Journal of Nutrition & Food Sciences

Open Access

ISSN: 2155-9600

ISSN: 2155-9600

Review Article - (2023)Volume 13, Issue 3

Fruits and vegetables are crucially important because they contain good nutrients and bioactive components that keep the body healthy and control disease. However, the main challenges of fruit and vegetable include stress physiology, quality management, marketing, and food safety. Any postharvest handling technique used to keep harvested crops fresh for an extended period of time causes some stress to that tissue. Temperature extremes, desiccation, microbial invasion, gaseous atmosphere, light, and mechanical handling can all induce stress in a harvested fruit or vegetable. Furthermore, certain fruits and vegetables are susceptible to disorders, such as chilling, freezing, and CO2 injury. Quality assurance is an integral part of most manufacturing industries, including food processing. There is less motivation to develop quality management programs for fresh produce than for other food items, partly because of the generic nature of produce marketing and the difficulty of applying principles developed for processed foods to living respiring tissue. Fresh produce is a major profit center for supermarket food chains. The growing demand for fresh fruits and vegetables by health-conscious consumers also results in increased concern about food safety. It is not clear how much pesticide use can be reduced without loss of visual quality of fresh fruits and vegetables, nor is it clear how lower visual quality would affect consumption. Therefore, this review updates information on the challenges in postharvest handling fruit and vegetable that affect the final consumer acceptability.

Fruit and vegetable; Stress physiology; Postharvest handling; Temperature extreme; Food safety; Quality management; Precooling

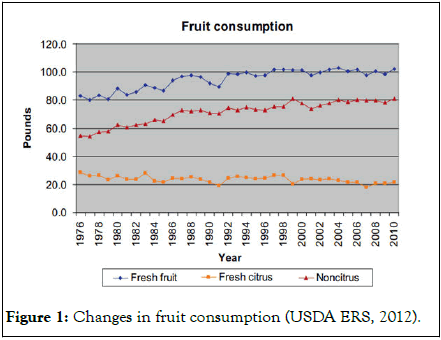

Despite campaigns to consume more fruits and vegetables, American consumers have shown little or no change in per capita consumption of fresh fruits or vegetables since 2000. Health concerns are the driving force for recommending increased fruit and vegetables in the dietary guidelines. Fruits and vegetables are low in calories and fats and are rich sources of nutrients, including dietary fiber, vitamins, and minerals. Unfortunately, American consumers are not making major shifts in their diets to fresh produce, and their selection is limited to a few popular fruits and vegetables. They are consuming more fruits and vegetables in food service outlets (42% of the total), but retail markets still claim the biggest segment of the business (57%) with direct sales accounting for less than 2%.

Fresh fruits and vegetables displayed on supermarket shelves are unlike a fresh tomato grown in a backyard garden, picked at the peak of flavor, and eaten minutes after harvest. Before appearing in the supermarket display, a fruit or vegetable has taken a long and sometimes circuitous journey. Part of each shipment becomes unacceptable and is discarded at culling points within the system because of over-ripening and the development of physiological disorders, handling damage, visible decay, or other causes. Some of these losses are diverted to secondary markets. Estimates of postharvest losses in the United States of fresh fruits are 30% and vegetables are 32% when including waste by consumers. Losses in developing countries can exceed 50% from harvest to consumption.

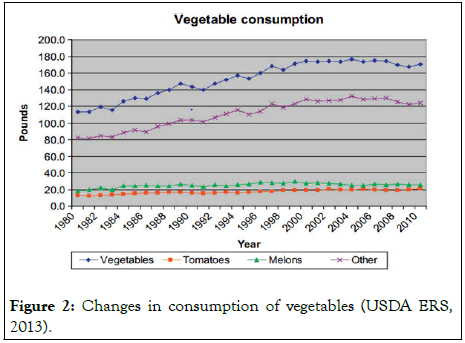

Since, fresh produce is living, respiring tissue, physiological processes occurring between harvest and consumption can result in the loss of quality characteristics. In some cases, quality degradation leads to a discarded product, whereas in others it reduces consumer acceptability. Such losses are minimized by proper and efficient handling of the fruit or vegetable on the journey from farm to market. More subtle losses of quality result from production, harvesting, and handling strategies that emphasize appearance at the expense of flavor and nutritional quality. Postharvest technology seeks to understand the handling and storage conditions that lead to extended shelf life and better quality of harvested produce. Current review provides rationale information for the continued pursuit of a better understanding of postharvest handling, in order to reduce the losses of fresh fruits and vegetables from farm to consumer, as well as to improve quality and shelf life of these items when they reach the consumer. To achieve this goal, two disciplines have developed. Postharvest physiology seeks to understand the basic physiological changes and underlying mechanisms that occur in a detached plant organ during handling and storage (Figures 1 and 2).

Figure 1: Changes in fruit consumption (USDA ERS, 2012).

Changes in per capita use of citrus (◼), noncitrus (▼) and total fresh fruit (♦)1976-2010.

Figure 2: Changes in consumption of vegetables (USDA ERS, 2013).

Changes in consumption of tomatoes (◼), melons (▼), other vegetables (X) and total fresh vegetables (♦) 1980-2010.

Postharvest handling of fruit and vegetables

The post-harvest technology of fruits and vegetables envisages the developing of appropriate techniques to reduce post-harvest losses to prevent spoilage and help utilize maximum crops, in nutritious and safe manure. Efficient handling and distribution of fresh fruits and vegetables is the direct result of the current understanding of postharvest physiology and the development of new technologies from narrowly focused studies. This encouraged the development of a broader-based program. Before studying the handling system, we suggested that the component handling steps must be understood [1-3]. Saha, et al., reported that post-harvest handling accounts for 20%-30% of the losses at different stages of storage, grading, packing, transport and finally marketing as a fresh produce or in the processed form.

Harvesting: Postharvest handling begins at harvest. Numerous reviews emphasize the importance of the maturity of the crop at harvest for subsequent postharvest quality and shelf life. Determination of the harvest date is based on yield, visual appearance, anticipated prices, estimated culling losses to achieve shipping quality and field conditions. Harvesting is accomplished by hand, by mechanically assisted picking devices or by mechanical harvesters. Robotics offers the long-term potential of combining the efficiency of machines with the selectivity of humans. Factors during harvesting operations that can influence postharvest quality include the degree of severity of mechanical damage induced by machine or human, the accuracy of selecting acceptable rather than unacceptable fruit, the time of day of harvest and the pulp temperature at harvest [4,5].

Maturity at harvest is the most important determinant of storage life and final produced quality. Immature produced are high susceptible to shriveling and mechanical damage are of inferior quality. Hence, fruits and vegetables are harvest at proper stage of maturity. Many leafy vegetables and immature fruits and vegetables (such as cucumbers, sweet corn, green beans peas and okras), attain optimum eating-quality prior to reaching to full maturity. This often results in delayed harvest and consequently in producer of low quality [6].

Quality is depends on timing the harvest correctly for most vegetables. Size, flavor, tenderness, texture and color are influenced by harvest timing. Snap bean must reach a certain sieve size, summer squash and cucumbers must be harvested within a narrow size range melon must be reach an acceptable sugar content tomatoes to be shipped must be harvested at “mature green” or as “breaker” but usually no post the “pink stages” tomatoes for direct sales can be harvested when ripe. Cabbage winter squash pumpkin peppers have a wider harvest window.

The methods of harvesting (hand vs. mechanical) can be significantly impact up on the composition and post-harvest quality of fruits and vegetables. Mechanical injuries (such as brushing, surface abrasions and cuts) can accelerate loss of water and vitamin C resulting in all increased susceptibility to decay causing pathogens. Most fresh fruits and vegetables an all flowers are harvested by hand. Root crops (such as carrot, onion, potato and sweet potato) and some commodities destined for processing (such as processing tomatoes, European plums and tree nut crops) are mechanically harvested [7].

Sorting and grading: Most fruits and vegetables are sorted and graded for marketing and have a role in protecting and enhancing product quality. These are generally an important part of field or packinghouse operations and help in reducing cross contamination of healthy stock destined for storage, transport, distribution, marketing, and processing. Immediately after harvest, the produce is sorted according to size, shape, color, and appearance. The damaged and immature fruits must be removed, as these might become sources of ethylene gas, which will increase the rate of respiration, ripening, and senescence of healthy produce. Many products are sorted according to color, mass, profile, and size after passing the minimum requirements of quality [8].

Grading determines whether the product meets a specific quality standard prescribed by local or international market, separates products into different quality grades to determine the price paid to the farmers or to determine the sale value, and enables removal of off grade products, which include damaged, undersized, immature, and diseased produce. Optimal maturity, color, sugar, solids, moisture content, size, and absence of defects are some of the factors considered for various fresh market products. The domestic marketing orders of the USDA specify mandatory grades for avocados, Irish potatoes, limes, filberts, raisins, onions, table grapes, walnuts, kiwifruit, dates, prunes, canned ripe olives, grapefruits, tomatoes, and oranges [9].

Pre-cooling: Fresh vegetables cannot be stored for a longer time under normal tropical ambient temperature. It is important to ensure the produce to be stored are free from diseases or any damages [10]. They also describe that proper storage practices include relative humidity control, adequate ventilation, avoiding incompatible product mixes and temperature management. In context of postharvest handling practices, vegetables are places in the storage for a period of time because of a few reasons. Storage of produce serves as a mean of delaying market until price rise, extending the season, provide more stable retail distribution or food service establishment [11]. Shelf life of perishable produce during storage is dependent on Relative Humidity (RH), optimal temperature as well as the use of chemical preservatives [12]. Pre-cooling prevents premature ripening and ageing of the fresh produce. Therefore, it is important to remove field heat of the harvested vegetables, especially when the harvesting is done during hot weather. Cooling, therefore, conserves weight of the fresh produce which gives an added advantage during the extended storage period. In fruits like tomato pre-cooling during storage can reduce physiological loss in of weight from 6% to 2.9%. While in vegetables which deteriorate very fast good cooling can reduce storage losses [13].

Processing and preservation: In order to preserve food, take action to stop it from breaking down, as it does naturally by killing or preventing the growth of microorganisms [14]. Today, the fresh produce can be preserved through different methods. By following a few easy steps, we can still eat those tasty fruits and vegetables when they are out of season. Beside, can preserve late-summer fruits and vegetables in four basic ways. These include freezing, canning, pickling and drying or dehydrating.

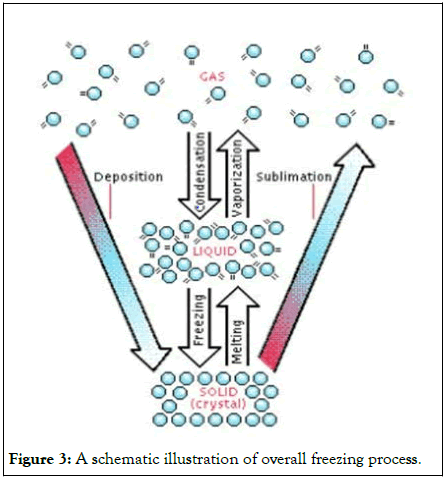

Freezing: Freezing is one of the oldest and most widely used methods of food preservation, which allows preservation of taste, texture, and nutritional value in foods better than any other method. The freezing process is a combination of the beneficial effects of low temperatures at which microorganisms cannot grow, chemical reactions are reduced, and cellular metabolic reactions are delayed [15]. As a method of long-term preservation for fruits and vegetables, freezing is generally regarded as superior to canning and dehydration, with respect to retention in sensory attributes and nutritive properties [16]. The safety and nutrition quality of frozen products are emphasized when high quality raw materials are used, good manufacturing practices are employed in the preservation process, and the products are kept in accordance with specified temperatures. The process involves lowering the product temperature generally to -18°C or below [17].

Freezing is the simplest way to save produce. It is important to freeze the produce as quickly as possible, and to do so in freeze-grade bags or other containers [18]. One problem to avoid is freezer burn, which can affect the taste and feel of food. To prevent this, use plastic bags, wraps or containers designed for the freezer. Good late-summer produce to freeze includes green beans, cabbage, apples and plums (Figure 3) [19].

Figure 3: A schematic illustration of overall freezing process.

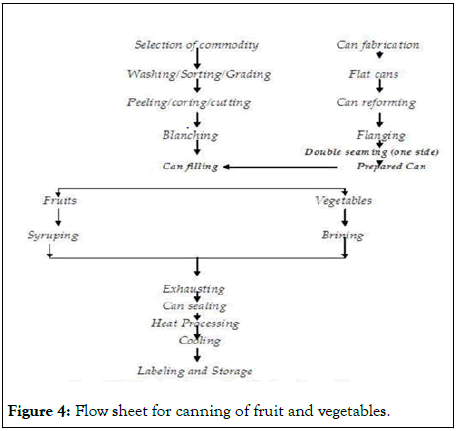

Canning: There are two main ways to can produce canning of the product. Boiling hot water baths and pressure canning. A boiling water bath involves putting food in glass canning jars and then heating the jars in a pot of boiling water. The heat forces air from the glass jars and frees the food from bacteria and microorganisms. Then, seal the jars. This method works best with naturally acidic foods like fruits. Pressure canning food requires a pressure canner. The pressure canner should be based on the kind of cooking equipment and the amount of food. Good late-summer fruits for water bath canning include apples, berries, cherries, figs and peaches. Good foods for pressure canning include carrots, corn, okra and bell peppers (Figure 4).

Figure 4: Flow sheet for canning of fruit and vegetables.

Pickling: There are many methods of preserving food in vinegar, salt brine or a similar mixture. Pickle whole vegetables, like green beans or okra are preserved by pickling. Another possibility is to make chutney or relishes. This is done by adding salt, pepper or other seasonings to small, cut pieces of vegetables. Good late-summer foods to pickle include cucumbers, hot chili peppers, watermelon rinds and eggplants.

Drying: A final way to preserve food is by drying it. When drying, try to find specific directions for each food to ensure quality and safety. Drying methods include air drying, oven drying and using a dehydrator. A dehydrator is probably the best choice. Good late-summer produce to dehydrate includes apples, mushrooms, grapes and hot and sweet peppers.

Packaging: Packaging contributes greatly to efficient marketing of fruits and vegetables.

• Serves as an efficient handling unit.

• Provides convenient warehouse or home storage unit.

• Protects quality and reduces waste by avoiding mechanical

damage, reducing moisture loss, providing beneficial modified

atmosphere, providing clean or sanitary produce, and

preventing pilferage.

• Provides service and sales motivation.

• Reduces cost of transport and marketing.

• Facilitates use of new modes of transportation.

Two types of packaging are common in fresh produce trade. Large-sized containers are used for transport and wholesale, and small-sized packagers for retail trade. The use of properly designed containers for transporting and marketing can maintain the produce’s freshness, succulence, and quality by significantly reducing mechanical damage during handling, transport, and storage. Proper packaging can protect fresh produce from the environment, such as sunshine, moisture, and light. The main purpose of packaging is to provide protection from mechanical damage. The container must be strong enough to withstand stacking and impact of loading and unloading, without bruising or scarring the produce. Thus, containers may require use of liners, pads, trays, or tissue wraps to prevent damage from contact with rough surfaces or adjacent produce. The produce can be packed in a box (wooden or paper) with absorbent, lining, or padding materials or in bags. The choice of packaging material is based on the requirements of stacking height, duration of storage, pretreatments, cooling, and cost. Lug and pallet boxes are also used. Pallet boxes are used for bulk handling, which saves loading and unloading time and manual labor.

Significant reduction of wastage of fresh fruits and vegetables is recorded as a result good packaging. In addition, good packaging also ensures protection against mechanical damage, undesirable physiological changes and pathological deterioration during storage, transportation and marketing, likewise freshness, succulence and flavour of fruits and vegetables can be maintained for a longer period through good and effective packaging. All the packages must be provided with some amount of ventilation in order to prevent the physiological break- down of the produce. If there is impermeability to Carbon dioxide (CO~, Oxygen (O2) and water vapour inside the package, there may be the development of off-flavour. While packing for transportation, care should also be taken to avoid bruising and damage of fruits. For this purpose, dry grasses or paddy straw can be successfully used between the layers of fruits. However, packaging is a highly innovative technology and newer techniques and material are being added every year, both for fresh vegetables and fruits and also for processed products. Packages can be flexible or rigid, each group having distinct advantages and limitations. An important application of flexible film is in wrapping the produce for low temperature. A mixture of gases can be inserted in film packs that delay post-harvest changes. Tetraking R, a D-shaped cylinder formed from two webs of polystryene and expanded polystyrene material has been recently introduced along with thermo formed pots for aseptic filling. Sterilization is carried out by either using liquid or vapour of Hydrogen peroxide or using ultra violet or gamma radiation

Storage: Within the handling system, fruits and vegetables are placed in storage for a period of time ranging from few hours up to several months, depending on the commodity and storage conditions. Storage of a commodity serves as a means of extending the season, delaying marketing until prices rise, providing a reserve for more uniform retail distribution or reducing the frequency of purchase by the consumer or food service establishment. The commodity must have sufficient shelf life to remain acceptable from harvest to consumption.

The shelf life of a fruit or vegetable during storage is dependent on its initial quality, its storage stability, the external conditions and the handling methods. Shelf life can be extended by maintaining a commodity at its optimal temperature, Relative Humidity (RH) and environmental conditions, as well as by the use of chemical preservatives or gamma irradiation treatment. An extensive list of optimal storage temperatures and RHs with anticipated shelf life is available. Controlled atmosphere storage is a commercially effective means of extending the season of apples and many other crops.

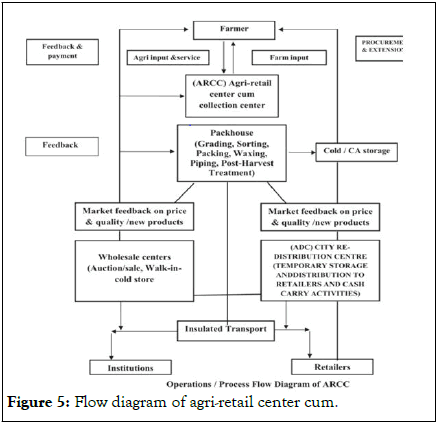

Atmosphere modification within wholesale or retail packages is a further extension of this technology. Modification of the atmosphere is achieved by setting initial conditions and using absorbent compounds within the packaging to limit Carbon Dioxide (CO2) and Ethylene (C2H4) concentrations. The use of gamma irradiation extends the shelf life of some commodities. The application of 1-Methylcylclopropene (1-MCP) can delay ripening by slowing respiration and volatile compound generation (Figure 5).

Figure 5: Flow diagram of agri-retail center cum.

Transportation and distribution: The ultimate destination of most fresh fruits and vegetables is the retail market, where a consumer makes the final decision to accept or reject an individual item or packaged product. Retail distribution is the most visible of all handling steps, and frequently the least controlled. Merchandising displays are designed to enhance quick, impulsive purchases, not necessarily to maintain quality. Conditions within the outlet (temperature, RH, lighting), close display of incompatible commodities, length of exposure to conditions or incompatible commodities and the degree and severity of handling by store personnel or consumers all affect quality and acceptability. Addition of ice to lower temperatures and maintain high RH and timed water misting are examples of techniques used to maintain quality. The most effective way to prevent quality losses at retail, however, is a rapid turnover of stock on the shelves. Because it is the only part of the process most consumers see, retail distribution provides an excellent opportunity to communicate with the consumer.

Factors affecting postharvest quality and shelf life of fruits and vegetables

In general, post-harvest losses of fruits and vegetables are influence by many factors. These factors include losses due to physical, physiological, mechanical and hygienic conditions. Fruits and vegetables are mainly characterized by high level metabolic activities and known to posse’s short shelf life. As a result of these factors, substantial percentage of loss occurs between harvesting to consumption of the produce. In addition, other factors such as insect and mite injury, diseases which occur due to non-infectious pathogens and pathological rots also cause post-harvest loss of fruits and vegetables. However, among the causes, the pathological rots are the most serious which is followed by mechanical injury. Pathological rots in combination with mechanical damage cause serious damage to the perishables. Environmental factors such as temperature, relative humidity and oxygen balance most especially during storage are also greatly responsible for damage also environmental conditions such as temperature and humidity are responsible for rendering fruits and vegetables susceptible for pathological attacks. However, the loss of fruits and vegetables due to physiological and biochemical damage are closely interrelated.

Challenges of postharvest quality and shelf life fruits and vegetables

After harvesting, the fruit and vegetable still remains alive and performs all functions of a living tissue. The climacteric burst of ethylene which makes the fruit palatable also triggers senescence and subsequent ripening in the fruits. The goal of any postharvest handling practice or treatment is to manage the concentration and timing of ethylene synthesis so that the fruit reaches the consumer at optimal eating quality.

Temperature: Temperature is the most important environmental factor which influences the postharvest life of a produce. The optimum storage temperature of commodities is differing among not only commodities but for species. Typically, for every increase of 10°C, the rate of deterioration increases between 2-and 3-fold. Proper temperature management between the period of harvesting and consumption has been found to be the most effective way to maintain quality. Keeping harvested fruit and vegetable cool at low temperatures of about 20°C will slow down many metabolic activities which lead to ripening; hence, allowing more time for all the postharvest handling of the produce. Generally, one hour of delay between harvesting the crop and cooling it will lead to one day loss of shelf life. Respiration and metabolic activities within harvested climacteric fruits like tomatoes are directly related to the temperatures of the ambient environment. High temperatures can hasten the rate of respiration (CO2 production) in harvested or stored fruits products. CO2 production in stored climacteric products like tomatoes can trigger ethylene production although this depends on other factors like O2 or CO2 levels, exposure time, and ripening stage. Minute amounts of ethylene can cause ripening in fruits even at levels of tens of nL per L. Heat stored in field-harvested fruits is a major source of high temperatures in fruits. Therefore, the time of the day at which harvesting is done must be considered to avoid excessive field heat which can cause more rapid deterioration in the harvested fruits.

Relative humidity: Water loss is a major cause of postharvest deterioration because it results not only in direct quantitative. Water loss from harvested fruit produce is predominantly caused by the amount of moisture present in the ambient air expressed as relative humidity. At very high relative humidity, harvested fruits maintain their nutritional quality, appearance, weight, and flavour, whilst reducing the rate at which wilting, softening, and juiciness occur. The maintenance of Relative Humidity (RH) after harvest is not always possible and can influence the quality of the raw material, especially when it is intended for minimal processing. Medina, et al., studied the influence of short-term postharvest exposure (36 h at 15°C) in various RH conditions such as high (99%), medium (85%) and low (72%) on the microbial quality as well as general quality and shelf life of minimally processed baby spinach. Counts of psychrophilic bacteria and Pseudomonas spp. on samples exposed to high RH were one log higher than those on samples exposed to low and medium relative humidity. Medina, et al., concluded that control of RH after harvest is critical because it can influence the microbiological population and the maintenance of acceptable visual quality losses, but also in impaired appearance and textural quality.

Combination gases: Respiration is the basic process causing deterioration on the harvested produce and is mainly depend on the atmospheric composition (level of O2 and CO2) as well as on the temperature, ethylene and water vapor. Therefore, regulating the gas concentrations in the surrounding atmosphere of the produce is highly important for reducing respiration and increasing preservation time. During respiration, O2 is consumed, and CO2, ethylene, and water vapor are generated, thus the packaging material allows the transfer of all of these gasses through the packaging material by regulating the inner composition at favorable levels to preserve the product.

Physical handling: Physical handling can have a drastic effect on the postharvest quality or life of harvested fruits. Rough handling during harvesting and after harvesting can result in mechanical injuries which affect quality. The primary cause of chilling injury is thought to be damage to plant cell membranes. Changes in molecular species composition of phospholipids during cold storage and after rewarming were determined in mature green tomatoes the minor molecular species shifted significantly towards unsaturation during cold storage. Typical industrial production systems associated with tomatoes may include mechanical harvesting, packing into crates, sorting, grading, washing, and transporting over long distances. At each of these stages there may be significant occurrence of mechanical injury which may be bruising, scarring, scuffing, cutting, or puncturing the fruits. In small-scale tomato production, mechanical injuries may result from the use of inappropriate harvesting containers and packaging materials. According to Miller the effects of mechanical injuries on fruit are cumulative. Injuries which are equivalent to or greater than the bio yield point lead to a total breakdown of the structure of the affected cells which is accompanied by unwanted metabolic activities which may include increased ethylene production, accelerated respiration rates, and ripening which results in either reduced shelf life or poor quality. It is therefore important to handle tomato fruit with care during the harvest and postharvest activities to minimize mechanical injuries to avoid losses (Table 1).

| Commodity | Time/temperature °C conditions for symptoms | Potential chilling injury symptoms |

|---|---|---|

| Asparagus | 10 days at 0°C | Darkened and water-soaked areas at the tips followed by bacterial-soft rot. |

| Beans, snap | 3 days below 4.5°C | Russeting and surface pitting |

| Cucumbers | 2 days below 5°C | Surface pitting starting at lenticel areafollowed by secondary pathogen rots. |

| Eggplant | 3-4 days below 5°C | Scald-like browning, surface pitting, and flesh browning and secondary pathogen rots. |

| Melons; Muskmelons | 15 days at 0°C-2.5°C | Water-soaking of rind, softening and surface |

| Honey dew | 15 days at 0°C-2.5°C | Becomes soft and sticky resulting in increased decay. |

| Watermelons | 7 days at 0°C | Surface pitting, loss of flavour and fading of red colour. |

| Okra | 3 days at 0°C | |

| Peppers, bell | 3-4 days at 7.5°C | Water-soaked appearance, sheet pitting, darkening and Pre-disposition to rots. |

| Potatoes | 20 weeks at 0°C-1.5°C | Mahogany browning and sweetening. |

| Sweet potatoes flesh discolouration, internal breakdown, increased. | 4–7 days at 7.5°C–10°C | Decay, off-flavours, hard-core when cooked. |

| Tomatoes | 6 days at 0°C | Rubbery texture, watery flesh, irregular ripening. |

| 9 days at 5°C | Seed browning |

Table 1: Fruits and vegetables susceptible to chilling injury.

Challenges amenable to systems solutions

Research with fruits and vegetables reveals several critical problems that require systems studies in order to provide meaningful solutions. Particular attention is required to identify conditions encountered in postharvest handling that affect consumer acceptability as well as pre-harvest factors that influence postharvest quality. Research challenges that are particularly amenable to systems solutions include stress physiology, quality management, marketing and food safety. It is also important that we recognize the benefits of appropriate technology for constrained handling systems and working at the interfaces of postharvest handling with the crop production and consumer handling systems.

Stress physiology: An “aberrant change in physiological processes brought about by one or a combination of environmental biological factors” is known as the stress response. Almost any handling technique used to keep harvested crops fresh for an extended period of time causes some stress to that tissue. Temperature extremes, desiccation, microbial invasion, gaseous atmosphere, light and mechanical handling can all induce stress in harvested fruits or vegetables. Certain fruits and vegetables are more susceptible to disorders such as chilling, freezing and CO2 injury than others. One complicating factor is that damage, such as bruising or chilling injury, may be incurred at one point in the system but not become evident until a later point. Whoever “owns” the item when damage becomes evident usually “pays”, rather than the “owner” when the damage was incurred. Many factors are implicated in the syndromes which are associated with stress response, but the physiological mechanisms of these responses remain elusive. Advances in molecular biology promise to provide techniques that will help unravel the physiological basis of quality degradation.

Quality management: Quality Assurance is an integral part of most manufacturing industries, including food processing. There has been less motivation to develop quality management programs for fresh produce than for other food items, but widely publicized food poisoning outbreaks involving fresh produce have led to increased scrutiny of fresh items. The primary differences between fresh and processed foods that affect quality management factors include the following:

• Fresh fruits and vegetables are maintained in recognizable

form whereas processed products are modified.

• Variability in response to storage conditions among different

items in the same lot is much greater in fresh fruits and

vegetables than in processed products.

• The relationship between physiological processes and food

quality has not been defined clearly in many fresh fruits and

vegetables.

The fruit and vegetable processing industry is able to avoid these problems by (1) Treating the crop as raw material, thus mixing lots of varying composition to produce a product that meets uniform product specifications, and (2) Inactivating physiological processes during food processing operations. Several articles have provided frameworks for the quality management of fresh produce including the implementation of HACCP plans.

Marketing: Fresh produce is a major profit center for supermarket food chains. Fierce competition among chains is changing the merchandising of fresh items. Brands are used in the marketing schemes of shippers directed at wholesale distributors, but whether brands will have an impact at retail distribution is still uncertain, with some studies suggesting that product quality is more important than branding while others indicate that brand is an important factor in a purchase decision.

Food safety: The growing demand for fresh fruits and vegetables by health-conscious consumers also results in an increased concern about food safety. Media attention to the use of agricultural chemicals to maintain the “cosmetic” quality of fresh produce has heightened this concern. It is not clear how much pesticide use can be reduced without losing some visual quality of fresh fruits and vegetables, nor is it clears how reduced visual quality would affect consumption. Safety must become the responsibility of all handlers through the system, as contaminated items that are allowed to pass through an early step can lead to the spread of contamination later in their journey from farm to consumer.

It is becoming more apparent that the true safety dangers of fresh produce come from pathogenic microorganisms and not from pesticides. Sanitizers in the packinghouse can be effective for some items, but they should not be seen as a substitute for good sanitation practices within the handling system. Refrigeration temperatures, once thought to guarantee the safety of fresh fruits and vegetables, do not protect fresh produce from psychrotropic pathogens such as Listeria. Edible coatings can contain inhibitors of microbial growth on fresh and fresh-cut fruits and vegetable. Modified atmosphere packaging is effective in extending shelf life, but microbial growth must be carefully monitored, as the modified atmospheres can favor pathogen growth while inhibiting spoilage microbes.

Constrained handling systems: The challenges facing handlers of fresh fruits and vegetables in countries that lack infrastructure and advanced postharvest technology are different from those who do have these advantages. Most postharvest research has been directed at complex systems which provide fresh fruits and vegetables to mass markets. Thus, different circumstances require different solutions. When transferring technology from one country to another, a systems approach requires a basic understanding of the handling system and existing infrastructure. In sub-Saharan Africa postharvest losses are caused on the farm due to inappropriate cultivar selection or harvesting method and in transit due to poor packaging, poor temperature management, rough handling and unpaved roads. Lack of adequate cooling facilities leads to a greater need to move the product to market more rapidly, but produce harvested when too ripe or soft results in rapid moisture loss or decay. In general, many postharvest handlers in these countries have little or no training in appropriate techniques, and many well-meaning outsiders do not have an appreciation of the handling system.

Globally, over half of the food supply is produced through the efforts of non-mechanized human labor. Investments in training and low-cost improvements in simple handling systems can provide dividends in reducing losses and increasing grower income. Such improvements can eventually impact poverty, health and food security.

Postharvest handling is the final stage in the process of producing high quality fresh produce. Being able to maintain a level of freshness from the field to the dinner table presents many challenges. A grower, who can meet these challenges, will be able to expand his or her marketing opportunities and be better able to compete in the marketplace. The fruits harvested at the advanced stage of maturity have increased fruit size and eating qualities (taste and aroma) but decreased shelf life. Furthermore, the postharvest quality status and shelf life of the fruits and vegetable in part will depend on postharvest handling practices and treatments carried out after harvest. Even though, the quality of any fruit after harvest cannot be improved by the use of any postharvest handling practices or treatment methods; but, it can be maintained. Postharvest handling practices like harvesting, precooling, cleaning or disinfecting, sorting and grading, packaging, storage, and transporting played an important role in maintaining quality and extending shelf life of the fruits and vegetable after harvest. In addition, the uses of appropriate postharvest treatment methods like refrigeration, postharvest heat treatment Modified Atmosphere Packaging (MAP) application also vital. It is concluded in this review that the quality of the harvested fruit can be maintained and shelf life extended by using appropriate postharvest handling practices and treatment methods.

[Crossref] [Google Scholar] [Pubmed]

[Crossref][Google Scholar] [Pubmed]

[Crossref] [Google Scholar] [Pubmed]

[Crossref] [Google Scholar] [Pubmed]

[Crossref] [Google Scholar] [Pubmed]

[Crossref] [Google Scholar] [Pubmed]

Citation: Lencho GW (2023) Review on Challenge and Post-Harvest Handiling Consideration for Fruits and Vegetables. J Nutr Food Sci. 13:023.

Received: 21-Feb-2023, Manuscript No. JNFS-23-21888; Editor assigned: 23-Feb-2023, Pre QC No. JNFS-23-21888 (PQ); Reviewed: 09-Mar-2023, QC No. JNFS-23-21888; Revised: 08-May-2023, Manuscript No. JNFS-23-21888 (R); Published: 15-May-2023 , DOI: 10.35248/2155-9600.23.13.023

Copyright: © 2023 Lencho GW. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.