Advances in dairy Research

Open Access

ISSN: 2329-888X

ISSN: 2329-888X

Research Article - (2022)Volume 10, Issue 2

The aim was to evaluate the effect of hydroxypropylation on rice starch performance as partial casein replacer in the novel sweet Mozzarella cheese analogue with the light on the rheological and functional properties of the final product with the presence of sucrose and mango pulp. Native rice starch was modified with Propylene oxide at the levels of 5% and 10%. Sweet mango Mozzarella analogue was made from rennet casein and palm oil, casein was replaced at rates of 0%, 10% and 20% with either native, 5% or 10% hydroxypropylated rice starch. The results indicated that replacing casein with rice starch reduced the values of protein, ash, pH, cohesiveness, gumminess, springiness, adhesiveness, stretch extension, breakpoint, and flow behavior index in a concentration-depending way, as well as increased shredding efficiency, stretch maximum load, tenacity, critical strain, and consistency coefficient (K). The degree of starch hydroxypropylation had no effect on the dry matter, protein, fat, ash, and hardness. The shredding efficiency and storage modulus K were increased with increasing the hydroxypropylation degree. The 10% hydroxypropylated starch cheeses were distinguished with the highest values of melt distance, free oil, stretch extension and K. Hydroxypropylated rice starch may be a promising material for enhancing the functionality of Mozzarella cheese sweet analogue and altering the cold storage related rheological defects through the partial replacement of casein.

Propylene oxide; Shredding efficiency; Stretch profile; Critical strain

Cheese is one of the most diverse groups of the food products and perhaps the most interesting and challenging one. More than 900 varieties of cheeses are being produced in the world, and newer versions are predicted to arise [1]. The consumption and demand of Mozzarella cheese and cheese in the form of Pizza toppings, cheese blends, salads, sandwiches, and stuffing, have increased in the recent years due to dietary likeness, ease, and flexibility in use. Because of the expensive cost of the conventional Mozzarella cheese, the analogue cheese may form a promising chance to substitute a conventional product and offer the same or better nutritional and functional characteristics with lower cost by using different blends of dried dairy ingredients, vegetable fats [2]. Cheese analogues are easy to prepare and require less time for Manufacture (i.e. about 1 h for analogue versus 5-7 h for conventional Mozzarella cheese) and can be ‘tailor-made’ as per the specifications of the pizza retailer [3]. Caseinate specially rennet casein is commonly used as the main protein source in the Mozzarella cheese analogues and plays a key role in structure, functionality, and rheology of those cheese analogues. In the recent era the global prices of the dairy ingredients were increased many folds and consequently the attention of research concerned with the cost reduction and inventing new competitive products that can take a part of the saturated market share (Grand View Research, 2021). Trivedi, et al. studied the suitability of substituting caseinate with vegetable proteins (Peanuts, cottonseed, soy proteins and chickpea) in the analogue cheese and reported that those proteins were not very suitable [4]. Many researchers used starches in partial replacement of expensive caseinate and found that starch plays an important role in the rheological and functional characteristics of the analogue Mozzarella cheese such as flow, stability, melatability and mouthfeel. Mounsey, et al. compared native starches from different sources as casein substitute on imitation cheese rheology [5]. They found that the starches with higher amylose contents (maize, potato, and wheat) increased imitation cheese hardness but reduced meltability. Butt, et al. used the pre-gelatinized starches to partially replace protein and fat in the production of imitation cheese and found that cheeses were softer, more cohesive, and had improved melting properties [6]. The internal structure was reinforced and meltability was improved due to these replacements. Most of the confectionery products are poor in protein, while most consumers prefer the sweet taste as humans prefer it since birth and that taste was related to happiness. The salty taste of Mozzarella cheese restricts its addition to the sweetened bakery products and there is no sweet pizza because Mozzarella cheese is a key ingredient in pizza with its meltability, stretchability and springiness. The conventional manufacture of Mozzarella cheese does not allow the addition of sucrose as it would inhibit the growth and activity of starter lactic acid bacteria also the sodium chloride has its important role in controlling the growth and activity of lactic acid bacteria and inhibiting the spoilage bacteria, besides achieving more shortness, crumbliness and drying in the outer layers of cheese leading to make it more shreddable. All the foregoing improving attempts did not investigate the interactions of sugars and fruit extracts in the Mozzarella cheese analogue matrix. For that in view, the present study was conducted to study the effect of hydroxypropylation on rice starch performance as partial casein replacer in the novel sweet fruity Mozzarella cheese analogue with the light on the rheological and functional properties of the final cheese analogue product.

Dried 90 mesh rennet casein was obtained from Fonterra brands, Ltd-Newzeland. (83.14% protein, 0.6% fat, 7.971% ash and 8.212% moisture). Food grade palm oil was obtained from United Oils and Foods Co., 10th of Ramadan, Egypt. Native rice starch was obtained from Tiba company for starch and glucose manufacturing, Al- Salheya Al-Gadeda city, 1st industrial zone, Egypt. Tri-sodium citrate dihydrate was obtained from Qualigens Fine Chemicals, Mumbai, India. Potassium sorbate was obtained from SJZ Chem-Pharm Co., Ltd. China. Anhydrous citric acid (99% purity) was obtained from Guangzhou Rikewei Chemical Co., Ltd., China. Food grade L-lactic acid (80%) was obtained from BBCA Glactic (B and G) Co.,Ltd, Road, Bengbu, Anhui, China. β-carotene powders were obtained from Shaanxi Zhengsheng Kangyuan Biomedical Co., Ltd, Shaanxi, China. Mango fresh juice: ZEBDA (Mangifera indica L.) cultivar was obtained as a gift from Mass Land Company for food industries, El-Obour, Egypt.

Experimental procedure

Preparation of modified rice starch: Hydroxypropylated rice starch was prepared according to the method of Lawal (2011) with some modifications as follows: 500 g of native starch was dissolved in 1000 mL distilled water; a 100 g of sodium sulphate was then added with stirring [7]. The pH was adjusted to 10.5-11.0 using 1 M sodium hydroxide. Propylene oxide at the levels of 5% and 10% (based on dry starch weight) was then added to the slurry with stirring. The mixture was kept at 34 ± 2°C for 24 h, after incubation it was neutralized by 1 M H2SO4, and then centrifuged at 2500 × g for 5 min. The obtained starch was washed until sulphate content was negative with BaCl2 and then oven dried.

Manufacturing of Mozzarella cheese analogues: The recipes illustrated in Table 1, were applied. At first, the palm oil was heated to 85°C, and a mixture of rennet casein and native or Hydroxypropylated rice starches was added. Whereas casein was replaced at rates of 0%, 10% and 20% with either native, 5% or 10% Hydroxypropylated rice starch. The foregoing mixture was heat treated at the same temperature for 2 min. or until reaching a pourable, homogeneous, thick paste having the appearance and consistency of oatmeal. Water, mango juice, potassium sorbate, sucrose and tri-sodium citrate were mixed, and heat treated at 85°C for 2 min, then these two mixtures were mixed by blending in the cheese cooker (Stephan universal machine UMSK 24 E). The mixing speed was adjusted to 120 rpm for about 2 min. at the same temperature, where a viscous lumps free paste was obtained. At the end of processing, the acids and flavor were added and mixed well. The paste was then casted in stainless steel trays to form cubic cheese blocks and a medium fast cooling was applied. Control was made without starches. Three replicates were done for each treatment in Table 1.

| Ingredient | Degree of casein replacement | ||||||

|---|---|---|---|---|---|---|---|

| 0% (control) | 10% | 20% | |||||

| Palm oil | 22 | 22 | 22 | 22 | 22 | 22 | 22 |

| Rennet casein | 23 | 20.7 | 20.7 | 20.7 | 18.4 | 18.4 | 18.4 |

| 0%Hydroxy propylated rice starch (Native starch) | 0 | 2.3 | 0 | 0 | 4.6 | 0 | 0 |

| 5%Hydroxy propylated rice starch | 0 | 0 | 2.3 | 0 | 0 | 4.6 | 0 |

| 10%Hydroxy propylated rice starch | 0 | 0 | 0 | 2.3 | 0 | 0 | 4.6 |

| Tri-sodium citrate | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 | 1.7 |

| Sucrose | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Mango pulp | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| Citric acid | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Lactic acid | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Potassium sorbate | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Flavour | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| β-carotene | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| Water | 43.6 | 43.6 | 43.6 | 43.6 | 43.6 | 43.6 | 43.6 |

| sum | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

Table 1: Recipes of novel mango Mozzarella cheese analogues made with different rates of casein replacement with native and hydroxypropylated rice starches.

Analytical methods

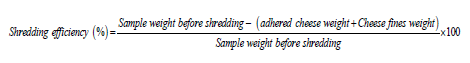

Dry matter, fat, total nitrogen, and ash contents were determined according to AOAC (2007). The pH values were measured using a microprocessor pH meter (model 8417, Hanna Instruments, Singapore) at 20°C after calibrating with fresh pH 4.0 and 7.0 standard buffers. For determination of shreddability of Mozzarella cheeses analogue, the experimental samples were cut into blocks of about 4 cm width, 4 cm height and 8 cm length taking in consider that the cheeses were cut so that the fibers were parallel to the shredding blade along the length of the rectangle of cheese. This was done to eliminate any effects that fiber orientation may have on shreddability because of the anisotropic nature of Mozzarella cheese [8]. Before shredding, the blocks of cheese were weighed (about 500 g) and placed overnight in a refrigerator (5°C). The shredder was adjusted to produce long strips (5 mm wide × 20- 30 mm long × 0.3 mm-0.5 mm thick) and operated for 1 min., the shredded strips were allowed to go out of the shredder and weighed to calculate the percent of the cheese that adhered to the blades. The shredded cheese was shaken for 10 seconds through a sieve with opening of 6.35 mm2; the shreds that fell through the sieve were classified as fines and weighed to calculate the percent of shred fines. The shredding efficiency was calculated as follows:

The adhesive force was measured using CT3 Brookfeild-Texture analyzer. Free oil was determined according to Kindstedt, et al. [9]. The meltability of Mozzarella cheese analogue was determined using the method of Poduval, et al. with a slight modification as follows; 10.0 g of finely grated Mozzarella cheese was transferred into a glass tube measures 24 mm internal diameter × 250 mm length × 3 mm thickness [10]. The cheese was firmly packed using a plunger and the glass tube was closed using a rubber stopper having a hole in the middle so that during heating the hot air inside the tube can escape. The closed tubes containing the cheese plug, were placed vertically overnight in a refrigerator (5°C). The length of the cheese plug was measured in each of the tubes. The glass tubes containing the cheese plugs were placed horizontally in a preheated hot air oven and the cheese plugs were allowed to melt at 110 ± 1°C for 90 min. The glass tubes were air cooled for 10 min. and the length of the melted cheese plugs was measured again. The difference in initial and final lengths of the cheese plugs was represented as the melt distance. The textural profile analysis test (TPA) for some textural properties (hardness, springiness, cohesiveness, gumminess and adhesiveness), were measured by CT3 Brookfeild- Texture analyzer using computer interface software (Texturepro CT V1.2 Build 9) [11]. For the evaluation of stretchability of Mozzarella cheeses, a test was developed which uses a custom-made triple-hook spindle, measured 35 mm in length and was shaped in the form of a hook, this cross bar was welded to a spindle of 150 mm length and 1.5 mm diameter. The spindle was attached to LLOYD LR10K plus extensometer (10 kN Universal Materials Testing Machine) to conduct the test. An aliquot of 50 g of cheese was weighed into a glass beaker containing a spindle placed in the middle of the beaker without touching the sides and perpendicular to the bottom of the beaker. Care was taken to raise the spindle approximately 5 mm from the bottom of the beaker before conducting the stretch test. This would avoid lifting of the cheese plus from beaker. The beaker was covered with an aluminum foil and dipped in a water bath at 60°C for 1 h. The melted samples were placed under the load-cell of the extensometer and the spindle was attached to the 100 N load cell using a U-clip, and stretched at 300 mm/min. The force exerted by the cheese on the spindle was recorded along with the instantaneous distance of load cell movement. NEXYGENPlus software was used to collect data such as extension at which the strands broke, peak load before breaking and break point during the stretch tests. The weight of a 100 mm cheese strand (cut from the middle of the stretched strand) was taken using an analytical balance and compared among the tested cheese samples. Analogue cheese rheology was studied using controlled stress HR-1 hybrid rheometer (TA® Instruments, USA). Experimental samples were shaped at the form of discs of 40 mm diameter and 5 mm depth. Geometry and trim gap were set to 2000 μm and 2100 μm respectively. Amplitude sweep was measured at a set 6.28 rad/s frequency at room temperature within 0.1% to 50% strain to form a linear viscoelastic region. Critical strain (εcr) was also determined. Power law was applied using the following equations: G'=Kωn and G"=Kωn, where, G' is storage modulus (Pa), G" is loss modulus (Pa), ω is the frequency (rad/s), K is the consistency coefficient (Pa. sn) and n is the flow behavior index. The obtained results were exposed to the ANOVA procedure followed by Duncan’s multiple range tests according to statistical analyses system user's guide (SAS, 2004). Design was completely randomized with replications [12].

Physicochemical properties of the novel sweet fruity Mozzarella cheese analogue

Data shown in Table 2 revealed that, the rate of casein replacement with rice starch had no significant effect on both the dry matter and fat contents of the cheese analogue samples. That could be due to the convergent moisture contents of rennet casein and dry starch samples. Similarly, the protein and ash levels of cheese samples were decreased with increasing the starch levels. The pH values of the experimental cheeses were lower than the control one and decreased with increasing the casein replacement rate. Possibly due to the decrements in protein with its strong buffering capacity [13]. The degree of starch hydroxypropylation had no significant effects on the levels of all chemical studied criteria. The highest significant pH values were for the cheeses made with the lowest degree of hydroxypropylated modified starch, while it was lowered in the cheese with the highest level of hydroxypropylation. That could be ascribed to the residues of the modification chemicals. Cheeses with native starch obtained the lowest pH values in Table 2.

| Source of variation | Dry matter(%) | Protein (%) | Fat (%) | Ash (%) | pH |

|---|---|---|---|---|---|

| Rate of casein replacement with rice starch (RR) | |||||

| 0% (control) | 50.37a | 18.38a | 21.97a | 3.938a | 5.96a |

| 10% | 50.16a | 16.61b | 21.68a | 3.761b | 5.65b |

| 20% | 49.95a | 14.75c | 21.65a | 3.594c | 5.56c |

| P value | 0.1227 | <.0001 | 0.2192 | <.0001 | <.0001 |

| Degree of starch hydroxypropylation (DH) | |||||

| 0% | 50.18a | 16.56a | 21.74a | 3.761a | 5.63c |

| 5% | 50.17a | 16.58a | 21.81a | 3.769a | 5.81a |

| 10% | 50.12a | 16.60a | 21.75a | 3.763a | 5.73b |

| P value | 0.9491 | 0.9791 | 0.9367 | 0.9553 | <.0001 |

| RR × DH | |||||

| 10% RR × 0% DH | 50.18 | 16.6 | 21.63 | 3.761 | 5.57 |

| 10% RR × 5% DH | 50.2 | 16.63 | 21.72 | 3.764 | 5.65 |

| 10% RR × 10% DH | 50.1 | 16.59 | 21.7 | 3.758 | 5.74 |

| 20% RR × 0% DH | 50 | 14.7 | 21.62 | 3.584 | 5.42 |

| 20% RR × 5% DH | 49.94 | 14.73 | 21.73 | 3.604 | 5.68 |

| 20% RR × 10% DH | 49.9 | 14.83 | 21.59 | 3.594 | 5.59 |

| P value | 0.9991 | 0.9976 | 0.9975 | 0.998 | <.0001 |

Note*: Values with different letters (a-c) within the same column are significantly different at P<0.05.

Table 2: Ls means values for rate of casein replacement with rice starch, degree of starch hydroxypropylation and rate of casein replacement with rice starch × degree of starch hydroxypropylation on the physicochemical properties of the novel sweet fruity Mozzarella cheese analogue.

Texture profile analysis of the novel sweet fruity Mozzarella cheese analogue

Data of Table 3 revealed that the control sample was harder than the experimental cheese samples when fresh, possibly due to that starch reduced the continuity of the protein matrix of cheese. The increase in hardness upon storage was greater in the experimental samples, where the casein replaced samples were harder than control at the end of the studied cold storage period. The storage related increase in the hardness of the casein replaced cheese analogue samples could be ascribed to the phenomenon of starch retrogradation which is defined as the recrystallization of the starch polymers amylose and amylopectin upon cooling of starch containing systems. The increase in cheese hardness upon storage was greater in the native starch containing samples compared to the hydroxypropylated starch containing ones. That could be ascribed to the role hydroxypropylation in inhibiting the reassociation of amylose chains resulted in lower short-term retrogradation of the modified starch containing cheese samples. These findings were in accordance with those of Ørskov, et al. who reported that starch retrogradation occurs during imitation cheese storage and causes increasing its hardness [14]. The results of cohesiveness elucidated that the cohesiveness values were reduced by increasing the rate of casein replacement with rice starch. The hydroxypropylated rice starch containing samples gained higher cohesiveness than the native starch containing ones. The 5% hydroxypropylated samples were the most cohesive samples of all the casein replaced samples and kept their cohesiveness unchanged through storage, possibly due to the considerable high strength of the formed starch gel in the matrix of those cheese samples. Prolonging the cold storage period had no effect on the cohesiveness of the control cheese, while the native rice starch containing cheese analogues showed a decrease in their cohesiveness, probably due to the effect of starch retrogradation on reducing the availability of amylose for intermolecular hydrogen-bonding which disrupts long-range interactions resulting in decreasing the cohesiveness [15]. The casein replacement reduced the gumminess of the experimental samples, possibly due to weaking the protein matrix by the presence of starch. The hydroxypropylated starch containing cheeses were gummier than the native starch containing ones. That could be ascribed also to the relatively strong gel formed in the former cheese samples. The gumminess values were stable through storage in the control cheese, while it was increased upon storage in the starch containing samples, especially when the native starch was added. Regarding the springiness, the reduction in protein by replacing it by starches led to decrease the springiness of the final cheese samples. The decrease in cheese springiness was increased by increasing the rate of casein replacement with starches. That could be due to the non-interrupted bonds inside the casein network of the control sample. Amongst the casein replaced samples, the 5% hydroxypropylated starch containing cheese had the highest springiness, possibly due to the low hydration power of the starch resulted from that rate of hydroxypropylation compared to either the higher rate or the native starch. The springiness of the control cheese was increased significantly at the end of the cold storage period; possibly due to the dynamic interactions within the cheese occur during storage, namely a transfer of intact caseins and calcium to the serum phase while moisture and sodium are transferred to the casein micelles. This observation was supported by the findings of El-Sayed, et al. [16]. On contrary, the springiness values of the starch containing samples were decreased upon storage and the decrease was more obvious in the native starch containing cheese compared to the cheeses with the hydroxypropylated starches. That could be due to that native starch decreased the flexibility and recovery capacity of the protein network after deforming stress was withdrawn, probably because of the interruption of casein-casein chains interactions caused by the highly hydrated starch molecules. Concerning the adhesiveness, replacing casein with rice starches led to reduce the cheese adhesiveness as replacing casein with starch at the rate of 20% led to attain the lowest adhesiveness. Moreover, the 10% hydroxypropylated rice starch cheese gained the lowest adhesiveness of all samples. That could be ascribed essentially to the good distribution of moisture caused by the hydrophilicity of the hydroxypropylated rice modified starch. The adhesiveness of all samples was slightly increased through storage, possibly due to the role of starch and emulsifying salt in inhibiting the crossbonds between the casein strands as well as plasticizing the casein networks. The round figures of these textural results were in accordance with those reported by Zheng, et al. [17].

| Source of variation | Hardness (g) | Cohesiveness | Gumminess (g) | Springiness (mm) | Adhesiveness (mJ) |

|---|---|---|---|---|---|

| Rate of casein replacement with rice starch (RR) | |||||

| 0% (control) | 391.89a | 0.6225a | 243.95a | 4.178a | 0.3726a |

| 10% | 408.77a | 0.5256b | 214.04b | 3.455b | 0.1270b |

| 20% | 401.50a | 0.4943c | 195.31c | 3.158c | 0.0923c |

| P value | 0.265 | <.0001 | <.0001 | <.0001 | <.0001 |

| Degree of starch hydroxypropylation (DH) | |||||

| 0% | 403.54a | 0.4788c | 188.58c | 3.147c | 0.2918a |

| 5% | 405.66a | 0.5925a | 240.24a | 3.897a | 0.1578b |

| 10% | 403.54a | 0.5711b | 224.48b | 3.747b | 0.1423c |

| P value | 0.4198 | <.0001 | <.0001 | <.0001 | <.0001 |

| Cold storage period (CSP) | |||||

| fresh | 375.10b | 0.5600a | 212.58b | 3.691a | 0.1965b |

| 2week | 426.32a | 0.5350b | 222.95a | 3.502b | 0.1981a |

| P value | <.0001 | <.0001 | <.0001 | <.0001 | 0.0198 |

| RR × DH | |||||

| 10%RR × 0% DH | 395.39 | 0.433 | 166.52 | 2.85 | 0.281 |

| 10%RR × 5% DH | 427.11 | 0.5865 | 250.5 | 3.892 | 0.053 |

| 10%RR × 10% DH | 403.78 | 0.5575 | 225.1 | 3.622 | 0.047 |

| 20%RR × 0% DH | 422.68 | 0.3705 | 150.76 | 2.427 | 0.216 |

| 20%RR × 5% DH | 398.4 | 0.576 | 229.48 | 3.636 | 0.0395 |

| 20%RR × 10% DH | 383.4 | 0.5365 | 205.7 | 3.411 | 0.0215 |

| P value | 0.1751 | <.0001 | <.0001 | <.0001 | <.0001 |

| RR × CSP | |||||

| 0%RR × fresh | 391.88 | 0.6233 | 244.27 | 4.176 | 0.3723 |

| 0%RR × 2week | 391.89 | 0.6216 | 243.63 | 4.181 | 0.373 |

| 10%RR × fresh | 378.57 | 0.547 | 209.17 | 3.549 | 0.127 |

| 10%RR × 2week | 438.96 | 0.5043 | 218.91 | 3.36 | 0.127 |

| 20%RR × fresh | 354.87 | 0.5096 | 184.31 | 3.349 | 0.0903 |

| 20%RR × 2week | 448.12 | 0.479 | 206.32 | 2.967 | 0.0943 |

| P value | 0.0002 | <.0001 | 0.0003 | <.0001 | 0.0327 |

| DH × CSP | |||||

| 0%DH × fresh | 329.24 | 0.5116 | 172.63 | 3.424 | 0.2903 |

| 0%DH × 2week | 477.82 | 0.446 | 204.54 | 2.871 | 0.2933 |

| 5%DH × fresh | 403.39 | 0.5923 | 238.85 | 3.905 | 0.1566 |

| 5%DH × 2week | 407.92 | 0.5926 | 241.63 | 3.889 | 0.159 |

| 10%DH × fresh | 392.68 | 0.576 | 226.27 | 3.746 | 0.1426 |

| 10%DH × 2week | 393.22 | 0.5663 | 222.69 | 3.748 | 0.142 |

| P value | <.0001 | <.0001 | <.0001 | <.0001 | 0.0561 |

Note*: Values with different letters (a-c) within the same column are significantly different at P<0.05.

Table 3: Ls means values for rate of casein replacement with rice starch (RR), degree of starch hydroxypropylation (DH), cold storage period (CSP), RR × DH, RR × CSP and DH × CSP on the texture profile analyses of the novel sweet fruity Mozzarella cheese analogue.

Shreddability of the novel sweet fruity Mozzarella cheese analogue

The results of Table 4 elucidated that, the control cheese which was made without casein replacement produced higher adhered cheese weight when compared to the casein partial replaced samples. Moreover, the adhered cheese weights were decreased with increasing the rate of casein replacement with rice starch. The starch hydroxypropylation process led to reduce the adhered cheese weight of the final cheese analogue samples in a concentrationdepending manner. These results are in parallel with the findings from the instrumental adhesiveness in the texture profile analysis. Regarding the lost cheese as fines through shredding, the results elucidate that, the 10% rate of casein replacement led to obtain the highest weights of cheese fines followed by the cheese made with 20% rate of casein replacement, while the control cheese came in the latest order. The application of the hydroxypropylated rice starch let to increase the cheese fines upon shredding, the highest increments were for the cheeses made with the 5% hydroxypropylated starch. That could be due to the relatively high hardness of those cheeses. Concerning the adhesive force, it is the maximum force required to separate teeth after biting sample. It represents the maximum negative force generated during the probe of the texture analyzer return. The obtained results elucidated that, casein replacement with starch led to decrease the adhesive force of the final cheese, regardless the rate of replacement. The moderate degree of starch hydroxypropylation was associated with the highest values of cheese fines weights, possibly due to the increased proteinwater interactions occured in the cheese made with that degree of starch modification. Regarding the overall shredding evaluation indicator, i.e., the shredding efficiency, the obtained results indicated that the control sample reflected the lowest shredding efficiency. Whereas the shredding efficiency was increased with increasing both the rate of casein replacement and the degree of starch hydroxypropylation (Table 4).

| Source of variation | Adhered cheese | Cheese fines | Adhesive | Shredding efficiency (%) |

|---|---|---|---|---|

| weight (g/500g) | weight (g/500g) | force (g) | ||

| Rate of casein replacement with rice starch (RR) | ||||

| 0% (control) | 114.66a | 6.13b | 26.70a | 75.84c |

| 10% | 77.33b | 6.86a | 18.70b | 83.16b |

| 20% | 68.66c | 4.76c | 16.70b | 85.31a |

| P value | <.0001 | <.0001 | <.0001 | <.0001 |

| Degree of starch hydroxypropylation (DH) | ||||

| 0% | 98.00a | 4.20c | 23.36a | 79.56c |

| 5% | 84.33b | 7.20a | 20.36b | 81.69b |

| 10% | 78.33c | 6.366b | 18.37b | 83.06a |

| P value | <.0001 | <.0001 | <.0001 | <.0001 |

| RR × DH | ||||

| Control | 120.66 | 5.53 | 28.03 | 74.76 |

| 10% RR × 0% DH | 94.66 | 4.03 | 22.03 | 80.26 |

| 10% RR × 5% DH | 69.66 | 8.53 | 18.03 | 84.36 |

| 10% RR × 10% DH | 67.66 | 8.03 | 16.03 | 84.86 |

| 20% RR × 0% DH | 83.66 | 2.23 | 21.03 | 82.82 |

| 20% RR × 5% DH | 62.66 | 7.53 | 15.03 | 85.96 |

| 20% RR × 10% DH | 59.66 | 4.53 | 14.03 | 87.16 |

| P value | <.0001 | <.0001 | <.0001 | <.0001 |

Note*: Values with different letters (a-c) within the same column are significantly different at P<0.05.

Table 4: Ls means values for rate of casein replacement with rice starch, degree of starch hydroxypropylation and rate of casein replacement with rice starch x degree of starch hydroxypropylation on the shredding parameters of the novel sweet fruity Mozzarella cheese analogue.

Meltability and stretchability profiles of the novel sweet fruity Mozzarella cheese analogue

As shown in Table 5, the variations in the melt distance values among samples upon both, the rate of casein replacement and degree of starch hydroxypropylation were very little. That could be due to the convergent hardness degrees of all the samples. Likewise, a slight decrease in the meltability of cheese analogues was noted at the end of the studied cold storage period. The 5 % hydroxypropylated rice starch was associated with the lowest melt distance values compared to either the 10% hydroxypropylated one or the native starch. That could be ascribed to the relatively low degree of fat emulsification caused by the excessively swollen starch particles occurred through the moderate degree of hydroxypropylation. Its noteworthy to mention that the cheese of the 10% degree of starch hydroxypropylation kept its meltability unchanged throughout the studied cold storage period, possibly due the role of the hydroxypropyle in increasing the gel stability of starch. This result was in accordance with the findings of Senanayake, et al. who studied the role of hydroxypropylation on improving the functionality of the sweet potato starches [18]. The free oil of samples took the same trends as the melt distance, possibly due to the very convergent fat contents of all samples occurred by adjusting the amounts of added palm oil to the formulas. The control cheese kept its free oil unchanged up to the end of storage, possibly due to the strong uninterrupted protein network of that cheese which prevented the fat to ooze out. Furthermore, the protein replaced samples reflected a significant decrease in the free oil upon storage. That could be ascribed to the role of starch retrogradation in increasing the hydration of the protein network which in turn decreases the dense of protein network and created large channels for the flow of fat. Regarding the stretch extension, the application of rice starch as casein partial replacer led to reduce the instrumental stretch extension significantly. The highest casein replacement rate was associated with the lowest stretch extension, possibly due to weaking the protein network by the presence of starch. Moreover, the hydroxypropylation process led to increase the stretch extension regardless the concentration of the added propylene oxide. Unlike the casein replaced samples, the control cheese kept its extension un decreased whole over the cold storage period. That could be due to the changes in the casein hydration degree occurred through storage as a result of starch retrogradation. The highest resistance to the age decreased stretch extension was noted when the propylene oxide was added to starch at the rate of 10%. Concerning the Tex values of cheeses, increasing the rate of casein replacement led to decrease the Tex values. Moreover, the native starch led to obtain the highest cheese Tex compared to the modified starch, while the degree of hydroxypropylation had no significant effect on the cheese Tex. Possibly due to the different water holding capacities between the native and modified starches which in turn affected the degree of moisture loss during the stretchability evaluation test. Furthermore, the Tex values of all the starch containing cheese samples showed significant increments at the end of the cold storage period. That could be ascribed essentially to continuing the starch transition phenomena. These findings were in agreement with those of Donmez, et al. [19]. Regarding the stretch maximum load, the results indicate that, replacing the casein with starch a rate of 10% led to increase the stretch maximum load compared to both the control and the cheeses made with 20% casein replacement rate. Moreover, increasing the degree of starch hydroxypropylation to 10% led to lower the maximum load of stretching. Nevertheless, the stored samples reflected higher stretch maximum load values than the fresh ones possibly due to the increase in cheese hardness. With regard to the break point values, the results of the LLOYD LR10Kplus extensometer state that, the control cheese possessed the longest break point value, and that value was decreased with increasing the rate of casein replacement with starch. Amongst the casein replaced samples, the hydroxyproylated starch containing cheeses possessed similar break point values to each other’s regardless the degree of hydroxypropylation, and higher values than the native starch containing ones. That could be ascribed to the role of the hydroxypropylation process in limiting the interactions between starch and casein. The break point values were decreased upon storage, possibly due to the storage-depending decrease in the free oil which was necessary to lubricate the cheese stretched and keep it intact (Table 5).

| Source of variation | Melt distance (mm) | Free oil (% of total fat) | Extension1 (mm) | Tex2 (g/1000m) | Stretch maximum load (gf) | Break point (mm) | Tenacity3 (gf/Text) |

|---|---|---|---|---|---|---|---|

| Rate of casein replacement with rice starch (RR) | |||||||

| 0% (control) | 67.14a | 24.46a | 577.83a | 18366.67a | 28.16b | 558.00a | 0.00153c |

| 10% | 56.06b | 20.36b | 437.16b | 13770.00b | 35.00a | 412.33b | 0.00252b |

| 20% | 65.89a | 25.22a | 240.83c | 9896.67c | 29.16b | 218.16c | 0.00291a |

| P value | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 |

| Degree of starch hydroxypropylation (DH) | |||||||

| 0% | 63.81a | 24.26a | 325.83b | 14185.00a | 31.00a | 302.66b | 0.00227b |

| 5% | 59.06b | 21.46b | 466.00a | 13953.33b | 32.16a | 447.16a | 0.00247a |

| 10% | 66.22a | 24.33a | 464.00a | 13895.00b | 29.16b | 438.66a | 0.00221b |

| P value | 0.0013 | 0.0025 | <.0001 | 0.0129 | 0.0058 | <.0001 | 0.0015 |

| Cold storage period (CSP) | |||||||

| fresh | 68.33a | 25.35a | 432.00a | 13738.89b | 28.00b | 412.22a | 0.00214b |

| 2week | 57.72b | 21.35b | 405.22b | 14283.33a | 33.55a | 380.11b | 0.00249a |

| P value | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 |

| RR × DH | |||||||

| 10%RR × 0% DH | 62.56 | 23.44 | 246 | 13725 | 33 | 219.5 | 0.00236 |

| 10%RR × 5% DH | 49.06 | 17.54 | 536 | 13650 | 38 | 518 | 0.00278 |

| 10%RR × 10% DH | 56.56 | 20.11 | 529.5 | 13935 | 34 | 499.5 | 0.00243 |

| 20%RR × 0% DH | 63.06 | 25.61 | 151 | 10315 | 31 | 129 | 0.0029 |

| 20%RR × 5% DH | 60.06 | 21.83 | 288 | 9850 | 31 | 268 | 0.00314 |

| 20%RR × 10% DH | 74.56 | 28.23 | 283.5 | 9525 | 25.5 | 257.5 | 0.00268 |

| P value | 0.0004 | 0.0023 | <.0001 | 0.0044 | 0.0037 | <.0001 | 0.0125 |

| RR × CSP | |||||||

| 0%RR × fresh | 67.22 | 24.48 | 577.66 | 18433.33 | 28 | 557.33 | 0.00151 |

| 0%RR × 2week | 67.06 | 24.44 | 578 | 18300 | 28.33 | 558.66 | 0.00154 |

| 10%RR × fresh | 63.06 | 22.71 | 461.33 | 13283.33 | 31.33 | 443 | 0.00234 |

| 10%RR × 2week | 49.06 | 18.02 | 413 | 14256.66 | 38.66 | 381.66 | 0.00271 |

| 20%RR × fresh | 74.72 | 28.86 | 257 | 9500 | 24.66 | 236.33 | 0.00258 |

| 20%RR × 2week | 57.06 | 21.59 | 224.66 | 10293.33 | 33.66 | 200 | 0.00323 |

| P value | <.0001 | 0.0007 | 0.0004 | <.0001 | <.0001 | <.0001 | 0.0003 |

| DH × CSP | |||||||

| 0%DH × fresh | 78.56 | 30.12 | 361.33 | 13283.33 | 23.33 | 341.66 | 0.00181 |

| 0%DH × 2week | 49.06 | 18.39 | 290.33 | 15086.66 | 38.66 | 263.66 | 0.00274 |

| 5%DH × fresh | 60.39 | 22 | 470 | 13906.66 | 31.33 | 450.33 | 0.00241 |

| 5%DH × 2week | 57.72 | 20.91 | 462 | 14000 | 33 | 444 | 0.00253 |

| 10%DH × fresh | 66.06 | 23.92 | 464.66 | 14026.66 | 29.33 | 444.66 | 0.00221 |

| 10%DH × 2week | 66.39 | 24.74 | 463.33 | 13763.33 | 29 | 432.66 | 0.00221 |

| P value | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 |

Note*: Values with different letters (a-c) within the same column are significantly different at P<0.05.1Extension: distance that cheese stretched; 2Tex: measured as g of strand per 1000m; 3Tenacity: Stretch maximum load divided by Tex.

Table 5: Ls means values for rate of casein replacement with rice starch (RR), degree of starch hydroxypropylation (DH), cold storage period (CSP), RR × DH, RR × CSP and DH × CSP on the meltability and stretchability profiles of the novel sweet fruity Mozzarella cheese analogue.

Power law model coefficients of the novel sweet fruity Mozzarella cheese

As obvious in Table 6, the rate of casein replacement with starch led to affect the critical strain of Mozzarella cheese analogue samples, where the control cheese obtained the lowest value followed by the cheese of 10% rate of casein replacement, while the cheese made with 20% replacement rate was the rubberiest of all samples and obtained the highest critical strain, possibly due to that starch restricted the mobility of water in the cheese matrix. Similar findings were reported by Faber, et al. [20]. Its noteworthy to mention that the relatively low critical strain values in cheese analogues means that the cheese is less stable and more prone to the strain deformation. With respect to the effect of degree of starch hydroxypropylation on cheese critical strain, the cheese of the higher degree of hydroxypropylation was associated with the highest rubbery structure of all cheese samples followed by the native starch cheese, while the cheese of the 5% hydroxypropylation came in the latest order. The rice starch application in the cheese making led to increase the consistency coefficient (K) values of the final cheese samples in a concentration-depending manner through both storage and loss modulus. The degree of starch hydroxypropylation affected the storage modulus consistency coefficient significantly as the native starch cheese reflected the lowest consistency followed by the 5% hydroxypropylated starch cheese, then the 10% one. That could be due to the interactions occurred between the native starch and protein through cooking which in turn weakened the cohesiveness of cheese matrix. These observations were in agreement with those of Kamath, et al. [2]. The casein replaced samples were distinguished with relatively high loss modulus consistency coefficient values compared to the control cheese regardless the replacement rate [21]. The consistency coefficient in the loss modulus took the same trends as the critical strain towards the factor of degree of starch hydroxypropylation, where the 10% hydroxypropylated starch cheese were the most resistant to deformation. It was crystal clear that all samples reflected the pseudoplastic flow behaviour as the index of the flow behaviour (n) values were less than one. The storage modulus flow behaviour index was decreased significantly by increasing the replacement rate of cheese casein by starch. That could be due to the stronger water binding ability of casein than that of starch. Likewise, the 5% hydroxypropylted starch cheese gained the highest flow behaviour index of samples. These observations were in agreement with the findings of Senanayake, et al. who studied the effect of hydroxypropylation on the functionality of potato starch in Table 6 [16].

| Source of variation | εcr (%) | G' | G" | ||

|---|---|---|---|---|---|

| K | n | K | n | ||

| (Pa.sn) | (Pa.sn) | ||||

| Rate of casein replacement with rice starch (RR) | |||||

| 0% (control) | 9.46c | 14137.7c | 0.252a | 6694.7b | 0.207b |

| 10% | 12.53b | 16689.4b | 0.179b | 7149.6a | 0.203c |

| 20% | 14.45a | 17163.3a | 0.169c | 7178.2a | 0.208a |

| P value | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 |

| Degree of starch hydroxypropylation (DH) | |||||

| 0% | 12.15b | 14575.0c | 0.114c | 6698.2b | 0.203b |

| 5% | 11.43c | 15384.2b | 0.247a | 6555.2c | 0.203b |

| 10% | 12.85a | 18031.2a | 0.237b | 7769.2a | 0.213a |

| P value | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 |

| RR × DH | |||||

| Control | 9.74 | 14187.3 | 0.254 | 6694 | 0.2 |

| 10% RR × 0% DH | 12.93 | 14688 | 0.049 | 6670 | 0.2 |

| 10% RR x 5% DH | 11.22 | 15844.6 | 0.247 | 6493.3 | 0.199 |

| 10% RR × 10% DH | 13.45 | 19535.6 | 0.241 | 8285.6 | 0.212 |

| 20% RR × 0% DH | 14.23 | 14994 | 0.044 | 6668 | 0.198 |

| 20% RR × 5% DH | 13.35 | 16120.6 | 0.241 | 6478.3 | 0.211 |

| 20% RR × 10% DH | 15.77 | 20375.3 | 0.221 | 8388.3 | 0.217 |

| P value | <.0001 | <.0001 | <.0001 | <.0001 | <.0001 |

Note*: Values with different letters (a-c) within the same column are significantly different at P<0.05.

Table 6: Ls means values for rate of casein replacement with rice starch, degree of starch hydroxypropylation and rate of casein replacement with rice starch x degree of starch hydroxypropylation on the power law model coefficients of the novel sweet fruity Mozzarella cheese analogue.

Including the fruit pulps in Mozzarella cheese analogue may form a new style of cheese and encourage the emergence of innovative applications like the sweet pizza. Casein could be replaced by rice starch at rates up to 20% without any adverse effects on the functionality of cheese analogues. Hydroxypropylated rice starch could be used for enhancing the functionality of Mozzarella cheese sweet analogue and reducing the costs of manufacture. The degree of the used starch hydroxypropylation could be increased up to 10% depending on the desired attributes of the final cheese analogue product.

[Cross Ref][Google Scholar] Grand View Research. (2021). Dairy alternatives market share & growth Report, 2021-2028.

Citation: Emam AO (2022) The Technological Suitability of Rice Starch Modification: As Casein Replacer in the Novel Sweet Fruity Mozzarella Cheese Analogue. J Adv Dairy.10:603.

Received: 06-Jul-2022, Manuscript No. ADR-22-18243; Editor assigned: 08-Jul-2022, Pre QC No. ADR-22-18243 (PQ); Reviewed: 25-Jul-2022, QC No. ADR-22-18243; Revised: 01-Aug-2022, Manuscript No. ADR-22-18243 (R); Published: 08-Aug-2022 , DOI: 10.35248/2329-888X.22.10.603

Copyright: © 2022 Emam AO. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.