Forest Research: Open Access

Open Access

ISSN: 2168-9776

ISSN: 2168-9776

Research - (2021)Volume 10, Issue 2

The source of energy at household level in Ethiopia mostly comes from wood biomass. The increasing population and shrinkage of natural forests resulted in shortage of wood supply for energy. Hence, looking for fast-growing with better fuel wood characteristics is required to access wood and for the supply of fuelwood consumption. This study aims to select tree species with better biomass and good fuel wood characteristics. Seven tree species: Acacia polyacantha, Acacia abyssinica, Eucalyptus camaldulensis, Albizia lophantha, Acacia melanoxylon, Acacia decurrens, and Eucalyptus globulus were selected to study the growth performance, biomass and fuel wood characteristics. Six trees per species were randomly selected and harvested for fuel wood property (wood moisture, ash content and fiber content) analysis. Acacia abyssinica, Acacia polyacantha and Eucalyptus camaldunesis showed better survival rates than other species. The better height performance was recorded from Acacia decurrens, Acacia polyacantha, Eucalyptus camaldulensis, and Eucalyptus globules. A. polyacantha and A. decurrens provided the highest biomass. A. decurrens showed the lowest wood moisture (31.1%) and wood density (0.76 g/cm3), and the lowest ash content (2.2%). Hence, A. decurrens and A. polyacantha are recommended for fuel wood due to high density, low moisture, and low ash content and good biomass production.

Ash; Cellulose; Biomass; Density; Fuel wood; Lignin; Tree species

About 14% of the world's energy supplies come from biomass sources including fuel wood, charcoal, crop residues and animal dung [1,2]. About 35% of the energy supply in developing countries is from biomass [3]. According to Belward et al. [4] charcoal and firewood account for more than 80% of the energy use in the Sub- Sahara African countries. Charcoal energy covers more than 95% of urban energy demand [4]. As the population increased in urban areas the demand for charcoal increased. The demand in rural areas also grows for charcoal. Wood fuel production in the sub-Saharan countries reaches 600 million m3/year. Biomass energy sources also play a vital role in industrialized countries. For instance, in the United States, nearly 4% of its energy [5] and Sweden close to 14% of their energy come from biomass [3,6].

Similarly, biomass is one of the major energy sources in Ethiopia, which triggers a huge loss of indigenous trees and natural forests [7]. The supply of energy about 85% of urban communities in Ethiopia comes from natural forest sand farmlands of rural community.

From Ethiopian households, approximately 90% of energy source comes from wood, charcoal and animal dung [8]. Modern energy source development and usage in Ethiopia is mainly focused. On petroleum and electricity/Electricity consumption in the country per capita is 28 KW/h [9]. Among biomass resources wood constitutes 95% of supply [7]. In poor countries, wood is the major energy source since it requires no further processing [10].

The wood shortage for fuel wood led to use crop residues and animal dung for energy sources [11,12]. Burning of dung and crop residues which were previously sources of soil humus and fertility resulted in poor crop production and productivity. This has exposed farmers' to food in security and increased poverty [13]. In Ethiopia, energy strategies and programs in the past have focused on to improve the fuel use efficiency i.e., to promote improved stoves [10]. However, it should be beyond promoting improved stoves. It should focus also on low cost energy efficient technology and fast growing species [10]. Ethiopia's green economy strategy emphasizes the environmental and economic benefits of forest resources [14]. Some of the strategies are distributing fuel-saving stoves, encouraging agroforestry practices and planting trees. Hence, there is a growing interest in renewable biomass energy.

In the past decades, the introduction and expansion of Eucalyptus trees in Ethiopia have contributed a lot in terms of fuel and construction wood supplies. Lately, other alternative fastgrowing tree species were introduced in the country to solve the fuel wood shortage and to minimize the ecological effects of Eucalyptus. However, those newly introduced tree species are not being identified properly based on studies [15]. Studies on fuel characteristics of both exotic and indigenous tree species for fuel wood are also limited in Ethiopia, specifically in the North Shewa. Selecting a tree species with desirable fuel wood characteristics is required to improve wood supply for energy. Therefore, this study aimed to select tree species suitable for fuel wood in North Shewa.

A retrospective study was conducted using data collected from twin and sibling pairs that received a FASD diagnostic evaluation at the University of Washington Fetal Alcohol Syndrome Diagnostic & Prevention Network (FASDPN).

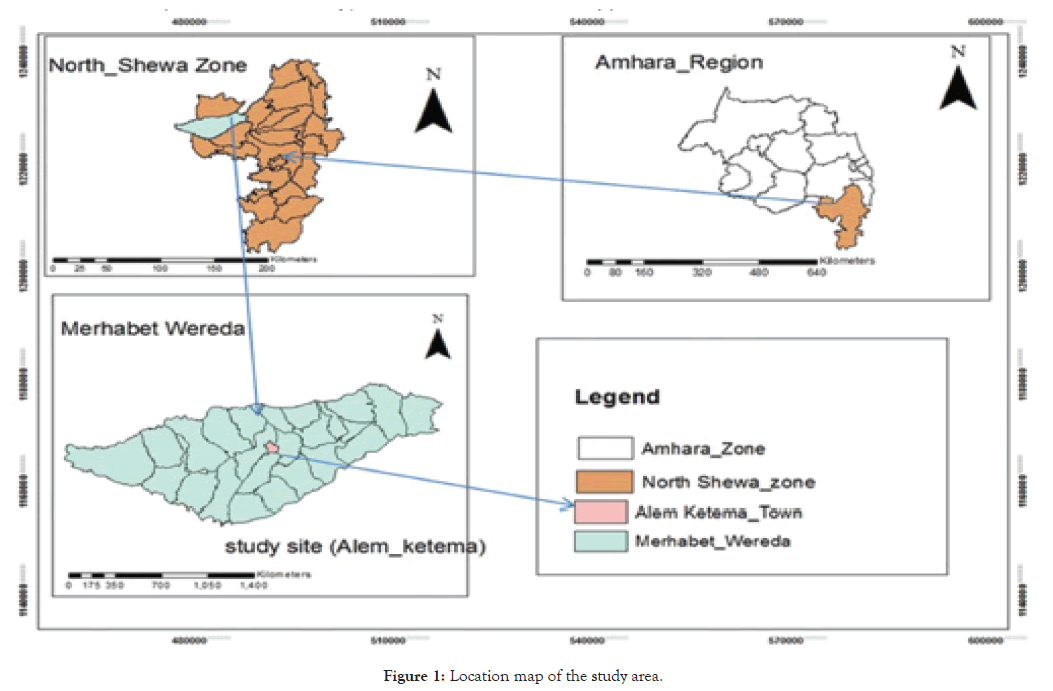

Study site

The study was carried out at Merabete district in North Shewa Zone for seven years (2011 to 2018). The site is located at Latitude 10°04'06.3" N and Longitude 38°59'42.1" E. The altitude of the study area is about 2200 Meters above sea level. The minimum and maximum temperatures of the study area were 13.1°C and 25.3°C, respectively. Annual rainfall is about 100 mm. The geology of the study area is basalt series and is intermittent with limestone or gypsies layers, at altitudes between 1700 m and 2500 m [16]. The soil type of study area is Eutric Vertisols. Soil texture is mainly clay. The soil depth of the study site is about 50 cm. Surface soil pH is about 6.3 (a little acidic), especially in subsurface horizons. The soil has very little organic carbon (0.659%) and poor total nitrogen (0.088%) [17]. Merhabete is a drought-prone area. Variety of crops like Teff (Eragrostistef) and sorghum are grown in the area.

Experimental design and sampling

Seven selected tree species were planted in a randomized complete block design (RCBD) with three replications. The spacing between trees was 2 m × 2 m. The spacing between blocks and plots were 3 meters. Sixteen seedlings were planted in each plot. Tree species used in the experiment were A. polyacantha, A. abyssinica, E. camaldulensis, A. lophantha, A. melanoxylon, A. decurrens, and E. globulus. Two trees of each species were randomly selected in each plot and a total of six trees per species were cut to characterize wood properties for fuelwood. The sample was taken at DBH. Graduated cylinder was used for volume measurement using displacement method. Wood samples with bark having 6 cm long were taken to analyze fuelwood characteristics. These samples were dried at 105°C in an oven for 48 hours to measure density, moisture content and ash content.

Moisture content

The moisture content of the wood was determined after drying at 105°C for 48 hours

Based on the following formula [18]:

Water content (%) = (Fresh weight – Oven weight) / (Fresh weight) *100

Wood density

Wood density was determined with the volume replacement method [19]. The volume of fresh stem sample immersed in a volumetric flask which was filled with water and the difference was subtracted from initial water volume to calculate the volume of the sample. For volume measurement, the sample size was 6 cm which was easily fitted with a 1000 ml volumetric flask. Then the wood density was calculated according to the following formula:

Wood density (g/cm3)=Sample oven mass/Fresh sample volume

Ash content

Ash content was determined by burning wood samples in the furnace [20]. Samples were grounded and placed in a Carbolite furnace at 575°C for 4 hours. Six grams of dried wood samples put into the crucible and burned in a furnace until all volatile elements vaporized. Then, the remaining ash was cooled and weighed using a sensitive analytical balance with an accuracy of 0.0001 g of ash percent calculation. The following formula was used to get ash percent.

Ash % = Ash weight/Sample weight × 100

Cellulose and lignin content

Moisture free samples of wood with bark were chopped in to pieces and grounded in a laboratory using sample mill (Cyclotec™ mill, Foss, Denmark) to the size of 1mm mesh screen. A sample of l g grounded wood was taken for acid detergent fiber (ADF) and acid detergent lignin (ADL). Cellulose was calculated by subtracting ADL from ADF and lignin was taken equivalent to ADL. The acid detergent fiber was analyzed using acid detergent solution store cover cellulose and lignin. It boiled and refluxed for 2 hours in the fiber apparatus. ADF was determined gravimetrically as the residue remaining after extraction. Acid detergent lignin (ADL) was determined from residues of the ADF by treating it with 72% sulfuric acid solution (H2SO4) for three hours. The residues were dried at 105°C over night, weighed and burned to obtain ash at 550°C for three hours. Wood chemical analysis was carried out based on the wet chemistry method with which developed for fiber content analysis [21]. The instrument used for fiber analyses was Fibertec Hot Extractor Model 1010.

All statistical analyses were performed with the statistical software R version 3.4.3 [22]. Descriptive statistical analysis was carried out to note the overall result. Statistical differences between species were determined using one way ANOVA (p<0.05). Means separation was done using the Tukey HSD test at p<0.05 significance level. All graphics were done with gg-plot-2 packages developed for R software.

Survival, growth parameters and biomass

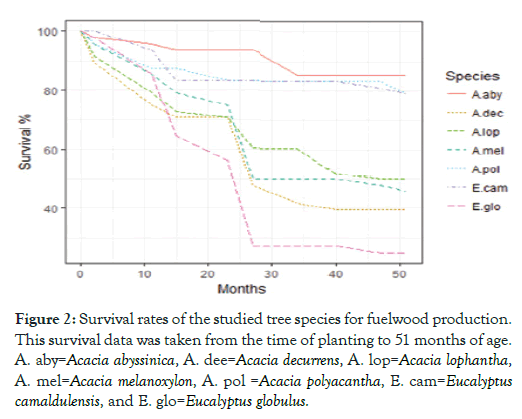

Survival rates of the studied tree species varied significantly (p<0.001) (Figure 1). A. abyssinica, A. polyacantha and E. camaldulensis had shown better survival rates with more than 75%. The other four species A. lophantha, A. melanoxylon, A. decurrens, and E. globulus had shown less than 70% of survival rate. Survival rates declined after fifteen months of the planting of those tree species showed lower survival. E. globules and A. decurrens had shown the lowest survival rates compared to other tree species (Figure 2).

Figure 1: Location map of the study area.

Figure 2: Survival rates of the studied tree species for fuelwood production. This survival data was taken from the time of planting to 51 months of age. A. aby=Acacia abyssinica, A. dee=Acacia decurrens, A. lop=Acacia lophantha, A. mel=Acacia melanoxylon, A. pol =Acacia polyacantha, E. cam=Eucalyptus camaldulensis, and E. glo=Eucalyptus globulus.

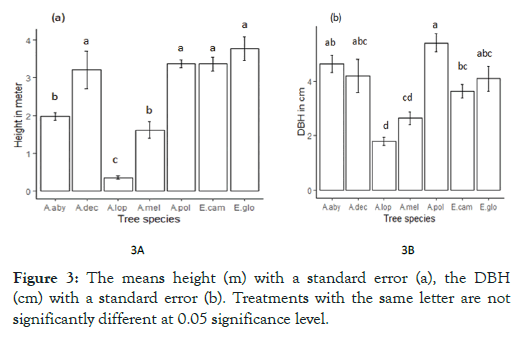

Analysis of one-way ANOVA showed there was a significant difference in tree height between tree species (p<0.001). The height of A. polyacantha, A. decurrens, E. camaldulensis, and E. globulus was higher than the rest of the tree species in the experiment (Figure 3A). The lowest height was recorded in A. lophantha.

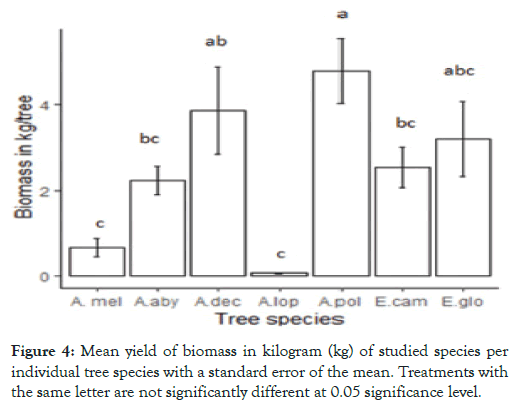

Diameter at breast height was also significantly different among tree species (p<0.001). A. polyacantha demonstrated better DBH and similarly, A. abyssinica, A. decurrens, and E. globulus showed better DBH (Figure 3B). The lowest DBH observed in A. lophantha and A. melanoxylon. Biomass was significantly different among studied tree species (p<0.001). A. polyacantha showed high biomass yield per tree at 7 years of age (Figure 3). At the same time, A. decurrens and E. globulus were provided better biomass yield. The lowest biomass yield recorded in A. lophantha and A. melanoxylon tree species (Figure 4).

Figure 3: The means height (m) with a standard error (a), the DBH (cm) with a standard error (b). Treatments with the same letter are not significantly different at 0.05 significance level.

Figure 4: Mean yield of biomass in kilogram (kg) of studied species per individual tree species with a standard error of the mean. Treatments with the same letter are not significantly different at 0.05 significance level.

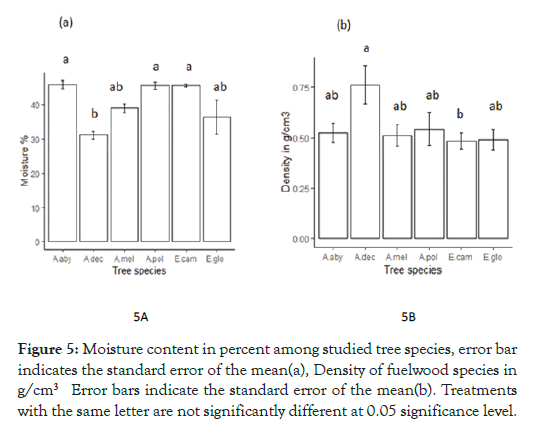

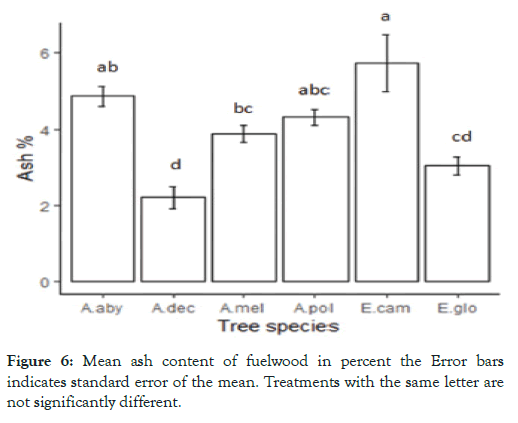

Wood moisture, density and ash

One way ANOVA analysis showed that here was a significant difference in wood moisture and density (p <0.001). Ash content was also significantly different (p <0.001) among tree species. The highest moisture content was scored by A. abyssinica, A. polyacantha and E. camaldulensis while the lowest was by A. decurrens (Figure 5A). The overall mean moisture content was 40.6% in this study. Basic density also varied among studied species (p<0.05). The highest density was recorded in A. decurrens (0.76 g/cm3) and lowest density observed in the rest of tree species (Figure 5B). The mean density was 0.55 g/cm3 for all studied species. There was a significant difference in ash content between tree species (p<0.001). The highest ash content was measured in E. camaldulensis (5.7%), A. abyssinica (4.8%) and A. polyacantha (4.3%) (Figure 5B). The lowest ash content was recorded in A. decurrens (2.2%) as well as in E. globulus (3.0%) (Figure 6).

Figure 5: Moisture content in percent among studied tree species, error bar indicates the standard error of the mean(a), Density of fuelwood species in g/cm3 Error bars indicate the standard error of the mean(b). Treatments with the same letter are not significantly different at 0.05 significance level.

Figure 6: Mean ash content of fuelwood in percent the Error bars indicates standard error of the mean. Treatments with the same letter are not significantly different.

Lignin and cellulose content

Tree species were significantly different in lignin content as it is obtained from one-way ANOV Analysis (p<0.001) (Table 1). Fuelwood species also significantly differed in cellulose content (p<0.01) (Table 1). The overall mean of 2 lignin and cellulose content was 22.1 and 43.2%, respectively. The lowest lignin and cellulose content was measured in A. abyssinica (Table 1). The highest lignin content was measured in E. globulus (Table 1).

| Tree Species | N | Lignin* (Mean ± SD) | Cellulose* (Mean ± SD) |

|---|---|---|---|

| A. abyssinica | 6 | 17.1 ± 2.7c | 39.8 ± 2.3c |

| A. decurrens | 6 | 22.3 ± 3.6abc | 42.3 ± 1.0abc |

| A. melanoxylon | 6 | 23.8 ± 3.4ab | 44.5 ± 3.1ab |

| A. polyacantha | 6 | 19.3 ± 3.6bc | 41.6 ± 1.2bc |

| E. camaldunesis | 6 | 24.5 ± 2.5ab | 44.8 ± 3.4ab |

| E. globulus | 6 | 25.8 ± 1.1a | 46.1 ± 3.0a |

Table 1: Mean Standard Deviation (SD) and mean separation of a wood fiber of fuelwood species. Mean separation was done with the Tukey HSD test (p: S 0.05).

Survival, tree height and biomass

The growth performance and productivity of trees can be determined by tree genetic qualities, edaphic conditions, environmental situations and management factors [23]. A. abyssinica and E. camaldunesis had the highest survival rates than other species. Acacia polyacantha also showed comparable survival rates. A. decurrens, A. lophantha, A. melanoxylon and E. globulus had shown lowest survival rates in this study. Animal grazing could be another reason for low survival of A. decurrens and A. lophantha. These two species were browsed and damaged by animals especially after 15 months of planting. The poorest performance of the rest of tree species may be related to low moisture in the experimental site. E. globulus also occurs mostly in wetter and high rainfall areas [24] especially above 2000 m [25]. A. decurrens tolerates acidity and grows better in light, deep and drained fertile soils [26], but the experimental site was poor in fertility.

Height was different among tested species. A. decurrens, A. polyacantha, E. camaldulensis, and E. globulus showed better performance in terms of height which is in line with the study [27]. This study reported that E. globulus had highest height soil management i.e., mulching compared to other species. Similarly, Mekonnen et al. [28] reported that E. globulus and A. decurrens scored the highest growth in 64m on the sold as compared to other indigenous and exotic trees and shrubs species. However, A. abyssinica showed the lowest growth performance. Biomass is one of the most important criteria for fuelwood production. Our study showed also a variation in tree biomass between tree species. A. polyacantha and A. decurrens had the highest biomass relative to other species. However, the result of this study was lower than; Mekonnen et al. [28] reported A. decurrens provided 29.9 kg/tree and E. globulus with 10.4 kg/tree. However, this study showed that A. decurrens and E. globulus provided 3.8 kg/tree and 3.1 kg/tree, respectively. The low biomass in our study was related to poor fertility, soil moisture and tree management.

Wood moisture, density and ash

Acacia decurrens had the lowest moisture content compared to the rest of the studied tree species. Lower moisture content increases the net calorific value of wood for heating [29]. High moisture in wood decreases the heating value of fuelwood [30]. When wood fuel has moisture, it absorbs high energy during combustion and this resulted in heat escaping [31]. One of the limiting issues in fuelwood combustion is moisture because of its effect on heating value. Because the combustion reaction is exothermic, but water evaporation is highly end other moisture content [32]. Selfsupporting combustion for the majority of biomass–based fuels is about 65% moisture content on a wet basis [32]. Moreover, most of the energy is used to evaporate water rather than combustion [32]. The results in our study showed that moisture content was below 65% on a fresh basis for all tree species. In biomass burning some of the energy is used to change water to vapor, this reduces the availability of energy for heating. Therefore, moisture content determines the energy value of biomass [33].

Wood density varied among the tested tree species. A. decurrens has the highest density and the lowest density was recorded in A. abyssinica. The density of A. decurrens in our study was 0.76 g/cm3 and this is higher than Searle and Owen [34] report i.e., 0.64 g/ cm3. High-density characteristics make A. decurrens an excellent for firewood [35]. The species suitable for fuelwood have a density of 0.55-0.58 g/cm3 as indicated by Kumar et al. [36]. The density in E. globulus (0.49 g/cm3) and E. camaldunesis (0.48 g/cm3) in our study was less than 0.55-0.58 g/cm3 [36]. Higher basic density is an important parameters to fuelwood characteristics. Trees with the highest density can generate large energy per unit volume [37].

Ash content is one of the important factors which directly affect the heating value of firewood [38]. The average ash content observed in this study was 4% which is high. Alemu et al. [39] reported 1.86% for Acacia abyssinica, Acacia seyal, Albizia gummifera, Croton macrostachyus, Grevillea robusta, and Millettia ferruginea. The result of our study was also higher than Friedl et al. [40] who reported 2.9% for wood materials. The lowest ash content was observed in A. decurrens and E. globulus in our study. Ash value in A. decurrens was 2.2%, which is lower than 2.7% in Hybrid poplar reported by Jenkins et al. [32]. High ash results may be related to wood bark. Ash contents in wood bark are high compared to ash contents in wood tissues [41]. Woods with less than 1% ash have high heating values when ash increases there is a decrease in heating value, even though some elements in the ash may catalyze thermal decomposition [32]. On the ash-free basis, almost all non-woody plant biomass has more or less the same energy value [33].

Lignin and cellulose content

The overall mean value of lignin content in this study was 22.1%. This value was smaller than Demirbas et al. [42] with an overall average value of 32.0% for different conifer and broad leaf trees and some crop husks. The overall lignin content was ranged from 14% to 28% in our study and this is different from Rowell et al. [43] reported that the content of lignin in wood ranges between 24-35%. Our results showed E. globulus has the highest lignin (25.8%) and cellulose content (46.1%) compared to the remaining species and this is supported in other studies. Eucalyptus woods have higher lignin content compared to Acacia woods [44]. However, higher lignin content in E. globulus in our study was not in agreement with Rencoret et al. [45] study which presented the lowest lignin content of E. globulus compared with other studied Eucalyptus species. Still the lignin and cellulose content of E. globulus in this study was higher than Stackpole et al. [46] reported 20.5% and 43.4% for lignin and cellulose, respectively. The lowest lignin and cellulose content was found in A. abyssinica in this study. Lignin content mostly and strongly correlated with a higher heating value of wood [42,47,48]. The higher heating value increases with the increase in lignin and cellulose content. However, the thermal degradation process is complicated and affected by temperature and moisture content. Lignin contains high hydrogen and carbon and high calorific values compared to cellulose and hemi celluloses [49]. There is also a correlation between extractive contents and the high heating value of woodfuels [50]. Therefore, it is not only lignins that affecting the heating value or calorific value of woodfuels but, also extractives like phenolic compounds and resins have a greater effect [51]. High extractive contents directly influence the heating value of the fuelwood material and these extractives also varied from species to species [38,52]. Ligno cellulose materials with high extractive contents are preferred for fuelwood because of extractives increase the heating value of the fuelwood [48,50]. Kataki et al. [53] described heating value affected directly by the content of extractives present in fuelwood. Extractives in Eucalyptus grandis reach up to 4.1% [54] and in E. globulus reaches up to 4.7% [46]. Acacia decurrens contain 74% tannin which is an extractive and part of polyphenol compound [55]. Extractive content in Acacia meamsii is higher than Eucalyptus. This is due to the presence of tannin and gum substance in Acacia meamsii [56]. E. globules have 0.26% dichloro methane lipophilic extractives which are lower than A. mangium 1.32% [57]. In general, higher calorific value due to high lignin content by itself could not be the only criteria to select fuel wood. The low moisture content and higher basic density of wood compensate for low carbon presence in fuelwood [56].

This study revealed that tree species were different in terms of biomass yield and fuelwood properties. Desirable woodfuel characteristics such as high density, low moisture, and low ash content were obtained from Acacia decurrens. This species is suitable tree species compared to other species in this study. Higher biomass was provided by A. polyacantha and E. globulus. These species can be considered as an alternative species for the area. Fast growth performance combined with good fuel characteristics are the best criteria to recommend a species for fuelwood production. Alternative species through adaptation are needed that are adaptable in the degraded mid altitude areas of the region to reduce risk of disease and insect including biodiversity. The new direction to solve the fuelwood shortage should focus not only growth performance, but also fuelwood characteristics (wood properties).

Citation: Bekele M, Habteyohannes L, Teshome G, Ababu D, Minale M, Eshetu R, et al. (2021) Screening of Tree Species for Fuelwood Production in the Mid-Altitudes of North Shewa, Ethiopia. J Forest Res. 10:248.

Received: 20-Jan-2021 Accepted: 18-Feb-2021 Published: 25-Feb-2021 , DOI: 10.35248/2168-9776.21.10.248

Copyright: © 2021 Bekele M, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.