Journal of Nutrition & Food Sciences

Open Access

ISSN: 2155-9600

ISSN: 2155-9600

Review Article - (2023)Volume 13, Issue 2

Perishables crops are the crops which have high moisture content and short shelf life. Most of them are seasonal and some are highly perishable due to their moisture content. The storage of perishable crops is extraordinarily cooperated inside a quick time of harvest except the crop must be cooled directly to manipulate post-harvest losses. The major problem during storage is post-harvest losses and changes quality parameters. According to most of research and review show, approximates 40%-50% perishable crops loss in the supply chain at globally level. In Ethiopia also, post-harvest loss of perishable crops is 50% due to lack of appropriate post-harvest handling practice and improved storage technologies. In order to reduce post-harvest loss of perishable crops and enhance food and nutrition security, contribution and roles of low cost and improved storage technologies is great. Improved storage technologies reduce post-harvest losses of perishable crops by controlling temperature, concentration of gases and relative humidity of the storage area. Therefore, the aim of this review paper is to review studies made by several researchers and reviewers on the roles of improved storage technologies in post-harvest loss reduction of perishables crops and enhances food and nutrition security. Hence, proper storage of the perishable crops using improved storage technologies would prolong their shelf life and availability by reducing the post-harvest loss. Some storage technologies like low cost storage can be beneficial for farmers needing a small-scale storage system. On the other hand, improved storage technology includes refrigerated storages like cold storages, controlled atmospheric storage, modified atmosphere storage and hypobaric storage play great role to reduce post-harvest loss of perishable crops. So to mitigate or alleviate high post-harvest loss of perishable crops and to solve problems of food and nutrition security, using improved storage technology is very important and determinant.

Food security; Improved technology; Perishable crops; Storage; Nutrition

Back ground information

Perishables crops are the crops that have high moisture content and soft structure result not last long and they have a limited shelf life. Production of those crops has complexity due to their perishable nature characteristics, so horticulture industry in Sub- Saharan Africa and in Ethiopia particular stays at its infant stage. Production of those crops in Ethiopia small, when compared to other crops. World population is expected to reach 10 billion by 2050 which will require a 70% increase in food production [1]. According to report of FAO indicate, 870 million people were food insecure and chronically undernourished during the year 2010-2012. Agricultural products of perishable crops are plays a central role in increasing food availability and incomes and contributing to the overall economy and a key issue to improve food and nutrition security. Not only production, PHL reduction of perishable crops such as of fruits and vegetables including roots and tuber are very important which necessary to income enhancement of the community and economic development of a country in general. In addition to contribute income enhancement, perishable crops are very important as sources of nutrients for human beings consumption and for health benefits. Reducing post-harvest loss of perishable crops also important in supplementary source of nutrition and improves food security. Therefore, enhance production of agricultural products (fruits and vegetables) and falling of PHL increased food security as well as better nutrition intake which could leads to economic development [2].

Annual quantitative perishable crops loss in the supply chain globally, approximates 40%-50% fresh produces. The major post-harvest losses in the developing countries are those that are related to temperature and humidity, due to lack of proper or adequate storage facility. Post-harvest losses in South East Asia can range from 10%-50% depending on a particular country. FAO point out that, the post-harvest loss of perishable crops in Ethiopia is as high as 50% attributed due to lack of different appropriate post-harvest handling practice and improved storage technology. In India, according to the recent report of ICAR, the post harvests losses in fruits and vegetables ranged between 5.77%-18.05% due to storage problems and therefore, prevention of such damages is the most appropriate method to make available more quality vegetables and fruits and is a complementary means of increasing income and production [3]. Therefore, it must maximize and manage agricultural production to minimize the post-harvest losses and enhance food and nutrition security by using storage technology through managing storage temperature and relative humidity. In 2017, 3.9 million deaths worldwide were attributable to not eating enough fruit and vegetables. Insufficient intake of fruits and vegetables is estimated to cause around 14% of deaths from gastro intestinal cancer worldwide, about 11% of those, due to ischemic heart disease and about 9% of those caused by stroke. Perishable crops play a significant role in human nutrition. Particularly, fruits and vegetables have health benefits for consumers, due to their content of fiber, vitamins (A and C), minerals and antioxidant compounds. On all of these countseconomics, nutrition acceptability perishable crops play a major role in developing countries, amply justifying the contortion that something should be done to reduce the high losses that presently occur in these commodities [4].

For perishable crops, being less hardy than cereals, post-harvest losses can reach 50%. Approximately one third of all fresh fruits and vegetables are lost before it reaches to the consumers. Another estimate suggests that about 30%-40% of total perishable crops production is lost in between harvest and final consumption [5]. According to research done in Kenya by, PHL of perishable crops high as 50% mainly due to poor storage and handling practices. Factors like temperature, relative humidity and oxygen balance are the most factors storage that great responsible for damage fruits and vegetables. However to control those factors, improved storage technologies including refrigerated storages like cold storages, controlled atmospheric storage, modified atmosphere storage and low-cost storage technologies and including on-site storage, sand and coir, clamps, pits, cellars, ventilated storage and evaporative cooling or ZECC are very important. Those storage technologies play great roles in reducing PHL of perishable crops and enhance food and nutrition security [6].

Post-harvest losses of perishable crops due to improper handling and storage are enormous. The high moisture and nutrient content of perishable crops make their post-harvest loss high.

The post-harvest losses of perishable crops are about 30% due to the presence of high moisture content (65%-95%) and lack of using storage technology. Massive quantity of fruits and vegetables are lost every year due to the lack of proper storage technology and post-harvest management. Nearly 20% of losses of fresh fruits and vegetables are due to product deterioration [7]. In Africa, post-harvest losses are not properly documented but experts have projected the losses up to 80% however, both low cost and high cost storage technologies are crucial for storage of perishable crops in order to reduce the problems of PHL and enhance food security. The keeping longevity of perishable crops requires high cost storage and energy consuming technology and this is difficult for most farmers due to farmers cannot find the money. This is one of the important sources of food insecurity in Africa. In sub Saharan Africa, about 27% or 234 million people have no sufficient food available [8].

Access to adequate food is limited in currently at world level especially in Ethiopia country. Therefore, has a need to grant food security by increasing perishable crops production and reducing PHL from harvest to consumption. Production and reducing PHL of fresh produces can be one of the solutions to enhance food availability and relieve undernourishment. So to reduce PHL of perishable crops and enhance food and nutrition security both storage technologies specially, improved storage technologies are important. Therefore, improved storage technologies contribution is high to enhance food and nutrition security in multiple ways by reduces PHL of perishable crops [9].

Objective

The main aim of this review is to review and summarize role improved storage technology on post-harvest loss reduction of perishable crops and enhance food and nutrition security [10].

Post-harvest loss of perishable crops and food and nutrition security

Perishable crops: In developing countries, approximately 30% of food consumed is perishable. The presence of high moisture content in perishable crops accelerates the reaction response making them highly perishable. Reducing the moisture content of the crops to a recommended level through using storage technologies like, improved storage technology that could improve the shelf life. There is scope to control storage life and quality of produce through post-harvest management respiration and transpiration physiological factors. The quality loss of perishable crops after harvest happens as a result of different factors such as physical, biochemical, physiological and biological factors, the rates of which are influenced primarily by product temperature at harvesting and relative humidity surrounding the produce. Fresh produce needs low temperature and high relative humidity during storage [11].

Decreasing the temperature of the product as quickly as possible after harvest will maintain a great level of quality remaining attractive for customers. The rate of spoilage increases by 2 or 3 folds with in temperature of 10°C. By reducing the produce temperature as soon as possible after harvest the following effects achieved [12].

• Respiration rate and water loss reduced

• Ethylene production is suppressed

• Sensitivity to ethylene is reduced

• Inhibit the growth of decay producing microorganisms

Fruits and vegetables: Fruits and vegetables crops are the living tissue and very perishable in nature, are subject to respiration, water loss and cell softening throughout the post-harvest system. The amount of loss in fruits and vegetables are estimated at 35%-40% due to outrageous Post-Harvest Management (PHM). The main influence of lack of storage temperature and relative humidity for fruits and vegetables after harvested leads to the reduction the quantity of fruits and vegetables that get to the market which also has an immediate impact on the distribution and consumption of the required amount for the sound living. Therefore, storage consideration is required to control storage life and quality of crops through post-harvest management of physiological process such as respiration and transpiration [13].

Roots and tubers: Root and tubers provide a substantial part of the world’s food supply. The contribution of roots and tubers to the energy supply in different populations varies with the country. The relative importance of these crops is evident through their annual global production which is approximately 836 million tons. At global level, approximately 5% of root and tuber crops production is consumed as food, while the rest is used as animal feed or for other purpose like industrial processing products such as starch, distilled spirits and a range of minor products [14].

Importance of perishable crops

Perishable crops are essential for a nutritionally balanced diet. Specially, vegetables and fruits contribute considerably to improving the quality of diet and human nutrition and income. These crops are excellent sources of Vitamins (A and C) and minerals (iron, calcium), carbohydrates and proteins. They also provide protein. In addition; perishable crops add variety, enjoyment and a sense of satisfaction with the diet because of their characteristics (appealing colours, flavours and textures). On all of these counts economics, nutrition, acceptability perishable crops play a major role in developing countries, amply justifying the contortion that something should be done to reduce the high losses that presently occur in these crops. At global starchy root and tuber crops are second only in importance to cereals as sources of carbohydrates [15].

Nutritionally, roots and tubers have a great potential to provide economical sources of dietary energy, in the form of carbohydrates. Tuber has high in terms of energy. The energy from tubers is about one-third of that of an equivalent weight of rice or wheat due to high moisture content of tubers. Generally, roots and tubers are important diet components for human’s diet. In addition to the main role as an energy contributor, they provide a number of desirable nutritional and health benefits such as ant oxidative. Tubers may serve as functional foods and nutraceutical ingredients to attenuate non- communicable chronic diseases and to maintain wellness. However, roots and tubers are poor in most other vitamins and minerals but contain significant dietary fibre grains [16].

The role of roots and tubers:

Root and tubers are mainly contributed for:

• Supporting food and nutrition security

• Industrial raw material source

• Animal feeding

• Income generating for producers and traders

A weight loss becomes an economic loss when the produce is marketed on a weight basis as well as being less attractive to potential customers and it is directly related with cost. It is very difficult to give precise data on transpiration weight loss, because of factors such as temperature, relative humidity, the rate of air movement surrounding the tuber, permeability of the skin and how this may have been affected. Roots and tubers are susceptible to extremely low or high storage temperatures. Crops like, yams, cassava and sweet potatoes are known to suffer from chilling damage at 12°C or below, while for potatoes, cocoyams and sweet potatoes this type of damage occurs at 2°C or below. The extent of chilling damage usually depends on a time/ temperature interaction. There are many common symptoms of internal tissue of those crops such as internal tissue breakdown, increased water loss, susceptibility to decay, failure to sprout and changes in culinary qualities, cooking and taste. Potatoes respire strongly at temperatures of 30°C and above [17].

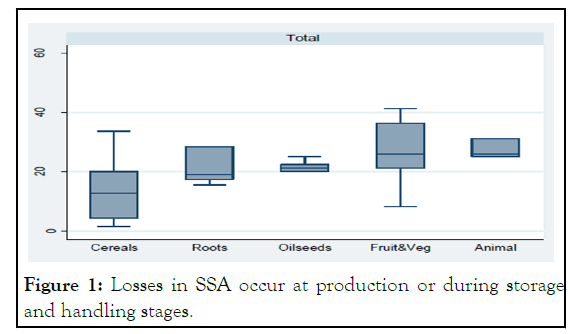

Post-harvest losses of perishable crops

A large amount of food and products are not reaching the consumer particularly due to post-harvest losses during harvesting, handling, transporting, storage, processing, packaging and distribution. According to FAO post-harvest losses in developing countries can range from 15 up to 50%. Horticultural crops are perishable products and they are more prone to greater losses than for nonperishable crops. Latest research reports estimated that, annual quantitative food loss in the supply chain globally approximately 40%-50% fresh produce; 30% for cereals; 20% for oilseeds. One of the most important reasons attributing to lower availability of fresh produce is its huge quantity loss that occur at different phases of supply channel like storage [18]. Factors for perishable crops loss in developing countries are an outcome of comprehensive, administrative and technical constraints in harvesting methods, storage, transport, process, cold chain, road infrastructures, package and market integration system also demonstrated that a 40% decrease in food loss along supply chain in the European would lead to, small, but positive, a decrease in food prices (0.2%) while an increase in food consumption (0.04%) in Sub Saharan Africa. The problem of post-harvest loss is especially acute for perishable crops. A recent review of the literature reported estimates that, loss for these crops ranged from over just 20% to 35%. As observed in Figure 1, PHL of fruits and vegetables are extreme or far higher than those of other cereal crops.

Figure 1: Losses in SSA occur at production or during storage and handling stages.

The major post-harvest losses often occur on or immediate the farm-gate in the developing countries, where the primary choice of crop type and variety as well as, the success of harvesting methods are central in retaining losses lower. Traditionally, most efforts to reduce post-harvest losses have focused on-farm, predominantly crop storage, for motives of food security [19].

Wide use of mechanization and cold chain know-how in developed countries preserve on-farm PHLs lower than those in developing countries, even though they might still happen, such as when automated harvesters harm portions of the crop. Roots and tubers are living organisms that can follow respiration process. The respiration process results in the oxidation of the starch contained in the cells of the tuber, which converts it into water, carbon dioxide and heat energy. During this transformation of the starch the dry matter of the tuber is reduced [20].

Post-harvest loss of roots and tubers

Root and tuber crops are vital as starchy and in some areas are more important than grains. Total production of roots and tuber crops in Sub-Saharan Africa was estimated as 254 million tonnes/annum in 2012 and out of this cassava was the most important with a production of 132 million tonnes/annum followed by yam at 56 million tonnes/annum and sweet potato at 17 million tonnes/annum. Their importance is related to their agronomic advantages and limited requirement for inputs. Cassava roots give a high yield of carbohydrates and it has good tolerance to drought, resistant to pest infestation and disease and can be stored in the ground until required. Like cassava, sweet potato also produces the highest quantity of energy of any of the major tropical crops [21].

Once harvested, roots and tubers are more perishable than grains due to their higher moisture content, greater susceptibility to physical damage and higher metabolic activity. Primary physiological deterioration is the initial cause of loss of market acceptability and secondary deterioration is due to microbial spoilage. Where crop like cassava is harvested and processed or consumed locally this is not a great problem, but it is a serious constraint for the development of marketing, where the distance between production and consumption/process increases. As well as direct physical loss of the crop, post-harvest deterioration causes a reduction in quality that results in price discounts and so contributes to economic losses [22]. Furthermore, there can be additional losses due to change in use. If harvested cassava roots cannot be marketed within two or three days of harvest then they may be processed into dried products of low quality, which have lower value.

There are few reliable estimates of the extent of losses. A systematic assessment of physical losses worldwide by FAO suggests that losses of root and tuber crops are in the range of 30% to 60%. In the case of cassava in Africa losses in 2002 were estimated as 19 million tonnes from a total continent wide production of 101 million tonnes. Yet, the magnitude of losses significantly differs across countries and different value chains within a single country as they depend largely on how cassava is produced, processed and consumed and on the level of coordination among value chain actors. When cassava is for household consumption, the farmers harvest just the quantity necessary for the preparation of individual dishes or immediate processing. Moreover, as the product deteriorates it is used for other purposes such as animal feed [23].

According to the report, the PHL of cassava in Sub-Saharan Africa as listed below:

• Physical losses of the dried commodity (cassava chips) range from 3% to15%.

• There are financial losses when handling older fresh roots, as there is price discounting in anticipation of physical losses.

• Losses due to change in use.

• Lost potential because of failure to harvest at the optimum time. Cassava harvest time is flexible but there is a loss in potential earnings if the timing is not optimal.

• The value of dried cassava is related to its quality, so poor qualities represent a loss of income. For example, cassava chips of different qualities sell for different prices in Northern Tanzania and in Ghana there is a 25% price premium for dried cassava chips that are free of mould.

Physical losses of cassava to be 12% in Ghana, 7% in South- West Nigeria, 3% in Vietnam and 2% in Thailand. It has been stated that, the key to reducing losses is by using improved and appropriate storage technologies and in value addition through processing. Sweet potato and yam are different as they have relatively long shelf lives under ambient conditions. If immediately after harvest the product is stored for a few days in a warm, high humidity environment then the healing of harvest damage is promoted which reduces water loss so that quality is retained [24].

Causes of losses in perishable crops

There are so many causes for losses in the perishable crops and they are classified into two group namely primary and secondary losses.

Primary causes of loss: Factors or causes that are directly affect the fruits and vegetables shelf life and quality. It includes microorganism, physical factors, physiological factors and etc.

Secondary causes of loss: Secondary causes of loss are those that load to conditions that encourage a primary cause of loss. They are usually the result of inadequate or non assistant capital expenditures, technology and quality control. Some factors

which encourage directly loss of perishable crops are lack of different and listed below.

• Inadequate harvesting, packaging and handling skills

• Lack of adequate containers for the transport and handling of perishables

• Storage facilities inadequate to protect the crops

• Transportation inadequate to move

• Inadequate refrigerated storage

• Traditional processing and marketing systems can be responsible for high losses

Ways of reducing loss of perishable crops

One of the major problems which contribute for high PHL of perishable crops is lack of improvement capability and insufficiencies infrastructure and information/knowledge/ sharing. Perishable crops are highly prone to losses because they are composed of living tissues. These tissues must be kept alive and health throughout the process of marketing. These are composed of thousands of living cells which require care and maintenance. Therefore, the reduction of PHL of perishable crops particularly, fruit and vegetables is a complementary means for increasing production. It may not be necessary to considerably step up the production of fruits and vegetables with the growing demand if the post-harvest loss is reduced to a great extent (Table 1).

| Harvesting | Careful handling during harvest to reduce bruising, scratching and punctures harvesting during the cooler hours of the day (e.g. the early morning); shading crops once harvested |

| Handling | Protecting the crops from injury can minimize pest attacks and physiological and dehydration damage |

| Sorting and cleaning | Sorting and cleaning can increase shelf-life considerably. By separating higher and lower quality crops, the risk that fungi or bacteria spread form damaged crops to others is reduced. Quality parameters like size and color can be determined through the use of visual charts, and allows the crops to be targeted to appropriate markets to maximize revenue |

| Packaging | Proper packaging to maintain freshness prevents quality deterioration as well as acting protecting against physical damage during transportation. Clean, smooth and ventilated containers are key, but the specific type depends on the crop |

| Transportation | Use of clean, cool, ventilated and covered vehicles for the transport of perishable crops, with transport during the colder hours of the day advised. The smoothness of the road |

| Storage | Only crops that meet specific quality standards should be stored (correct level of maturity, undamaged). Optimal temperatures for each commodity should be known and used as shelf-life is longer when stored in optimal temperature conditions |

Table 1: PHL reduction strategies for fruit and vegetables.

Storage of perishable crops

One of the main reasons for post-harvest losses of perishable crops is inappropriate storage. Storage of fruits and vegetables becomes essential step to make them available during off season and also to control surplus situations in the market. Appropriate storage like improved storage technologies for safe storage of perishable crops become essential for regular supply of commodities. According to research done show, India is the second largest producer of fruits and vegetables in the world with huge post-harvest losses due to lack of appropriate storage 6%-18%. So to reduce this PHL there is greater need for improved storage technologies. Lack of refrigeration capacity is mostly accountable for the big post-harvest losses experienced in developing countries.

Root and tuber crops are still living organisms after they have been harvested and losses that occur during storage arise mainly from their physical and physiological condition. To ensure effective storage of root and tuber crops, these major causative factors need to be properly understood and where appropriate, be properly controlled; taking into account the socio-economic factors which prevail in the areas of production and marketing. Control of temperature has a great effect on many factors that cause loss during storage. It is the single most important factor affecting the rate of respiration and it also influences the rate of sprout growth, the development of rotting microorganisms and insect infestation. At 10°C, the rates of sprout development, rotting and respiration are shown to be moderate but at 4°C, sprouting is stopped, while rotting and respiration continue but at very low levels.

Two classification of storage perishable crops are there based on the requirement of refrigeration, those requiring refrigeration and those that do not. Clamps, cellars, ventilated structures and evaporative cool chambers are some of the cost effective traditional storage structures; whereas cold or refrigerated storage, controlled atmospheric storage, modified atmospheric storage, hypobaric storage etc are costly, modern storage techniques. There are many low cost storage technologies for perishable crops. Some of the low-cost storage technologies have been listed below.

Low-cost storage technologies: Storage technologies perishable crops hold huge importance considering in mind the amount of post-harvest losses taking place in world developing countries. To reduce the PHL of those crops low cost storage technologies for holding fruits, vegetables and other crops produce is more important. Low cost storage technologies or traditional storage structures can be beneficial for farmers needing a small-scale storage system. In the countries where major population of farmers is poor, stay in the remote locations they can afford construction of low cost storage technologies to overcome gluts, limiting price falls and overcome shortage of a particular commodity when prices are high.

On-site or field storage: This storage technology technique of storage involves in the delaying the crop harvest through leaving it with inside the soil. The crop is left within side the soil until there may be marketplace demand. This technique is in particular used for root and tuber crops. But the main principle hassle of on site or field storage technique is that land stays occupied in which the produce is grown and new crop plantation would possibly get delayed. It should be ensured that the crops are blanketed from pest and disorder attacks, chilling and freezing injuries.

Cellars and sand and coir: In India, covering potatoes underground using sand and coir is a low cost storage technology. The crop can be stored for longer period of time of time by this method. Another example of the low cost storage technology is the cellar. Cellar refers to the underground or partially underground structures that are used to store vegetables, fruits and cellars must ideally be dark and cold. Cellars storage technology keep perishable crops such as fruits and vegetables at lower temperature and steady humidity conditions. Especially this storage technology used to prevent perishable crops from freezing injuries. It helps in keeping the produce safe from freezing during winters and keeps cool during summers. Some roots and tubers are stored in pits in the ground, known as clamp storage. Well-designed clamps tend to change the atmosphere to some extent by reducing oxygen and increasing the carbon dioxide content.

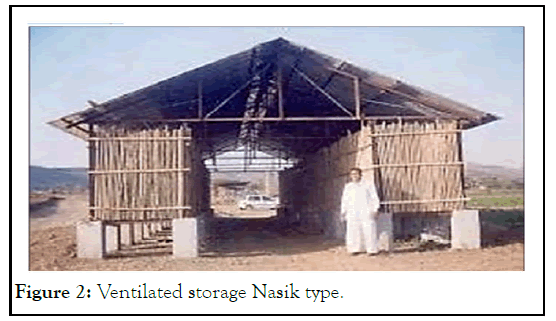

Ventilated storage structures: Ventilated storage have a flow of air that ensures minimal storage temperature. The natural ventilation storage where the heat around the product is continuously removed by natural airflow along with humidity generated by product respiration. This storage technology used for the storage of fruits and vegetables such as roots and tubers (Figure 2).

Figure 2: Ventilated storage Nasik type.

Like natural ventilation, forced air ventilation is running through the using of supporting fan to boom the rate of warmth and gases exchange. Related with the running ideas of this technology factor out that, the air is compelled via the stored crop and forcing the air used for improved the exchange of gases and warmth into the storage systems with the assist of a fan.

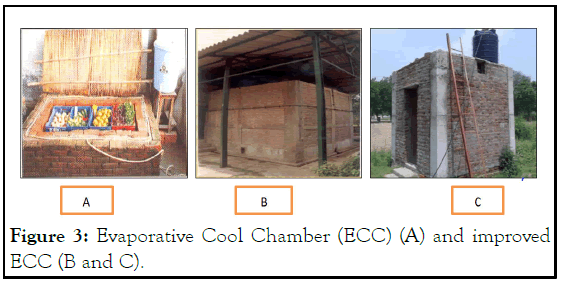

Evaporative cool chambers: The work of show evaporative cooling is methods to cool the environment through temperature drops and humidity increases. It is one of the methods to cool the environment temperature drops and humidity increases considerably to a suitable farm storage shortterm of perishables. Evaporative cooling chambers is also known as Zero Energy Cool Chambers (ZECCs), are a subset of evaporative cooling devices, which are simple and inexpensive ways to keep vegetables fresh without the use of electricity. This storage technology chambers made from locally available materials such as bricks, sand, wood, dry grass. The ZECC designed by Roy and Khurdiya enhanced shelf life of fruits through controlling temperature and relative humidity. ZECC working through lowering temperature and maintaining high humidity inside the chamber and it contributed great role to the reduce post-harvest losses and maintaining the quality of the produced. This storage technology system can reduce the temperature of the crop by 10°C-15°C and maintain a high humidity of nearly 90%. According to the work of storage conditions of mature avocados fruits at 5°C and a relative humidity of 85%-90% could result in maintain a shelf life two to three weeks. National horticulture board also giving farmers a grant aid of 100% for ZECC due to its simplest technology and play great role in reduction of PHL. ZECC also enhance the shelf-life of perishable crops through controlling and restricting the transpiration and respiration of perishable crops.

The principle working of ZECC is based on evaporative cooling. During working of ZECC cooling effect formed, because of evaporation water. The temperature variations inside the cool chamber happen to be very low as compared to outside fluctuation in mercury. Therefore, zero energy cool chambers are a simple, low cost, effective and farmers friendly storage. According to the research done in Ghana showed that, the storage perishable crops like vegetables in ZECC, produce available for sale increased to 62% of the original harvest, compared to 42 percent without a cooling chamber. The weight losses reduced by 20% and vegetable shelf-life increased from one day to between five and six days. The higher humidity and lower temperature maintained in the chamber helped the produce retain water and maintain their weight and visual appearance (Figure 3).

Figure 3: Evaporative Cool Chamber (ECC) (A) and improved ECC (B and C).

Pits: Pits are the ground in the floor normally made by digging a gravel pit. These dug holes and cavities should coat with cut grass, wood shreds, sand or soil. Pit storage must be prepared on the boundaries of the field and at an increased point in which there's availability of small or less rainfall accumulation in the cultivated field. If this situation is there the stored products will be remains cooler compared to the air temperatures due to submersion in the pits. This storage technology can practice for crops like tubers, carrot, onion, cabbages and beets are covered up with straw and soil till the marketplace call for the crop arises.

Pot-in-pot: Report, to prevent the losses of crops this technologies, storage pot is placed in an earthenware bowl containing water. During this work, the pot has to close with a damp cloth that is dipped or hollowed into the reservoir of water. Water drawn up the cloth evaporates keeping the storage pot cool (Table 2).

| Cause of PHL | Technology | Effects of the technology |

|---|---|---|

| Wilting and weight loss of produce | Shade at field level: Cloth shade structures for tomatoes | Reduce field heat and sun-induced physiological damage/wilting; cooler temperature by 6°C-10°C |

| Mechanical damage during marketing | Plastic crates, for containers, smaller containers | Reduced damage by 30%-60% Improved market value by 40-140% |

| Bad appearance due to damage=lower value | Proper harvesting, sorting/grading and packaging practices along the value chain | Field packing of tomatoes reduced losses improved market value from 50%-100% |

| High temperatures in the value chain speed up degradation of the produce | Short term storage in ‘zero energy cool chambers’ for fruits and vegetables | Temperatures reduced to 5°C-10°C depending on crop, increases shelf life by days or weeks reduces weight losses and losses overall |

Table 2: Low-cost technologies for the reduction of PHL in perishable crops chains in developing countries.

Improved storage technologies in PHL reduction of perishable crops

The major problem which contributes for high post-harvest losses relates with poor storage. This is the most important harvest practices of the fruits and vegetable to reduce losses. Much post storage are built to control the rate of transpiration, respiration, microorganism growth and to preserve the fruits and vegetables. They also preserve perishable crops by decreasing biological activities and avoiding the physiological disorder such as chilling injury, sprouting, rotting, greening and toughening of certain fruits and vegetables. Controlling temperature is an important factor in reducing post-harvest losses of perishable crops.

Cold storage of perishable crops: Now day several improved and storage technologies have been investigated for perishable crops like fruits and vegetables. These include refrigerated cold storage, CAS, MAS and hypobaric storage. Cold storage is the one widely practiced method for bulk handling of the perishables between production and marketing processing. It is one of the methods of reserving perishable commodities in fresh and whole some state for a longer period by controlling temperature and humidity within the storage system. Maintaining adequately low temperature is critical, as otherwise it will cause chilling injury to the produce. Also, relative humidity of the storeroom should be kept as high as 80%-90% for most of the perishables, below or above which has harmful effect on the keeping quality of the produce. Most fruits and vegetables have a very limited life after harvest if held at normal harvesting temperatures. Post-harvest cooling rapidly removes field heat, allowing longer storage periods. Therefore temperature is an important factor that influences the postharvest life of fruits and vegetables. Lowering of temperature leads to a decline in the rate of respiration of the produce, which further reduces the rate of biochemical reaction and improves the shelf life of the product. A cold chain ensures quality maintenance right from harvest to consumer use.

Cold storage reduces the PHL of perishable crops and extends the shelf life through:

• Reduces respiration rate, transpiration and reduces water losses

• Decreases ethylene production and enhances resistance to ethylene action thus slows ripening of fruits and perishable crops

• Reduces growth and multiplication of microorganism (microbial activity)

• Decreases browning and maintains texture

However, when certain perishable crops specially fruits and vegetables are exposed to low temperatures or not optimum temperature, they undergo chilling injuries problems. These chilling injuries affect the physiological changes, including changes to the metabolism, which results affect the appearance of bruises on the crops surface and irregular ripening. The management of temperature and relative humidity are the most important factors determining storage life of perishable crops produce.

Control Atmosphere Storage (CAS: Quality perishable crops are taken under controlled atmosphere conditions. Under control atmosphere conditions, products can be stored for 2 to 4 times longer than usual. In a CAS system, the produce is kept at reduced O2 and high CO2 concentrations with an appropriate temperature range and RH. So this form of storage is the addition or removal of gases resulting in an atmospheric composition surrounding the commodity that is different from that of the air 79% of nitrogen, 21% of oxygen and traces of carbon dioxide. Controlled atmosphere storage generally refers to keeping produce at low level of oxygen and high carbon dioxide concentrations and at suitable range of temperature and RH (Table 3). CAS extends the shelf life and maintains the quality of perishable crops by:

• Decreasing respiration and ethylene production rates, softening and retard senescence of perishable cro

• Reduce fruit sensitivity to ethylene action and alleviate physiological disorders such as chilling injury

| Perishable crops | Temperature (°C) | %O2 | %CO2 |

|---|---|---|---|

| Apple | 0-5 | 2-3 | 1-2 |

| Banana | 12-15 | 2-5 | 2-5 |

| Strawberry | 0-5 | 10 | 15-20 |

| Cantaloupe | 3-7 | 3-5 | 10-15 |

Table 3: Recommended conditions for controlled atmosphere storage of some perishable crops.

However, the main problems of CAS at very low of oxygen concentration and very high volume of carbon dioxide is change of an aerobic into anaerobic respiration which leads to formation of fermentation process. Anaerobic respiration and fermentation due to low oxygen and high carbon dioxide volume can lead to the development of off-odours and offflavours. Also according to the work of at low levels of oxygen and/or very high levels of carbon dioxide, development of microorganism may occur.

Modified Atmospheric Packaging (MAP): MAP consists of storage of fresh produce in environments whose gas composition has been changed compared to that of air to decorate the retaining quality, shelf existence and reduce the metabolic interest rate of the product. A composition of CO2, O2 and N2 is injected into the headspace that replaces the package atmosphere. However, a few of things affecting the effectiveness of MAP are there. Such elements are the rate of respiration of the produce, oxygen and carbon dioxide permeability (penetrability) of packaging substances, storage temperature of produce and additionally headspace quantity of gases present inside the packaging substances is likewise determinants.

Generally, in modified atmospheres or controlled atmospheres storage technologies to maintain general quality and reduce PHL of perishable crops, there is an addition or removal gas to produce. An atmospheric composition around the crops that is different from that of air (78.08% N2, 20.95% O2, and 0.03% CO2). Usually this involves reduction of O2 and/or elevations of CO2 gases concentrations. MAS and CAS differ only in the degree of control; CAS is more exact.

In MAP, respiration rate is reduced by decreasing O2 concentration. This metabolic response is due to the decrease in the activity of oxidizing enzymes such as polyphenol oxidase, glycolic acid oxidase and ascorbic acid oxidase. Hence, a decrease in respiration rate delays enzymatic degradation of complex substrates, thereby extending the shelf life of the produce. A reduction in oxygen concentration below 8% and/or increase in carbon dioxide concentration slow down fruit ripening.

Hypobaric storage: The storage technology of hypobaric storage is developing which keeps reduced pressure in the refrigerated storage chamber. In this technology, the crops placed in a flowing stream of extremely moistened or humidified air which is kept at a reduced pressure and controlled temperature. Reports imply that, the storage life of certain fruits and vegetables is prolonged substantially by this procedure. This technology requires an-energy intensive and capital-intensive and it is unsuited for less developed countries. Hypobaric storage technology is a highly much less understood sort of managed atmospheric storage wherein low oxygen surroundings is created at sub-atmospheric pressure ranges; which in turn reduces the respiration rates and metabolism kinetics of commodities, thereby increasing storage life. The relationship among pressure and oxygen attention is directly. So discount in pressure is proportional to the lower with inside the oxygen partial pressure. The product is stored under a partial vacuum in a chamber. The chamber is vented continuously with saturated air to preserve the low oxygen partial pressure ranges. Generally, the work of estimate that, a 10 kPa lower with inside the air pressure same with oxygen partial strain of 2.1 kPa that allows a 2% discount in oxygen attention at regular atmospheric pressure.

The contribution of improved storage technologies in perishable crops

According to numerous studies, will increase in agricultural productivity will now no longer be sufficient; it'll also be essential to lessen post-harvest losses so that you can increase the amount of food available. The FAO estimated that, each year, about one third of the world's food production for human consumption is lost.

Reducing post-harvest losses: In this world the production of fruits and vegetables high with huge post-harvest losses. One of the main reasons for large post-harvest losses is lack of appropriate storage technology and also factors like physical damage, rough handling, poor packages, poor temperature management and lack of education as main causes. Post-harvest losses in sub-sahara Africa are approximately over 30% mainly due to lack of post-harvest management skills. Post-harvest management of fruits and vegetables are highly perishable so good storage and handling is important. Fruits and vegetables have a very high water content compared to other crops and are also a good source of nutrients. Due to their high water content, they can be easily damaged and deteriorate quickly. Due to these characteristics, managing post-harvest losses of perishable crops is significant. Reducing post-harvest losses provide an opportunity to improve food security. High losses of perishable crops reduce the availability of nutritious produce for consumption. It also causes a loss of investment as farmer resources and investments used to grow fruits and vegetables are lost when fresh produce is not sold nor eaten.

Enhancing food and nutrition security: Food security is the availability and access to food and it exists when all people have physical, social and economic access at all times to sufficient, safe and nutritious food to satisfy their nutritional needs and food preferences for an active and healthy life. Today one of the foremost worldwide issues is a way to make sure food security for a global developing population even as making sure long time period sustainable development. The reduction of post-harvest loss is a crucial way to food and nutrition security in sub-saharan Africa. Agriculture of perishable crops plays a central role in increasing food availability and incomes and a key factor to improve food and nutrition security. identify the importance related to reducing PHL such as an increase in supply of the crop that may eventually increase food security, mostly through increased food availability; increase in household incomes of crops that could reduce poverty; and reduced pressure on water. Perishable crops such as fruits and vegetables are providing an abundant, cheap source of fiber and several vitamins and minerals. Many research reports indicated that an estimated five million people are suffering from lack of vitamins and essential minerals due to PHL of perishable crop.

To prevent such activities fruits and vegetables play a number of important roles in human health through supplying antioxidants vitamin A, C and E and minerals and also phytochemicals that are important in neutralizing free radicals) to manage chronic diseases. The nutritional and health value of perishable crops vegetables is well recognized in countries like Ethiopia because they play important roles in human health by way of providing antioxidants. According to research done in the Mekong delta of Vietnam perishable crop vegetables contributed 38% of vitamin A, 35% of vitamin C, 30% of calcium and 17% of iron consumed by women and all vegetable accounted for up to 33% of folate consumed. Therefore, the subject of PHL is very importance to prevent problem like hunger, raise income and enhance food and nutrition security in the poorest word countries. Improving post-harvest storage and reducing losses is critical to food security. Therefore reducing post-harvest losses play a critical role in eliminating extreme hunger and feeding a growing worldwide population. This implies that PHL reduction of perishable crop by using storage technology and food and nutrition security is direct.

Post-harvest losses of perishable crops due to high moisture content and improper storage are major problem for producers and seller perishable crop of this world. After harvest, perishable crops need to be handled with care to maintain their general quality and to reduce PHL due to they are highly perishable. Storage technologies is critical to reducing post-harvest losses of perishable crops including maintain quality, preserve nutrient content and get higher prices at market. Different storage technologies are developed based on temperature and environment control to reduce these losses and retain the crop quality until their demand in the market. Low cost storage technologies like clamps, pits, pot in pot, cellar and evaporative cooling chambers are being low cost storage technology used and help the farmers generate greater income. However, these are incompetent to store a bulk of products for an extended time. To solve those problems, improvement in high cost storage technology are coming up. Now, improved storage technologies are being utilized, which include storage in cold stores, CAS, MAS and hypobaric storage. These techniques have proved effective in reducing PHL and enhancing the shelf life of numerous perishable crops by creating an appropriate storage environment for them. Despite progress in perishable production, failure to reduce post-harvest loss can decline food availability due to increase in physical loss and decrease in income from the diminished market opportunities. Therefore, mitigation of PHL of perishable crops by using low cost and improved storage technologies contributes to increase food and nutritional security.

Horticultural crops are very perishable; therefore maximum care is needed during storage to reduce damage and losses. Reduction of losses could contribute to enhance food and nutritional security; hence attention should be given towards improving post-harvest handling practices. Temperature management is the most critical factor in reducing post-harvest losses of perishable crops and extending their shelf life. Awareness and training about building and use of both low cost and high cost storage technology to reduce PHL have to give for producer of perishable crops. Therefore, the subject of PHL is very important in the efforts to prevent problem like hunger, raise income and enhance food and nutrition security in the world countries.

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Citation: Aemu TT (2023) Review on the Role of Improved Storage Technologies in Post-Harvest Loss Reduction of Perishable Crops and Enhancing Food and Nutrition Security. J Nutr Food Sci. 13:895.

Received: 11-Mar-2022, Manuscript No. JNFS-23-16237; Editor assigned: 16-Mar-2022, Pre QC No. JNFS-23-16237 (PQ); Reviewed: 30-Mar-2022, QC No. JNFS-23-16237; Revised: 28-Feb-2023, Manuscript No. JNFS-23-16237 (R); Published: 28-Mar-2023 , DOI: 10.35248/2155-9600.23.13.895

Copyright: © 2023 Aemu TT. This is an open-access article distributed under the terms of the creative commons attribution license which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.