Journal of Aeronautics & Aerospace Engineering

Open Access

ISSN: 2168-9792

ISSN: 2168-9792

Research - (2020)Volume 9, Issue 2

The use of high power lasers has recently picked up in Engineering, especially Aeronautics and Aeronautical Engineering. This paper gives an overview of such applications with emphasis on the role of Erbium doped Fiber lasers, and diode-pumped solid-state lasers. Some Novel lasers like Random Lasers, X-Ray free electron lasers, Photonic Nano cavities, Ring resonators, and Spin lasers have been mentioned. Efforts being made in finding their new applications in various fields including research have been pointed out. The interest shown by defaces organizations and research institutions in investing lots of funds for new applications have been outlined. Some discussion on the Carbon dioxide lasers, Hydrogen fluoride lasers, and Cascaded Raman lasers has been presented. Erbium doped Fiber amplifiers and Diode-pumped solid-state lasers have been discussed at length. Some experimental results available in the literature have been technically discussed. A qualitative review of the important studies in this field has been given. The paper should be useful for the optical engineers engaged in the research work in this evolving field.

High power lasers; Fiber lasers; Directed-energy (DE) applications; High power Diode-pumped solid-state lasers; Aeronautics; Carbon dioxide lasers; Cascaded Raman lasers

Brief history of high power lasers

With the requirement of the increasing efficiency and power, the high power lasers, especially fiber lasers and diode-pumped solidstate lasers have been replacing the conventional technologies. Also, there is good awareness of the recent fast development of high power semiconductor lasers. The need in industry was demonstrated for the first time in 1962, when it was noticed that the electrons were converted to 500 mw laser pointers, and a great progress followed, all of which resulted in considerable improvements in the conversion of electrons to high-yield laser processes. These developments, in turn, supported a range of important applications, including optical storage, optical networking, and a wide range of research and industrial applications.

The innovations of the past lasers led to great improvements. Particularly, the improvements in brightness are excellent. An exciting development was observed in 1985, when the state of the art high-power semiconductor laser could be used to couple 105 mill watts of power into a 105 micron core-diameter fiber. In addition, the State-of-the-art high power semiconductor lasers are now able to produce over 250 watts, and have a single wavelength of 105 micron optical fiber-a 10x increase every eight years.

The great improvement of high-power semiconductor 200 mw laser pointer brightness has led to the development of many novel techniques. Based on this trend, we can believe that many new innovations in semiconductor laser technologies are still to come. We can expect that the quantum dot gain media can significantly improve efficiency over current quantum well devices. Another exciting prospect is that of slow axis brightness offering another order of magnitude improvement potential. Also, the advent of new packaging materials with improved heat dissipation and extended matching will provide the enhancements needed for continuous power regulation and simplified thermal management, which in turn will lead to the development of high-power semiconductor lasers in future.

It is to be noted that the improvements in high-power semiconductor lasers make it possible to develop downstream 30 mw laser pointer technology, in which doped crystals are pumped (diodepumped solid-state lasers) or optical fibers (fiber lasers) are doped. However, the problem in semiconductor lasers is that even though they provide high efficiency, low cost laser energy sources, they suffer from two limitations: They are not able to store energy and their brightness is limited. So these lasers can be used for (i) Converting electricity into a laser emission and (ii) Enhancing the brightness of the laser emission.

In the 1980’s, the use of pumped solid-state 50 mw laser pointer with semiconductor lasers started to be useful in commercial applications. Diode-pumped solid-state lasers (DPSSLs) have led to the reduction in the size of Diode-pump, and complexity of thermal management systems (primarily recirculating chillers), and have resulted in modules, which traditionally incorporate arc lamps for pumping solid-state laser crystals. The high power lasers have found applications in wavelength multiplexing, and photometric conversion.

Recent important studies

As a result of the success and utility of the lasers in many fields, a lot of interest has also been shown by the Researchers on exploring the various types of Aeronautics and Aerospace engineering. As an example, ytterbium doped fiber laser is the most cost effective, and commonly used for high power applications in aerospace manufacturing. Ytterbium fiber lasers operate at wavelength of 1.07 μm, with powers in the order of few hundreds of watts to few thousands of watts. Lasers are also used in Material Processing for Aerospace Applications. Another important use of lasers is in Aerospace Industry Manufacturing. There are many Engineering Laser Systems for Aerospace and Defense Systems. It is important to mention here that the Lasers for aerospace applications present a unique set of challenges including harsh environments and limited volumes. Lasers have been found to be useful in Lasers and Optical Diagnostics e.g., in Aerospace at Illinois, USA. Some of the important research in this field includes the development of new techniques, instrumentation, lasers, processing and sensors. In addition, Aerospace and aviation are two industries making extensive use of laser cutting technologies. Nicholas Swaruk and Andrew Schober [1] have discussed in detail that, Lasers for aerospace applications pose a unique set of challenges including harsh environments, limited volumes, power and thermal capacity of platforms. M/s Fibertek has presented the examples of lasers transitioned from the lab to operational environments. Fiber lasers are very versatile because they offer so much control to their users, and so they are used in many industries around the world, including aerospace and Aeronautical engineering.

Fiber lasers are generated and delivered by an inherently flexible medium, which allows very easy delivery to the focusing location and target; and therefore, can be important for laser cutting, welding, and folding of metals and polymers. Phillip Sprangle et al. [2] have reviewed and discussed the research programs at the Naval Research Laboratory (NRL) on high-power lasers for directed-energy (DE) applications in the atmosphere. It is now well understood that many Physical processes affect the propagation, which mainly are: absorption, scattering, turbulence, and thermal blooming. As discussed by Sprangle et al. [2], the power levels needed for DE applications require combining a number of lasers. In atmospheric turbulence, there is a maximum intensity that can be placed on a target that is independent of the initial beam spot size and laser beam quality. By combining a number of kW-class fiber lasers, scientists at the NRL have successfully demonstrated highpower laser propagation in a turbulent atmosphere and wireless recharging. In the NRL experiments, four incoherently combined fiber lasers having a total power of 5 kW were propagated to a target 3.2 km away. These successful high-power experiments in a realistic atmosphere formed the basis of the Navy’s Laser Weapon System.

Recently, lasers have also been used to counter aerial threats at sea [3]. A Naval ship has turned its laser weapon system to the skies to take out a nearby flying drone. The amphibious transport dock ship Portland has successfully disabled an unmanned aerial vehicle, while it was in flight during a test at sea, by using a commercially available Solid State Laser Weapons System [3]. In fact, it has been claimed that a Video footage of the test appears to show the drone on fire before it suddenly disappears. The Portland was equipped with the Solid State Laser Weapons System Demonstrator (developed by M/s Northrop Grumman) for performing this at-sea test. The weapon system is claimed to be of about 100 kilowatts, which is expected to be enhanced up to 150 kilowatts. It has been stated that this test shows that the laser’s capabilities are redefining war at sea for the Navy.

Gina Harkins [3] has reported 1st-of-its-Kind Sea test, in which Amphibious Ship has Obliterated Drone with Laser Weapon. In addition, many unconventional lasers have been the subject of interest [4-10]. These lasers have potential for applications in different areas of engineering. Fiber amplifiers have been found to very effective as high power laser sources.

Theory of ultra-fast Mid-IR lasers

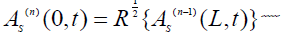

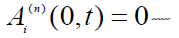

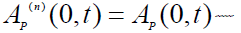

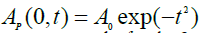

The mid-IR synchronously pumped optical parametric oscillator (SPOPO) can be easily studied by the very novel approach given by Haizhe Zhong et al. [11], in which three interaction waves are made to interplay within the OPO cavity for many round trips. Interestingly, for each round trip, the initial pump and idler pulses interact according to the requirement of the synchronous pump. In fact, the initial pump pulses propagate through the in-coupler, and combine with the signal already present in the cavity. After the nonlinear frequency conversion in the Magnesium-doped periodically poled Lithium Niobate (MgO: PPLN) crystal, amplified signal pulses are again propagated to the input coupler back and forth, but a part of the energy is made to transmit through the output coupler. During this operation, the residual pump wave and the byproduct of idler are transmitted together out of the optical cavity. All pump and signal pulses are made to undergo these steps. Following this approach, these are subject to the following boundary conditions:

(1)

(1)

(2)

(2)

and

(3)

(3)

where AS, Ai and AP are respectively the envelopes of signal (s), idler (i) and pump (p) lasers in the nonlinear interactions, n is the number of round trips, R is the total signal reflectivity in the resonator, and L is the length of nonlinear crystal. The initial incident pump is assumed to be a Gaussian profile, given by  . Thus, it is clear that to get the required optimum results for the Synchronously pumped optical parametric oscillator, the designer has to choose the proper combination of various parameters including n ,R, and L, besides taking care of the required envelopes of signal (s), idler (i) and pump (p) lasers in the nonlinear interactions. The time duration t also plays an important part in making the proper combination.

. Thus, it is clear that to get the required optimum results for the Synchronously pumped optical parametric oscillator, the designer has to choose the proper combination of various parameters including n ,R, and L, besides taking care of the required envelopes of signal (s), idler (i) and pump (p) lasers in the nonlinear interactions. The time duration t also plays an important part in making the proper combination.

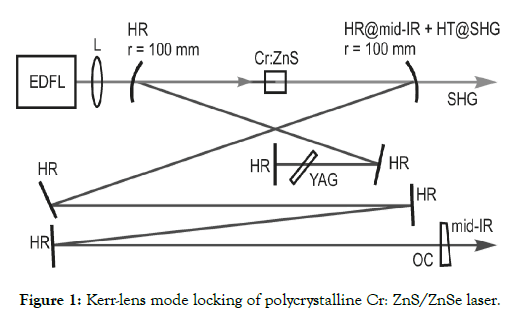

Vasilyev et al. [12] have reported very simple design of the first Kerrlens mode-locked polycrystalline Cr2+: ZnS and Cr2+:ZnSe lasers, with pulse duration of 125 fs at a pulse repetition rate of 160 MHz, emitting around 2.3-2.4 μm, in which the mode-locked lasers are pumped by a radiation of 1550 nm Er-fiber amplifier seeded by semiconductor laser. The long-term stable Kerr-lens mode-locked laser operation with the output power of 30 mW (Cr2+:ZnS) and 60 mW (Cr2+:ZnSe) has been obtained, and the amplification of the fs laser pulse train in a cw pumped single-pass polycrystalline Cr2+:ZnS laser amplifier has been demonstrated. The schematic of this system has been given below in Figure 1.

Figure 1: Kerr-lens mode locking of polycrystalline Cr: ZnS/ZnSe laser.

In this laser, as can be seen, the components required are: EDFL, Cr:ZnS crystal, YAG rod, OC and thin films coated components for doing so many functions like: (i) High reflection at mid IR, along with high transmission at SHG; and (ii) only High reflection at mid IR.

The highly reflective coatings are designed, and deposited, so that the radiation is stopped from escaping through the totally reflecting mirror (HR). The multilayer coating is designed to have high reflection in broad band around the wavelength under consideration. The coating design is of various alternate layers of high and low refractive indices represented as:

Substrate/(HLHL-HLH)2n+1)-----(4),

where H and L are respectively the quarter wave optical thicknesses (OTs) of high and low refractive index material at the desired wave length, n being the number of L layers; (n+1) the number of H layers, so that (2n+1) is some number like 23, 25, or 27 etc. depending on the degree of optimization of the Process control parameters and optical thickness OT is given by:

OT=Product of Refractive index and geometrical thickness-----(5).

However, for the output coupler (OC), the design is slightly varied to get the desired output (0.1-0.2%). Another point to be noted is, that the dual Ion beam sputtering coating technique (one beam for sputtering, and the other for assisting/cleaning while the coating is going on) has to be used for keeping the scattering loss to nearly zero value, which also helps in increasing the damage threshold of the mirror. The sputtering materials commonly used for this purpose are Ta2O5/SiO2, and TiO2/SiO2. The thicknesses of the various layers in the design have to be very carefully controlled by using In-situ film thickness monitor (Quartz or Optical). For optimum results, the substrates should have very smooth and polished surfaces with very low root mean square value of the roughness (about 2 Angstroms) of the surfaces, with scratch/dig of 10/5, and optical flatness of Lambda/10.

Erbium doped fiber amplifier

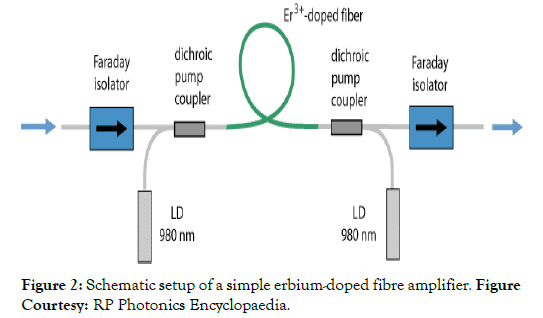

The schematic of the general setup of Erbium doped Fiber amplifier is shown below in Figure 2. The active fibers, containing some laseractive dopants are very important for use in many applications. Though, the most important application of fiber amplifiers is in optical fiber communications, e.g., data transmission through optical fibers; they are now very much in use for applications in high-power laser systems, where fiber amplifiers boost laser radiation to very high power levels for both, the continuous-wave and also for short and ultrashort pulse sources. The rare earth ions in Fibers are shown below in Figure 3.

Figure 2: Schematic setup of a simple erbium-doped fibre amplifier. Figure Courtesy: RP Photonics Encyclopaedia.

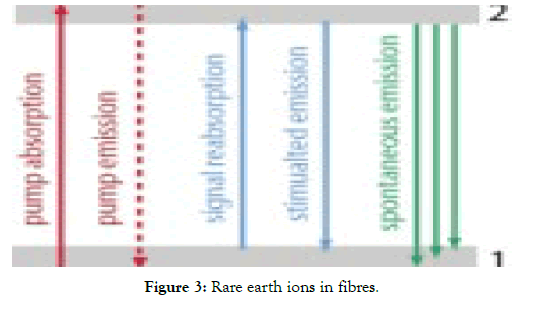

Figure 3: Rare earth ions in fibres.

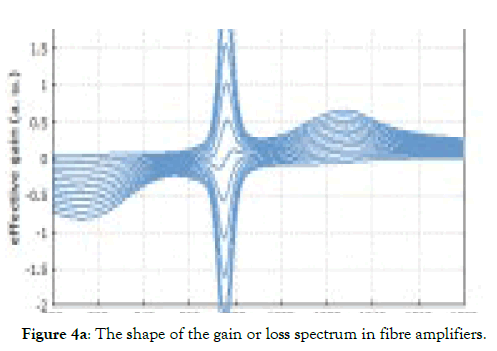

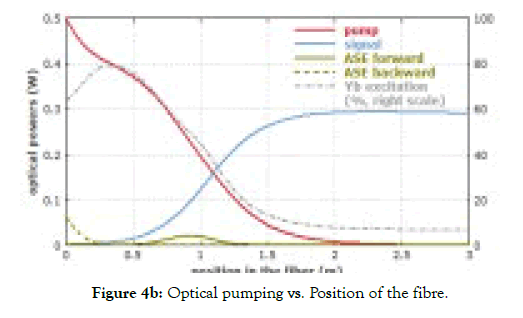

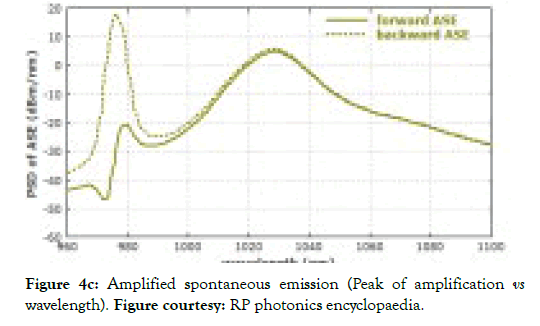

Erbium or ytterbium ions in a fiber amplify light. We can describe the behavior of such ions with complex Stark level manifolds and effective transition cross sections, which are temperaturedependent. The working of in band pumping is quite complex, and the saturation effects are generally very strong in fibers. Some of the results of shape of the gain or loss spectrum in fiber amplifiers, Optical pumping vs Position of the fiber curves, and the Amplified Spontaneous Emission (Peak of amplification vs. wavelength) curves, as reported in the literature, have been reproduced and technically discussed below in Figure 4a.

Figure 4a: The shape of the gain or loss spectrum in fibre amplifiers.

This figure illustrates the variation of the gain or loss with wavelength. As is expected, the curves show a great amount of symmetry, about the central wavelength, especially along the vertical axis, depicting resonance type behavior. It is easy to compute the gain and pump absorption from the excitation densities by the standard formulae, and also by commercially available software. The shape of the gain or loss spectrum is generally observed to depend on the degree of excitation, as is the case with erbium-doped and ytterbium-doped fiber amplifiers (Figure 4b).

Figure 4b: Optical pumping vs. Position of the fibre.

The self-consistent steady-state solution for optical powers and excitation densities along the fiber can be computed by the shooting method and relaxation method. In certain cases, it is difficult, and so the commercially available software can be used to find it easily (Figure 4c).

Figure 4c: Amplified spontaneous emission (Peak of amplification vs wavelength). Figure courtesy: RP photonics encyclopaedia.

Amplified spontaneous emission (ASE) or super luminescence is light, produced by spontaneous emission that has been optically amplified by the process of stimulated emission in a gain medium. It is inherent in the field of random lasers. The power and spectral shape of ASE is strongly depending on the propagation direction. In fact, ASE often limits the achievable amplifier, since ASE ultimately arises from a quantum effect (spontaneous emission), and is an unavoidable amplifier noise effect. Therefore, any phaseinsensitive amplifier must at least add the excess noise to a signal corresponding to ASE in ideal four-level laser amplifiers. Some commercially available lasers (Blue Spyder, Green Spyder and Red Pulsar Lasers) are shown below in Figure 5.

Figure 5: Blue Spyder, green Spyder and red pulsar lasers. Figure courtesy: "Wicked Lasers" by Marco Nero.

Carbon dioxide lasers

Carbon dioxide (CO2) lasers are the highest-power continuous wave lasers at present that are also quite efficient, providing the ratio of output power to pump power as large as 20%. The CO2 laser produces a beam of IR with the principal wavelength bands centered at 9.4 and 10.6 μm. Since at these wavelengths, glass is not transmitting, ZnSe substrates are used for making the laser mirrors for CO2 lasers. Their polishing is indeed very difficult, as the ZnSe material is very soft. Because of the high power levels available, CO2 lasers are frequently used in industrial applications for cutting and welding.

Hydrogen fluoride lasers

Hydrogen fluoride (HF) laser is an infrared chemical laser, capable of delivering continuous output power in the megawatt range. These lasers operate at the wavelength of 2.7-2.9 μm. This wavelength is absorbed by the atmosphere, and is thus effectively attenuated, which reduces its reach. However, when deuterium is used instead of hydrogen, the deuterium fluoride lases at the wavelength of about 3.8 μm, which makes the deuterium fluoride laser usable for terrestrial opera fluoride.

High power cascaded Raman fiber lasers

Cascaded Raman fiber lasers based on random distributed feedback (RDFB) have been found to be useful for providing high powers at wavelengths outside the rare-earth doped emission windows. Their working is simple: By properly choosing the input pump power and wavelength, high-power lasers can be designed and developed at any wavelength within the transmission window of the optical fibers. However, further power scaling and applicability of these lasers is limited by:

(i) The degree of wavelength conversion or spectral purity, due to intensity noise transfer of input pump source to Raman Stokes intensity leading to incomplete power transfer.

(ii) The output power range over which the high degree of wavelength conversion is maintained, due to unwanted Raman conversion to the next Stokes order with increasing power.

However, high-power, cascaded Raman fiber laser with near complete wavelength conversion over a wide wavelength and power range, can be achieved by using (i) Filtered feedback mechanism to terminate Raman conversion at arbitrary wavelengths, and (ii) Technique of low-intensity noise pump sources (Fiber ASE sources) to achieve high-purity Raman conversion.

Diode-pumped solid-state lasers

Diode-pumped solid-state lasers (DPSSLs) are an interesting type of solid-state lasers made by pumping a solid gain medium e.g., ruby or a neodymium-doped YAG crystal, with a laser diode.

DPSSLs have many advantages over other types in compactness and efficiency. High power DPSSLs have been very useful, and have replaced ion lasers and flash lamp-pumped lasers in many scientific applications. The wavelength of laser diodes is tuned by temperature to produce an optimal compromise between the absorption coefficient in the crystal and energy efficiency, which means the level of lowest possible pump photon energy. Since the waste energy is limited by the thermal lens, it results in higher power densities compared to high-intensity discharge lamps. Though, the High power lasers use a single crystal, but many laser diodes are arranged in strips in the form of multiple diodes next to each other on one substrate, or even stacks of substrates.

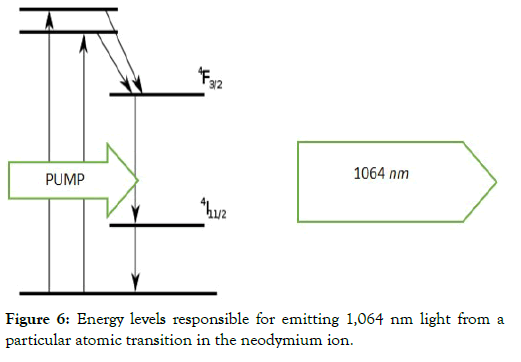

Some DPSSLs in use

Common DPSSL processes are as given below in Figure 6. It has been observed that Neodymium ions in various types of ionic crystals, and also in glasses, act as a laser gain medium, mainly emitting 1,064 nm light from a particular atomic transition in the neodymium ion, on being “pumped” into excitation from an external source. It is also possible to select 946 nm transitions light. The DPSSL is commonly used as 532 nm wavelength green laser pointer. A powerful (>200 mW) 808 nm wavelength infrared GaAlAs laser diode is used to pump a neodymium-doped yttrium aluminum garnet (Nd:YAG) or a neodymium-doped yttrium orthovanadate (Nd:YVO4) crystal, which produces 1064 nm wavelength light from the main spectral transition of neodymium ion. This light on frequency doubling by using a nonlinear optical process in a KTP crystal produces 532 nm light. Green DPSSLs have usually 20%-35% efficiency, implying that a green DPSSL using a 10 W pump diode is expected to output around 2-3.5 W of 532 nm light. However, in optimal conditions, Nd:YVO4 has a conversion efficiency of 60%, while KTP has a conversion efficiency of 80%, which means a green DPSSL can provide an overall efficiency of 48%. For the case of very high output powers, the KTP crystal becomes susceptible to optical damage. In order to avoid this, highpower DPSSLs generally have a larger beam diameter, as the 1064 nm laser is expanded before it reaches the KTP crystal, thereby reducing the irradiance from the infrared light. Still, for a lower beam diameter, a crystal with a higher damage threshold, e.g., lithium triborate (LBO), is used. In Blue DPSSLs the 808 nm light is converted by an Nd:YAG crystal to 946 nm light, which is then frequency-doubled to 473 nm by a LBO crystal or a beta barium borate (BBO) crystal. In case of Yellow DPSSLs, an 808 nm pump diode is used to generate 1,064 nm and 1,342 nm light, which are summed in parallel to become 593.5 nm light.

Figure 8: Energy levels responsible for emitting 1,064 nm light from a particular atomic transition in the neodymium ion.

High-power diode lasers have proved to be the most efficient sources of utilizing electrical energy for material processing, like welding, cutting, soldering, and various other high‐power applications. Though the IR lasers have been the subject of interest during the last five decades, and also useful in industry for two decades, GaN high‐power lasers have only recently picked up as useful for material processing, mainly for welding and soldering of copper. In this direction, the blue wavelength has been found to have great advantages over IR for industrial applications. At present, Blue‐ray GaN lasers of 1.5 kW power, with efficiencies of 40%, and lifetimes of 65 khr are available; which are increasingly been used in Aeronautics and Aerospace industry [13-17].

High power laser systems have recently been found to be making more and more useful industrial applications e.g. cutting steel, drilling via holes in silicon, and marking plastic. At present, a whole range of processes make use of the laser to produce results, which were not previously practically possible. They are also being tried to be used in military applications for destruction purposes. These lasers with moderate power are also finding applications in medical and scientific fields. In addition to finding the new applications, it has been observed that recently, a lot of interest has been shown [13-17] by the researchers in investigating various types of novel lasers like Random Lasers, X-Ray free electron lasers, Photonic Nano cavities, Ring resonators, and Spin lasers. Efforts have also been made in finding their new applications in various fields including research. Many defense organizations and research institutions are investing lots of funds for new applications. Some discussion on the Carbon dioxide lasers, Hydrogen fluoride lasers, and Cascaded Raman lasers has been given to explain their usefulness. Erbium doped Fiber amplifiers and Diode-pumped solid-state lasers have been discussed in detail. The most powerful laser beam created has recently been reported to be fired at Osaka University in Japan, where the Laser for Fast Ignition Experiments (LFEX) has been boosted to produce a beam with a peak power of 2,000 trillion watts for an incredibly short duration, approximately one picosecond. To have an idea about it, we can say that such large values are billion times more powerful than a typical stadium floodlight. It may be concluded that the field of high power lasers and their applications is on a sound footing and evolving fast.

The author is grateful to Dr. Nand Kishore Garg, Chairman, Maharaja Agrasen Institute of Technology, GGSIP University, and Delhi for his moral support. The author is thankful to Dr. M. L. Goyal, Vice Chairman for support. Thanks are also due to Dr. Neelam Sharma, Director, and Dr. V. K. Jain, Deputy Director for their encouragement. The author is grateful to Prof. V. K. Tripathi of Physics Department, Indian Institute of Technology, Delhi, for motivating to work in this fascinating field; and to Shri G Krishna Rao, Director, Electro Optical Instruments Research Academy (ELOIRA), Hyderabad, and Shri Hari Babu, Director, Laser Science and Technology Centre, DRDO, Delhi, for many interactions and useful discussions culminating in huge improvements in the presentation and concepts of this paper. Finally, thanks are also due to an anonymous reviewer of the paper, whose very constructive comments helped in substantially improving the presentation and readability of the paper.

Citation: Chopra KN (2020) Technical Analysis and Qualitative Overview of High Power Lasers with Emphasis on Fiber Lasers and Diode-pumped Solid-State Lasers having Potential for Applications in Aeronautics and Aerospace Engineering. J Aeronaut Aerospace Eng. 9:224. doi: 10.35248/2168-9792.20.9.224.

Received: 20-Jun-2020 Accepted: 29-Jul-2020 Published: 07-Aug-2020 , DOI: 10.35248/2168-9792.20.9.224

Copyright: © 2020 Chopra KN. This is an open access article distributed under the term of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.