extrudates produced from potato-maize. Ding et al. [29] reported that water solubility index is used as an indicator of measurement of the degree of starch conversion during extrusion, which depicts the amount of soluble polysaccharides released from the starch component after extrusion.

| Samples (Cereals:potato) |

Bioactive Composition | In vitro digestibility | In vitro digestibility | ||

|---|---|---|---|---|---|

| Total phenolic content (mgGAE/100g) | Antioxidant activity (% RSA) | Total flavonoid content (µg Quercetin/mg) | Starch digestibility (g/100g) |

Protein digestibility (g/100g) | |

| Rice:Potato (100:0) |

1.06 ± 0.04j | 62.39 ± 0.67i | 170.81 ± 1.03l | 16.68 ± 0.08cd | 61.16 ± 1.30a |

| Rice:Potato (90:10) | 1.80 ± 0.11i | 69.97 ± 0.32g | 211.13 ± 0.99jk | 16.84 ± 0.01cd | 53.84 ± 1.21b |

| Rice:Potato (80:20) | 2.76 ± 0.09f | 75.66 ± 0.12e | 218.56 ± 0.67jk | 17.56 ± 0.09b | 57.89 ± 0.92cd |

| Rice:Potato (70:30) | 3.80 ± 0.08c | 77.21 ± 0.45d | 226.44 ± 1.19i | 18.22 ± 0.10a | 58.58 ± 1.01e |

| Maize:Potato (100:0) |

1.74 ± 0.09i | 73.29 ± 0.24f | 582.06 ± 1.02d | 14.52 ± 0.05 | 60 ± 0.96f |

| Maize:Potato (90:10) | 2.54 ± 0.10g | 75.09 ± 0.83e | 660.19 ± 1.01c | 14.72 ± 0.01 | 56.19 ± 1.0b |

| Maize:Potato (80:20) | 3.29 ± 0.09d | 79.12 ± 0.41c | 716.44 ± 0.76b | 15.18 ± 0.05 | 56.48 ± 1.02f |

| Maize:Potato (70:30) | 4.11 ± 0.06a | 85.07 ± 0.24a | 724.25 ± 0.89a | 16.4 ± 0.09e | 58.49 ± 1.26b |

| Rice:Maize:Potato (50:50:0) | 1.16 ± 0.03j | 67.29 ± 0.22h | 408.94 ± 1.21h | 15.28 ± 0.11 | 59.40 ± 1.05f |

| Rice:Maize:Potato (45:45:10) | 2.22 ± 0.08h | 70.52 ± 0.18g | 480.50 ± 1.01g | 15.68 ± 0.00f | 58.76 ± 0.99b |

| Rice:Maize:Potato (40:40:20) | 3.08 ± 0.09e | 77.02 ± 0.11d | 511.44 ± 1.43f | 16.32 ± 0.09e | 58.18 ± 1.05j |

| Rice:Maize:Potato (35:35:30) | 3.90 ± 0.10b | 80.20 ± 0.32b | 597.69 ± 1.00e | 17.56 ± 0.12b | 59.59 ± 1.03e |

Table 2: Effect of various blends on bioactive composition and in vitro digestibility of potato - cereal extrudates.

Color

Color is an important physical characteristic and is directly related to the acceptability of the product. Table 2 illustrates the color values (L*, a* and b*) including hue angle and chroma of cereal-potato extrudates. For potato-rice based extrudates prepared at varying levels of potato, the L* values ranged between 69.33-73.97, a* value between 2.87-3.93 and b* value between 19.50-23.83. Similarly, L* a* b* values of potato-maize extrudates varied between 67.50-73.77, 0.17-2.83 and 1.67-2.83, respectively. Higher hue angle was observed for potato-maize (10%) extrudates whereas lower values of hue angle was observed potatorice (20%) extrudates. Chroma values also varied significant (p<0.05) with respect to feed composition and an overall increase in chroma with increase in potato level was observed for all combinations. These results agreed with the work reported by Takahashi et al. [30] who reported the similar color changes of milled rice flour heat treated in an autoclave (120oC for 60 min) and oven (160oC for 60 min) compared to their raw flours.

Hardness

The hardness is the peak force required for a probe to penetrate the extrudates. The higher the value of maximum peak force required, the higher the hardness of sample [31-33]. The hardness of cereal-potato extrudates at different potato levels is portrayed in the Figure 2. The hardness of extrudates from potato- rice, potato-maize and flour in combination with potato ranged in between 45.71-56.73, 45.00-49.10 and 40.37-49.07 N, respectively. The highest mean value of hardness was observed in potato-rice (10%) extrudates (56.73 N) while lowest mean hardness was noticed in the extrudates prepared from flour (rice+maize) in combination with potato (40.37 N). The extrudates prepared from flour (maize+rice) in combination with potato were less hard than that prepared from the potato-rice extrudates as measured by the texture analyzer. Variable trend was observed in the hardness of cereal-potato extrudates as affected by feed composition. Increasing the potato level decreased the hardness of extrudates, similar trend was observed in expansion ratio of extrudates. Chang and El-Dash [34] found that the hardness is associated with the expansion property of extrudates. Similar trend between hardness and expansion ratio have been reported by many workers [35-37]. The results of the present study are in consistent to those reported by Liu et al. [38].

Overall acceptability

The overall acceptability, which takes into consideration several attributes like appearance color, flavor and texture of cereal-potato extrudates prepared by incorporation of potato in rice, maize and flours in combination is illustrated in Figure 3. The highest overall acceptability was found for rice potato extrudates prepared from 20% incorporation of potato, followed by cereals used in combination with potato (20%). The highest score for potato-rice extrudates may be attributed to the fact that rice and potato being the staple food of most of people.

Bioactive composition

Phenolics, flavonoids, polyamines, and carotenoids are the important phytochemicals found in potato, which are very much desirable in the diet because of their valuable and beneficial effects on human health. The concentration and constancy of these constituents are affected by several factors such as genotype, agronomic factors, postharvest storage, cooking and processing conditions. Polyphenolic compounds are effective in preventing the oxidative stress, thus they contribute a protective and beneficial role for the human health [39].

Total phenolic content and antioxidant activity: Total Phenolic Content (TPC) and antioxidant activity of potato incorporated extruded products prepared from rice, maize and cereals in combination is reflected in the Table 2. Incorporation of potato revealed positive effect on bioactive composition of extrudates. An increase in potato level (0 to 30%) depicted significant increase in total phenolic content of extrudates by 28% in rice potato extrudates, 42% in maize potato extrudates and 30% in rice-maize potato extrudates. The highest total phenolic content was observed in potato-maize (30%) extrudates. Anti-oxidant activity by DPPH radical scavenging effect was ranged between 69.97 to 77.21% in rice potato extrudates, 75.09 to 85.07% in maize potato extrudates and 70.52-80.20% in rice-maize potato extrudates. Adom and Liu [40] reported that the various cereal grains differ significantly in total phenolic content and antioxidant activity (Figure 4).

Total flavonoid content: Flavonoids are a group of compounds which provides health benefits through cell signaling pathways and antioxidant effects. These molecules are found in a variety of food commodities. Quercetin is the most frequently occurring flavonol compound in foods. The interactions between flavonoids and metal ions especially iron and copper may result in the antioxidant mechanism of flavonoids [21]. Total flavonoid content of cereal-potato extrudates ranged between 170.81 to 724.25 μg Quercetin/mg (Table 2). Potato-maize based extrudates showed highest total flavonoid content (TFC) followed by maize-rice potato extrudates. Lowest total flavonoid content was observed in potato-rice extrudates. The variation in total phenolic content, antioxidant activity and total flavonoid content in extruded products prepared from various cereal grains may be due to varying initial level of bioactive compounds in cereal grains. These results are in flow with those previously reported by [41,42] for buckwheat and sweet potato, respectively, upon thermal processing.

In vitro starch digestibility

Starch susceptibility to enzyme digestion is influenced by the plant source of the starch and also by the processing conditions. Digestion of starch is critically significant for infants, people with physical exhaustion, senior citizens having reduced digestive capacity and emotional stress or medical disorders leading to disturbed digestion [43]. In vitro starch digestibility of potato-maize based on release of maltose content ranged in between 14.72-16.40 g/100 g. A higher digestion was observed in potato-rice extrudates and extrudates from flours (rice+maize) in combination with potato which ranged in between 16.68-18.22 g/100 g and 15.28-17.56 g/100 g, respectively (Table 2). Increasing potato level from (0 to 30%) showed an increase in starch digestibility. Madhusudhan et al. [44] reported that higher digestibility of processed flours may be due to comparatively less branches and low molecular weight of the constituent fractions.

In vitro protein digestibility

In vitro protein digestibility of potato-rice extrudates ranged 53.84- 58.58 g/100 g. There was increase in protein digestibility with elevated levels of potato flour from 10% to 30%. The digestible protein content of rice based extrudates was higher as compared to maize based extrudates as given in Table 2. This may be due to higher protein content of rice flour in comparison to maize flour. The protein digestibility of potatomaize and (rice+maize)-potato ranges between 56.19-58.49% and 58.76-59.59%.

Incorporation of potato flours in combination with rice and maize flours can be effectively used to produce extruded snacks by extrusion cooking. Higher expansion ratio was obtained for potato-rice snacks whereas no significant change was observed in bulk density of snacks. Potato-maize based snacks exhibited higher water absorption index. Potato level evinced a positive co-relation with water solubility index. Luminosity of extrudates enhanced with increased potato flour level. Potato-rice snacks showed higher values of hardness (56.73 N) which decreased with increase in potato level. In vitro starch digestibility improved with increase in potato level. Hence, utilization of potato for the development of non-gluten based potato-cereal extrudates is a good alternate to enhance the nutritional, functional characteristics, in vitro digestibility and consumer acceptability.