Advances in dairy Research

Open Access

ISSN: 2329-888X

ISSN: 2329-888X

Research Article - (2023)Volume 11, Issue 2

The solar heating system was used for the production of yoghurt. The possibility of reaching the temperature of the solar heating room at 42 degrees Celsius for about 7 hours per day was maintained. The experiment was conducted in two stages. The 1st stage was carried out using the solar dryer system equipped with a fan and a turbine to facilitate the heat of the solar heated air upwards (S1) and it was compared to the yogurt prepared in the traditional method (T1). The 2nd stage was conducted after turning off both the fan and the turbine in the solar heating system and to find a source of pure water to reduce the speed of the solar heated air and maintain the level of relative humidity (S2) and compare it with the traditional way (T2). Total solids, protein, fat, acidity (%) and pH were estimated. The rheological properties, viscosity of yoghurt, lactic acid bacteria, yeasts, fungi, coliform group and sensory tests were determined. The yoghurt was also stored for one week in the refrigerator at 4°C. Data showed the success of yoghurt production by solar energy, especially after modification, with a high quality close with that produced by the traditional method.

Solar energy; Yogurt; Composition; Quality; Storage stability

Sun is a very large, inexhaustible source of energy. The power from the sun intercepted by earth is approximately 1.8 MW × 1011 MW, which are many thousands of times larger than the present consumption rate on earth of all commercial energy sources. In general, solar food processing fetches in two emergent concepts together to resolve the two major issues of the world: The first one is how to produce sufficient energy for the global population, and the second is how to meet their demands of feeding and living [1]. The food industry is a large consumer of industrial energy. A very large portion of this energy is needed in the form of thermal energy at medium to low temperatures. Fossil fuels remain the dominant source of this energy. The solar energy provides various possibilities to reduce energy consumption and CO2 emissions with heat recovery [2].

Considering the growing energy crisis, the need for green energy alternatives is inevitable. Food processing must consider the application of renewable energy for replacing conventional and energy intensive unit operations; drying/heating in particular. The utilization of solar energy for heating/drying of foods remains to be attractive in terms of energy efficiency, cost-effectiveness, and rural applicability. However, a great technological gap exists; developing low-cost and energy-efficient heaters/dryers for the production of high-quality foods is a challenge. Proper design and selection of components for a solar heater/dryer are mandatory for the effective utilization of thermal energy [3]. In the conventional methods of food processing, hot air (thermal energy) is being generated by fuels like kerosene, fire wood, diesel, electricity. The conventional heating methods although are popular but have some problems such as: Higher cost of fuels and requirement of bulk quantity of fuels, depletion of conventional fuels, environmental impacts from emission of CO2, and cost of electricity and load shedding. Solar air heating system makes maximum use of the air heating potential of sunlight. Special solar heat absorber is used for food processing applications by absorbing the heat and using for hot air generation [4]. Present energy scenario indicates that these sources are costly and depleted day by day. They also pollute the environment and responsible for hazards like global warming. Renewable energy bridges the gap between mounting energy demand and diminishing supply of conventional sources of energy. Need of a cleaner environment and the increase in the demand of more healthy and hygienic food products encourages the use of renewable energy in the agro-industrial production process. Solar energy, the mother of renewable energy sources, is an inexhaustible, clean, cheap source of energy [5].

Solar radiation, in the form of solar thermal energy is an alternative source of energy for heating/drying. This producer is applicable in the so called "sunny belt" worldwide, in regions where the intensity of solar radiation is high and the sunshine duration is long. Solar energy is a rather economical procedure for agricultural products. Solar heaters are friendly to environment. It enhances the heating process in two ways. Firstly, the translucent or transparent glazing over the collection area traps heat inside heater chamber, raising the temperature of the air. Secondly, the flexibility of enlarging the solar collection area allows for greater collection of the sun's energy [6]. Solar heating/drying technologies have been classified by Sencan depending on the design arrangement of system components and the mode of utilization of the solar heat into three types as follows:

• Direct (integral) type solar dryers are those in which the

material is directly exposed to the sun's rays and use only the

natural movement of heated air.

• Indirect type solar heating/drying is not directly exposed to

solar radiation. In this case, a separate unit termed as solar air

heater is used for solar energy collection for heating of

entering air. The heated air is connected to a separating

heating/drying chamber where the product is kept.

• Mixed mode or hybrid dryers are those which combine the

characteristics of the 2 types.

Rural food processing, particularly in under-developed and developing countries, majorly relies on solar energy [7]. To develop greener technologies, the food processing sector is considering approaches to replace/reduce the use of fossil fuels. For example, various renewable energy sources such as solar, geothermal, wind and biomass have been used for the drying of food products. Among these, solar energy has been used to dry grains, spices, plantation crops, fruits and vegetables, vegetable waste, and fish. However, the use of these applications on a small scale as a solar dryer only is considered inefficient and incomplete in practical and economic terms, and it is necessary to think about using the device for more than one purpose besides being a solar dryer. With few exceptions, most countries of the developing world are located in climatic zones receiving reasonably higher insolation than the world average figure that varies from 1600 to 2200 kWh/m2/year [8]. In comparison with artificial drying/heating systems, solar drying/heating systems require much lower capital and operational costs. Solar dryers have been even coupled with desalination systems for drying of agricultural products with the simultaneous production of distilled water.

Fermented dairy products like yogurt have long been known for their functional value, particularly in the management of intestinal disorders such as lactose intolerance or acute gastroenteritis. Yogurt is a very popular functional dairy product that is made by acid fermentation of milk with the thermophilic homofermentative lactic acid bacteria Streptococcus thermophilus and Lactobacillus delbrueckii ssp. bulgaricus. The manufacturing processes of yogurt differ according to the country, but it always comprises a lactic fermentation that brings milk to gelification due to destabilization of the protein system. The texture of yogurt as a fermented milk product is important regarding the quality of the products. It is related to the sensory perception of the food products. The textural characteristics of yogurt are generally studied in the cup, using a spoon, or in the mouth by sensory methods [9]. The most common sensory evaluation related to yogurt texture are thickness/viscosity, smoothness (opposite to lumpiness, graininess, grittiness), and sliminess (or ropiness). Determination of the yogurt texture usually includes sensory structure and rheology analyses.

Cleaning/sanitizing procedures for equipment’s must be evaluated for adequacy through evaluation and inspection procedures. A cleaning and sanitizing process is one of the most important prerequisite programs in the food processor’s tool box. It has always been a key element for ensuring food safety and quality. The correct order of events for cleaning/sanitizing of food product contact surfaces is:

• Rinse

• Clean

• Rinse

• Sanitize

Therefore, the purpose of this research was to maximize the use of the solar dryer instead of using it only in drying food in preparing yogurt as a heat source equivalent to what is provided by the traditional electric incubator used in preparing yogurt in the normal method and comparing the quality attributes of yogurt prepared with the aid of solar energy with that traditionally prepared (control).

The solar drying/heating system

The system designed in the present study (Figures 1 and 2) consists of a warm air generator (A) (solar collector), cabinet dryer (B) used in our study as an incubator for preparing yogurt, reflection panel (C), turbine (D), door (E), fan (F). The solar collector was 3 m long and 0.75 wide [9]. Absorbing corrugated steel sheet surface thickness of 0.8 mm was painted black. A glass sheet 6 mm thickness was placed on the absorbing surface. The collector was connected to a heating cabinet containing 3 stainless steel trays (1.00 m × 0.75 m × 0.05 m). A turbine at the top part of the heating cabinet was 1.5 m wide and 0.5 m long. Fan was fitted at first part of collector. Incubation was carried out by putting the cubs containing prepared milk on the tray and the process was continued until the required texture of yogurt was achieved. Figure 1 illustrates the design of the solar dryer used in the present study. The solar dryer was fitted with copper constant and the thermocouples fixed at the top and bottom part of cabinet dryer, first and end part of solar air collector. All temperature data were measured through thermocouple digital sensor which was connected to a manual selective switch distributor [10].

Figure 1: General view of solar dryer/heater system (A) Solar collector, (B) Cabinet dryer/heater, (C) Reflection panel, (D) Turbine, (E) Door, (F) Fan.

Figure 2: A photo of solar dryer/heater system.

Fresh buffalomilk was obtained from the agricultural secondary school, damanhour district, Behera governorate, Egypt. All the chemicals used in the analysis were purchased from sigma chemical company, USA. For microbiology determined; plate count agar, MaCconkey broth, Potato Dextrose Agar (PDA) were obtained from Oxoid Ltd., Basingstoke, and Hampshire, England.

Cleaning and disinfecting the solar heater. The solar heater was cleaned followed by disinfection withMiller® disinfectant. The antimicrobial effect of the Miller® disinfectant includes the complete range of microorganisms. The effectiveness of the Miller® disinfectant against numerous pathogens has been tested and confirmed in more than 250 assays carried out by well-known international institutions. Miller® disinfectants are effective against:

• Gram positive and gram negative bacteria.

• Viruses, including bacterophagus.

• Spore-forming organisms.

• Yeast, fungi and mould.

• Protozoa.

The concentration used was 2% as recommended by technical data sheet, Miller® disinfectants, effective safe ecological for equipment, machines, containers in dairy industry (Milk processing industry, dairies, cheese making, yoghurt producers, etc.) [11].

Yoghurt making procedure

Fresh low-fat buffalo milk was heat treated at 90°C for 10 minutes, then cooled to 45°C suitable for making yogurt followed by inoculation with 2% starter and stirred. 100 yoghurt cups of 80 ml capacity were filled and half of the cups were placed in the electric incubator to produce yoghurt by traditional method while the rest of the cups were put in the solar heater chamber at eleven o'clock morning while the temperature inside the heating chamber reached 42°C. The time required to obtain a good consistency of the yogurt by the traditional incubation method was 5 hours, while the yogurt prepared in the solar heater needed only 2.5 hours. The yoghurt produced by both methods was kept in the refrigerator (4°C ± 1°C) for 1 week. Two replicates of the experiment were made (day 1 and day 2, expressed in the results as T1 for the traditional method and S1 for the solar heating method). The experiment was also repeated (2 replicates) after performing modifications to the solar heater system, so that both the fan and the turbine were stopped to reduce the speed of the hot air flow inside the solar heater chamber to avoid what was observed in the first attempt (days 1 and 2) by a slight concentration in the yogurt content, as the drying effect of such solar heater/drier, especially appeared in the surface layer. The modification also included placing a cup of water in the middle of the solar heater chamber to prevent the concentration/drying effect previously occurring in the first attempt. The second attempt, after modification, which followed during the third and fourth days, and the average of the two days was expressed as T2 and S2 for yogurt manufactured by the traditional method and by solar heated, respectively [12].

Chemical analysis

The samples were analyzed for total solids by dry oven at 105°C for 6 hrs as described in AOAC [13]. Protein, fat, and titratable acidity were determined as described by AOAC [14]. The pH was determined using a Delta 320 pH meter (Mettler-Toledo, Switzerland). The pH meter was calibrated at 25°C, and all measurements were compensated for temperature.

Microbiological tests

Streptococci were determined using M-17 agar containing 1% lactose (M17-lactose) and incubation at 45°C for 24 h, Lactobacilli, were determined using MRS according to Walstra P. Total coliform was detected using the Most Probable Number (MPN) technique [15]. Yeasts and molds were enumerated on Potato Dextrose Agar (PDA) followed by incubation at 25°C for 5 days [17].

Texture profile analysis of yoghurt

Texture Profile Analysis (TPA) was done for yoghurt samples using the double compression test (Multitest1dMecmesin, food technology corporation, Slinfold, W. Sussex, UK). The following parameters were determined according to the definition given by the international dairy federation [18].

• Hardness (N)=Maximum force of the 1 compression

• Cohesiveness=Area under the 2 compression/area under the 1 compression (A2/A1)

• Adhesiveness (N.s)=Negative area in the curve (A3)

• Springiness (mm)=Length 2 compression/length 1 compression (L2/L1)

• Gumminess (N) g=Hardness x cohesiveness

• Chewiness (mJ) g/mm=Gumminess x springiness

Viscosity of yoghurt

The viscosity of yoghurt was measured.

Sensory evaluation: The sensory evaluation of the products was carried out 1, 3, and 7 days after treatment. Each yoghurt treatments were evaluated using a hedonic scale from 9 to 1 (9=like extremely, 5=neither like nor dislike, 1=dislike extremely) [19].

Statistical analysis

The experiment was independently replicated two times for each of the before and after solar heater modification. The data were analyzed using Duncan’s multiple range tests using a statistical software package (SPSS 19). Differences were considered significant at p<0.05. The results were reported as mean ± standard deviation.

Solar heater temperatures: It was necessary first to obtain information about the weather conditions during the daylight hours, including maximum and minimum temperatures, relative humidity, wind speed, and direction. Table 1 shows this data from 7.00 AM until 7.00 PM according to the local time of Egypt [20].

In general, the minimum temperatures during the four days varied in a narrow range and did not have a specific behavior. In contrast, the maximum temperatures varied in a wider range with a specific behavior so that the temperature increased gradually followed by a gradual decrease one more time until the end of the sunshine duration. However, the minimum temp. Ranged between 17°C and 21°C for 1st 2 days and ranged between 21°C and 23°C for 2nd 2 days (after solar heater modification). Meanwhile, the maximum temp. Varied from 23°C to 31°C and from 26°C to 32°C for 1st 2 days and 2nd 2 days, respectively. On contrary to the maximum temperature, the Relative Humidity (RH) showed a gradual decrease followed by a gradual increase in the end of sunshine duration. The RH % decreased from 83% to 43% and from 83% to 58%, then increased to 61% and 79% at sunset, for 1st 2 days and 2nd 2 days, respectively.

| 07:00 AM | 08:00 AM | 09:00 AM | 10:00 AM | 11:00 AM | 12:00 PM | 01:00 PM | 02:00 PM | 03:00 PM | 04:00 PM | 05:00 PM | 06:00 PM | 07:00 PM | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1st day | 23°C | 25°C | 26°C | 27°C | 28°C | 30°C | 31°C | 30°C | 31°C | 29°C | 28°C | 27°C | 26°C |

| 19°C | 19°C | 19°C | 19°C | 19°C | 19°C | 18°C | 18°C | 17°C | 17°C | 18°C | 18°C | 18°C | |

| 7 km/h | 11 km/h | 15 km/h | 15 km/h | 19 km/h | 15 km/h | 17 km/h | 19 km/h | 20 km/h | 15 km/h | 17 km/h | 17 km/h | 15 km/h | |

| 78% | 69% | 65% | 61% | 58% | 48% | 46% | 45% | 43% | 58% | 58% | 58% | 61% | |

| W | W | W | WN W | WN W | WN W | WN | NW | NW | NW | NW | NNW | NNW | |

| 2nd day | 24°C | 26°C | 27°C | 29°C | 29°C | 29°C | 30°C | 31°C | 31°C | 30°C | 30°C | 28°C | 27°C |

| 21°C | 20°C | 20°C | 19°C | 20°C | 20°C | 20°C | 19°C | 19°C | 17°C | 20°C | 18°C | 18°C | |

| 7 km/h | 6 km/h | 11 km/h | 13 km/h | 15 km/h | 19 km/h | 19 km/h | 17 km/h | 19 km/h | 19 km/h | 13 km/h | 13 km/h | 9 km/h | |

| 83% | 69% | 65% | 55% | 58% | 58% | 55% | 49% | 49% | 45% | 55% | 54% | 58% | |

| W | WNW | WNW | NW | NW | NW | NW | NW | NW | NNW | NW | NW | NNW | |

| 3rd day | 26°C | 27°C | 28°C | 28°C | 30°C | 30°C | 30°C | 30°C | 30°C | 29°C | 29°C | 27°C | 26°C |

| 22°C | 22°C | 21°C | 21°C | 22°C | 21°C | 21°C | 21°C | 21°C | 21°C | 22°C | 22°C | 22°C | |

| 19 km/h | 19 km/h | 22 km/h | 26 km/h | 26 km/h | 22 km/h | 26 km/h | 26 km/h | 28 km/h | 22 km/h | 19 km/h | 22 km/h | 15 km/h | |

| 78% | 74% | 66% | 66% | 62% | 58% | 58% | 58% | 58% | 62% | 66% | 74% | 78% | |

| W | NW | WNW | WNW | WN W | NW | NW | WN | NW | NW | N | NW | NW | |

| 4th day | 26°C | 28°C | 29°C | 31°C | 31°C | 31°C | 31°C | 32°C | 31°C | 30°C | 30°C | 28°C | 27°C |

| 23°C | 22°C | 22°C | 22°C | 22°C | 22°C | 22°C | 22°C | 22°C | 22°C | 22°C | 22°C | 23°C | |

| 15 km/h | 19 km/h | 17 km/h | 15 km/h | 15 km/h | 19 km/h | 19 km/h | 20 km/h | 19 km/h | 20 km/h | 20 km/h | 19 km/h | 15 km/h | |

| 83% | 70% | 66% | 58% | 58% | 58% | 58% | 55% | 58% | 62% | 62% | 70% | 79% | |

| E | WNW | NW | NW | NW | WN W | NW | WNW | WN W | NW | NW | NW | NW | |

| Source: Borg El Arab Airport Archive, Alexandria, Egypt. | |||||||||||||

| Mt: Maximum Temp; mt: minimum temp; WS: Wind Speed; RH: Relative Humidity; WD: Wind Direction | |||||||||||||

Table 1: Weather conditions in Alexandria, Egypt during the days of the experiment.

The direction of the air during the experiment was between western and northwestern, and the air speed ranged between 6 km-7 km/h in the early morning to 19 km-20 km/h in the midday to decrease again gradually until sunset during the first two days of the experiment. The same pattern was repeated during the third and fourth days of the experiment, where the wind speed ranged between 15 km/h and 28 km/h (Table 1).

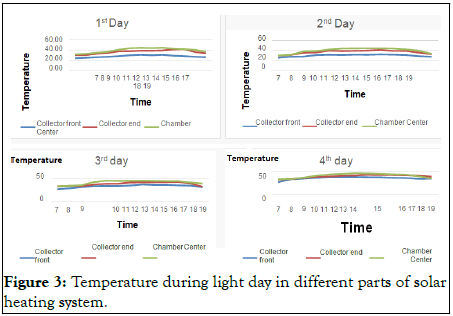

The temperatures in the different parts of the solar heating system during the four days of the experiment were shown in Figure 3. The solar collector was able to raise the temperature by 8 degrees Celsius, while the design of the solar heating chamber and its black paint helped add about 4 degrees Celsius-6 degrees resulted in the temperature of the solar heating chamber raised by an amount of 12 degrees-14 degrees Celsius. This caused the maintaining temperature of the solar heating chamber to be in the range of 41 degrees Celsius-44 degrees Celsius for a continuous period of about 7 hours per day. This suitable zone is located between 11:00 AM and 6:00 PM.

Figure 3: Temperature during light day in different parts of solar heating system.

Chemical composition of yoghurt

The data on the chemical composition of the yoghurt manufactured by two different methods is presented in Table 2. It was clear that there were significant differences in the contents of total solids, protein, and fat between yoghurt manufactured using the solar heating system and those manufactured by the traditional method. The contents of total solids, protein, and fat were significantly higher in the yoghurt manufactured with solar energy in the first attempt that was made during the first two days. This is due to the fact that the solar heating system equipped with a fan and a turbine to assist the movement of hot air is more suitable for drying food, which led to the evaporation of some amount of moisture resulting in the apparent increase in the contents under determination. Therefore, it was the second attempt of the experiment, which was repeated during the third and fourth days after the proposed modification, was made to ensure that the yogurt was completely compatible with that made in the traditional way. The proposed modification was to stop the fan and turbine from working and to place a cup of water in the middle of the solar heating chamber. Accordingly, there were no significant differences in each of the total solids, protein, and fat contents between the yogurt manufactured by the solar heating system after modification and the yogurt produced by the traditional method during the two trials (that is, during the four days of experiment). However, the mean contents of total solids, protein, and fat were 14.72%, 5.22%, and 3.16%, respectively, in the 3 attempts, i.e., 2 traditional attempts and 2nd solar energy attempt after modification. Meanwhile, the corresponding data for yogurt made by the solar heating system before modification were 15.66%, 5.96%, and 3.36%, respectively. As for the change in the chemical composition during storage for a week in the refrigerator at 4°C, there is a slight apparent, unnoticeable and insignificant increase that does not exceed 3% in all components under study. In general, the fat content in the prepared yoghurt was not less than 3% and the total solids were not less than 9%. This is in accordance with the Egyptian specifications of the yoghurt made from half-fat buffalo milk for 2005 [16].

| Treatment | Fresh (%)+ | 3 days (%) | 7 days (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| TS | Protein | Fat | TS | Protein | Fat | TS | Protein | Fat | |

| T1 | 14.7 ± 612b | 5.15 ± 0.07b | 3.13 ± 0.06b | 14.96 ± 0.09b | 5.37 ± 0.07b | 3.23 ± 0.08b | 15.23 ± 0.11b | 5.56 ± 0.10b | 3.33 ± 0.06b |

| S1 | 16.6 ± 6 13a | 5.96 ± 0.05a | 3.36 ± 0.03a | 16.89 ± 0.12a | 6.13 ± 0.10a | 3.45± 0.03a | 17.10 ± 0.07a | 6.43 ± 0.08a | 3.56 ± 0.07a |

| T2 | 14.59 ± 11b | 5.21 ± 0.11b | 3.15 ± 0.06b | 14.88 ± 0.03b | 5.40 ± 0.08b | 3.24 ± 0.05b | 15.14 ± 0.17b | 5.47 ± 0.08b | 3.35 ± 0.10b |

| S2 | 14.80 ± 10b | 5.30 ± 0.03a | 3.19 ± 0.06b | 14.97 ± 0.13b | 5.39 ± 0.11b | 3.28 ± 0.10b | 15.19 ± 0.09b | 5.51 ± 0.07b | 3.39 ± 0.07b |

| *T1 and T2=mean ± SD yoghurt manufactured by traditional method and S1 and S2=mean ± SD yoghurt manufactured by solar system, with and without fan and turbine, respectively. +Mean of triplicate determination followed by the same right small superscript within the same column is not significantly different at p = 0.05. |

|||||||||

Table 2: Chemical composition of yogurt manufactured by different methods during storage at 4°C ± 1°C.

Table 3 displays the acidity (%) and pH of yogurt produced in the traditional way as well as those manufactured using the solar heating system, whether fresh or during a week of storage in a temperature of 4°C in the refrigerator. The results showed that there were no significant differences between the three attempts of the experiment, which are two attempts to manufacture yogurt in the traditional way and those produced by solar heating after making the adjustment. At the same time, the yoghurt prepared by the solar heater showed a slight increase in acidity (%), which corresponded to an equivalent decrease in the pH when it was fresh at zero time, and this difference almost disappeared after a week of keeping in the refrigerator. In general, acidity (%) increased and pH decreased significantly in all four attempts at the end of the cold storage period. It is worth noting that all four attempts of yogurt, whether fresh or during cold storage, not reach the acidity valued of 1.5%. Therefore, it is in line with the requirements of the Egyptian standard (No. 1000/2003) for fermented milk as a yogurt product. In general, the means of acidity (%) in yoghurts prepared in this experiment were 0.96%, 1.03%, and 1.14%, while the means of pH were 4.49, 4.38 and 4.23, for fresh, 3 days and 7 days of cold storage at 4°C, respectively [17].

| Treatments | Fresh | 3 days | 7 days | Fresh | 3 days | 7 days |

|---|---|---|---|---|---|---|

| T1 | A0.94 ± 0.03b | B1.03 ± 0.02b | C1.12 ± 0.03b | A4.50 ± 0.04a | B4.38 ± 0.03a | C4.25 ± 0.05a |

| S1 | A1. 03 ± 0.03a | B1.10 ± 0.03a | C1.18 ± 0.03a | A4.49 ± 0.03a | B4.33 ± 0.05a | C4.20 ± 0.03a |

| T2 | A0.92 ± 0.04b | B0.99 ± 0.06b | C1.13 ± 0.03b | A4.52 ± 0.08a | B4.37 ± 0.07a | C4.23 ± 0.06a |

| S2 | A0.95 ± 0.03b | B1.01 ± 0.038b | C1.15 ± 0.03b | A4.47 ± 0.09a | B4.36 ± 0.05a | C4.24 ± 0.08a |

| *T1 and T2=mean ± SD yoghurt manufactured by traditional method and +Mean of triplicate determination followed by the same superscript (right small superscript between columns, left capital superscript between rows) is not significantly different at p = 0.05. | ||||||

Table 3: Acidity (%) and pH of yoghurt prepared by different methods during storage at 4°C ± 1°C.

Physical properties

Texture of prepared yoghurt: Texture is one of the most essential components of yoghurt quality. It defines the disposition and arrangements for the different parts of a system. For food products, according to the international standard organization, texture represents the rheological and structural attributes perceptible by means of mechanical, tactile, and, when appropriate, visual and auditory receptors. Rheology and structure of a product evaluated by instrumental methods also give relevant information on its textural properties [18].

Data mentioned in Table 4 show the convergence of the results of the rheological tests of both yogurt produced by the solar heating system (2nd attempt, after modification, S2) and those processed by the traditional method (2 attempts during the 4 days of the experiment, T1 and T2) in terms of hardness, springiness, cohesiveness, gumminess and chewiness. In general, there are no significant differences between those three aforementioned attempts (the two attempts of the traditional method and the attempt of the solar heating system after modification) that belong to all the texture profile parameters tested. Notwithstanding, the texture profile of the yoghurt prepared by solar heating system (before modification) showed significant higher values than the corresponding other yoghurt preparations mentioned above. The reason for this may be due to the partial loss of moisture as a result of the movement of hot air during the preparation of yogurt by the method of the solar heater system before modification, S1.

| Sample | Hardness (N) | Springiness (mm) | Cohesiveness | Gumminess (N) g | Chewiness (N/mm) |

|---|---|---|---|---|---|

| T1 | 0.71 ± 0.02b | 0.511759 ± 170*10-6b | 0.453565 ± 143*10-6b | 0.320295 ± 233*10-6b | 0.163914 ± 255*10-6b |

| S1 | 0.82 ± 0.04a | 0.585931 ± 188*10-6a | 0.469063 ± 173*10-6a | 0.338144 ± 264*10-6a | 0.178821 ± 238*10-6a |

| T2 | 0.73 ± 0.01b | 0.518755 ± 268*10-6b | 0.454455 ± 165*10-6b | 0.320863 ± 148*10-6b | 0.164231 ± 142*10-6b |

| S2 | 0.75 ± 0.02b | 0.522458 ± 272*10-6b | 0.455764 ± 259*10-6b | 0.323814 ± 239*10-6b | 0.165621 ± 267*10-6b |

| *T1 and T2=mean ± SD yoghurt manufactured by traditional method and +Mean of triplicate determination followed by the same right small superscript within the same column is not significantly different at p ≤ 0.05 |

|||||

Table 4: Texture profile analysis of yoghurts prepared by traditional and solar energy methods.

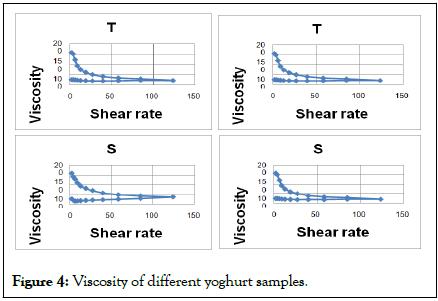

Apparent viscosity of yogurts

Apparent viscosity is one of the most important properties for yogurt quality. Figure 4 shows the effect of shear rate on the prepared yogurt apparent viscosity. As illustrated, the apparent viscosity of yoghurts made with traditional or solar heating system methods were not significantly affected by the change of shear rate up or even down. Yoghurt appears a variety of non- Newtonian effects, such as yield stress, shear-thinning, viscoelasticity, and time-dependency [19].

Figure 4: Viscosity of different yoghurt samples.

Sensory evaluation of yoghurts

The results of the sensory evaluation tests on the different yoghurt samples are presented in Table 5 for each of the fresh yoghurt samples and those stored in the refrigerator at 4°C for 3 days and 7 days. It was clear that all samples were sensory acceptable to a high degree for all characteristics under test and there are no significant differences between the 4 attempts except only in the case of the texture property in the fresh sample prepared by the solar heating system before modification (S1), as its value decreased slightly. This may be due to some dehydration that occurred as a result of the movement of hot air inside the solar heating chamber. This was remedied in the modification that was made in the second attempt. In other words, there are no significant differences in all sensory characteristics among the three trials, which are T1, T2, and S2, whether those samples were fresh or stored refrigerated at 3 days and 7 days. However, a gradual decrease was observed within the same attempt through the storage period but still had a very good score and all tested samples were accepted from all sensory evaluation characteristics point of view [20].

| Treatment | Fresh | 3 days | 7 days | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Color | flavor | Texture | Overall accept | Color | flavor | Texture | Overall accept | Color | flavor | Texture | Overall accept | |

| T1 | 9.0 ± 0.1a | 8.9 ± 0.1a | 8.9 ± 0.1a | 8.9 ± 0.1a | 8.7 ± 0.2a | 8.6 ± 0.1a | 8.6 ± 0.2a | 8.4 ± 0.1a | 8.6 ± 0.2a | 7.8 ± 0.1a | 7.5 ± 0.2a | 7.4 ± 0.2a |

| S1 | 9.0 ± 0.2a | 8.7 ± 0.1a | 8.2 ± 0.3b | 8.4 ± 0.1b | 8.6 ± 0.1a | 8.6 ± 0.2a | 8.0 ± 0.1b | 8.0 ± 0.2b | 8.4 ± 0.1a | 7.7 ± 0.1a | 7.0 ± 0.2b | 7.0 ± 0.2b |

| T2 | 8.7 ± 0.1a | 8.6 ± 0.1a | 8.7± 0.2a | 8.7 ± 0.1a | 8.7 ± 0.1a | 8.9 ± 0.1a | 8.6 ± 0.2a | 8.6 ± 0.1a | 8.5 ± 0.3a | 8.0 ± 0.1a | 7.5 ± 0.1a | 7.5 ± 0.1a |

| S2 | 8.8 ± 0.3a | 8.7 ± 0.2a | 8.8 ± 0.1b | 8.7 ± 0.1b | 8.8 ± 0.1a | 8.7 ± 0.2a | 8.5 ± 0.2a | 8.5 ± 0.2a | 8.6 ± 0.2a | 7.9 ± 0.1a | 7.6 ± 0.2a | 7.4 ± 0.1a |

| *T1 and T2=mean ± SD yoghurt manufactured by traditional method and +Mean of triplicate determination followed by the same right small superscript within the same column is not significantly different at p ≤ 0.05. | ||||||||||||

Table 5: Sensory evaluation of yoghurt prepared by traditional and solar energy methods.

Microbiological examination lactic acid bacteria

Table 6 shows the numbers of lactic acid bacteria (log cfu/g) as Streptococcus and Lactobacillusin different yogurt samples processed by each of the traditional methods (T1 and T2) and solar heating system (S1 and S2) [21-23]. It was noted that the number of bacteria was significantly greater in the case of yogurt manufactured by solar incubation in comparing with that produced by traditional methods. However, the count of Streptococcus ranged between 6.19 log cfu/g (T1) and 6.37 log cfu/g (S1), while the count of Lactobacillus varied from 5.31 log cfu/g (T1) and 5.47 log cfu/g (S1). It is noteworthy that the higher number of lactic acid bacteria in the yoghurt samples prepared using the solar heater system was also associated with a lower incubation time (2.5 hr) compared to the 4 hours required for yoghurt preparation in the traditional method [24-26]. An amount of solar ionizing radiation can penetrate the glass cover of the solar collector and thus pass through the solar heating chamber, which results in the activation of lactic acid bacteria cells and the permeability through their membranes, utilization of nutrients and thus multiply their numbers more quickly in the case of incubation by the solar heating system (S1 and S2) compared to the traditional method (T1 and T2).

| Treatments | Streptococcus (log cfu/g) | Lactobacillus (log cfu/g) | Yeast and mold (cfu/g) | Coliform group (MPN) |

|---|---|---|---|---|

| T1 | 6.19 ± 0.03b | 5.31 ± 0.07b | n.d | n.d |

| S1 | 6.37 ± 0.05a | 5.47 ± 0.03a | n.d | n.d |

| T2 | 6.24 ± 0.07b | 5.34 ± 0.04b | n.d | n.d |

| S2 | 6.33 ± 0.05a | 5.41 ± 0.06a | n.d | n.d |

| *T1 and T2=mean ± SD yoghurt manufactured by traditional method and S1 and S2=mean ± SD yoghurt manufactured by solar system, with and without fan and turbine +Mean of triplicate determination followed by the same right small superscript within the same column is not significantly different at p ≤ 0.05 respectively. |

||||

Table 6: Lactic acid bacteria, yeast and mold (log cfu/g) and Coliform group (MPN) of different fresh yoghurt samples.

The LAB strains of Lactobacillus acidophilus LA-K and Lactobacillus delbrueckii ssp. bulgaricus LB-12 were treated by mild PEF with the electrical field strength of 1 kV.cm-1, pulse width of 3 μs, and pulse period of 0.5 s. The results obtained showed that the mild PEF treated culture reached the logarithmic phase of growth an hour earlier than the untreated cells [27]. Meanwhile, the mild PEF-treated L. acidophilus LA-K had a longer exponential phase (11 h) of growth compared to the control (8 h) without PEF, L. delbrueckii ssp. bulgaricus LB-12 subjected to mild PEF had an extended logarithmic phase (7 h) of growth in contrast to the untreated cells (6 h) [28]. It was suggested that these effects could be explained by the formation of pores in the cell membrane by PEF treatment, which facilitates the uptake of nutrients from the growth medium and the excretion of metabolites from the cells. The permeability of the cell membrane increases during the PEF treatment, which may enhance the accumulation of ions inside the bacteria. For example, zinc and magnesium ions are important micronutrients for the proper function of the human body, they are cofactors of many essential enzymes, participate in cell metabolic processes, as well as in gene expression. Their deficiency increases the risk of anemia, depression, loss of appetite, heart disease, and immune system defects. The appropriate concentration of both ions is recommended daily to maintain human health [28].

The same table shows that yogurt samples produced by solar heating system or traditional method were free of yeast and mold and coliform group. It is essential that when using a device designed to produce food with a certain technology as carried out here in trying to use a solar dryer/heater in the production of yogurt that it can be cleaned and disinfected before use and this is what was actually applied, the results proved that all yogurt samples were completely free of yeasts and mold as well as the coliform group. This complies with the requirements of the relevant Egyptian Standard. The Egyptian standards require that the number of fungi does not exceed 10 cells per ml and free of colon bacteria meet the standard Egyptian standards for yogurt [29-32].

The success of using the solar heating system with high efficiency in a time not exceeding 2.5 hours in producing high quality yogurt was clearly demonstrated. It is worth noting that maintaining the temperature of the solar heating chamber at about 42 degrees Celsius between 11 am and 6 pm gives the opportunity to produce twice the amount of yogurt per day. It should be noted that both the fan and the turbine must be stopped if they are within the system to reduce the speed of the heated air passing through the solar heating system in order to avoid the occurrence of surface dryness or concentration, and it is also recommended to have a source of pure water to maintain the relative humidity.

Data used and/or analyzed in the study are available from the corresponding author on reasonable request.

The authors declare that this study has no conflict of interest.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Damanhour university ethical approval number: Du FA-2022-14

No funding was used in this study.

[Crossref]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

Citation: Ziena AH, Nasser SA, Ziena HM (2023) Solar Energy as a Promising, Cheap, Clean, And Environmentally Friend Source for Yogurt Production. J Adv Dairy Res. 11:624.

Received: 28-Mar-2023, Manuscript No. ADR-23-22606; Editor assigned: 30-Mar-2023, Pre QC No. ADR-23-22606 (PQ); Reviewed: 13-Apr-2023, QC No. ADR-23-22606; Revised: 28-May-2023, Manuscript No. ADR-23-22606 (R); Published: 05-Jun-2023 , DOI: 10.35248/2329-888X. 23.11.624

Copyright: © 2023 Ziena AH, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.