Advances in dairy Research

Open Access

ISSN: 2329-888X

ISSN: 2329-888X

Review - (2019)Volume 7, Issue 4

Historically, whey was considered as a waste by-product of dairy processing and especially of cheese making while, nowadays, the intrinsic value of its components are widely recognized. As the amount of whey in the dairy industry is constantly increasing, new sustainable methods of whey utilization/processing must be sought after. This review suggests that, amongst other uses, the development of dairy-type whey beverages will provide consumers with a highnutritional quality product, while creating innovation opportunities for the dairy industry. Whey-derived bioactive components have antimicrobial, anti-inflammatory, and antioxidant properties hence the functional quality for the health-conscious consumer. Utilization and exploitation of whey results to reduction of the environmental impact and leads to sustainable practices by the dairy industry.

Whey; Valorization; By-product; Added-value; Whey proteins; Health benefits

Whey is the yellow-green liquid with sour, slightly salty aftertaste that is separated from the curd during cheese-making and is classified into two categories based on the method of milk coagulation; sweet and acid whey [1-3]. Sweet whey is obtained as a result of enzymatic milk coagulation by chymosin, and has a pH value of 6-7 and it is also known as cheese whey. Acid whey is a by-product of milk coagulation by acidification with a pH value <5 [4].

The use of whey and its products date back in the 1970s. At that time, whey was used in whey baths because of the beneficial active ingredients, which not only have anti-inflammatory qualities but also nurture the skin [5]. The good reputation of whey started to fade in the 19th century when whey was considered as a burdensome, environmentally damaging waste by-product of the dairy industry [6,7]. The majority of whey was utilized for animal food or it was treated as a waste and was poured into rivers in vast amounts. Farmers often used the phrase “out of sight out of mind” to describe their concern for whey.

According to the International Dairy Federation, cheese production increased by 13% in 2017 including 56 countries worldwide, while in 2018 cheese production increased further by 16% (IDF, 2017, 2018). Therefore, “the challenge” continues to grow; many dairy companies have led the way to a new era for the use of whey. Based on the positive effects of whey, new products have been discovered and this has resulted in minimizing the overall waste of whey. The world’s largest dairy companies have already introduced a new generation of products based on whey. For instance, Arla Food Ingredients has recently developed a low-volume, high-protein medical beverage which contains 10 g of high quality whey protein and is low in lactose. This product is suitable for patients recovering from malnutrition due to its low-volume dietary treatment. Furthermore, Nestlé Health Science has developed a whey powder, called Resource Whey Protein powder which is a powder-based soluble protein designed for the dietary management of malnourished patients. Nestlé Health Science has also introduced a whole new product series called Boost; the series include a line of nutritional drinks with high-quality protein, vitamins and minerals, including calcium and vitamin D. Many other companies continue to develop whey-based powders, such as Fonterra with the Whey Protein Concentrate (80% protein) and Whey Protein Isolate (approximately 90%) along with Lactalis with FloWhey-whey powders and Pronativ, Native Whey Protein. These products are a great source of protein digested by the body allowing fast absorption of its nutritional benefits into the body.

Environmental Issues and Legislation

There is a worldwide need for being environmentally friendly and community pressure forces the dairy industry to reconsider their management of whey as it is considered a major pollutant co-product owing to its high Biological Oxygen Demand (BOD) (40,000 to 60,000 mg/L) and Chemical Oxygen Demand (COD) (50,000 and 80,000 mg/L) [8-10]. The main component causing BOD and COD high values is lactose, which is the main constituent of whey i.e. 70-72% of the total solids [11,12]. It is estimated that 4000L of whey could cause the environmental damage equivalent to that caused by fecal waste produced by 1,900 persons [13].

Currently, across the world, volumes of whey are growing at about the same rate as milk volumes (42% per year; FAO, 2006). The worldwide production of whey is estimated at around 190 x 106 ton/year [7,14]. It is worth mentioning that for every 1kg of cheese made, approximately 9L of whey is produced [15]. The cheese industry produces about 115 million tons of whey annually and 47% of it is being directly disposed in the drains. This is causing serious environmental pollution problems [15] and as a result, the high polluting potential makes disposal of surplus whey expensive. In Brazil, there is a high demand for cheese whey because there is a now growing production of wheybased foods and beverages. As a result, it is reported that in 2010, Brazil imported US$39 million in whey and exported US $8,145 million [16]. Europe is the worldwide leader in cheese production and consequently the largest whey producer. With an estimated 10 million tons of cheese consumed in the European Union annually; Europeans consumed 14.2 kg of cheese in 2017. According to the projected cheese consumption per capita in the EU, by 2025 Europeans will consume 16 kg of cheese, while distinct consumption differences are present between the countries. Concerning the amount of whey that is produced, 4.03 million tons of whey were produced in 2016 in the EU. EU exported more than 557 thousand tons of whey globally and China was the top importer of EU whey with 158,212 tons imported in 2016 [17]. Traditionally, whey used to be disposed, but the environmental damage being triggered by the disposal of untreated whey is now recognized [18].

Statutory laws towards started back in the mid of the 20th century, many governments around the world banned the disposal of whey on agricultural land or the dump in rivers and the sea. The strict environmental legislation in most dairy producing nations is due to the highly harmful effects that whey has on aquatic life. The most ignominious example of the disposal of whey was a spillage of acid whey in a waterbody in Ohio in the US in 2008. This spillage killed more than 5400 wild animals, mostly fish due to the depletion of the dissolved oxygen leading to eutrophication [19]. The disposal of whey has a negative effect not only on aquatic life but also on plant life. Crop kills have been noticed because of the rapid consumption of oxygen in the soil from the breakdown of milk sugars and proteins present in whey. Land spreading for the disposal of whey can cause a reduction of soil redox potential resulting to high soil salinity and reduced crop yield [20,21]. In Europe, the practice of landfill disposal of cheese whey has been discontinued because of newly developed markets for whey proteins and regulatory requirements based upon the EU Landfill Directive 1999/31/EC [22].

Composition of whey and health benefits

Whey has a high nutritional value and is easily digested and assimilated. It is a rich source of minerals (calcium, phosphorus, sodium, potassium, chlorine, iron, copper, zinc, magnesium), as well as B-complex vitamins [23-25]. Table 1 presents the gross chemical composition of sweet and acid whey while Table 2 reports the content of minor bioactive proteins in. Whey proteins represent about 20% of the total protein in milk and the principle fractions are β-lactoglobulin (β-Lg), α- lactalbumin (α-La), bovine serum albumin (BSA), immunoglobulins (Igs) while the minor proteins are lactoferrin, glycomacropeptide (GMP), lactoperoxidase, proteose peptone [5,23]. These globular proteins (α-la, β-lg) are more watersoluble than caseins, are heat-sensitive and can be precipitated by heat treatment under appropriate conditions of pH and ionic strength [26]. All protein components, except GMP, are naturally present in whey, while GMP is produced from casein during the first step of enzymatic cheese processing [27]. Whey protein composition and the casein/whey protein ratio depend on the milks of different mammal species and it may range from 6 to 10 g/L of proteins. The casein/whey protein ratio ranges from 3.2:1 up to 4.7:1 in goat, sheep and cow, respectively, while it is 0.4:1 in human, 1.1:1 in horse and 1.3:1 in donkey milk [28]. The highest content of total proteins 5.2% w/v is in sheep milk [29] whereas it is 3.2% in cow and goat milk. Also, seasonal variation in protein content in sheep and goat whey was reported [30].

| Component | Sweet whey | Acid whey |

|---|---|---|

| Total solids | 63.0-70.0 | 63.0-70.0 |

| Total protein | 6.50-6.60 | 6.10-6.20 |

| Lactose | 46.0-52.0 | 44.0-47.0 |

| Milk fat | 0.20-0.50 | 0.3 |

| Minerals (ash) | 5.00-5.20 | 7.50-7.90 |

| Lactic acid | 2 | 6.4 |

| pH | 5.90-6.40 | 4.60-4.70 |

| Calcium | 0.4-0.6 | 6.0-8.0 |

| Phosphates | 1.0-3.0 | 2.0-4.5 |

| Lactate | 2 | 6.4 |

| Chlorides | 1.1 | 1.1 |

| Free Amino acids (total) | 0.133 | 0.45 |

| Free Amino acids (essential) | 0.051 | 0.356 |

| Amino acids in proteins (total) | 0.006 | 0.006 |

| Amino acids in proteins (essential) | 0.003 | 0.003 |

Table 1: Typical composition (g/l) of sweet and acid whey.

| Variables | Cow | Sheep | Goat |

|---|---|---|---|

| Total whey proteins | 5.0-9.0 | 8.8-10.4 | 3.7-7.0 |

| β-lactoglobulin (β-Lg) | 3.2-4.0 | 2.7-5.0 | 1.8-2.8 |

| α-lactalbumin (α-La) | 1.2-1.5 | 1.2-2.6 | 0.6-1.1 |

| Immunoglobulins | |||

| IgA | 0.14 | n/a | 0.03-0.08 |

| IgM | 0.05 | n/a | 0.01-0.04 |

| IgG | 0.59 | 0.25 | 0.1-0.4 |

| Lactoferrin (Lf) | 0.1 | 0.07 | 0.02-0.2 |

| Lysozyme | 0.001 | 0.001-0.004 | 0.00025 |

Table 2: Concentration (g/l) of major and minor whey proteins in cow, sheep and goat milk.

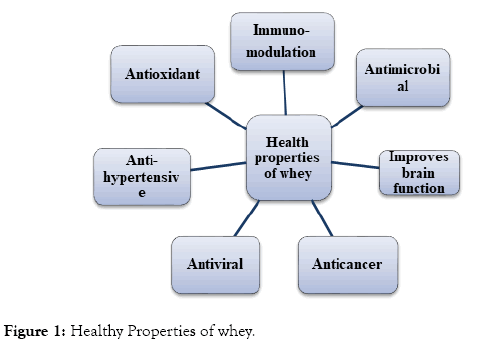

Nowadays, there is rising consumer awareness towards the health benefits of foods. This becomes the driving force for scientific research to support the notion that diet may fulfill nutritional needs and exert a beneficial role in human health [24]. The concept of functional food products is clearly not new and it was started 2,400 years ago, when Hippocrates, the father of medicine, wrote the tenet “Let food be thy medicine and medicine be thy food” [24]. It is an undeniable fact that whey is more than just a high-quality protein source because of the health benefits that offers (Figure 1).

Figure 1: Healthy Properties of whey.

β-Lactoglobulin (β-Lg)

β-lactoglobulin is the principal protein in whey, accounting for approximately 58% w/w of all bovine whey proteins [31]. It occurs as a number of variants, and the molecular weight (MW) of this protein ranges from 18.20 to 18.36 kDa with 162 amino acids in its peptide chain [32]. Solubility of this protein is mainly dependent on pH and ionic strength and it exists as a monomer only outside the pH range 3.5-7.5. Inside this range, it generally exists as a dimer although, under certain circumstances, some variants may form an octamer [26,32]. Moreover, β- lactoglobulin is comparatively heat-sensitive and the heat denaturation occurs between 70°C and 75°C and forms aggregates at 78 to 82°C [26,33]. The precipitation of β-LG occurs before that of α-La [33]. β-lactoglobulin can be characterized as a protein of high biological value as is a rich source of essential amino acids (leucine, isoleucine and valine) [23,34]. Table 2 presents the differences in whey proteins concentration in cow, sheep and goat milk [34].

The biologically active peptides can be released by in vivo or in vitro enzymatic hydrolysis during food processing (including intestinal digestion and the fermentation of milk). These peptides, as being released and absorbed, play an important role in reducing the risk of certain health conditions because of their antihypertensive, antioxidant, immunomodulating, antithrombotic and antimicrobial properties. They also reduce stress by increasing brain serotonin levels and improve liver function and reduce blood pressure. In general, the performance of physically active individuals is enhanced [23,35].

α-Lactalbumin (α-La)

α-lactalbumin comprises about 11% of the total whey proteins, has a monomer molecular weight (MW) of about 14 kDa and is slightly more heat-resistant than is β-lactoglobulin [26,32,36]. α-La is a tryptophan-rich protein and it has been proved it improves brain function and helps in alleviating stress and depression. A diet enriched with α-La increases the ratio of tryptophan to the other large neutral amino acids (valine, isoleucine, leucine, tyrosine and phenylalanine), which has the negative effects of an imbalance of brain serotonin (5-hydroxytryptamine). The improvement in this imbalance leads to better cognitive performance, mood and sleep [23,36]. Additionally, α-LA has other beneficial uses i.e., helps in the absorption of minerals, possesses antibacterial activity, and shows immunomodulatory effects and antitumor activity [37].

Immunoglobulins (Igs)

Immunoglobulins constitute a complex group of elements produced by B-lymphocytes and their concentration in whey is 0.7 g/l. There are three basic classes that Igs are divided into: IgG, IgA and IgM. IgG, which represents up to 80% (w/w) of all Igs in milk or whey, has been extensively studied and serves as a model of basic structural unit of all Igs [31,38]. There are numerous studies that have proved the therapeutic potential of immunoglobulins as they possess many important antimicrobial and antiviral properties. The physiological function of Ig is to provide immunity to the body. More specifically, they provide protection against diseases in the newborn through passive immunity. In addition, immune milk is an excellent source of blood pressure lowering [23,39-41].

Bovine serum albumin (BSA)

Whey protein consists of around 5-6% in bovine serum albumin (BSA). Bovine serum albumin (BSA) is a very heterogeneous protein with a molecular mass of 66.26 kDa [41]. BSA contains 582 amino acids residues and has a denaturation temperature of 64°C, which is almost similar to that of α-LA (62°C) [32,42]. Due to its size and higher levels of structure, BSA is the principal carrier of fatty acids and other lipids, as well as flavor compounds. It should be noted that upon denaturation this activity is deteriorated [43,44]. Another advantage of BSA is that it can be used as a source of essential amino acids, but due to availability of other sources, there is no real demand for it [37].

Lactoferrin (Lf)

Lactoferrin (Lf) is a low-abundance glycoprotein with a molecular weight of 80 kDa, representing 1% or less of the protein content of whey. Its concentration depends on the lactation period and in bovine milk is 0.02-0.35 mg/ml [45,46]. Lf presents a bacteriostatic effect due to its ability to bind free iron, essential for the growth of bacteria (e.g. E. coli). It represents one of the first defense systems against microbial agents and it is an important host defense molecule and performs a range of physiological functions such as antimicrobial, antiviral, immunomodulatory and antioxidant activity [46,48]. Due to the various therapeutic properties, lactoferrin is the most valuable biomedical protein present in whey [23,45,47]. As a result, lactoferrin seems to have great potential in practical medicine and for this reason it has been the focus of intense research [46].

Lactoperoxidase (LPO)

Lactoperoxidase is a naturally existing enzyme in raw milk. It is a member of the peroxidase family, with molecular weight of approximately 78kDa and contains a number of carbohydrate groups. It accounts for 0.25-0.5% of total protein found in whey [49]. The biological significance of this enzyme is that it has a natural protection system against the invasion of microorganisms [50]. As a result, the principal value of lactoperoxidase (LPO) is as a protective factor against infectious microbes [51].

Branched chain amino acid (BCAAs)

Whey proteins are a naturally rich source of branched chain amino acid (BCAAs), containing the highest known levels in any natural food source [52]. They are of great importance to athletes, since they are directly metabolized into the muscle tissue. Moreover, they are the first amino acids used during periods of exercise and resistance training [53]. Whey protein isolates (WPI) in particular, are high in branched-chain amino acids (20-23 g/100 g protein), which increases satiety, protects against muscle-protein loss, enhances muscle-protein synthesis, and improves glycemic control [25,54].

Glycomacropeptide (GMP)

Glycomacropeptide (GMP) constitutes about 10%-15% of protein in whey. It is a peptide constituent of whey protein (derived from casein) and it presents many beneficial effects on satiety and phenylketonuria management [55]. GMP is one of the few amino acid sources phenylketonuria patients can tolerate because pure GMP does not contain phenylalanine [23]. In general, GMP protects against toxins, bacteria, and viruses, promotes bifidobacterial growth, and modulates immune system [34].

Lactose

Lactose (4-O-b-D-galactopyranosyl-D-glucose) is the main constituent of whey (~70% based on dry matter basis) and is a very important source of energy. Most milk carbohydrates pass into the whey after cheese making of which 90% is lactose including some glucose, galactose, oligosaccharides and amino sugars, it can be recovered from cheese whey or more likely from whey permeate by crystallization [56]. Heat treatment of whey converts lactose into lactulose, which is one of the growth promoters of the Bifidobacteria [57]. Lactose presents many beneficial aspects and has dietary fiber-like and prebiotic properties while it facilitates the intestinal absorption of several minerals such as calcium, phosphorus and magnesium [34,58]. Additionally it establishes a mildly acid reaction in the intestine and thereby the growth and multiplication of harmful bacteria is prevented.

Lactose is commercially available in different qualities, of which major categories are food-grade and pharmaceutical-grade. Due to its low sweetness, lactose is widely used in the food and confectionery industries [59]. Especially, it is used in the baking industry to promote crust browning through the Maillard reaction. Lactose is also used in the pharmaceutical industry as an excipient [56].

Technological approaches for utilization of whey As the worldwide production of whey will continue to rise in the coming years the dairy industry is faced with a challenge. By optimizing this valuable industrial by-product, the following opportunities are presented:

1. New dairy product i.e., beverage development that meet consumer expectations and fit into the newly-created consumer trends.

2. By-product utilization will result in added profits for the company.

3. Actionable initiatives towards environmental protection.

In connection to the constantly increasing amount of whey and its valuable properties, this raw material is widely used and has numerous applications in the food production [60]. New methods of whey utilization contribute to the further development of applied technology [2]. Analyzing the latest trends in whey processing, it seems that one of a pivotal and perspective directions of whey management is beverages production [1]. The idea of the development of a whey-based beverage is not new as it was initiated in Switzerland in the early 1950s where Rivella, an example of carbonated soft drink, has been manufactured.

Functional food and drinks are one of the most dynamic and innovative categories in the food industry and continue to generate strong interest among many consumers. Beverages are being considered as functional foods because they provide health benefits beyond basic nutrition [61]. Among the most important advantages of the beverages are:

• Packaging convenience related to the successful design (i.e., size, shape, and appearance) and portability

• Shelf-stable products that offer ease of distribution and storage

• Delivery of high concentrations of functional ingredients and bioactive compounds [62,63].

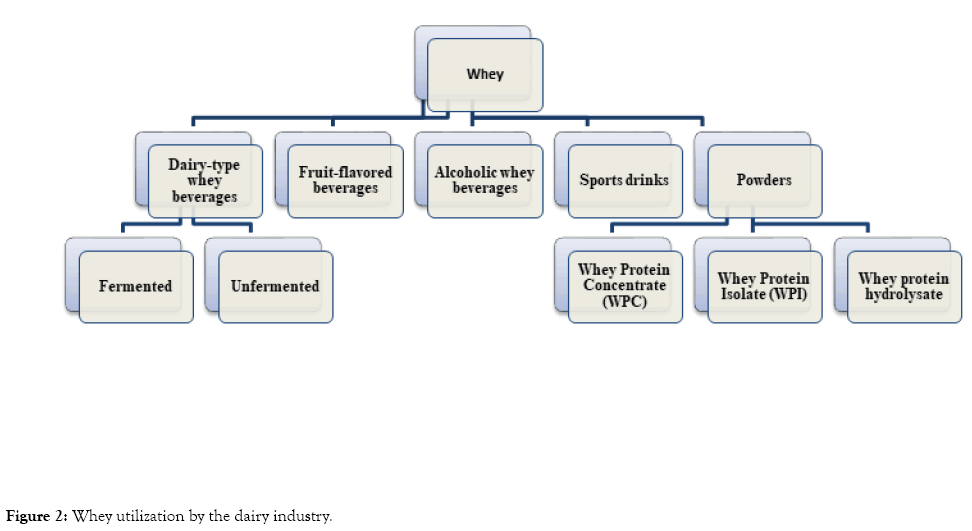

The beverages currently developed can be divided into the main groups: unfermented and fermented beverages, probiotic beverages, refreshing soft drinks, alcoholic beverages, diet beverages, high protein sport drinks, beverages for direct consumption and powder beverages [53,64] (Figure 2).

Figure 2: Whey utilization by the dairy industry.

Dairy-type whey beverages

Dairy beverages are produced from milk or its derivatives, with or without the addition of other ingredients, in which the dairy base represents at least 51% (v/v of the formulation, and can be submitted to a fermentation process using yogurt cultures [65].

There are two basic types of dairy beverages:

i. Unfermented milk and milk derivatives, milk shakes, flavoured milk and similar products (based on skim, partially skimmed, full-fat or even fat-enriched products). These products can be a mixture of liquid or dried whey with such components as whole or skimmed milk, buttermilk, vegetable oils, hydrocolloids or emulsifiers.

ii. Fermented products such as sour milk, buttermilk, kefir and other similar cultured dairy beverages.

The main difference of the types is the pH value; pH is to the neutral range (pH 6.2-6.5) in the unfermented dairy products, while most fermented dairy products and acid whey, have a pH of 4.8-4.5 [66].

The first generation of functional foods were fermented dairy products and processed liquid milk supplemented with functional ingredients [67,68]. Nowadays, functional dairy products have a prominent place in the food industry, accounting for over 40% of this market [69].

Fermented dairy-type beverages are considered as healthpromoting products due to their high nutritional and low energy value. There is a growing trend for this group of products especially in Europe, North America and Asia-Pacific countries and consumers are willing to reach for new fermented dairy products, as they are becoming increasingly aware of the need to embrace healthier lifestyles [70-72]. Other types of fermented whey beverages undergo alcoholic fermentation involving yeast mainly of the genus Kluyveromyces or Saccharomyces or mixed fermentation with both lactic acid bacteria and yeast [53,64].

The dairy industry has realized that the huge market potential created by the numerous positive health benefits of probiotic bacteria [73]. Probiotic foods, including dairy products, have been classically defined as ‘ ‘ foods containing live microorganisms believed to actively enhance health by improving the balance of micro-flora in the gut ’ ’ [74]. In order to produce therapeutic benefits, a suggested range for the minimum level for probiotic bacteria in probiotic milk is from 106 to 107 cfu/ml [75]. Several health benefits have been claimed for probiotic bacteria including lowering cholesterol level in blood, improving lactose metabolism, lowering blood pressure, anticancer properties and immune system stimulation [76].

The most commonly incorporated probiotic bacteria include Lactobacillus acidophilus, Lactobacillus rhamnosus and Lactobacillus casei among Lactobacillus and Bifidobacterium bifidum among bifidobacteria. There are even some indications that fermentation of whey using yoghurt culture (Lactobacillus delbrueckii sp. bulgaricus and Streptococcus thermophilus) produces a more intense yoghurt flavor compared to the one obtained when skim milk is fermented [78,79]. The specific organism used as a probiotic and its health promoting effects makes the major difference among products, apart from the amount and type of supplementation [77]. A well-known whey beverage obtained by fermentation with Lactobacillus rhamnosus is ‘Gefilus’ produced in Finland using demineralized whey or whey protein concentrates with prior lactose hydrolysis flavored by addition of fruit juices or fruit aromas and fructose as sweetening agent. Bifidobacterium bifidum and Lactobacillus reuteri have been considered important bacteria for human health; the main probiotic effects attributed to these bacteria include the improvement in lactose utilisation, prevention of diarrhea, hypercholesterolemia, improvement of vitamin synthesis and calcium absorption [80]. Additionally, the development of longer villi and significantly deeper crypts in the ileal region of the gut and production of substances of low molecular mass with antimicrobial activity [81]. Mendoza managed to produce an acceptable probiotic whey beverage with Lactobacillus reuteri and Bifidobacterium bifidum and with addition of sugar and pectins [82]. Finally, in order to enhance the health benefits of whey-based beverages, calcium phosphate, and calcium lactate were added together with vitamin D3 and prebiotic dietary fiber [72].

Fruit-flavoured beverages

As lactose intolerance and cholesterol content may concern a number of consumers [83], new products containing probiotic strains have been launched, particularly beverages based on fruit, vegetables, cereals, and soybeans [84]. In particular, fruit juices have been suggested as a substrate for the development of non-dairy probiotic beverages. The high content of nutrients and sugars are necessary for the growth and survival of probiotic microorganisms [85,86].

Fruit juices have taste profiles that are pleasant and are easily acceptable from all age groups [87]. Some fruit used in commercial preparations include cranberry, blueberry, pomegranate apple, blackcurrant, acai, acerola, guarana, mango, bilberries, grapes, cherries, kiwifruits, strawberries, feijoa, peach, and plums [88]. Other beverages with fresh fruit blends (oranges, pears, peaches and apples) with addition of citric acid and sucrose were developed [89]. Other researchers developed a functional fermented product; whey based with black mulberry. The results showed that the acidity, antioxidant activity, total phenolic, and anthocyanins contents were increased by increasing the percentage of black mulberry juice. Moreover, the viability of L. rhamnosus GG and Bifidobacterium animalis ssp. lactis Bb-12 remained high up to 14 days then started to decline [90]. According to another study, whey was successfully utilized to develop an orange-based fruit beverage with sugar in appropriate proportion. This beverage presented optimum sensory and nutritional properties and good storage stability [91].

It was reported that beverages made from either sweet or acid whey had good quality properties, although the sweet whey beverage received higher sensory scores [92]. Also, it has been reported that the acid whey from the manufacture of quark or cottage cheese is suitable for fruit-juice type whey-based beverages, as it is more compatible with the acidic flavor of fruit [93]. A plant-based substrate for probiotic non-dairy beverages was prepared using drumstick leaves (Moringa oeifera) and beetroot juice fermented by Lactobacillus plantarum and Enterococcus hirae. The new beverage combined the antibacterial activity of Moringa leaves with the antioxidant activity of beetroot juice [94].

Sports drinks

Sports drinks, generally do not contain caffeine and they can be consumed before or during physical activity, provide an excellent alternative to plain water for athletes as they prevent dehydration [95,96]. The majority of sports drinks are formulated to deliver carbohydrates and electrolytes (such as sodium, potassium, calcium, magnesium) for fluid absorption and energy. Furthermore, some sports drinks may include protein and vitamins and other nutrients [96]. The generally recommended protein intake for the athletes is about 1 g (general training) and 2 g (intense training loads, adolescents in a growth spurt, muscle building) of protein/kg bodyweight per day [97]. Many sports drinks contain a combination of glucose, fructose, sucrose, and maltodextrin/glucose polymers [64]. Many athletes consume whey protein for its rich branched chain amino acid (BCAA) content; important constituents for protein synthesis and muscle growth during the recovery period after endurance exercise [97].

Alcoholic whey beverages

Whey could be utilized for the production of alcoholic beverages due to the fact that the main constituent of the solid content is lactose (~70%). Alcoholic whey beverages can be categorized to beverages with low alcohol content (≤ 1.5%), whey beer and whey wine [53]. Whey used for beer production may be combined with the wort in varying proportions or may be fermented alone [53,64]. An example of beer whey is English brand "The Blue Brew", in which some of the wort is replaced by whey derived from the production of Stilton cheese [1]. For wine-type beverages demineralised and deproteinised whey is used [20]. In particular, the production of whey wine can be reported after deproteinization of the whey by heating at 82°C for 5 minutes, adding approximately 22% dextrose depending upon the amount of alcohol desired in wine and then fermentation for seven days at room temperature (22-25°C) using yeast Saccharomyces cerevisiae var. ellipsoideus [98]. More recently, an alcoholic beverage (35.4% v/v ethanol) was produced by distillation of the fermented broth obtained by continuous whey fermentation with a lactose-fermenting yeast Kluyveromyces marxianus. According to the researchers whey can be used for production of a novel spirit with acceptable sensory characteristics [99].

An interesting example from the first alcoholic whey beverages is a clear light golden wine of 11% alcohol from deproteinized whey concentrates, without sugar [100].

Whey powders

Dried whey ingredients are usually produced in large dairy industries as in small and medium scale cheese plants, the volume of whey to be processed does not justify the costs associated with the installation of such equipment. As a result, whey disposal represents a major problem and, in some cases, a high operational cost [101-105]. In general, the main industrial processing of whey is drying, which is 70% of the annual production of whey [25].

Apart from the beverages in which whey is the main or major raw material there is also a large number of beverages containing ingredients derived from whey; i.e., whey protein concentrate (WPC), whey protein isolate (WPI) and whey protein hydrolysate (WPH). These ingredients are added in high protein drinks, mainly sport drinks and drinks for malnourished [101]. Whey-based beverages may be produced directly from sweet cheese whey but also from milk enriched with WPC or WPI [6]. Deproteinised whey or whey powder is usually used in the manufacture of whey-based beverages so that the risk of sedimentation during storage will be minimized [102,103]. WPI is produced commercially by ultrafiltration or ion exchange chromatography and contains at least 90% protein, is low in fat and sugar, and has high solubility. WPC has fat and lactose along with the quintessential proteins (29-89%). WPI is produced commercially by ultrafiltration or ion exchange chromatography and contains at least 90% protein, is low in fat and sugar and has high solubility. The hydrolyzed whey protein is the semi-digested form of the protein and is often used in infant formulas and sports and medical nutrition products [104]. Because of their nutritional importance, whey powder, whey proteins and whey protein fractions represent a global market value of approximately 6.3 billion euros (Global opportunities for whey and lactose ingredients 2010-2014). Small tonnage of WPC and to a lesser extent WPI are produced every year, and the remaining permeate can be used to produce lactic acid, bioethanol or lactose [105-120].

The continuous growth of the dairy industry generates large amounts of whey as a by- or co-product, forcing the industry to find ways of treating/valorizing it. The fact that the health benefits of sweet whey for human health are becoming nowadays widely known is important as in this scenario, whey as a dairy industry by-product holds immense significance. The review highlights the importance of developing dairy-type whey beverages with outstanding nutritional qualities that will be accepted by consumers. Additional research into creatively utilizing whey will be essential in order to establish and expand the future of functional dairy beverages in the global dairy industry.

Citation: Papademas P, Kotsaki P (2019) Technological Utilization of Whey towards Sustainable Exploitation. J Adv Dairy Res 7: 231. doi: 10.35248/2329-888X.7.4.231

Received: 04-Nov-2019 Accepted: 27-Dec-2019 Published: 06-Jan-2020

Copyright: © 2019 Papademas P, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.