Journal of Pollution Effects & Control

Open Access

ISSN: 2375-4397

ISSN: 2375-4397

Research Article - (2017) Volume 5, Issue 2

Unconventional well development is an energy intensive process, which relies heavily on diesel fuel to power high-horsepower engines. To reduce emissions and fuel costs, and increase natural gas utilization, industry has employed a limited number of dual fuel compression-ignited and dedicated natural gas spark-ignited engines. However, little in-use data are available for conventional engines or these new technologies. We measured regulated gaseous emissions from engines servicing the unconventional natural gas well development industry to understand better their in-use characteristics such that insight into real world emissions factors could be developed for use by researchers, regulators, or industry. Data collection efforts were limited by low utilization of these new technologies, therefore these data may not be representative of the current distribution of engines either nationally or by shale play. Emissions and fuel consumption were collected from two drilling engines operating as Tier 2 diesel only and dual fuel, two drilling engines that were dedicated natural gas, and two hydraulic fracturing engines operated as diesel only and dual fuel. Emissions for diesel only operation were below Tier 2 certification standards for carbon monoxide and non-methane hydrocarbon plus oxides of nitrogen. Dual fuel engines require use of oxidation catalysts to reduce carbon monoxide and non-methane hydrocarbon emissions resulting from this mode of combustion. For dual fuel engines with diesel oxidation catalysts, carbon monoxide emissions were reduced below Tier 2 diesel only standards by an order of magnitude. Dual fuel operation showed varied effects on non-methane hydrocarbon plus oxides of nitrogen emissions depending on configuration. These variations were mainly driven by some technologies increasing or decreasing oxides of nitrogen emissions. One dual fuel drilling engine failed to meet Tier 2 standards, as it did not include a diesel oxidation catalyst. Of the two dedicated natural engines tested, one had a failed catalyst and did not meet off-road standards for spark-ignited engines; however, emissions from the engine with the properly functioning catalyst were well below standards. Dedicated natural gas engines also demonstrated potential to meet Tier 2 carbon monoxide regulations while producing significantly lower oxides of nitrogen emissions than diesel only or dual fuel engines.

Keywords: Regulated emissions; Unconventional wells; Horizontal drilling; Hydraulic fracturing; Natural gas; Dual fuel

CFR: Code of Federal Regulations; CI: Compression- Ignited; CH4: Methane; CO: Carbon Monoxide; CO2: Carbon Dioxide; DOC: Diesel Oxidation Catalyst; ECU: Engine Control Unit; EPA: Environmental Protection Agency; KW: Kilowatt; LLT: Low Load Transient; NMHC: Non-Methane Hydrocarbons; NOx: Oxides of Nitrogen; SCFM: Standard Cubic Feet per Minute; SI: Spark-Ignited; SS: Steady State; TCF: Trillion Cubic Feet; THC: Total Hydrocarbon; US: United States

The United States (US) has experienced growth in the natural gas industry over the past decade due to unconventional well development. In 2015, SNL Financial reported that natural gas use exceeded coal for the first time in domestic electric power production [1]. The US Energy Information Administration forecasts natural gas consumption to grow in 2017 and 2018. Though natural gas production declined in 2016, it was the first time in over 10 years and net exports still increased [2]. The US Energy Information Administration also predicts natural gas production to increase through 2040 to meet energy demands [3] but that technically recoverable reserves will last for 93 years [4]. Therefore, natural gas may serve as a source of reliable energy for much of the next century. Increases in natural gas extraction are possible due to the development of technologies such as horizontal/directional drilling and hydraulic fracturing. In addition, the depth of these new wells has increased steadily over time [5]. Horizontal drilling rigs utilize highhorsepower engines to power their draw works, drills, mud pumps, and other equipment. Most current drilling rigs are electrical and use two to three stationary engines coupled to electric generators to produce this onsite electricity. On average, drilling rigs consist of 2.15 operating engines, with a per engine power of 1381 horsepower. These engines are estimated to operate 62.6 hours per 1000 feet drilled at an average load of 48.5% [6]. High-horsepower diesel engines also power hydraulic fracturing pumps. A typical fracturing fleet features total engine capacities over 20,000 horsepower. On average, each well requires 8 to 12 pumps for fracturing, but some may require up to two dozen, each rated between 1500 and 2500 horsepower [7]. As well development and completion is an energy intensive process, industry is seeking methods to reduce fuel costs. One approach is to displace some diesel fuel with natural gas using dual fuel conversion kits while another is the complete replacement of diesel fuel consumption by using dedicated natural gas engines. Little data are available on the in-use performance of these new technologies so we conducted in-use measurement campaigns to assess the effects of these new technologies on regulated emissions as compared to conventional Tier 2 diesel only engines. Dual fuel conversions, also used for automotive applications, Tiwari et al. [8] allow for substitution of natural gas into the engine intake, providing energy for combustion and in turn decreasing the diesel fuel demand. All kits tested under this work used natural gas fumigation and included two versions of the Caterpillar Dynamic Gas Blending (DGB) kit, an Altronics-GTI Bi- Fuel kit, and a Cummins-ComAP kit. Currently these systems receive exemptions from the EPA and are required to ensure their operation does not increase regulated gaseous pollutants of oxides of nitrogen (NOx), non-methane hydrocarbons (NMHC), and carbon moNOxide (CO), as well as particulate matter (PM), relative to the original diesel engine. The DGB systems are certified by the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) for Nonroad Compression-Ignition (CI) Tier 2 emissions defined by the US Code of Federal Regulations (CFR) in section 40 CFR 1039.102.

The DGB kit can be used on the land drilling Caterpillar 3512B and C and the higher horsepower 3512B-HD for hydraulic fracturing applications. The conversion kit is advertised with specifications of 70% displacement of diesel fuel for drilling applications and 60% displacement for well stimulation activities [9]. Altronic’s GTI Bi- Fuel System is advertised to displace up to 70% of diesel fuel and reduce exhaust emissions and costs [10]. The QSK 50 engine with the Cummins-ComAP kit is advertised with substitution rates up to 70% with equivalent power output as similarly sized engines [11]. Generally, substitution limits are controlled by concerns that natural gas should not knock under high compression, nor fail to ignite for being too lean [12].

Due to increased availability of natural gas and possible reductions in NOx and CO2 emissions, the application of dual fuel conversion kits to conventional diesel engines continues to receive significant research focus [13-17]. Early research examined operation of on-road dual fuel engines utilizing technology similar to current off-road dual fuel kits. Data showed that CO emissions increased by 390% and NMHC increased by 52% without the use of an oxidation catalyst [18]. Similar results were demonstrated for older Caterpillar C-10 dual fuel engines when employed in commuter buses [19]. Another study showed the addition of catalysts reduced NMHC by 40% and reduced CO emissions by over 500% [20]. Similar trends were shown with recent dual fuel research on diesel engines that utilized alternative emissions control strategies such as exhaust gas recirculation and full 2010 compliant after treatment systems [21,22]. Overall, the general trend is increased NMHC and CO emissions from dual fuel technologies. The application of these dual fuel conversion kits that are emissions compliant, require the addition of a diesel oxidation catalyst (DOC) to meet NMHC and CO Tier 2 emissions standards. DOCs typically use platinum group metals including platinum and palladium. The operation of such catalysts and their high CO and NMHC reduction potential are reported in literature [23,24]. It is noted that DOCs offer little reduction of methane (CH4) and NOx emissions, and are employed on lean engines where the exhaust contains excess oxygen.

To examine the effects of dual fuel operation in unconventional well development we measured exhaust emissions from four different engine and dual fuel kit configurations-two focused on dual fuel drilling and two on dual fuel stimulation. Engines of Campaigns 1-3 were equipped with DOCs while the early model conversion of Campaign 4 did not include a DOC. Engines operated in diesel only and dual fuel modes, and we collected data pre and post-oxidation catalyst for both configurations. Continuous measurements of natural gas and diesel fuel flow rates occurred in parallel along with the collection of engine control unit (ECU) data.

An alternative to dual fuel engines are dedicated natural gas engines such as the Waukesha L7044GSI engine. These engines are spark-ignited (SI) and can use various sources of natural gas-well, local pipeline, compressed natural gas (CNG) or liquefied natural gas (LNG). The engines are certified to meet the Nonroad Large SI Engine Exhaust standards defined in 40 CFR 1048.101. These engines are outfitted with three-way catalysts (TWCs) and air/fuel ratio control [25]. Applications of TWCs to stoichiometric or rich burn engines offer reductions in NMHC, CO, and NOx and these benefits have long been established [26,27]. Waukesha advertised post-catalyst emissions of 1.61 g/kWh CO and 0.94 g/kWh NMHC+NOx. This is a significant reduction compared to engine-out certified emissions of 15.01 g/kWh CO and 18.29 g/kWh NMHC+NOx [25]. This shows that the engine outfitted with a catalyst could produce over 20 times less NMHC+NOx and over 11 times less CO than one without a catalyst. To examine the effects of dedicated natural gas engines we collected in-use data from two drilling rigs outfitted with L7044GSI engines.

Exhaust emissions for comparison with EPA standards were sampled pre-catalyst for diesel only operation to represent Tier 2 engineout emissions. Dual fuel engines were sampled pre and post-catalyst, but only post-catalyst emissions are presented here for comparison with certification standards. Emissions from the dedicated natural gas engines were sampled post-catalyst for comparison. ECU data were collected from diesel engines with a VIA Model HDV100A1 [28]. Dedicated natural gas engine data were collected via Modbus. These data were used to determine the speed and load of the engine allowing for the calculation of engine brake power. Diesel fuel flow was measured with meters on the inlet and return line of the engine-yielding net fuel consumption. KRAL OME20 Volumeters® provided fuel flow rates for drilling Campaigns and OME32 models for hydraulic fracturing Campaigns. The OME20 and OME32 Volumeters® measured diesel flow rates of up to 45 and 150 l/min, respectively [29]. These fuel meters each had an accuracy of 0.1% of the measured value. Temperature, pressure, and density affected accuracy and an analysis showed the combined accuracy during all data collection Campaigns was less than ± 2%. A KURZ MFT-B flow meter with a range of 0-252 standard cubic feet per minute (SCFM) of natural gas flow measured the flow rate of natural gas into the engines [30]. The natural gas flow meter was calibrated on methane and as such, fuel corrections were applied. The accuracy of the thermal based flow meter was a function of temperature and an analysis showed that accuracy throughout all Campaigns was less than ± 2%. The regulated emissions recorded included exhaust CO, NOx, and total hydrocarbons (THC). Non-regulated gaseous emissions of CO2 and CH4 were also measured. The measurement of both THC and CH4 allowed for calculation of regulated NMHC emissions. Exhaust emissions were sampled through 15 meters of heated line and passed through a heated filter prior to measurement with an MKS Multigas™ 2030 FTIR Continuous Gas Analyzer [31]. It should be noted that during the first Campaign, at a hydraulic fracturing test facility, a SEMTECHDS and California Analytical heated flame ionization detector with a CH4 cutter were used to measure exhaust emissions.

All engines operated at rated speed. We compare our emissions with the respective CI and SI Tier 2 emissions standards. When tested for certification, these engines are subjected to the ISO-8178 D2 test cycle. This test applies to constant speed engines and the engines are subjected to the loads presented in Table 1, which also shows the emission-weighting factor for each mode.

| Mode | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Torque (%) | 100 | 75 | 50 | 25 | 10 |

| Speed (rpm) | Rated Speed | ||||

| D2 Weighting Factors | 0.1 | 0.3 | 0 | 0 | 0 |

Table 1: ISO-8178 D2 Test cycle operating points and weighting factors.

Campaign 1 examined a dual fuel stimulation engine at a hydraulic fracturing test facility. The test engine’s [11] hydraulic pump was connected to a closed circuit water system, with cooling tower, and employed a choke on the outlet of the pump to produce engine loads common to the hydraulic fracturing industry. Data from this Campaign are presented from an average load of approximately 70%.

Campaign 2 focused on a dual fuel drilling engine [9] that operated continuously during the drilling of two separate wells. Emissions were measured in three-hour windows, spanning different sampling arrangements. A total of 12 hours of data was collected at each sample position. Data were subdivided into two categories: low load transient (LLT) and steady state (SS) drilling. The average engine loads during LLT and SS operations were 23.3% and 55.2%, respectively. Figure 1 presents an example of SS and LLT drilling activity.

Campaign 3 focused on a dual fuel stimulation engine [9] that operated during hydraulic stimulation of the two wells drilled under Campaign 2. Three stages of hydraulic fracturing activity were recorded for each sampling position. The hydraulic stimulation activity was steady state during the individual stages, but not all stages occurred at the same engine load. The average engine load during the fracturing stages used for this study was 75.9%.

Campaign 4 focused on a dual fuel drilling engine [10] that operated during the drilling of a natural gas well. Note that this early dual fuel conversion did not include a DOC. Data were again categorized by engine activity type. The average engine load during LLT activity was 18.2% and during SSD was 46.5%.

Campaign 5 focused on a dedicate natural gas engine [25] that operated during the drilling of a natural gas well. The catalyst on this system appeared to be faulty based on pre and post-catalyst emissions. Data were categorized by activity type with an average load of 55.1% during SS and 14.1% during LLT operation.

Campaign 6 focused on a dedicated natural gas engine [25] that operated during the drilling of a natural gas well. The engine operated continuously and had an average SS load of 55.9% and LLT load of 20.9%. All engine emissions were processed using SS emissions calculations outlined in the CFR to determine the brake specific emissions. The emissions from Campaigns 1-4 were compared to the standards defined in the CFR for Nonroad Tier 2 CI engines greater than 900 kW. The standards for these engines were 6.4 g/kW-hr of NMHC+NOx and 3.5 g/kWh of CO. Emissions from Campaigns 5 and 6 were compared to Nonroad large Tier 2 SI engines standards. The engine tags on the SI engines advertised emissions of 0.8 g/kWh of NMHC+NOx and 20.6 g/ kWh of CO. Table 2 provide a summary of the Campaigns.

| Camp-aign | Activity | Engine Activity Type | Engine Make | Engine Model | Rated Speed (rpm) | Rated Power | Combustion Type | Dual-Fuel Kit | Modes Sampled | Fuel | Reported Exhaust Sample Location |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (kW) | |||||||||||

| 1 | Hydraulic | SS | Cummins | QSK50 | 1900 | 1678 | CI | ComAP | Diesel Only | Diesel | Pre-DOC |

| Fracturing | Dual Fuel | CNG+Diesel | Post-DOC | ||||||||

| 2 | Drilling | SS | Caterpillar | 3512C | 1200 | 1101 | DGB | Diesel Only | Diesel | Pre-DOC | |

| LLT | Dual Fuel | FG+Diesel | Post-DOC | ||||||||

| 3 | Hydraulic | SS | Caterpillar | 3512B-HD | 1800 | 1678 | DGB | Diesel Only | Diesel | Pre-DOC | |

| Fracturing | Dual Fuel | FG+Diesel | Post-DOC | ||||||||

| 4 | Drilling | SS | Caterpillar | 3512C | 1200 | 1101 | Altronic GTI | Diesel Only | Diesel | N/A | |

| LLT | Dual Fuel | FG+Diesel | N/A | ||||||||

| 5 | Drilling | SS | Waukesha | L7044GSI | 1200 | 1253 | SI | N/A | Dedicated | CNG | Post TWC |

| LLT | |||||||||||

| 6 | Drilling | SS | Waukesha | L7044GSI | 1200 | 1253 | N/A | Dedicated | FG | Post TWC | |

| LLT |

Table 2: Summary of data collection campaigns. (FG: Field Gas).

Campaigns 1-4 diesel only operation emissions

Regulated gaseous emissions from diesel engines included CO, NMHC and NOx, with the last two regulated as a mass sum, NMHC+NOx, because of their joint contribution to formation of ozone, a regulated air quality species [32-34]. Emissions were normalized by power and time and are presented in g/kWh. NMHC+NOx and CO for diesel only operation during SS and LLT operation are shown in Figures 2 and 3, respectively. The dark horizontal line represents the Tier 2 standard for these engines, but it is important to note that emissions were measured under different operating conditions than certification tests. Error bars represent the standard deviations of respective data sets. The minimum sample size for any data set was three.

Figure 2 shows that diesel drilling and fracturing engines had NMHC+NOx emissions below the Tier 2 standard. Engine 1 had the highest emissions during SS operation at 6.12 ± 0.28 g/kWh. LLT operation of engines 2 and 4 showed similar emissions predominately from lower NOx emission at lower loads.

All engines had CO emissions below 1.5 g/kWh during diesel only SS operation-well below the standard. The engines from drilling Campaigns (2 and 4) were also subject to LLT operation. Due to the transient nature of operation, the CO emissions are higher than during SS operation but well below the standard.

Campaigns 1-4 dual-fuel operation emissions

Dual fuel emissions were measured post-catalyst (where applicable) for comparison with Tier 2 standards for engines outfitted with dual fuel kits. Further investigation into the effect of the different catalysts on emissions will be examined in a future study. During dual fuel operation, CH4 accounted for greater than 95% of THC emissions such that NMHCs were low. If THC+NOx emissions were examined, no dual fuel engine met the 6.4 g/kWh standard; therefore, care must be taken when analyzing emissions from dual fuel engines and comparing them properly to predefined standards. Methane is not regulated with NOx as a combined standard since its reactivity to form ozone is orders of magnitude lower than other HCs. We used an FTIR analyzer, which speciated lower alkanes based on spectral measurements. For researchers that utilize heated flame ionization detectors (HFID) care must be taken when calibrating the analyzers as they inherently have different response factors based on the HC emissions measured compared to the HC on which it was calibrated.

Figure 4 presents the post-catalyst NMHC+NOx emissions for dual fuel operation. Engine 2 was below Tier 2 standards during both SS and LLT operation. Even without a DOC, engine 4 was nearly within compliance during SS operation when accounting for variability of measurements, 6.62 ± 0.13 g/kWh from the engine compared to the 6.4 g/kWh standard. LLT operation of engine 4 exceeded the Tier 2 standard. In both cases of SS and LLT operation engine 4 saw increased NOx emissions, which would be difficult to reduce even with the addition of a DOC. We used current or previous natural gas compositions during data processing. In-use fuel quality of natural gas and diesel fuel can directly affect NOx and NMHC emissions, which raises an additional cautionary point when comparing in-use emissions to standards.

We found that engine out (pre-catalyst) CO emissions from dual fuel operation were on average 22.8 times higher than diesel only. Figure 5 shows the significant increase in CO emissions from dual fuel engines not equipped with DOCs. Dual fuel operation without DOCs led to CO emissions nearly four times higher than the CI standard during both SS and LLT operation. Engines 1-3, with DOCs, had CO emissions eight times lower than the Tier 2 standard. Figure 6 shows the comparison of diesel only and dual fuel CO emissions for engines 1-3. With engine 4 removed, one can see that dual fuel engines with DOCs have the potential to decrease engine out CO emissions below in-use diesel only rates. Net CO reductions ranged from 13 to 97% from dual fuel operation. Although CO in high concentrations has profound health implications, impacts for long exposures at low concentrations have received less study [35]. CO emissions can be reduced with dual fuel kits that include DOCs compared to Tier 2 in-use levels, while NMHC+NOx emissions did not show a single trend for dual fuel operation.

Campaigns 5-6 dedicated natural gas emissions

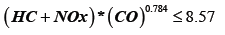

Emissions were also measured from two dedicated natural gas engines. While their fuels had different compositions, which can affect engine out emissions, it was difficult to assess these effects as these engines used closed loop control and three-way catalysts, and also due to engine-to-engine variations. The post-catalyst emissions were compared to the Nonroad Large SI Engine Exhaust standards defined in 40 CFR 1048.101. These standards allow for a number of different combinations of acceptable limits as long as the emissions comply with the following equation:

(1)

(1)

Where HC+NOx and CO are in units of g/kWh. For engines fueled by natural gas, the only HC emissions considered are NMHCs, and for diesel engines, it is well documented that the exhaust contains very low levels of methane. The engine tags on both engines stated compliance with a standard of 0.8 g/kWh of NMHC+NOx and 20.6 g/kWh of CO, and Waukesha advertised emissions of 0.94 g/kWh of NMHC+NOx and 1.61 g/kWh of CO. These numbers represent post-catalyst emissions, highlighting catalyst abilities to reduce emissions well below current Tier 2 standards. The difference in the conditions of the two catalysts showed a significant difference in emissions, which may have correlated to their previous operation and maintenance schedules. The post-catalyst NMHC+NOx emissions are shown in Figure 7 and CO emissions are shown in Figure 8. Figure 7 shows the advertised emissions are above the standard; however, because the advertised CO emissions are lower, the alternative standard of Equation 1 is satisfied. The NMHC+NOx emissions from the engine with the malfunctioning catalyst were 4.1 times higher than the Nonroad Large SI standards, and nearly 3.6 times higher than those advertised during SS operation. Similar trends were seen for LLT operation. The well-maintained catalyst of engine 6 had NMHC+NOx emissions well below both the standard and advertised emissions-13.2 and 11.2 times lower, respectively. However, it must be noted that the way in which the engine was loaded did not correspond to the weighted cycle used for certification purposes.

Figure 8: Post-catalyst CO emissions for dedicated natural gas drilling engines for steady state (SS) and low load transient (LLT) operation. Note the solid line represents the Tier 2 standard while the dashed line represents the advertised values. The advertised values and in-use emissions for engine 6 were not statistically different.

Post-catalyst CO emissions also varied greatly depending on the catalyst. The engine with the malfunctioning catalyst showed CO emissions 27 times higher than advertised emissions and more than double the Tier 2 standard. The engine with the well-maintained catalyst showed CO emissions that were 1.1 times lower than those advertised and nearly 14 times lower than the Tier 2 standard.

Table 3 shows SI emissions from both types of operation (SS and LLT) and the results of Equation 1. Table 3 highlights the impact of catalyst failure on CO, NHMC, and NOx emissions. Levels of CO from LLT operation are on average 1.96 times higher than those during SS operation. Dedicated natural gas engines with properly operating catalysts easily meet both Tier 2 CI and Tier 2 SI standards. These engines also offer the added benefit of significantly lower NOx emissions as compared to Tier 2 in-use diesel only or dual fuel operation.

| Campaign # | Fuel | Operation Type | Emissions (g/kWh) | Value from Equation 1 | |

|---|---|---|---|---|---|

| NMHC+NOx | CO | ||||

| 5 | CNG | SS | 3.28 | 43.64 | 63.37 |

| LLT | 2.99 | 86.62 | 98.65 | ||

| 6 | Field Gas | SS | 0.07 | 1.5 | 0.1 |

| LLT | 0.06 | 2.89 | 0.13 | ||

| Standard | N/A | 0.8 | 20.6 | 8.57 | |

| Advertised | 0.94 | 1.61 | 1.37 | ||

Table 3: Emissions from dedicated natural gas engines for steady state (SS) and low load transient (LLT) operation.

Tier 2 diesel engines currently dominate the off-road market and typically, emissions factors are used to estimate regulated emissions [36] for use in inventory or permitting analyses. Others have compared EPA, CARB, and AP-42 emissions factor methods for predicting emissions from CI engines and their results for a Caterpillar 3512C are shown in Table 4 along with our in-use data for diesel only operation [37,38]. The SS and LLT values are the average from two different inuse 3512C engines. We compared our NMHC emissions to VOCs. Our NOx and VOC emissions rates were lower than all estimated values. LLT operation led to slightly higher CO emissions than the CARB emissions factor but we note that during our Campaigns the time spent in SS and LLT modes of operation were nearly equal and therefore the average value of 1.6 g/kWh aligns with the CARB emissions factor for CO but is less than half of the other methods [36,37]. In-use regulated emissions of Tier 2 diesel engines may be substantially below emissions standards-this fact should be addressed in any inventory analysis.

| Emissions Factors | NOx | VOC | CO |

|---|---|---|---|

| CARB | 5.04 | 0.27 | 1.6 |

| EPA | 6.08 | 0.32 | 3.5 |

| AP42-Controlled | 7.91 | 0.43 | 3.4 |

| AP42-Uncontrolled | 14.6 | 0.43 | 3.4 |

| SS | 3.55 | 0.01 | 1.3 |

| LLT | 3.31 | 0.03 | 1.9 |

Table 4: Comparison of our diesel only in-use emissions with commonly used emissions factors. All units are g/kWh.

To reduce fuel costs and emissions, the unconventional natural gas well development industry is investing in dual fuel conversion kits and dedicated natural gas engines to power directional drilling rigs and hydraulic fracturing engines. Dual fuel and dedicated natural gas engines for unconventional well development have experienced low market penetration-only 5% in 2013. Recent data show that over 100 drilling rigs and stimulation spreads were dual fuel in 2015 and this number is expected to grow to 740 by 2024 [38]. To assess possible future impacts, emissions data were recorded during six separate campaigns, four of which utilized diesel engines outfitted with dual fuel kits and two that focused on dedicated natural gas engines. Of the six campaigns, four focused on drilling rig engines and two focused on engines used for hydraulic stimulation. For comparison with national emissions standards defined in the CFR, exhaust emissions were sampled pre-catalyst during diesel only operation for engines equipped with DOCs to represent Tier 2 engine out emissions and emissions were sampled post-catalyst for dual fuel and dedicated natural gas engines to represent engine out emissions. This study focused on regulated gaseous emissions, which included CO and the combination of NMHC+NOx. Regarding diesel only operation, we showed that in-use emissions from Tier 2 engines may be substantially below emissions standards-this fact should be addressed in any inventory analysis that would otherwise only rely on certification standards or older emissions factors.

While our limited study identified a dedicated natural gas engine with a failed catalyst, the other data highlight that these new technologies have potential to reduce regulated emissions. Dual fuel operation with DOCs can decrease CO emissions below Tier 2 in-use levels, while NMHC+NOx emissions did not show a single trend for dual fuel operation. Dual fuel operation without DOCs significantly increased CO and THC emissions and should be avoided. The use of dedicated natural gas drilling engines are capable of meeting both Tier 2 CI and Tier 2 SI CO standards while offering further reduced NOx emissions-two orders of magnitude compared to diesel only or dual fuel operation less than 0.1 g/kWh SS and LLT operation. These advantages are already of interest to on-road vehicles converting from older diesel to newer natural gas technologies [39,40]. Such technology implementation would be beneficial in regions where air quality standards for ozone and NO2 are of concern. The data set is small and future work should include additional in-use measurements, as these data may not represent all technologies or the exact distribution of engines currently employed by industry. See Figure 9 for general inuse emissions trends. Further analysis and data are required to develop more robust emissions factors compared to conventional methods or certification standards.

Dr. Derek Johnson* is a research assistant professor at West Virginia University (WVU) conducting research focused on emissions associated with the use of natural gas a fuel for internal combustion engines. Mr. Robert Heltzel, MSME, and Mr. Mahdi Darzi, MSME, are graduate research assistants at WVU’s Center for Alternative Fuels, Engines, and Emissions working towards their doctoral degrees. Dr. Andrew Nix is an assistant professor at WVU conducting research on natural gas reciprocating engines and gas turbines. Dr. Nigel Clark is a professor at WVU with extensive experience alternative fuels with specific focus on natural gas engines and vehicles.

We thank numerous industry collaborators for allowing us to collect these valuable data. This work was made possible under a grant from the Department of Energy’s National Energy Technology Laboratory, DE-FE0013689 under direction of Mr. William Fincham. Some data were also collected during a collaborative effort under a separate grant-DE-FE0024297. Observations and views expressed herein are those of the authors and do not necessarily represent the official views of the Department of Energy.