Journal of Nutrition & Food Sciences

Open Access

ISSN: 2155-9600

ISSN: 2155-9600

Research Article - (2018) Volume 8, Issue 1

The study explored the potentials of substituting breadfruit into cassava to obtain gari analogue of which proximate and mineral compositions were evaluated. A portion of matured but unripe breadfruit (Artocarpus altilis) and mature cassava tubers were co-fermented (100:0, 0:100, 80:20, 70:30, and 60: 40 Cassava to Breadfruit) to obtain gari analogue. The samples were evaluated for proximate and mineral analyses. Data obtained were subjected to descriptive and inferential statistics. The results showed that Co-fermentation of cassava and breadfruit produced gari and gari analogue with slightly enhanced protein content. The protein content of the samples ranged from 3.42%-5.68% with 100% cassava gari having the lowest protein content (3.42%) and 100% Breadfruit gari having highest protein content (5.68%). Co-fermented products did not have enhanced mineral content than that of whole breadfruit and cassava gari. Zinc content of 100% cassava gari was 13.71, which were significantly higher than that of the co-processed gari. 100% Breadfruit gari and 60%C: 40%B had no zinc content at all. Calorific values of the 100% cassava gari was significantly higher (p<0.05) calories (4442.85 Kcal) than other gari samples with 100% Breadfruit gari having the lowest calories (3652.44 Kcal). This study established that 20% of breadfruit c-fermented with cassava yields a novel food product that compares favorably with 100% cassava gari in terms of nutritional values thus, confirming that processing of breadfruit into a locally familiar from analogue to gari will increase its utilization, especially in several food deficit countries where fermented cassava products are already accepted as staple foods.

Keywords: Breadfruit; Cassava; Fermentation; Gari analogue; Proximate; Mineral; Calorific

The breadfruit (Artocarpus altilis) is a widely grown nutritious and versatile tree fruit. Breadfruit, a tropical fruit tree produces fruits twice a year, from March to June and from July to September with some fruiting throughout the year [1]. Breadfruit has been processed into many forms for utilization in the food industry. It has also been processed into starches [2] and into flour [3]. Studies on the modification of breadfruit starch involving heat-moisture-treatment and annealing, which entail modification of temperature and moisture content have been carried out and reported by Adebowale et al., [4]. Seeds are harvested from ripe fruits and boiled or roasted with salt. They are sometimes made into a puree in West Africa [2]. Breadfruit seeds are usually cooked with the raw breadfruit or are boiled or roasted. Seeded forms of breadfruit predominate on many atolls in Micronesia and seeds contribute to the daily diet [1].

Cassava (Manihot esculenta Crantz) is African’s second-most important staple food in terms of capita calories consumed; and a source of calories for two out of every five Africans [5]. The tubers are usually processed into a variety of products such as gari which is a granulated product that has a long shelf life and is in a ready-to-eat form [6,7]. Despite being a cheap source of food calories, cassava is nutritionally deficient in protein and contains cyanogenic glucosides (linamarin) which upon hydrolysis by linamarase produces hydrogen cyanide [8,9]. The high consumption pattern of cassava diet as witnessed in developing countries without adequate protein supplementation expose the vulnerable group (children, pregnant and lactating mothers) to incidence of protein-energy malnutrition [10]. Cyanide is very poisonous because it binds to an enzyme cytochrome oxidase and stops its action in respiration which is a key energy conversion process in the body. There are some reported cases of death linked to consumption of cassava meals [11]. Smaller (non-fatal) amounts of cyanide causes acute intoxication with symptoms such as dizziness, headache, stomach pains, vomiting and diarrhea [12]. Several disease conditions have been reported to be associated with dietary cyanide: konzo (tied legs) [13], tropical ataxic neuropathy [14] and goiter and cretinism [15].

Freshly harvested matured but unripe breadfruits and matured cassava tubers were purchased at Ita-Osa market, Ile-Ife, Osun-State, Nigeria. Microbiological media and chemicals of analytical grade were procured. Equipment was supplied by the Department of Food Science and Technology and Central Science laboratory, Obafemi Awolowo University, Ile-Ife, Nigeria.

Fermentation of breadfruit into gari

Matured green ripe breadfruits were weighed, washed, peeled and decored manually as shown in Figure 1. Afterwards they were sliced manually into 1 cm thick slices. The slices were grated mechanically and the mash obtained was put in a bag and subjected to hydraulic press for 5 days (72 h) during which fermentation occurred and the juice drained off. The dried cake was then sieved and roasted in a metal pan over wood fire. The products obtained (i.e. gari and gari analogue) were packaged in polythene bags for further analysis [16].

Figure 1: Process flow of gari analogue from breadfruit. [Source: Awoyemi [16]]

Fermentation of cassava

Cassava tubers were sorted manually as shown in Figure 2 to separate roots, leaves and debris; they were weighed and then peeled manually. The peeled tubers were thoroughly washed and grated with a mechanical grater. The mash obtained was put in a bag and subjected to heavy pressure for five days during which fermentation occurred and the juice was drained off. The gari produced was covered with plastic container for further analysis [17].

Co-fermentation of breadfruit with cassava

Both cassava and breadfruit were co-fermented as shown in Figure 3. Three blends were prepared by weighing and mixing breadfruit mash and cassava mash in the following proportion of 80:20, 70:30 and 60:40. Others were 100% cassava (control) and 100% breadfruit. Each of the blends obtained and the controls of the experiment were made to undergo microbiological and sensory analyses.

Proximate analysis

The proximate composition of the gari and gari analogue samples was determined using the methods of AOAC [18].

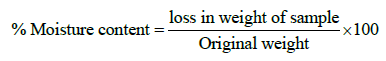

Moisture content determination

It was determined using “Gallenkamp” hot air oven method [18]. Exactly 5 g of the prepared samples was weighed into porcelain dish of known weight and was heated in a “Gallenkamp” hot air oven at 105°C for 3 h. Each sample was cooled in desiccators and weighed. The samples were subsequently heated, weighed and cooled until a constant weight was attained. The moisture content was determined as follows:

(1)

(1)

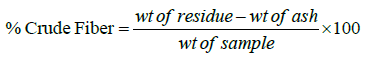

Crude fibre content determination

The fat free extract obtained after ether extract that has been collected was placed in a beaker and 700 ml boiling 1.25% sulphuric acid added. The beaker with its content was heated for 30 min. while being rotated periodically to remove adhered solids to its sides. Thereafter, the solution was filtered and rinsed with 50 ml boiling water. This was repeated with three 50 ml portions of water and subsequently sucked dry. The entire residue was removed and replaced in a beaker with boiling 1.25% NaOH added. Boiling was done again after which the contents of the beaker was removed and filtered as described above. This was then washed with 25 ml boiling 1% sulphuric acid, three portions of 50 ml water and 25 ml ethanol. The residue was transferred into an ashing dish and dried at 130°C. After cooling the dish in a dessicator, weight was taken. The residue was thereafter ignited at 600°C for 30 min., cooled in desiccators again and reweighed [18]. The percentage crude fibre in each sample was calculated as:

(2)

(2)

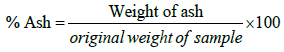

Ash content determination

Ash content determination was carried out by using the method which defines ash as the inorganic residue remaining after the organic matter has been burnt [19]. Ash content of samples was determined using AOAC method [18]. Exactly 2 g of well mixed samples was weighed into an ignited, cooled and weighed crucible. Few drops of glycerol was added and mixed thoroughly with the sample and was heated gently over a Bunsen burner until the sample charred. The crucible was transferred into a muffle furnace at about 550°C until a white grey ash was obtained. The crucible was cooled in a desiccator and reweighed. The percentage ash content was calculated as follows;

(3)

(3)

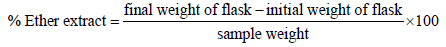

Determination of crude fat content

Exactly 2 g of the sample was weighed into a fat free extraction thimble and plugged lightly with cotton wool. The thimble was placed in the extractor and fitted up with reflux condenser and a 250 ml soxhlet flask which has been previously dried in the oven, cooled in a desiccator and weighed. The soxhlet flask was then filled to two-thirds of its capacity with n-hexane and boiled on a heating mantle. The heater was put on for 6 h with constant running water from the tap for condensation of hexane vapour. The n-hexane was left to siphon over several times until it was short of siphoning. Thereafter, n-hexane was drained into a stock bottle. The thimble containing the sample was removed and dried. The extractor, flask and condenser were replaced and the distillation continued until the flask was practically dry. The flask containing the oil was detached, its exterior cleaned and dried to a constant weight in the oven. The difference in the final and initial weights of the distillation flask represented the oil extracted from the sample [18] and the percentage ether extract was calculated as shown below;

(4)

(4)

Crude protein content determination

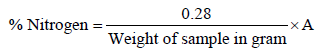

About 2 g of each sample was weighed into a digestion tube. Kjedhal tablet (0.8 g) was used as catalyst and the samples were digested with 15 ml of concentrated sulphuric acid using an automatic dispenser. The digestion tube was placed on a preheated digester at 420°C for about 30 min. in a fume cupboard and digested until a clear homogenous mixture was obtained. After digestion, the digestion tube was removed, cooled and diluted with about 50 ml of distilled water. The digestion tube was placed in a micro-kjedhal analyzer (digestion unit). The analyzer was dispensed; 50 ml of 40% NaOH into the digested sample and this was heated up to liberate ammonia which was distilled into a conical flask containing 25 ml of 2% boric acid for about 4 min. During the distillation process, the ammonia produced combined with the boric acid to produce ammonium borate solution which was titrated with 0.1 M sulphuric acid until a purplish-grey end point was obtained. The % nitrogen was calculated as follows:

(5)

(5)

Where, A=Volume (ml) of 0.1 M H2SO4

Carbohydrate content determination

The carbohydrate content of each of the sample was calculated by difference. The total of all the previously proximate parameters was subtracted from 100 represent the carbohydrate content that is;

%Carbohydrate=100%-(%moisture +%crude protein +%crude fat + %crude fibre +%ash). (6)

Calorific value determination using bomb calorimeter

The calorific value of each sample was determined using Bomb calorimeter [18]. Exactly 5 g of each sample was weighed in to the metal dish of bomb calorimeter. The bomb lid was tightened and inserted into the bomb chamber, covered and left for few minutes. The initial and main period readings were recorded. The reading was multiplied with some constant numbers i.e. (4 for protein, 4 for carbohydrates and 9 for Fat respectively). The bomb chamber was opened and degassed.

Mineral content

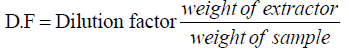

Mineral content was determined using the method of AOAC [18]. Exactly 0.5 g of gari sample was transferred into a 75 ml digestion tube, 5 ml of digestion mixture was added swirled and placed in a fume cupboard; digestion was made for hours at 150°C. This was removed from the digester, cooled for 10 min., and then 3 ml of 6HCL was added to each tube. The mixture was digested for another 90 min. This was removed from the digester, cooled and 300 ml of distilled water was added to each tube. Each tube was stirred vigorously using the vortex mixer and the mineral element of each sample determined using Atomic Absorption Spectrophotometer. Standard of each element was used to standardize the machine. The samples reading and standard reading was used to calculate the slope. The mineral content of each sample was calculated using:

Mineral (ppm)=M.R × slope × D.F (7)

M.R=Machine reading

Slope=Constant from AAS

Proximate composition of gari and gari analogue

The result of moisture, ash, fat, protein, crude fibre and carbohydrate content of gari samples are presented in Table 1. From the results, gari obtained from 100% breadfruit had a higher moisture (21%), protein (5.68%), fat (0.68%), ash (2.24%), and crude fibre (2.35%) than gari obtained from 100% cassava and co-processed gari samples. The moisture content of the samples ranged from 9.25% to 21.01% with 100% cassava gari having the least value (9.25%) and 100% breadfruit having the highest value (21.01%).

| Samples | Moisture (%) | Ash (%) | Crude fibre (%) | Protein (%) | Fat (%) | Carbohydrate (%) | Calorific value (Kcal) |

|---|---|---|---|---|---|---|---|

| 100%C | 9.25 ± 0.40e | 1.75 ± 0.01c | 2.49 ± 1.00b | 3.42 ± 1.07e | 1.84 ± 0.03a | 81.25 ± 5.08a | 4442.85 ± 34.51a |

| 100%B | 21.01 ± 0.05a | 2.35 ± 0.01a | 2.69 ± 0.60a | 5.68 ± 2.03a | 0.70 ± 0.20a | 67.57 ± 5.70e | 3652.44 ± 20.10e |

| 80%C:20%B | 10.68 ± 0.30d | 2.21 ± 1.00a | 1.96 ± 0.01e | 3.61 ± 0.20d | 1.40 ± 0.60a | 80.14 ± 7.04b | 4056.67 ± 30.10b |

| 70%C:30%B | 11.48 ± 0.45b | 2.06 ± 1.02b | 2.13 ± 0.05d | 3.83 ± 0.18c | 1.33 ± 0.53a | 79.17 ± 5.64c | 3835 ± 57 ± 23.02c |

| 60%C:40%B | 11.31 ± 0.04c | 2.24 ± 0.40a | 2.35 ± 1.10c | 3.98 ± 1.23b | 1.24 ± 0.40a | 78.88 ± 8.79d | 3668.56 ± 25.57d |

Note: C: Cassava; B: Breadfruit

Each value represents the mean of three replicates ± standard error.

Mean on the same column followed by the same superscript are not significantly different at 5% level of significance

Table 1: Proximate content of gari and gari analogue.

Moreover, the moisture content of co-fermented gari analogues, (80:20, 70:30, and 60:40) this study had the lowest value (9.25%) though the difference was not significant (p>0.05). The moisture content of the final product is a measure of quality and stability. The values obtained in this were lower than 100% breadfruit gari. Cassava gari (100%)which was regarded as control sample for study were lower than the values reported for gari by Salunkhe et al., [20] for gari samples processed from fresh tubers of different cassava cultivars (11.78 to 11.81), but higher than the values reported by Ekunola [21] for gari obtained from 100% cassava and breadfruit as well as blended gari at ratios 80:20, 70:30 and 60:40 (Cassava: Breadfruit) as (11.78% to 11.81%). The low moisture content of 100% cassava gari could have probably conferred longer shelf life on the gari samples during storage. The 100% breadfruit gari sample did not store long because of the higher moisture content.

Breadfruit 100% gari had the highest ash content (2.35%) while 100% cassava gari had the lowest value. The values (1.75-2.35%) obtained in this study were close to the value (1.10 to 3.30%) reported by Ekunola [21] for gari obtained from 100% cassava and breadfruit as well as from blended gari at ratio of 80:20, 70:30 and 60:40 (Cassava: Breadfruit). This means that gari obtained from either cassava or breadfruit or their blends may not be an adequate source of mineral elements.

The protein content of gari samples ranged from 3.42 to 5.68% with 100% breadfruit exhibiting highest value (5.68%) and 100% cassava gari showing the lowest value of 3.42%. The analysis of variance showed significant (p>0.05) differences in the protein content of gari samples and this could possibly be due to co-processing and substitution effects. The protein results in this study were higher than the values reported by Salunkhe et al., [20] that protein content of gari ranges between 1.04 to 1.20% and 1.30 to 1.40% respectively. Furthermore, Ekunola [21] reported protein values of 0.80 to 1.20% for gari samples from 100% cassava and breadfruit blended gari at ratio 80:20, 70:30 and 60:40 (Cassava: Breadfruit). Thus, protein values obtained in this study could be as a result of fermentation processes in which cassava and breadfruit were subjected into and incorporation of the breadfruit which was of high protein content into cassava. Hence, this result confirmed that breadfruit gari is slightly proteineous and nutritious than cassava gari.

The crude fibre content of gari samples ranged from 1.96% to 2.69% which is still within the nutritionally maximum level of 3.0% [22]. One hundred percent breadfruit gari had highest crude fibre value of 2.69% which also reflected in the gari analogues. This confirms that the crude fibre which is a measure of the undigested components of foods such as cellulose, hemi-cellulose and lignin also play a very important role in nutrition because it adds bulk and aids proper digestion of foods [23]. Cassava gari (100%) had the highest fat content of 1.84% while 100% breadfruit gari had the least value of 0.70%. Thus because of the low-fat content values exhibited by all the gari samples, rancidity will not be a problem during storage.

Gari is known to be one of the energy giving food that offers a lot of calories, the carbohydrate values in this study ranged from 66.88 to 82.39% with 100% breadfruit gari showing the least value of 66.88% and 100% cassava gari had the highest value of 82.39%. There was no significant difference (p<0.05) in all the samples except 100% breadfruit gari which was significantly lower than other samples. Therefore, gari in general should be taken in combination with other protein sources to improve its nutritional quality since it is one of the most staple foods consumed in Africa especially in Nigeria.

Mineral content of gari and gari analogue

Table 2 shows the mineral contents of the gari samples. Zinc content of 100% cassava gari was 13.71 which were significantly higher than that of the co-processed gari. Breadfruit gari 100% and 60%C: 40%B has no zinc content at all. This might be due to breadfruit contents which are more present in the samples because breadfruit is known to have little or no zinc as reported by Omobuwajo [1].

| Minerals | 100%C | 100%B | 80%C:20%B | 70%C:30%B | 60%C:40%B |

|---|---|---|---|---|---|

| Zinc | 13.71 ± 0.01a | 0.00 ± .0.00c | 1.11 ± 0.01b | 0.05 ± 0.01b | 0.00 ± 0.00c |

| Iron | 8.22 ± 0.06a | 0.49 ± 0.07e | 6.69 ± 0.03b | 4.80 ± 0.07c | 2.92 ± 0.03d |

| Potassium | 48.5 ± 0.71a | 20.21 ± 0.00d | 27.0 ± 0.00b | 25.25 ± 0.00c | 20.15 ± 0.07d |

| Magnessium | 4.00 ± 0.28a | 3.25 ± 0.04b | 3.00 ± 0.28b | 1.25c ± 0.00c | 1.00 ± 0.00c |

| Calcium | 9.2 ± 0.02c | 13.1 ± 0.01a | 6.3 ± 0.07e | 8.1 ± 0.07d | 10.2 ± 0.01b |

| Phosphorus | 18.7 ± 0.07e | 27.6 ± 0.01a | 19.4 ± 0.02d | 20.2 ± 0.01c | 22.8 ± 0.01b |

| Sodium | 2.3 ± 0.01b | 5.4 ± 0.02a | 1.9 ± 0.04c | 1.13 ± 0.04c | 2.0 ± 0.01b |

Note: C: Cassava; B: Breadfruit

Each value represents the mean of three replicates ± standard error.

Mean on the same column followed by the same superscript are not significantly different at 5% level of significance

Table 2: Mineral contents of gari and gari analogue of cassava, breadfruit and co-fermented cassava and breadfruit (mg/ppm).

Zinc is known to be a component of enzymes involved in most major metabolic reactions. About 2 g to 3 g of zinc is found in the body. Zinc aids the production of insulin by the pancreas of protein. A deficiency of zinc leads to a diminished sensitivity to taste (hypogausia) and to a decrease in odour sensitivity [24].The mineral composition of 100% cassava gari was higher than the other samples. This may be due to varietal differences, which could not be ascertained, as well as processing method used. Generally, fermentation seemed to significantly increase iron and zinc contents of cassava products. Iron, Calcium, phosphorus and sodium contents of 100% breadfruit gari which were 0.49, 13.1, 18.7 and 5.4 respectively were significantly higher than other gari samples. This is because breadfruit is found to be rich in such minerals as reported by USDA [25]. However, there was no improvement in the mineral content of the co-processed gari. Iron is responsible for the ability of hemoglobin to transfer oxygen throughout body tissues for internal respiration to occur. Deficiency of iron causes anemia and fatigue. Sodium helps to maintain the fluid and acid-base balance of the body, in the transmission of nerve impulses, in the absorption of glucose, in the relaxation of the muscles and in the maintenance of cell membrane permeability [19]. Calcium is required for all tissues and, in conjunction with phosphorus; it is largely responsible for the hardness of the bones and teeth. It is essential in the coagulation of blood, irritability of nerves and maintenance of acid-base balance of the body. The deficiency of calcium in the body leads to Rickets in infants in children and osteonelacia in adults. People with severe dehydration are liable to high blood potassium, a condition known as hyperpotassemia. Severe vomiting may lead to potassium deficiency. Magnesium regulates muscle contraction, while phosphorus plays an important role in the storage and release of energy [26].

Calorific value of gari and gari analogue

The result presented in Table 2 revealed that 100% cassava gari had a significantly higher (P<0.005) calorie (4442.85 Kcal) than other gari samples. Breadfruit gari (100%) had the lowest calorie (3652.44 Kcal). This is because cassava is a good source of carbohydrate which is rich in fat. However, the calorie values were within the same range reported by Akindahunsi, et al., [27] and Oboh and Akindahunsi [28] for cassava products in Nigeria as 4445.00 Kcal.

This study has established the possibility of producing a gari analogue with comparable proximate, mineral and calorific characteristics to gari from cassava. Because gari is already acceptable in several parts of Africa, the gari analogue from breadfruit will expand the food base in these areas, the acceptance of breadfruit and contribute to food security in these food-deficient countries. In addition, possibility of production of instant gari from breadfruit-substituted cassava unveiled. A procedure of co-fermentation of breadfruit and cassava should be explored in the production of gari in the future.