Journal of Pollution Effects & Control

Open Access

ISSN: 2375-4397

ISSN: 2375-4397

Research Article - (2016) Volume 4, Issue 1

In many welding processes, air pollutants are generated and take the form of dust, fume and gases. These particles generally remain suspended in air and in that way can be carried long distances from the welding arc. Plethora of studies have suggested that welding is insidious to the male reproductive system, other pernicious effect includes the development of benign pneumoconiosis, siderosis, respiratory impairment, headache, nausea, shortness of breath, muscle pain and a metallic taste in the mouth. The objectives of this study was to determine the personal exposure to total, inhalable and respirable particulate matter among welder in Benin City, subject the data to statistical analysis and compare the values obtained to the regulatory limits. The particles were captured using SKC Air Check Gravimetric Sampler. The sampling was done three times a week for six months between October 2011 to March 2012. The result showed that there was spatial variation in the measured TSP, respirable and Inhalable PM and also that the measured particulate matters were above the threshold Limit Value (TLV) in most of the locations studied except for welders in Oluku and Agbor which their TSP, Respirable and Inhalable are below this limit.

Keywords: Welding fume; Total suspended particle; Inhalable particle; Respirable particle

In Benin City and Nigeria at large welding workshops are found in every nook and cranny and these workshops are sandwiched in between residential houses. Recently, in Nigeria there has been an upsurge in welding related diseases and illnesses [1,2]. The concentration of welding fume that can engender diseases and illnesses has not been fully established. Welding fumes can cause non-specific changes in the lungs, in addition exposure to welding fumes can occur through inhalation and eye contact [3]. Exposure to welding fumes can result in metal fume fever, headache, and nausea shortness of breath, muscle pain and a metallic taste in the mouth. The respiratory effects appear to be potentiated by smoking. There is excess infertility among welders that led to the studies of sperm quality and welding exposure [3]. Different types of air pollution are caused by welding. Generally speaking, the welding method and consumable determines which impurities are generated (particles and gases) and in which amounts. The base metal can also contribute if it has been treated with a volatile substance, for example. Welding fumes are a result of the vaporization and oxidation of different substances in the arc which is caused by the high temperature. Sometimes a single exposure to a substance can be enough to trigger the outbreak of an illness. In other cases, it could take many years between exposure and outbreak. It is also known that various substances, when combined, can produce a synergistic effect [4]. In other words the health hazard of the combination is many times greater than the sum of the hazards of the substances individually.

Illnesses or conditions which could possibly arise as a result of the inhalation of excessive levels of fume and gases, include breathing difficulty, anemia, cancer, emphysema, headache, chronic bronchitis, pulmonary edema, metal fume fever and irritation of the mucous membranes and narrows branches of the respiratory organs. These particles consist of oxides of iron, manganese, chrome and nickel, for example. There are also different types of fluoride compounds. The adverse occupational health effects of welding fumes have been recognized by different authors [5-9]. The studies have revealed that the influences of welding fumes and gases generated during the welding process may be in the form of bronchitis, sensitivity, respiratory function changes, pulmonary infections and so on [10,11].

Historical cohort mortality studies on lung cancer risk of mild steel welders conducted from 1950s and extended through 1988 revealed that welders exposed to 6-7 mg/m3 of total particulate and 3-4 mg/ m3 of iron oxide for an average duration of 8.5 years did not have a significantly higher relevant standard mortality ratios compared with non-welders. The only other cause of death significantly elevated was emphysema among welders [12]. Historical follow up studies conducted among the arc welders exposed to fumes containing chromium and nickel identified increased risk of lung cancer resulting from exposure to welding fumes [7].

Epidemiological studies indicated that the welders might have a younger age of onset of Parkinson’s disease compared to sequentially ascertained Parkinson’s patients [5,13]. Some studies suggested a standard risk assessment method for welding fumes related diseases [14]. Welding is a common industrial process. Hazard that has both acute and long-term chronic effects is welding fume/particulate matters and toxic gases. Fumes are solid particles that originate from welding consumables, the base metal and any coatings present on the base metal. In welding, the intense heat of the arc or flame vaporizes the base metal and/or electrode coating. This vaporized metal condenses into tiny particles called fumes that can be inhaled. The thermal effects can cause agglomeration of the particles into particle chains and clusters that can be deposited in the human respiratory tract [15-17]. Toxic gases also produce from welding processes which include nitric oxide, nitrogen dioxide, carbon monoxide and ozone. These toxic gases can cause pulmonary edema, headache and drowsiness [18]. The hazards of welding depends on several factors: Type of welding being performed, material the electrode is being made, type of material being welded, presence of coatings on the metal, voltage and current used and type of ventilation [18,19].

Area of study

The observed welding activities utilize manual metal arc welding, in which the parent metal and the electrodes are heated using electrical arc into liquid phase, allowing the molten electrode to bridge the gap between parent metal pieces. The activities are conducted in small and large open workshops in street sidelines, with one to five welders per workshop while in large workshop you may have eight to fifteen which operate from 8.00 a.m. to 4.00 p.m., Monday to Sunday, although the welding intensity greatly depends on customers’ order. The materials being welded are mild steel, which consists mostly of iron, as parent metal, and electrodes containing carbon, silica, selenium, phosphorus, and manganese. The study was initiated by observing small scale and large welding workshops throughout the Benin City areas. Large numbers of welding workshops emitting insidious metals and other compounds that could exacerbate the pollution in Benin City. The correct data showing the correct figure of welding workshops is still oblivious, but in general, welding workshops in Benin City are quite numerous and geographically distributed, making them difficult to monitor. In all welding processes, air pollutants are created in the form of fume and gases. The fume consists mainly of metal oxides and is formed when metal vapour condenses and oxidizes. Gases are created due to the high temperature and ultraviolet radiation from the arc. They plethora examples of insidious gases formed in welding include ozone, nitrogen dioxide, nitric oxide and carbon monoxide. The level of emission of air pollutants and their composition depends on a number of different factors such as; welding method used, welding parameters, filler metal and surface coatings or contaminants on the base metal surface.

Fume particles consist mainly of oxides. Oxides are formed when the melted metal is vaporized in the arc and then condenses and oxidizes in contact with the surrounding air. In gas metal arc welding, it is the filler metal which is the main source of fume while the base metal contributes very little. In flux-cored arc welding, the flux in the wire also contributes to the formation of fume. Plate 1 shows a welder in his welding workshop in Benin City with the meter by his waist.

Sampling procedure for TSP

Airborne particulate matter was collected on a Whatman glass fiber filter using a portable SKC Air Check XR 5000 high volume Gravimetric Sampler. The sampling unit consists of a gas pump, a filterholder- manifold connected to the sampling pump by a Teflon tube, with a gas flow rate meter of 1000 to 5000 ml/min, used to measure the flow rate during sampling.

Before sampling, all unloaded glass fiber filters were dried in a desiccator at room temperature.

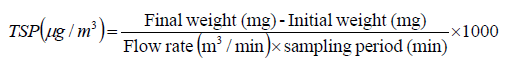

The particulates were collected on the pre-weighed filter by pumping 2000 ml/min (2l/min) volume of air through it for eight (8) hrs. After sampling, the loaded filters were again desiccated and reweighed to determine the final weight. The concentration of the Total Suspended Particulate (TSP) in the air was determined from the difference in weight of the filter paper after and before sampling, the duration of sampling and the flow rate [20,21].

Sampling procedure for respirable and inhalable fraction

SKC Air check XR5000 High volume Gravimetric sampler Model 210-5000 serial No. 20537 and the I.O.M multi fraction dust sampler (Institute of occupational medicine).

A sampling device was used which includes sampling train with an air mover, a flow measuring device and a sample collection. A flow of air was created by the air mover which allowed the capture of contaminants in the air into the sample collection. The collection mechanism was made of cassette cover front plate, two-o-rings, cassette rear front and the sampler body which was connected to a vacuum pump with a Teflon tube. The inbuilt flow meter had a rating of 1000 ml/min to 5000 ml/min of air samples which was calibrated into 2000 ml/min (2l/min). Before sampling, the unit was carefully calibrated against a standard meter to determine the quantity of air flows and all unloaded glass fiber filter and the foam were dried in the desiccators at room temperature. The respirable foam was affixed to 25 mm diameter filter for inhalable dust sampling with a flexible sample head to determine the respirable particle. The filter and cassette rear was pre-weighed to determine the initial respirable dust, while the filter, foam and whole cassette together was pre-weighed to determine the initial inhalable. After sampling, the filter, foam, with the whole cassette together was re-weighed to determine the inhalable fractions. The respirable fraction was determined by weighing the cassette rear and the filter only. These particles were collected at a flow rate of 21/min for eight hrs and the sampler was placed between heights of 1.5-2 m to reflect the breathing zone of man.

The difference between the final weight and the initial weight was the amount of respirable and inhalable dust collected [20,21].

The Concentration in μg/m3 was calculated by

Method of data analysis

The study employed both descriptive statistics (mean and standard deviation) as well as inferential statistics (Analysis of Variance- ANOVA, Multivariate linear regression analysis) to check for significant differences and significant relationships. The level of significance was set at 0.05. The analysis was carried out using STATA Student Edition version 12 computer software.

Air pollutants have different effects on man. In order to evaluate the hazards, many substances have hygienic threshold values. These values can be used in assessing the quality of the breathing air. People are exposed to the effects of many different chemical substances. In order to reduce the hazards, enormous efforts have been devoted to assessing the toxicity of these substances and defining hygienic threshold limit values. Welding fume particle size can be divided into groups; Fine or respirable particle which has diameters less than 2,5 micronmeters,Coarse or Inhalable particle which has a diameter greater than 2.5 micronmeter but less than ten micronmeters while the ultrafine particle has a diameter less than 0.1 micrometer and the total suspended particle which has a particle of 100 micrometers [22].

Table 1 presents the statistical mean concentrations of total suspended particulate matter, respirable particle and inhalable particles at the various sites of Benin City. For TSP, the highest value was measured in Sokponba (7430.56 μg/m3), followed by Second East Circular (6666.89 μg/m3) while Oluku was the lowest (3958.33 μg/ m3). The result of Total Suspended particulate matter above showed that there was significant difference (p<0.05) in the studied locations (Figure 1). The major significant differences were witnessed between Second East Circular and Agbor, Oluku and New Benin; also between Sokponba and Agbor, Oluku and New Benin. But no statistical significance was observed between Second East circular and Sokponba. The high concentration recorded in Sokponba and East Circular could as a result of the volume of work done. The concentration obtained in this study can be compared to other studies [23].

| Locations | Agbor | Oluku | New Benin | Second East Circular | Sokponba |

| TSP | 4062.67 ± 2244.50a | 3958.333 ± 492.27a | 5930.553 ± 853.35a | 6888.89 ± 331.23b | 7430.56 ± 1690.73b |

| Inhalable | 4687.50 ± 1310.74a | 2743.05 ± 489.82b | 5384.723 ± 602.41a | 5298.61 ± 409.37a | 6819.44 ± 1103.79a |

| Respirable | 1284.72 ± 227.69a | 1284.72 ± 250.38a | 1597.22 ± 125.19ab | 1354.17 ± 262.15ab | 3020.84 ± 579.98b |

Table 1: The Mean and Standard Deviation of Total Suspended Particulate Matter, Respirable Particle and Inhalable Particle (μg/m3).

For Inhalable Particulate matter, the highest measured value was also measured in Sokponba (6818.44 μg/m3) and the lowest measure value is in Oluku (2743.05 μg/m3). The result from the Analysis of Variance (ANOVA) showed that there was significant difference (p<0.05) in the mean measured inhalable particulate matter in the five (5) different locations (Figure 2). The Scheffe’s post hoc test showed that the differences was mainly Oluku having a significant decreased Inhalable PM when compared to the other four locations. The values obtained here can be compared to other studies [1].

For the respirable particulate matter, the highest measured particulate matter was recorded in Sokponba (3020.84 μg/m3) and the least value was measured in Agbor and Oluku (1284.72 μg/m3). The ANOVA showed that there was significant difference (p<0.05) in the studied locations. On further analysis using Scheffe’s post hoc, the result showed that the significance was between Agbor and Sokponba; Oluku and Sokponba (Figure 2) shows the mean concentration of total suspended particle, inhalable particle and respirable. From the results in Table 1, it was observed that there was a steady decline from Total suspended particulate matter (TSP) to respirable suspended particulate matter, this distinctive in concentration, is due to the particle size of the particulate matter. The smaller the particle in the atmosphere the lesser the effect of meteorological impact on the particle. However, The smaller the particle size in the atmosphere the higher the residence time [23,24]. Though the concentration of respirable particle in the atmosphere is lower than inhalable and total suspended particle but more destructive [23].

A hygienic threshold limit value is the highest permissible concentration of a substance in the breathing air. Levels which fall below the threshold limit values represent little hazard to people. However, threshold limit values do not represent strict boundaries between hazardous and un-hazardous levels of a substance. There are two types of hygienic threshold limit value: time weighted averages and ceiling threshold limit values. These are specified as concentrations by weight, such as mg/m3, or concentrations by volume, for example ml/m3 or ppm (parts per million). The time weighted average, TWA, specifies the maximum permissible average level of an air pollutant in the breathing zone during a working day. This value may be exceeded during brief periods. From Table 1 the results revealed that concentration level of the respirable dust was less than (Threshold Limit Value) TLV of 5000 μg/m3 recommended by [25]; except Sokponba which has TSP and Inhalable particulate matter higher than this threshold limit.

In Figures 3-5 showed that a strong positive relationship was established among the pollutants (TSP, Inhalable and Respirable). This implies that in this study as the Inhalable and respirable particulate matters increase the TSP also increase. This assertion is only credible independently of other particulate matter, i.e. in the absence of other particulate matter inhalable showed significance relationship, also respirable showed significant relationship with TSP. We therefore want to in the next section consider an interactive association of the two independent variables (Inhalable particulate matter and Respirable particulate matter) on the Total Suspended Particulate Matter (TSP). This relationship is in agreement with other studies [1,23].

Multivariate relationship between inhalable particulate matter, respirable particulate matter and TSP

After performing a univariate relationship between inhalable and TSP, Respirable and TSP which showed a significant positive relationship, we further the analysis by imputing both variables once into a regression model to look at the mixed effect on TSP (Figures 3-5 and Table 2).

| Coefficient | Std. Error | t | Sig. | |

| Constant | 775.669 | 1138.077 | 0.682 | 0.508 |

| Inhalable | 0.622 | 0.362 | 1.72 | 0.111 |

| Respirable | 0.834 | 0.836 | 0.997 | 0.339 |

Table 2: Multivariate relationship between Inhalable particulate matter, respirable particulate matter and TSP.

The multiple R is 0.75 shows that the degree of association between the (dependent variable) and (independent variables) is about 75% (strong association), again the R2 is 0.56, this shows that 56% of the changes in TSP are explained jointly by variation of the explanatory variables (Inhalable and respirable) in the model, the remaining 44% accounted for shows other external factors which are not capture in the model. This shows that there is a 56% predictability power of TSP by inhalable and respirable particulate matters.

Furthermore, the F–statistics is 7.58 and is significant at 5% level, indicating that the model is adequate, from the regression results obtained; we can see that there is a positive relationship between Inhalable PM and Respirable PM. This is because the coefficients of the explanatory variable are seen to be positive which are 0.62 and 0.83 respectively. But none of the particulate matter showed a relationship that was significance at 5% level of significance. This implies that on controlling for respirable PM, inhalable PM was not significant and vice versa.

This study has captured the total suspended particulate matter (TSP), Respirable particles and Inhalable particles. The particulate matter captured exceeded the regulatory some of the locations while others fell within the purview of the permissible limit. The high particulate loading can be adduced to high volume of work. However, it was observed that the smaller the particle sizes the smaller concentration of the particulate matter in the atmosphere. Respirable particle which has a diameter less than 2.5 micron has the smaller concentration of particulate matter while the total suspended particulate matter which has a diameter of about 100 micron has the highest concentration. The welders in Sokponba and other residents of the area can easily experience pulmonary and respiratory diseases due to the high concentration of particulate matter recorded from the area. The welder workshop should be relocated to a secluded area outside the residential areas where the fumes and dust generated will be effectively captured, diverted and treated to ensure healthy environments.

We sincerely appreciated the assistance of Mr. E. Omofowan and Dr. Magnus Legemah during this work.