Journal of Agricultural Science and Food Research

Open Access

ISSN: 2593-9173

ISSN: 2593-9173

Research Article - (2019)Volume 10, Issue 2

Valuable leafy green vegetable kale/Brassica oleracea var. Sabellica L. also known as a curly cabbage, firstly was introduced in Armenia, and its high productivity and prospectively were studied and established in water steam hydroponics experimental modules (gully, cylindrical and continuous), classical hydroponics, as well as in soil culture. In kale revised from hydroponically different systems the raw material and the output of pharmaceutical indices (vitamin C, extractive substances, flavonoids and tannins) are higher 1.5-1.8 times and 1.2-2.3 times, respectively, compared with soil culture. Water stream hydroponics is safer radio-ecological, biotechnological method for production of raw material than classical hydroponics and soil culture.

Water stream hydroponics; Kale; 90Sr; 137Cs; Bio-pharmaco- chemical analyses

Vegetables take big place in human's food being inseparable part of meals. They have important role in regulation of human's nervous system, digestive and other organs activity; as well they increase organism’s resistance. Especially such said salad vegetables that are used in raw condition without cooking have great value. During recent years non-traditional cultivated plants that already have large demand in consumer market have conquered their specific place in the range of vegetable cultivated plants. The range of such cultivated plants includes the Brussels sprout, pak choi, broccoli and etc. from the cabbage family, which are considered as delicacy cultivated plants, differing from the other kinds of cabbage with their nutritional properties.

Taking into account above mentioned, valuable prospective leafy green vegetable kale was firstly introduced into Armenia by us and it was purposed to study the growing possibility and productivity of this cultivated plant in soilless culture conditions (hydroponics), as well as to detect optimal conditions to receive quality, ecologically more safe plant raw material in the Institute of Hydroponics Problems (IHP).

Experiments were done in experimental modules of water stream hydroponics of IH, as well as in conditions of classical hydroponics (CH) and soil culture.

Kale is a biennial vegetable that belongs to the Brassicaceae family. It has green or violet curly leaves that do not form cabbage head [1,2]. Kale is nearer to the wild cabbage with its properties and chemical content. In food there are used mainly its leaves. The plant blooms and gives seed in the next year [3-7].

Kale contains huge amount of proteins equal to meet products (4.3%), all 9 essential amino acids (Val, His, Leu, Lys, Trp and etc.) and 11 non-essential amino acids. In fresh kale leaves the amino acids glutamic acid, proline and aspartic acid are dominant in total amino acid content (12%, 12% and 10%, respectively) [8,9]. The amount of Leu, Lys, Val, Arg and Ala is between 6-8% of total amino acid content and the amount of Tyr, Phe, Thr, His, Ser and Gly is between 3-5% of it. The sulphur containing amino acids cystine (1.6%) and Met (2%) have the lowest proportion [10]. It is rich also with fatty acid omega 3, vitamins (A, C, K, PP, B and etc.), easily digestible Ca (120-150 mg), Mg (34-47 mg) and other mineral substances (K, P, Na, Fe, Zn, Se, Mn, Cu and etc.) [11,12]. Due to content of lutein existed in plant it protects human eye from sun’s ultraviolet rays. Frequent use of this plant in diet protects human organism from a number of diseases, particularly from cardiovascular, gastrointestinal, eye (glaucoma) diseases, diabetes, malignant tumors and etc. [6]. Kale contains 45 different kinds of flavonoids (sulphoraphane, indole-3-carbinol and etc.) that provide the antioxidant and anti-inflammatory properties of this plant, too [9,13-15]. They increase organism’s immunity, decrease the cholesterol level in blood. Regulating glucose level it promotes the decrease of weight. High amount of calcium, contained in the plant (2 times more than in milk) influences on the bone cells generation and regeneration, by that preventing rickets, osteoporosis, teeth fragility. At present kale is widely spread in USA, Western Europe, Japan and in several other countries [16].

The experiments were done in conditions of water stream (cylindrical, gully, continuous), classical hydroponics on the volcanic red slag substrate with the 3-15 mm diameter and in conditions of soil culture with 8 plant/m2 density. Plants’ nutrition was done with Davtyan 0.75 N nutrition solution [4]. In water stream hydroponics the nutrition solution was pumped periodically, irreversibly like a jet during a day about 6-20 times (dependent on climate conditions) with 10-15 second duration to the root-bearing stratum of each plant. The amount of one-time giving solution was 20-50 ml. Plants were nourished 1-3 times during a day in CH and once during 3-4 days in soil culture, maintaining all adopted agro-technical rules (soil aeration, weeds removal, periodic watering, fertilization and etc.) [12]. Leaves harvest was done during June-October.

During vegetation biometric measurements, also bio-pharmacochemical analyses were done. In plant raw material the content of extractive substances, tannins and humidity was determined according SPh XI, flavonoids were identified according Borisov, and vitamin C was estimated according Yermakov [2,17-19]. Techno genic RN (radionuclides) in samples was determined through radiochemical methods with small UMF-1500 background radiometer [14]. The concentration limit values (ACL) have been given according state standards of Russian Federation [8,18] that have been officially accepted also in Republic of Armenia. Received results were statistically analyzed according Dospekhov [5].

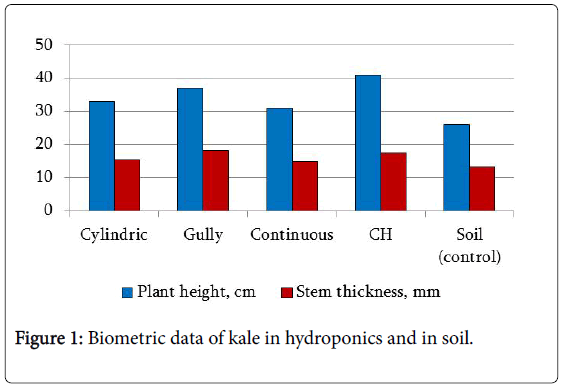

From the analysis of the data presented in the Table 1 it was revealed that during vegetation in all variants, except continuous hydroponics, maximal output of fresh plant raw material was ensured in July during first harvest. Besides, kale raw material received using different hydroponic systems 1.5-1.8 times exceeded soil culture, at the same time gully and classical hydroponic systems 1.1-1.3 times surpass the experimented other hydroponic variants with the yield, plant height and stem thickness (Figure 1).

| Variant | July | August | September | October | ∑ |

|---|---|---|---|---|---|

| Cylindrical | 263 | 132 | 95 | 100 | 590 |

| Gully | 293 | 184 | 142 | 100 | 719 |

| Continuous | 108 | 198 | 161 | 114 | 581 |

| CH | 289 | 141 | 133 | 143 | 706 |

| Soil (control) | 224 | 80 | 65 | 31 | 400 |

| LED05 | - | - | - | - | 28.7 |

LED-The least essential difference [1]

Table 1: Fresh mass of kale during vegetation in hydroponics and soil, g/plant.

Figure 1: Biometric data of kale in hydroponics and in soil.

In all hydroponic variants, except continuous hydroponics the maximal accumulation of fresh plant raw material (1.6-2.9 times) was observed in July. It is important to mention that it was noticeably high (2.8-7.0 times) in soil control during first month.

It is necessary to emphasize that growth conditions have significant influence on the pharmaco-chemical indices of plant raw material (Table 2). The increase of extractive substances content (1.2-1.5 times) was stated in all water stream hydroponic modules and relatively high content of flavonoids was established in gully system (10-35%). In hydroponics the content of tannins was fluctuated between 2.0-2.2% that conceded insignificantly the same index of soil (2.4%). It was revealed also the influence of cultivation conditions on the biosynthesis of vitamin C: cylindrical and continuous hydroponic systems exceeded 1.3-1.5 times the conditions of gully, classical hydroponics and soil by the content of vitamin C (Table 2). Due to high crop capacity of hydroponic plants the difference between plants of hydroponic systems and soil is significant from the point of mentioned indices: in the case of extractive substances the difference is 1.7-2.3 times, for flavonoids it is 1.2-2.0 times, in the case of tannins it is 1.2-1.6 times and for vitamin C it is 1.8-2.2 times.

| Variant | Extractive substances | Total flavonoids, according luteolin | Tannins | Vitamin C | β-carotene | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| % | output, g/plant | % | output, g/plant | % | output, g/plant | mg% | output, mg/plant | mg% | output, mg/plant | |

| Cylindrical | 34.7 ± 0.9 | 205 | 2.8 ± 0.10 | 16.5 | 2.0 ± 0.10 | 11.8 | 195 ± 2.5 | 1151 | 11.2 ± 0.20 | 66.1 |

| Gully | 36.2 ± 0.9 | 260 | 3.8 ± 0.15 | 27.3 | 2.2 ± 0.10 | 15.8 | 134 ± 2.1 | 964 | 12.8 ± 0.42 | 92 |

| Continuous | 38.0 ± 1.0 | 221 | 3.4 ± 0.15 | 19.8 | 2.2 ± 0.12 | 12.8 | 189 ± 2.1 | 1098 | 11.0 ± 0.21 | 63.9 |

| CH | 26.2 ± 1.2 | 185 | 3.4 ± 0.10 | 24 | 2.2 ± 0.11 | 15.5 | 150 ± 2.5 | 1059 | 13.1 ± 0.26 | 92.5 |

| Soil (control) | 28.1 ± 1.4 | 112 | 3.4 ± 0.11 | 13.6 | 2.4 ± 0.12 | 9.6 | 132 ± 2.0 | 528 | 13.7 ± 0.42 | 54.8 |

Table 2: The pharmacochemical indices of kale in hydroponics and in soil.

Plant cultivation conditions influenced specifically on the RN accumulation in plant raw material (Table 3). Thus, plants in water stream hydroponics conceded by the content of 90Sr and 137Cs plants grown as in classical hydroponics (1.2-1.3 and 1.1-1.2 times), as in soil (1.8-2.0 and 1.4-1.5 times) conditions.

| Variant | 90Sr | 137Cs | OR, 90Sr/137Cs | 90Sr | 137Cs |

|---|---|---|---|---|---|

| Bq/kg | AC | ||||

| Cylindrical | 9.9 ± 0.32 | 8.7 ± 0.25 | 0.08 | 22.5 | 290 |

| Gully | 8.8 ± 0.25 | 8.3 ± 0.20 | 0.07 | 20 | 277 |

| Continuous | 9.5 ± 0.42 | 8.0 ± 0.15 | 0.08 | 21.6 | 267 |

| CH | 11.8 ± 0.20 | 9.8 ± 0.26 | 0.08 | 26.8 | 327 |

| Soil (control) | 17.6 ± 0.20 | 11.9 ± 0.21 | 2.1 | 2.4 | 1.2 |

| ACL [1. 4] | 50 | 130 | - | - | - |

Table 3: The content of 90Sr, 137Cs in kale's plant raw material and RN relative indices in hydroponics and in soil.

In different hydroponic systems the content of 90Sr in kale's plant raw material exceeded the content of 137Cs in all 1.1-1.2 times and in soil culture it exceeded 1.5 times.

Probably, RN has entered into kale as through the roots from the nutrient solution or irrigation water and soil, as through over ground organs by the out of root way from the air basin (atmospheric precipitations, hydro and aerosols, dust).

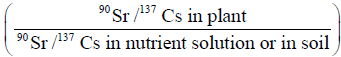

Calculation showed that the values of observed ratios (OR) of 90Sr-137Cs pair for kale  in systems of nutrient solution-plant and soil-plant were 0.07-0.08 in hydroponics and 2.1 in soil. That is OR<1, which means that from the nutrient solution the cultivated plants absorbed more intensively 137Cs in hydroponics and 90Sr in soil (Table 3). It was confirmed through the values of RN accumulation coefficients (OC) of cultivated plants.

in systems of nutrient solution-plant and soil-plant were 0.07-0.08 in hydroponics and 2.1 in soil. That is OR<1, which means that from the nutrient solution the cultivated plants absorbed more intensively 137Cs in hydroponics and 90Sr in soil (Table 3). It was confirmed through the values of RN accumulation coefficients (OC) of cultivated plants.  . For the kale in hydroponics 137Cs AC>90Sr AC 12.2-13.8 times, and in soil 90Sr AC>137Cs AC 2 times.

. For the kale in hydroponics 137Cs AC>90Sr AC 12.2-13.8 times, and in soil 90Sr AC>137Cs AC 2 times.

Kale cultivated in different hydroponic systems exceeded with fresh plant raw material and with a number of biochemical indices (vitamin C, extractive substances, flavonoids and tannins) and conceded with radiochemical indicators to the same indicators of soil culture. Modern water stream hydroponic way is radio ecologically more safe biotechnological way for plant raw material production, than classical hydroponics and soil culture. Despite of the cultivation conditions the content of controlled techno genic RN (90Sr, 137Cs) in kale’s plant raw material did not exceed ACL. Kale production with modeling of the innovation technology of modern water stream hydroponics on hectares may satisfy the demand of our Republic.

Citation: Daryadar M, Mairapetyan KH, Tovmasyan AH, Aleksanyan JS, Tadevosyan AH, Kalachyan LH, et al. (2019) Productivity of Leafy Green Vegetable Kale in Soilless Cultivation Conditions. J Agri Sci Food Res 10:260. doi: 10.35248/2593-9173.19.10.260

Received: 06-Sep-2019 Accepted: 24-Apr-2019 Published: 01-May-2019 , DOI: 10.35248/2593-9173.19.10.260

Copyright: © 2019 Daryadar M, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.