Journal of Chemical Engineering & Process Technology

Open Access

ISSN: 2157-7048

ISSN: 2157-7048

Short Communication - (2021)Volume 12, Issue 7

Industrial case studies play an increasingly important role in the teaching of systems engineering and sustainability within an industrial ecological framework utilising metacognitive and experiential learning principles. The principal classroom teaching tool of the experiential learning combines the student’s development of self-awareness and selfevaluation skills whilst they focus on providing optimal solutions to challenges provided by industrial case study examples. The learning process here relies on developmental and experiential learning with students attempting at iterative improvements to the industrial processes and plant operations being studied with a view to create a “best fit” to the efficiency of use of the resources at hand, specific ecological setting and circular economy constraints regarding recycle, re-use and regeneration of resources. Two alternative approaches of iterative case study evaluations are presented and compared here; one relying on the “bottom-up” approach to systems identification and development to enable the use of new material and energy resources and the other on a “top-down” approach to evaluate and improve an existing system of complex and integrated process plant operations. In each case, the student is challenged in an increasing order of complexity of issues through a self-learning and evaluation process which also requires the necessary deepening of engagement with the normative knowledge base comprising of core engineering and applied science teaching curricula. The additional benefit of the student-centered teaching and learning (see also Tuzun 2020 [8]) is the ability to draw upon core scientific and engineering science “hands-on”; as opposed to classic passive learning by lectures and tutorials in advance of any case study applications to real-life challenges.

Sustainability; Holistic Systems; Metacognitive Learning; Heuristics

Bio-product manufacture and bioenergy generation as well as treatment and regeneration of bio-waste require fundamental scientific knowledge of the bioreactors and bio-separation processes; see for example Shuler et al., 2017 [7], for a thorough coverage of the processes and the process chemistry knowledge required. In addition, a precursor appreciation of the environmental emission types such as volatile organics (VOCs) and (CO2) and particulate emissions at different limits of micron and sub-micron sizes is required to be able to design, and integrate individual unit operations to facilitate environmentally-friendly process plant operation Erickson and Brase, 2019 [3].

One of the significant challenges of the design, construction and operation of biotechnology plants is the coupling of process chemistry with environmental chemistry; that is the ability to address chemical interactions and conversions within the process units as well as those in the atmosphere and in effluent streams which represent the bio-environment around the physical plant layout. It is possible to affect this coupling in the conceptual design stage of a bioprocess by taking on board simultaneously the conversion and transfer of chemical species through the process plant and bio-environment boundary. In conventional design, the plant unit operations are designed and optimised for optimal product yield and best possible return on capital investment whilst minimising operating costs but often with indifference to possible environmental impacts. The environmental impacts are subsequently assessed on the basis of compliance with regulatory control and health and safety considerations. The coupling of process and environmental chemistry in the design and operation of biotechnology plants allows for biosphere integration in raw materials storage and handling as well as in chemical processing and product delivery and in byproducts and emissions handling Erickson and Brase, 2019 [3].

Coupling environmental and process chemistry

In the industrial process case study example provided below (Figure 1), a “bottom-up” approach is used in dealing with the underpinning process science required to affect the process and environmental chemistry coupling in design and operation of a large-scale bio-methanol production plant. The design process starts with the identification of chemical components and chemical process variables and advances in steps to consider conversions and transfer of heat and materials through the process units as well as through the bio-environment and process plant boundary. The process design is then further iterated by consideration of possible in-process abatement of emissions or minimisation of emissions based on the identification of “high-emitters” and “emission bubbles” throughout the plant. The case study example goes through the actions 1-3 to be implemented to affect iterative improvements to the process design.

The students are expected to engage in project milestones identification, prioritization and task sharing with a view communicate and share knowledge within the task group as part of the collective scientific learning, data gathering and implementation and results evaluation in iterative steps of increasing complexity in going through the actions list (1-3) of the case study. This discoverybased approach relying on collective cognitive learning and selfassessment of progress is not entirely new; see for example Lucke et al., 2017 [6]. In conventional engineering research and design projects, university curricula often allow for a number of group projects to be run with a specific year student cohort by variation of product and process specifications of operating units specific to each group.

However, the approach introduced here goes further by allowing the student teams to assess the appropriate types and scales of plant units to abate and/or minimise adverse environmental impacts. In educational behavioural psychology, this challenge requires the advance from cognitive to metacognitive experiential learning where the case study group will have to engage in holistic reflection (thinking about what they already know) and holistic self-regulation (managing how they advance further learning within the constraints imposed by holistic reflection) to address the openended challenges introduced by the action steps 1-3 of the case study Darling-Hammond et al., 2008 [2].

Holistic decision-making processes are necessitated by the nature of action steps required of the case study that requires personal judgement and choice in a co-operative learning environment; Brehmer,1990 [1]. On the use of dynamic decision making in information processing in systems and organisations. For the case study considered in Figure 1, biogas reformer and synthesis reactor units are key operating units that require considerations of scale and types of mechanical design, process temperature and pressure. The flexibility of these primary units in coping with changes in biogas specification and possible production of byproduct gases (such as hydrogen) will also affect the levels of environmental burdens. Hence, holistic decision-making will have to be exercised through judgement and choice in response to the targeted levels of flexibility of the process which maximizes the efficiency of use of the resources at hand, specific ecological supply chain (including any geographical restrictions) and circular economy constraints regarding recycle, re-use and regeneration of resources. These higher-level considerations will in turn set the standards for longterm sustainability of the process plant operations and yields.

Coupling process automation with multi-product line hazop study

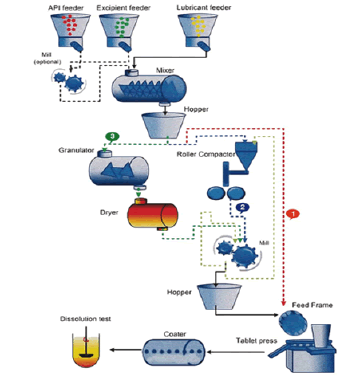

The section below illustrates the principles of iterative improvements on systems connectivity on a “top-down” basis using a pharmaceutical industry case study in contrast to the “bottom-up” approach introduced and discussed so far.

When a gated process plant structure is used to facilitate multiple products processing, this then allows for top-down control of the frequency and duration of production sequences of different products in response to fluctuations in sales demand and deliveries to different markets. The case study below introduces such a complex and integrated process plant unit operations structure that allows for the production line to be accessed and used in one or more of the three-way gated production system. Here, the “top-down” systems integration is affected by systems integration of product demand fluctuations with the responsive adjustment of frequencies and durations of alternative production lines; i.e. achieving in-plant control of supply and demand dictated by the consumer markets. Such flexibility ensures that the production quotas are always on target eliminating the need for long-term stockpiling of products with limited and restricted shelf-lives common to foods as well as drugs production Shuler et al., 2017 [7].

|

CASE STUDY EXAMPLE |

Figure 1: Industrial case study incorporating “Bottom-Up” iterative improvements to plant design and operations by coupling of environmental and process chemistry

In this industrial case study, the students are tasked to deliver a shut-down protocol for HAZOP emergency of the three-way gated process whilst maintaining maximum upstream product diversion capacity for as long as possible. The automated process plant monitoring sensors and control loops identified in 1-2 are subsequently to be used as the instrumentation and control systems layout for the challenges to be addressed in 3. Here, the management of risks, associated with different emergency plant shutdown strategies, are to be considered using different operating conditions; e.g. shutting down of one product line at a time versus closing all three product lines simultaneously as limiting possibility boundaries. A number of possible strategies can then be evaluated using linearly time-delayed sequential, and/or different coupled combinations in succession with respective time delays of the three-way gated plant structure seen in Figure 2 above. The challenge introduced here is deliberately left “open-ended” to encourage the students to exercise judgment and choice with regards to the possible location of the emergency incident in the plant layout seen in Figure 2.

| PHARMACEUTICAL INDUSTRY CASE STUDY Process automation and digital control of a partitioned large plant complex for manufacture of pharmaceutical tablets/pills/capsules Instrumentation of Unit Operations Analog and Digital Sensors Recording and Monitoring of Process Variables Process Control Loops Configuring Device Communications Loop Converters Multiplexer Platforms for Diagnostic Data Transmission Networking of Diagnostic Data for Product Quality and Process Efficiency Evaluation HAZOP Scenarios  Three-way gated system of pharmaceutical production Direct Compaction • Dry Granulation and Roller Compaction • Wet Granulation 1. Identify the partitioned and integrated control loops for process control in different segments of the plant complex for parallel processing of pharmaceutical products. 2. Identify categories of unit operation device diagnostics (e.g. fault detection, alarm settings, maintenance requirement) and process control diagnostic data sets (e.g. key variable set-point fluctuations, transient response, time-drift, process alarm settings) and suggest ways to couple diagnostic data transmission with I/O process variable field data surveillance for the triple-gated products manufacture. 3. Identify an appropriate HAZOP Scenario implementation that involves successive emergency shutdown of plant operations in different segments of the large plant complex to deliver minimal downstream disturbance with maximum upstream diversion capacity. Recommended further reading Caldwell, D.J; Mertens, B.; Kappler, K.; Senac, T. et al. 2016, A Risk-Based Approach to Managing Active Pharmaceutical Ingredients in Manufacturing Effluent, Environmental Toxicology and Chemistry, 35(4), 813-822; |

Figure 2: Industrial case study incorporating implementation of “top-down” process automation and control and hazop strategies

The important role of the systems integration design studies in the assessment and management of risks associated with environmental and business systems boundaries of chemical process and product manufacturing plants is illustrated here by contrasting “bottomup” and “top-down” systems integration approaches. The case study examples provided here can also be used to engage student cohorts with metacognitive and interactive learning methodology which builds on successive improvements with collective decisionmaking following the principles of holistic reflection and holistic self-regulation introduced above.

The support of academic and research staff at Oxford and Cambridge Universities in the UK and the consultations with Perl mutter Idea Development LLC in USA are gratefully acknowledged.

Citation: U. Tuzun (2021) Self-Evaluation of Industrial Case Studies with Iterative Improvements to Support Chemical and Biological Systems Engineering and Sustainability Teaching and Learning. J Chem Eng Process Technol 12:7

Received: 12-Jul-2021 Accepted: 26-Jul-2021 Published: 02-Aug-2021 , DOI: 10.35248/2157-7048.21.12.419

Copyright: U. Tuzun. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.