Journal of Thermodynamics & Catalysis

Open Access

ISSN: 2157-7544

ISSN: 2157-7544

Review Article - (2017) Volume 8, Issue 3

Keywords: Vinyl chloride; Dichloroethane; Pyrolysis; Conversion; Selectivity; Coke formation; Kinetics; Initiation; Inhibition; Simulation; Energy saving

Vinyl chloride, (world-recognized abbreviation-VCM-Vinyl Chloride Monomer) is the unique and most large-scale chemical industry product of complex processing of mineral and organic raw materials-sodium chloride and petrol. In 2015 its global production reached 40 million tons. Up to 98% of all produced VCM is used for the production of polyvinyl chloride (PVC), the most important polymer material that has been produced in industrial scale for more than 80 years and together with polyethylene and polypropylene is in the top three most common polymers.

For the first time, VCM was obtained in 1835 by the German chemist Justus von Liebig and his disciple, the French chemist Henri Victor Regnault, via the reaction of alcohol solution of caustic potassium with 1,2-dichloroethane (hereinafter referred to as EDC) [1]. In 1902, Blitz received VCM by catalytic EDC decomposition over pumice at a red heat temperature, and in 1908 - Senderens by EDC decomposition over dehydrated alumina at 370°C [2].

The real prerequisites for the industrial production of VCM were the reactions for VCM obtaining, discovered virtually simultaneously in 1912-1913, by acetylene hydrochlorination in the gas and liquid phases (Fritz Klatte, Germany) and its photopolymerization (Ostromyslensky, Russia). In 1929 the first industrial complex for VCM-PVC production was constructed in the city of Rheinfelden (Germany).

Beginning from the mid-1960s, the so-called balanced method of VCM production became widespread. Its essence is that VCM is obtained by EDC pyrolysis at 480-500°C, while the hydrogen chloride formed is directed to oxidative chlorination (oxychlorination) of ethylene with the production of additional EDC. In this case, the chlorine introduced into the system (directly-at the stage of direct liquid-phase chlorination of ethylene, as well as in the form of hydrogen chloride at the stage of ethylene oxychlorination) is almost completely bound to the target products.

In the process of oxychlorination of ethylene, there is a significant number of publications in the literature; we note [2-7] among them. The conformities of the process of direct chlorination of ethylene are described in detail in [2,5].

Pyrolysis of EDC to obtain the target product VCM is carried out in tubular furnaces. In most installations, the EDC conversion per pass is 50-55%. To achieve such conversion, the temperature of the gases leaving the reaction coil of the furnace is maintained at approximately 500°C. The pressure in the system is usually 2-2.5 MPa. The temperature profile along the length of the coil depends on the design of the furnace and the set process conditions. At high temperatures, the degree of pyrolysis increases, which, however, leads to increasing of the yield of organic by-products, as well as the hard carbon deposits on the walls of the coil. To clean the coil, it is necessary to regenerate it periodically. Virtually all of the EDC, remained unreacted in the furnaces, is separated and returned to the process again. In this case, an optimal balance of VCM throughput, its yield and purity with the cost of re-separation of EDC and downtime is established [3]. It is the gas phase process that makes it possible to obtain anhydrous hydrogen chloride, which is then utilized in the stage of oxychlorination of ethylene. The process of dehydrochlorination of EDC can be thermal only-the temperature in this case, as mentioned above, is 480-500°C; initiated the temperature is 400-450°C; or catalytic-the temperature is 325-380°C.

In this review, we consider data obtained at different time periods during laboratory researches of the process of EDC pyrolysis, as well as the main conformities of industrial use of this process.

Pyrolysis of EDC is an endothermic process proceeding upon the total reaction:

C2H4Cl2→C2H3Cl+HCl-73 kJ/mol (1)

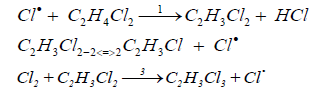

Below 350°C the rate of volume reaction is extremely low, and at 250°C EDC does not decompose at all. Pyrolysis of EDC is a free-radical chain process, which includes:

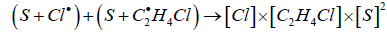

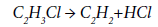

Chain initiation

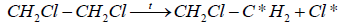

(2)

(2)

dichloroethane

Chain propagation and growth

Cl*+CH2Cl-CH2Cl→CH2Cl-C*HCl+HCl

Dichloroethane (3)

CH2Cl-C*HCl→CH2=CHCl+Cl*

Vinylchloride(4)

3. Termination of chain

CH2Cl-C*HCl+Cl→CH2Cl-CHCl2

1,1,2-trichloroethane (5)

2CH2Cl-C*HCl→CH2Cl-CHCl-CHCl-CH2Cl

1,2,3,4-tetrachlorobutane (6)

2CH2Cl-C*HCl→CHCl=CHCl+CH2Cl-CH2Cl

1,2-dichloroethylene (7)

Cl*+wall→termination (8)

Thus, the process begins with the breakdown of the C-Cl bond in the EDC molecule, followed by chain propagation-H atom abstraction with Cl* radical from the EDC molecule and the molecular decomposition of the 1,2-dichloroethyl radical; chain termination occurs homogeneously when radical recombination. The Cl* radical guides chain reactions of EDC, which explains, in particular, the acceleration or slowing down of the reaction by various additives, which, participating in the chain, promote its nucleation or termination.

By-products are formed, mainly in the case of overheating above 500°C. Particularly undesirable is the process of thermal decomposition of the formed VCM. This reaction at temperatures exceeding 500°C proceeds at a noticeable rate with the formation of acetylene:

CH2=CHCl→HC≡CH+HCl

Acetylene (9)

Further, a number of by-products are formed from acetylene, in particular, benzene, vinylacetylene, chloroprene, methyl chloride, etc. [2]. Some of the by-products are precursors in the formation of solid carbon deposits, the so-called “coke”.

The pressure, temperature and quality of EDC fed to pyrolysis are the main factors that influence the selectivity of the process. In modern industrial installations, the selectivity is usually at the level of 99%. The amount of organochlorine waste generated at this stage, however, is up to 50% of the total amount of organic waste in a balanced process and exceeds the corresponding amount formed in other stages of the process direct and oxidative chlorination of ethylene [2]. This indicates the need to use a number of techniques helping maintain the selectivity of the EDC pyrolysis process at the required level.

The pyrolysis process of EDC is reversible; its peculiarity is that in the reverse reaction of VCM and hydrogen chloride, according to the Markovnikov rule not EDC is formed, but its isomer, 1,1-dichloroethane.

The change in temperature and pressure can have a significant effect on the equilibrium composition of the pyrolysis products [2,8-10].

With an increase in pressure from 0.1 to 4 MPa, the equilibrium conversion of EDC somewhat decreases, but at temperatures above 600 K, even at a pressure of 4 MPa, the equilibrium conversion of EDC exceeds 90%. With an increase in pressure the equilibrium yield of VCM and acetylene slightly decreases, while that of 1,1-dichloroethane slightly increases.

With an increase in temperature, the output of VCM initially increases, and then, after reaching the maximum, begins to decrease. With an increase in pressure, the maximum yield of VCM shifts to higher temperatures: for a pressure of 0.1 MPa, the maximum yield (more than 99%) is possible at 500-600 K, for 0.5 MPa at 600 K, for 2-4 MPa at 700 K. Under these conditions, the equilibrium yield of acetylene remains equal to less than 1%.

In general, for conditions providing technologically acceptable process parameters (T=600-800 K, P=1.5-3.0 MPa), there are no thermodynamic limitations.

The beginning of systematic researches of the pyrolysis process of EDC dates back to the end of the 1940s, when the kinetic conformities of the process were first described by Barton et al. [11-14]. In [11,12], the pyrolysis of EDC was investigated in a tubular flow reactor made of refractory glass with a diameter of 15 mm and a length of 750 mm in the temperature range of 362-485°C. It was shown that the rate of the pyrolysis is described by a first order equation.

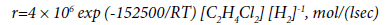

As a result of experiments in the reactor with walls covered with a carbon film, the authors obtained the following expression for the reaction rate constant:

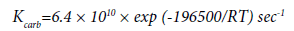

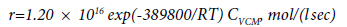

(10)

(10)

This expression differs markedly from the expression for the rate constant obtained by Barton for the reactor with clean walls:

(11)

(11)

At 758 K, kcarb/kcl=0.08; at 635 K, kcarb/kcl=6 × 10-3. Thus, when the walls are covered with the carbon film, the initiating capacity of the surface is significantly reduced.

According to [12], the presence in the system of small concentrations of propylene (less than 0.1%) significantly reduces the rate of pyrolysis of EDC. The authors of [12] interpret this fact as confirmation of the radical chain mechanism of the process. As opposed to EDC, the pyrolysis of ethyl chloride and 1,1-dichloroethane is not inhibited by propylene; the authors [13] explain this fact from the standpoint of a different mechanism of decomposition of the raw compound, in comparison with EDC. This is also indicated by the absence of an induction period of the reactions. It is assumed that the dehydrochlorination of these compounds proceeds upon a monomolecular mechanism.

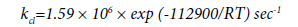

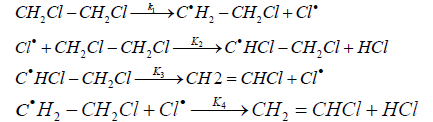

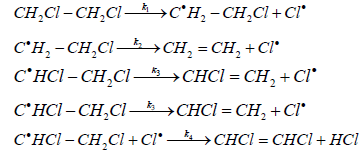

Howlett [14] proposed the following scheme for the free-radical chain dehydrochlorination mechanism of EDC:

On the basis of this mechanism, using the method of stationary

(12)

(12)

The values of reaction rate constants are as follows:

k1=1013exp(-292600/RT) sec-1

k2=108.62exp(-20900/RT) l mol-1 sec-1

k3=1010exp(-92000/RT) sec-1

k4=1010exp(-12500/RT) l mol-1 sec-1

The general expression for the rate constant corresponds to equation (10).

Doreiswami [9] studied the kinetics of the EDC thermal dehydrochlorination in the temperature range of 400-500°C, using a flow reactor. Assuming the first order of the reaction, the author deduced that the reaction rate constant for conversion degrees of less than 80% is expressed by the following equation:

k=1.49 × 1020 × exp(-59000/RT) sec-1 (13)

In contrast to Barton, Doreiswami carried out experiments with raw EDC (the distillation range of the latter is 82-84°C at 760 mmHg) and in his calculations, did not take into account the effect of an increase in the volume of the reaction mixture, which casts some doubt on the validity of the data obtained.

According to the data obtained by Kitabatake et al. [15], the rate constant of the first-order reaction in the temperature range of 470- 530°C is described by the following relationship:

k=1.15 × 107 × exp (-114500/RT) sec-1

Very close results were obtained by Takahashi [16].

k=3.3 × 107 × exp (-121800/RT) sec-1

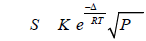

The authors of [16] did not find out any noticeably affect of the pressure change from 1 to 8 atm upon the reaction rate, while the surface-to-volume ratio (S/V) had a significant effect on the rate: the reaction rate is proportional to S/V to the power of ½.

Sonin [10], when studying the process in a glass gradientless reactor, obtained the following expression for the reaction rate constant:

k=6.47∙109∙exp (-154100/RT) sec-1

Thus, all the researchers agree that the reaction of thermal pyrolysis of EDC obeys the first-order equation. The difference in the values of the pre-exponential factors and the activation energies may be explained by a number of factors: the diameter and material of the reactor, the purity of the EDC used, the degree of carbonization of the reactor walls, etc. [17-22].

An important characteristic that has a significant effect on the rate of pyrolysis of EDC and its selectivity is the ratio between the homogeneous and heterogeneous components, i.e., the ratio of the reactor surface to its volume (S/V). According to Kitabatake et al. [15], the rate of the reaction of EDC dehydrochlorination somewhat decreases with increasing the diameter of the reaction tube, i.e., with a decrease in S/V. A similar opinion was held by Semenov [23]. However, in [24], it was shown using the calorimetry method that there is no correlation between the rate of decomposition of EDC in clean vessels and the S/V ratio. Based on this, the authors of [24] conclude that the given reaction is not heterogeneous, but initiates on the surface and propagates in volume. In contrast, Barton [11] showed that the reaction rate decreases when it is carried out on a glass packing, i. e. with an increase in the S/V ratio. This seems quite natural, because when using a packing, the relative value of the surface increases drastically and under these conditions the wall begins to inhibit the chain process, since not only the nucleation but also the termination of chains occurs on the surface.

According to the data of [10], the results obtained using reaction tubes of different diameters, 21, 50 and 60 mm, do not show a clear dependence in the change in the conversion at the same values of the linear flow velocity. At the same time, the reaction rate increases mainly due to an increase in the gas flow velocity characterized by the Reynolds value of up to Re=0.8÷1 × 105. Further increase in the flow velocity has virtually no effect on the reaction rate.

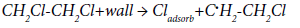

Detailed investigations of the effect of the surface on the rate of the EDC pyrolysis in a wide range of S/V ratios were made by Holbrook et al. [25]. The kinetic data obtained by the authors of [25] under the conditions of the pyrolysis of EDC in reactors with low and high S/V values show that for S/V values of 1.3-1.4 cm-1 the total order of the reaction is in the range 2.5-3, and the activation energy is of the order of 300 kJ/mol. At S/V=37.4 cm-1, the order of the reaction is 1.5, and the activation energy is 140 kJ/mol. The authors of [25] expanded the mechanism of the process proposed by Howlett [14], introducing into it the reaction of termination at the walls of the reactor:

Cl+S→SCl (17)

C2H3Cl2+S→C2H3Cl2S (18)

A hypothesis on autocatalysis by means of a chemisorbed chlorine atom was also proposed in [25]. The authors indicate that in a reactor filled with a glass packing, i.e., at high S/V values, the dechlorination of EDC proceeds to form ethylene and adsorbed chlorine:

C2H4Cl2 + S ⇔ (C2H4Cl2 )s (19)

(C2H4Cl2)s→C2H4+(Cl2)s (20)

The reaction of dechlorination of EDC has half the order; the activation energy is 196 kJ/mol. The desorption stage of chlorine is described by equation (21):

(Cl2)s→Cl+SCl (21)

where the fragment SCl is the main element determining the autocatalytic nature of the process. In general, according to the data of [25], the initial rate decreases substantially as the S/V ratio increases.

The authors of [26] proposed a model for the pyrolysis of EDC, which includes both homogeneous and heterogeneous components. It is shown that homogeneous and heterogeneous initiation of chain have the same rate. By analogy with [25], the authors of [26] believe that the heterogeneous component plays the most important role in the reactions of chain termination. It is also indicated that for small S/V values of 1.04 cm-1, the presence of the heterogeneous factor reduces the rate of homogeneous decomposition of EDC by a factor of 5, and with an increase in S/V up to 10 cm-1, this decreasing becomes even more noticeable. The authors of [26] conclude that the limiting stages of the process are the initiation and termination of the chains just on the walls of the reactor.

The positive effect of increasing the S/V ratio upon the process rate was noted in [27]. When researching the process in the temperature range of 460-500°C it was shown that an increase in the surface by ~ 6% leads to an increase in the conversion of EDC in 1.1-1.5 times, and this effect is more pronounced with decreasing temperature.

The totality of the data presented in [11,24,25] shows that the total rate of the process of EDC dehydrochlorination is the sum of the monomolecular, radical-chain homogeneous and heterogeneous components, while the role of each them depends on the conditions of the process. An attempt was made [28] to investigate the pyrolysis of EDC under strictly homogeneous conditions. The authors indicate that such conditions can be ensured by using the adiabatic compression method. It is shown that in the temperature range of 920-1050 K and the typical process time periods of 10-2 sec., EDC participates only in the dehydrochlorination reaction with the formation of VCM. From the degree of conversion ~45%, traces of acetylene appear. The activation energy of the process is 65 kcal/mol (272 kJ/mol). Under the selected conditions, the dehydrochlorination reaction of EDC is monomolecular [28]. The rationale for this approach is a higher activation energy in comparison with the data of Barton and Howlett [13,14] by 9 kcal/mole and the absence of radical recombination products at the conversion rates of EDC up to 45%.

One of the possible ways to reduce energy costs for the pyrolysis of EDC may be a decrease in temperature. Provided that the high rate of the process and, consequently, the conversion of EDC is maintained, this can be achieved through the use of the so-called initiating additives. Such additives can include, for example, chlorine, carbon tetrachloride, hexachloroethane, as well as other compounds, in which C-Cl bond breakage energy is lower in comparison with that of EDC. Table 1 shows the values of the energy of C-Cl and Cl-Cl bond breakage for EDC and some initiators [17].

| Name | The produced radical or molecule | Breakdown energy, kJ/mol |

|---|---|---|

| carbon tetrachloride | C•Cl3 | 297 |

| hexachlorethane | CCl3C•Cl2 | 290 |

| 1,2-dichloroethane | CH2ClC•H2 | 335.1 |

| ?hlorine | Cl• | 242.4 |

Table 1: The C-Cl and Cl-Cl bond breakage energy for some compounds.

Since the reaction of EDC dehydrochlorination proceeds through a radical chain mechanism, the presence of initiators significantly increases its rate. One of the most effective initiators is chlorine, which has the bond breakdown energy of 60-80 kJ/mol lower than C-Cl bond breakdown energy in chloroethanes.

Thus, in the presence of a negligible amount of chlorine, the conversion of EDC drastically increases [18]. This is evident from Table 2. It should be noted that the conversion of EDC increases only in the temperature range 300-400°C.

| Chlorine,% wt. | Reaction temperature, °C | Conversion of EDC, % |

|---|---|---|

| – 0.5 0.5 0.5 |

400 370 350 300 |

2 70 50 30 |

Table 2: Effect of chlorine additives on EDC conversion as a function of temperature.

The initiating effects of other halogens were also investigated. Thus, Smolyan [19] determined by calculation that the initiating capacities of fluorine, chlorine, bromine and iodine differ drastically not only because of the difference in their degree of dissociation, but also because of the strength of the H-hal bond. The rate constant for the chain transfer reaction is the highest for fluorine, but it cannot be used as an initiator of the EDC pyrolysis process for obvious reasons.

The relative values of the process rate when using chlorine and bromine are comparable with each other and by two orders of magnitude higher than the corresponding values when using iodine as an initiator. Similar researches were carried out by Barton [11]; for the data see Table 3.

| Halogen, % wt. | Conversion of EDC, % |

|---|---|

| Chlorine 0.5 Bromine 0.5 Iodine 0.5 |

44 33 1 |

Table 3: Dependence of conversion of EDC on the nature of halogen.

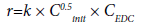

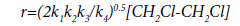

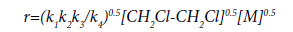

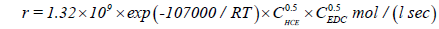

The process of gas-phase dehydrochlorination of EDC, initiated by chlorine, has been studied by a number of researchers [10,11,16,19]. Barton et al. [11,16] came to the conclusion that the reaction rate is described by a following kinetic equation:

(17)

(17)

i.e., the reaction is half the order with respect to initiator and the first with respect to EDC.

According to Barton [11], the expression for the rate constant has the following form:

k=1 × 1 × 103∙exp (-51000/RT) sec-1 (18)

According to Takahashi [16],

k=3.3∙103∙exp (-51800/RT) sec-1 (19)

Sonin [10] argues with the authors of [11,16]; according to Sonin the reaction rate of dehydrochlorination of EDC, initiated by chlorine, is described by the following equation:

(20)

(20)

The difference in the form of kinetic equations entails a different understanding of the mechanism of the process by the authors. In the homogeneous dehydrochlorination of EDC, the reaction can proceed either through a monomolecular or a free-radical chain mechanism. Dehydrochlorination of a chlorinated derivative proceeds according to the molecular mechanism in the case when the chlorinated derivative itself or its decomposition products are the chain inhibitors.

Barton et al. [14,20-22] divided the studied by them chloroalkanes into two groups. The first group included chlorides, the decomposition of which is slowed down by the addition of propylene, acetaldehyde and is accelerated by the addition of chlorine and, consequently, proceeds according to the radical chain mechanism. This group includes 1,2-dichloroethane, 1,1,1-trichloroethane, 1,1,2-trichloroethane, 1,1,2,2-tetrachloroethane and 1,1,1,2-tetrachloroethane.

The second group includes chlorides, the rate of decomposition of which is not sensitive to additives of propylene, chlorine, etc. This group includes ethyl chloride, 1,1-dichloroethane, 1,2-dichloropropane, 2-chloropropane, propyl chloride, butyl chloride and isobutyl chloride. The authors believed that these chlorides decompose according to the true monomolecular mechanism directly to an olefin and hydrogen chloride. This is due to the fact that the reaction of the chlorine atom with a molecule of such chloride most likely forms a radical that is incapable of being converted to an olefin by removing a chlorine atom. In this case, chain decomposition is constrained, and the molecular decomposition gains an advantage. For example, the interaction of 1,1-dichloroethane with a chlorine atom more likely forms a radical C•Cl2-CH3, which is incapable of removing the chlorine atom.

Conversely, under these conditions EDC gives predominantly the radical CH2Cl-C•HCl, which is capable of giving off the chlorine atom and form VCM, which promotes the propagation of the chain reaction.

This approach corresponds to the general principles of the mechanism of chloroalkane dehydrochlorination proposed by Semenov [23].

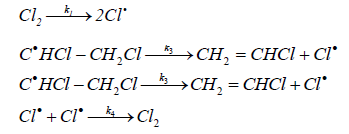

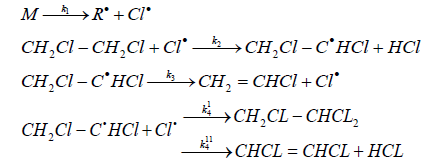

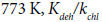

Considering the mechanism of the reaction of the initiated dehydrochlorination of EDC, various authors [16,19] concluded that the most probable stage of a chain nucleation is the thermal decomposition of the initiator. T. Takahashi proposed a scheme for the mechanism of initiated dehydrochlorination of EDC, which is described as follows:

The equation of the chain reaction rate of the initiated dehydrochlorination of EDC derived on the basis of this mechanism has the form:

(21)

(21)

and shows that the reaction has a common one-and-a-half the order and, in particular, half the order with respect to chlorine and the first order with respect to EDC.

Most authors who studied the decomposition of chloroalkanes and, in particular, EDC, believed that the chain reaction was initiated and terminated in volume, and the inhibitory effect of inhibitors was due to the termination of chains at them in the volume. Semenov [23] showed that the reaction initiates on the walls and propagates in the volume. The termination of chains occurs mainly on the wall, but partly in the volume as well. At the same time, Semenov notes that in the absence of the termination in the volume, the chain reaction of dehydrochlorination of EDC should proceed as that of the first order, if the chain termination is determined by the radical C•HCl- CH2Cl capture by the wall, and the chain nucleation on the wall occurs according to the reaction:

A comparison of the proposed mechanisms of thermal and initiated dehydrochlorination of EDC shows that the stage of the chain propagation does not differ in them. In principle, the stages of chain initiation do not differ as well, but the stages of termination differ from each other: if in the case of initiated dehydrochlorination of EDC chain termination involves the regeneration of the chlorine molecule (or in general, the initiator molecule), in the case of thermal dehydrochlorination of EDC recombination of chlorine and chloroethyl radicals occurs with the formation of neutral molecules.

Such a difference in the mechanisms of chain termination is criticized in [10], in which it was suggested that the reaction of thermal dehydrochlorination of EDC should have the following mechanism:

This mechanism is similar to that proposed by K. Howlett, but differs somewhat from the mechanism proposed by Barton: the chain initiation stage is considered as the thermal decomposition of EDC molecule into two radicals, which most likely occurs in the wall layer and is more energetically favorable than proposed by Barton monomolecular decomposition of EDC into ethylene and a chlorine molecule [13].

The chain termination occurs only via recombination of chloroethyl radical and chlorine radical and does not follow the scheme of the chlorine radicals’ association with formation of molecular chlorine. This was proved by special experiments on the thermal dehydrochlorination of EDC, which showed that there was no free chlorine in the reaction products, and at the same time an appreciable amount of dichloroethylenes was found (about 5·10-3 moles per a mole of VCM) [10].

Even if we assume that free chlorine is still present in the reaction products, but in quantities below than the sensitivity of the method for its determination, then the likelihood of the reaction of termination upon the proposed scheme will be incomparably greater than that upon the scheme with the molecular chlorine formation. Therefore, the last reaction can be neglected.

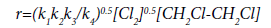

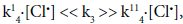

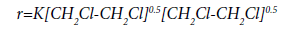

Assuming that k3 >> k4.[Cl•], the equation of reaction rate of the thermal dehydrochlorination of EDC, corresponding to the proposed mechanism, has the following form:

(22)

(22)

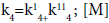

For the reaction of initiated dehydrochlorination of EDC, Sonin [10] proposed the following mechanism:

where M is a molecule of chlorine, hexachloroethane or another initiator.

In accordance with the proposed mechanism, the chain termination occurs mainly as a result of the interaction of chlorine with dichloroethyl radical, and not as a result of the recombination of chlorine radicals with the chlorine molecule formation.

Proceeding from the proposed mechanism and assuming that  the reaction rate is described by the equation (23):

the reaction rate is described by the equation (23):

(23)

(23)

where  is a molecule of chlorine, hexachloroethane or EDC.

is a molecule of chlorine, hexachloroethane or EDC.

This mechanism also allows considering the reaction of EDC dehydrochlorination from the same positions, regardless of whether it occurs in the presence of the initiator or without it. Since during the thermal dehydrochlorination of EDC the role of the initiator giving rise to the chain is fulfilled by EDC itself, equation (23) may be represented in the following form:

(24)

(24)

Which after simple conversion turns into equation (22), derived earlier for the reaction of the thermal dehydrochlorination of EDC.

Although both mechanisms are described experimentally, the general first order for both the reactions of thermal and initiated dehydrochlorination of EDC seems to be more logical and reliable than the change in the general order of the reaction from the first to the oneand- a-half one proposed by Barton et al. [10,29].

From a practical point of view, it is important to determine the minimum amount of chlorine necessary for the initiation. This is explained by the fact that chlorine introduced into the reaction zone forms ultimately chlorination products and, therefore, somewhat reduces the selectivity of the pyrolysis process. The author [10] showed that the initiation effect takes place in the range of chlorine concentrations of 0.3-1.1% mol. At chlorine content in the system of less than 0.3%, there is virtually no initiation.

Kinetic conformities of the chlorine conversion during the process of the initiated EDC pyrolysis under the assumption that chlorine, in addition to initiation, is consumed mainly in the reaction of the substitutive chlorination of EDC, can be written as follows [10]:

(25)

(25)

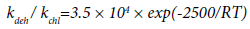

The ratio of the rate constants of the reactions of EDC dehydrochlorination and the conversion of chlorine is:

(26)

(26)

With an increase in temperature, the rate of the reaction of EDC dehydrochlorination increases faster than the rate of the chlorine conversion. At 573 K,  orders of magnitude, at

orders of magnitude, at ~ 3 orders of magnitude. However, the rate of chlorine conversion also increases with increasing of temperature, which can adversely affect the selectivity of the process.

~ 3 orders of magnitude. However, the rate of chlorine conversion also increases with increasing of temperature, which can adversely affect the selectivity of the process.

Detailed experimental data on the correlation of the rates of the reactions of EDC pyrolysis and its chlorination in the presence of small additions of chlorine, as well as of chlorine in a mixture with nitrogen oxide, were obtained by Ashmore [30,31]. The authors of [30] consider three main consecutive stages that occur when the process is initiated by small additions of chlorine:

It is shown that the initial rates of formation of both VCM and 1,1,2-trichloroethane decrease with operating time of the reactor increasing; the ratio k2/k3 remains constant at a constant partial pressure of EDC. The ratio increases with increasing of the partial pressure of EDC. Adding VCM to the system reduces the rate of its formation due to shifting of the equilibrium of the reactions to the left (2,-2). The authors of [30] confirm half the order with respect to chlorine by analogy [16] and indicate that the order with respect to chlorine increases up to 0.62 as the operating time of the reactor increases. In [31] the authors provide the developed by them model of transformations of the radical C2H3Cl2 according to the reactions (2,3) on the basis of the kinetic measurements. It is shown, in particular, that the activation energy of the reaction (2) is E2=84 kJ/mol, and the pre-exponential factor is 1014 sec-1.

Based on the data of [30,31], the authors of [26] also proposed a model for the pyrolysis of EDC upon initiation with chlorine. The model includes homogeneous and heterogeneous initiation, the chain propagation in the volume and the termination at the reactor walls. The addition of chlorine to the system increases the rate of the process due to the reaction:

Cl2 +S⇔Cl +ClS

which occurs much faster compared with both homogeneous and heterogeneous decomposition of EDC directly.

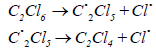

Initiation of the process of EDC pyrolysis can also be carried out using perchlorosubstituted saturated hydrocarbons C1 and C2: carbon tetrachloride and hexachloroethane, as initiators. At temperatures above 400°C hexachloroethane is able to decompose according to the scheme:

According to [10], the kinetic equation of the reaction of EDC dehydrochlorination, initiated by hexachloroethane, has the form:

(27)

(27)

Chiltz et al. [32] estimated by calculation that the activation energy of this reaction should be ~ 167 kJ/mol. According to Semenov et al. [24,33] as well as, the difference is explained by the catalytic effect of the carbonized reactor wall. In the pyrolysis of hydrocarbons and their derivatives, in the carbon deposition on the walls of the reactor free radicals exist, the concentration of which achieves 1015 spin per gram of the deposit [33]. The presence of these radicals facilitates the decomposition of the hexachloroethane molecule into perchlorethylene and two chlorine atoms.

For the pyrolysis of EDC initiated by carbon tetrachloride, the kinetic equation (28) is valid [34]:

(28)

(28)

It was shown in [33] that at 700 K (427°C) introduction of carbon tetrachloride in a concentration up to 1200 ppm into the system promotes an increase in the conversion of EDC by 13%, from 52.4 to 65.4%. This is accompanied, however, by the requirement for an additional (by ~20%) heat input. The authors of [35] note that the obtained by them calculated dependences of the conversion of EDC, the distribution of temperatures along the length of the reactor, the formation of by-products, in particular, acetylene, are in satisfactory agreement with the results of operation of industrial pyrolysis furnaces. This relies on a numerical analysis of 108 possible reactions that occur during the pyrolysis of EDC. In [35] these reactions are divided into initiation reactions, hydrogen abstraction reaction, chlorine abstraction reactions, condensation and decomposition radical reactions, molecular reactions and chain termination reactions. For each reaction, the values of the frequency factor and activation energy are given. On the basis of the analysis of these values, the authors conclude the most probable paths for the pyrolysis process of EDC.

The authors of [36-39] show that the initiating effect of a mixture of hexachloroethane and carbon tetrachloride on the pyrolysis of EDC is stronger than that of its most active component, hexachloroethane. With an increase in temperature, the initiating action of both the mixture and each component separately increases. The dependence of the conversion of EDC on the composition of the mixture has an extreme character at different temperatures. It should be noted that the maximum corresponds to a mixture containing 75% of hexachloroethane. The author of [34] points out that the synergistic effect is achieved due to the additional formation of hexachloroethane, one of the products formed as a result of decomposition of carbon tetrachloride. Hexachloroethane, in turn, decomposing at a lower temperature than carbon tetrachloride, initiates the decomposition of the latter at the same temperature. The authors of [37,39] carried out a regression analysis of the effect of various factors on the conversion of EDC in the temperature range of 460-540°C and indicated that the higher initiating activity of hexachloroethane in comparison with carbon tetrachloride is only manifested at temperatures exceeding 500°C. This fact contradicts the assumption proposed in [34], which supposes the higher initiating activity of hexachloroethane at relatively low temperatures.

The use of hexachloroethane as an initiator with a concentration of up to 1% by weight leads to an increase in the EDC conversion by 3-4% accompanied with a simultaneous decrease in the yield of by-product acetylene (by 1.2 times) and 1,3-butadiene (by a factor of 2) [40]. In our opinion, the combination of the increase in the EDC conversion with the decrease in the yield of basic impurity compounds raises certain doubts.

The authors of [40-42] proposed to use oxygen-containing compounds as initiators of the EDC pyrolysis. According to [41], chloral or chloral hydrate is an effective initiator of this process. The authors point out that at the concentration of chloral (chloral hydrate) at the level of 200-500 ppm wt. in EDC fed to pyrolysis, the yield of VCM increases, on average, by 10%. At the same time, the formation of byproduct monovinyl acetylene, as well as coke deposits, is significantly reduced. The mechanism of initiation is not considered in [41].

Similarly, the possibility of initiating the EDC pyrolysis by adding small amounts of hexachloroacetone was demonstrated in [42]. At temperatures of 460 and 500°C, the initiating action of 300 ppm hexachloroacetone is comparable to the initiating action of 100 ppm chlorine. The yield of VCM increases by 8-10% compared to the purely thermal process of EDC pyrolysis. The authors of [42] also point out an increase in the formation of by-products: acetylene, chloroprene and butadiene. The total amount of coke deposits increases slightly, but on the basis of the VCM formed it decreases by 1.2-2.5 times.

In the HOECHST AG-owned US patent [40], it was proposed to carry out the EDC pyrolysis in the presence of trichloroacetyl chloride, thionyl chloride, nitrosyl chloride. These compounds are strong initiators of the process, and their initiating capability is 3-4 times higher than the initiating capacity of chlorine. Unfortunately, the authors of [40] do not consider the possibility of water formation during the process, the presence of which in the system is usually strictly limited.

According to the data given in the HOECHST-owned patent [43], the presence of benzotrichloride in the raw EDC tends in a significant increase in the conversion of EDC. So, if for the pyrolysis of pure EDC at 490°C, conversion of the latter is 51.8%, the addition of benzotrichloride in a concentration of 250-1000 ppm promotes an increase in conversion to 76-85%. The yield of by-products is not reported. The reasons for such a pronounced initiating capability of benzotrichloride are also not discussed.

According to [38,39], the initiation of the pyrolysis process can be realized by adding hydrogen chloride to the being pyrolyzed EDC. The authors of [44] point out that in the temperature range of 450-490°C, the pyrolysis of EDC in the presence of hydrogen chloride, taken in a molar ratio to EDC equal to 0.1-1.8, proceeds with EDC conversion at the level of 95%; the main by-products are acetylene, ethylene, chloroprene, chloroform. The authors separately emphasize that the presence of hydrogen chloride in the system almost totally eliminates the formation of solid deposits on the walls of the reactor.

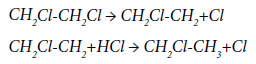

It was shown in [45] that the pyrolysis of EDC at 480-485°C, carried out at HCl concentration at the inlet to the reactor of up to 9,000 ppm (0.9%), promotes an increase in the EDC conversion from 33 to 49% with simultaneous reducing of the formation of impurities, such as 1,1,2-trichloroethane, trichlorethylene, perchlorethylene, and slight increasing of the yield of chloroprene. There are no indications of any change in the yield of acetylene and ethylene in [45]. The authors believe that a decrease in the formation of by-products with simultaneous increase in the conversion of EDC is due to the fact that during the EDC pyrolysis an additional chlorine atom is formed from the hydrogen chloride at the stage of nucleation of the free-radical chain process; and the chloroethyl radical, as the source of the formation of additional by-products, disappears according to the reactions:

Such an approach seems doubtful to us, first, because, according to [45], the content of ethyl chloride in the products of the process remains practically unchanged, and, second, the hypothetical reaction of hydrogen chloride with the chloroethyl radical is unlikely to occur under the conditions of the EDC pyrolysis due to a high H-Cl bond breakdown energy of 430 kJ/mol.

In general, the positive effect declared in [44,45] achieved when initiating the EDC pyrolysis by hydrogen chloride, needs, on our opinion, additional confirmation.

A strong initiating effect on the EDC pyrolysis is also provided by oxygen. The accelerating effect of oxygen upon the reaction of dehydrochlorination of chloroethanes was noted for the first time by Barton [46] and developed by him later [11]. Barton showed that the initiating activity of oxygen in the reaction of EDC dehydrochlorination is only slightly inferior to that of chlorine. According to Barton, the initiating action of oxygen is manifested in the reactions proceeding according to the radical-chain mechanism and is absent in the reactions proceeding according to the molecular mechanism (for example, for the reactions of dehydrochlorination of ethyl chloride, 1,1-dichloroethane, pentachloroethane).

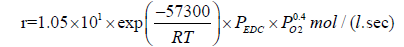

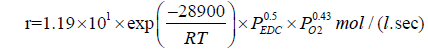

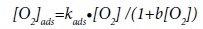

The effect of oxygen on the kinetics of the radical-chain processes on the example of the EDC dehydrochlorination was studied in [47]. The reaction rate is described by the kinetic equation:

(29)

(29)

The authors supposed that in the reaction of EDC dehydrochlorination, the accelerating effect of oxygen is due to its adsorption on the active sites of the wall. The decomposition of EDC proceeds according to the well-known mechanism with a crosstermination of the chain. Probably, the process of chain termination is preceded by the adsorption of radicals on the wall (S):

Oxygen, when being adsorbed on the wall, thereby reduces the area of active surface (S) and, consequently, leads to a decrease in the rate of chain termination, increase in chain length and rate of the process as a whole. The fractional order with respect to oxygen indicates that its adsorption proceeds in accordance with the Langmuir equation. The observed activation energy, calculated as the difference in the activation energy of the oxygen-free process (154,100 J/mol) and doubled the heat of adsorption of oxygen on the wall surface (2 × 54,300 J/mol), is 45,400 J/mol and is close to the experimental one.

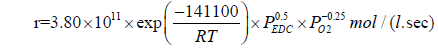

According to the data obtained in [34,48], the effect of oxygen on the process of EDC dehydrochlorination is rather complex. In the temperature range of 370-400°C, the dependence of the EDC conversion on the amount of added oxygen reaches its peak value, which shifts as the temperature rises towards a larger amount of oxygen fed. In the range, where the amount of oxygen does not exceed 1.5- 1.8% wt., it accelerates the reaction of EDC pyrolysis; in the range, where the amount of oxygen is more than 2% wt., it manifests itself as an inhibitor. The kinetic equations for each of the cases considered are as follows:

For initiation:

(30)

(30)

(31)

(31)

The rate of the radical-chain process can be written in the general form by the expression:

r=ri•l (32)

where r is the reaction rate, ri is the initiation rate, l is the chain length.

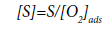

Thus, the reaction rate can be increased by either the initiation rate or the chain length. All the traditional initiators (chlorine, carbon tetrachloride, hexachloroethane) accelerate the process specifically by increasing the rate of initiation. Oxygen is, apparently, the only initiator that promotes an increase in the length of the chain [48]. Oxygen, adsorbed on the active sites of carbon deposits, blocks these centers and, thereby, prevents chain termination.

The author of [48] points out that, according to the assumption of the accelerating effect of oxygen on this process, the concentration of active sites should be proportional to the total surface area of the carbon deposit and inversely proportional to the concentration of adsorbed oxygen:

(33)

(33)

In turn, the concentration of oxygen adsorbed on the surface of the carbon deposit in accordance with the Langmuir equation is:

(34)

(34)

where kads is the adsorption constant of oxygen on the surface of pyrolytic carbon, b is the adsorption coefficient, and [O2] is the oxygen concentration in the reactor.

Taking into account Eqs. (33) and (34), the total rate of the EDC dehydrochlorination in the presence of oxygen is:

(35)

(35)

(36)

(36)

where k0, k2, k3 are the rate constants of the initiation, chain propagation and linear termination stages, respectively.

In favor of the proposed reaction mechanism is the fact that the initiating action of oxygen is only manifested, when the walls of the reactor are covered by pyrolytic carbon. The author of [48] confirms this by observing that the conversion of EDC in thermal and oxygeninitiated processes in non-carbonized reactors coincides within the first five minutes. It is during this period of time that pyrolytic carbon deposition on the walls of the reactor occurs [49].

The effect of oxygen additions on the kinetics of the EDC pyrolysis under adiabatic compression (under strictly homogeneous conditions) was studied in [50]. The authors pointed out that, by analogy with purely thermal pyrolysis, the process of EDC dehydrochlorination proceeds only through a monomolecular mechanism. It should be noted that the increase in the EDC conversion at high compression ratios is due to the reactions of homogeneous deep oxidation of EDC, and, to a greater extent, that of VCM. Homogeneous radical-chain reactions of oxidative dehydrogenation and dehydrochlorination do not make a significant contribution to the overall process. In [50] a hypothesis was also made on the causes of acceleration and inhibition of the process with a change in the oxygen concentration. The acceleration of the process under heterogeneous conditions may depend on the temperature increasing in the near-wall zone due to heat emission in the oxidation reactions. The authors attribute the inhibition of the process to the strong adsorption of water formed in the oxidation reactions. We have not found evidences of this assumption in literary.

According to [51], the process of EDC pyrolysis should be carried out in conditions of almost complete absence of oxygen (the content of the latter should not exceed 0.5-2.0 ppm). This is due to the fact that presence of oxygen in being pyrolyzed EDC in a concentration of 40- 200 ppm contributes to a drastic increase in the yield of by-products and coke. At the same time, the author of [51] points to an increase in the corrosion of the reactor walls. Quantitative estimates of the phenomena of coke formation and corrosion are not given; however, it is indicated that a decrease in the oxygen concentration from 43 to 0.5-2.0 ppm reduces the rate of coke formation by 22%. The last thesis raises some doubts, as the presence of oxygen in the system under the conditions of the EDC pyrolysis should contribute to the partial “burning out” of carbon deposits on the reactor walls.

Initiation of the process of EDC pyrolysis can also be carried out by exposure to external radiation sources. It was shown in [52] that in the presence of laser radiation with a power of 5 W/cm2, the EDC pyrolysis can be carried out at temperatures of 300-350°C, while achieving the EDC conversion that of the level of thermal pyrolysis at 500°C. An increase in the rate of chain initiation due to photodissociation of EDC with the formation of a chlorine radical was estimated. According to [52], the rate of “laser production” of chlorine radicals is 1014 particles/ cm3 sec, which is four orders of magnitude higher than the rate of the chlorine radicals’ formation at 700 K during thermal pyrolysis. This means that the upper limit of the laser acceleration of the chain reaction due to light absorption by the EDC molecules is approximately 102 ((104)0.5). The authors point out that as the temperature decreases, the magnitude of the acceleration should increase drastically, and as it increases should fall.

The authors of [53] point out that when initiating the process of EDC pyrolysis by a laser with a wavelength of 308 nm, the primary decomposition product is a dichloroethyl radical. Further conversion of the dichloroethyl radical is energetically most advantageous, when VCM molecule and the chlorine radical are formed. Theoretical calculations in [53] showed that under these conditions the target VCM is formed with high selectivity.

In [54], the effect of O2/Ar plasma on EDC is considered. Under the conditions of the process, EDC decomposes virtually completely (90- 99%) with the formation of a wide range of products, the main of which are hydrogen chloride, carbon oxide and dioxide. The formation of a wide range of chlorinated hydrocarbons, as well as phosgene, acetylene, ethylene, ethane was also observed. Obviously that this system cannot be used for practical purposes, associated with the production of VCM.

A number of organochlorine compounds are the inhibitors of the process of EDC pyrolysis [37-39]. These include allyl chloride, 1,2-dichloropropane, chloroprene, 1,1-dichloroethane, 1,2-dichloroethylenes, vinylidene chloride. Thus, the presence in the raw EDC of 0.5% wt. 1,2-dichloropropane, 1,2,3-trichloropropane or allyl chloride reduces the degree of conversion of the latter by a factor of 1.5-3. The effect of these compounds on the EDC pyrolysis is due to the fact that they give more stable radicals than EDC. In allyl chloride, the formation of a stable radical takes place by the addition of a chlorine radical, which requires much less energy than the formation of stable radicals from chloropropanes by breakdown of the C-H bond. In this case, the same stable CH2Cl-CHCl-C•H2 radical can form from 1,2-dichloropropane and allyl chloride. However, allyl chloride is a stronger inhibitor specifically because of its greater reactivity when forming a stable radical.

The quantitative characteristics of the process of EDC pyrolysis both in the purely thermal mode and under the conditions of the addition of carbon tetrachloride and chlorine as initiators to the system were considered [49]. A detailed analysis of the impurities formed as a function of the initiator concentration is given. It is shown that at 500°C the most noticeable impurities are acetylene, vinylidene chloride and chloroprene. It is pointed out as well that, at lower temperatures (350 and 400°C), the primary product of the EDC conversion is ethylene, which further undergoes secondary transformations. When the process is initiated with chlorine and carbon tetrachloride with a content of the latter of up to 1300 ppm, the acetylene concentration in the process products increases by a factor of 1.5-1.6, that of chloroprene- in 1.5 (CCl4)- 2.6 (Cl2) times. The content of benzene and trichlorethylene in the process products remains virtually unchanged.

The authors of [35] showed that when initiating the process of EDC pyrolysis by carbon tetrachloride at a concentration of up to 1200 ppm (mol), the acetylene concentration in the reaction gas increases from 300 to 430 ppm (mol). It is indicated that acetylene is a product of possible conversions, both directly of VCM molecule and of C2H3Cl, C2H2Cl, C2H3, CH2Cl and Cl radicals. The increase in the acetylene yield correlates with an increase in the EDC conversion, which is achieved both with increasing in temperature and with the presence of an initiator. It is also indicated [35] that acetylene is a compound, from which coke can be further formed under the conditions of the process.

In [55] the kinetic analysis of the main reaction and a number of by-reactions during the thermal pyrolysis of EDC was carried out. It is shown that an increase in the temperature of the process, as well as the residence time, most significantly affect the increase in the conversion of EDC. An increase in pressure from 1.0 to 1.4 MPa also increases the conversion of EDC, albeit to a much lesser degree. An increase in the residence time of the reaction mixture in the reactor promotes a drastic (by a factor of 1.5-2) increase in the yield of acetylene and 1,1-dichloroethane as well. The yield of ethylene increases insignificantly. The author [55] believes that ethylene is formed via an intermediate chloroethyl radical.

In a number of works the selectivity issues are considered in the context of the influence of impurities most commonly contained in EDC fed in the industrial pyrolysis furnaces. Typically, the quality of EDC, fed to pyrolysis in industrial conditions, is 99.7-99.8%. As impurities it can contain ethylene, as well as other organic compounds, the complete separation of which from the raw EDC is restricted due to the close boiling points. These include, in particular, benzene (Tboil=80.1°C) and trichlorethylene (Tboil=86.7°C). The boiling point of EDC is 83.47°C. EDC also usually contains a small amount of water.

Ethylene markedly inhibits the reaction of EDC pyrolysis; this effect is most noticeable for ethylene concentrations in the range of 0.1-1% [56]. Further increasing of the ethylene content in the reaction mixture has virtually no effect on the rate of the pyrolysis process. The order of the reaction with respect to ethylene in the area of strong inhibition is -1, the activation energy is 79.6 kJ/mol. The authors of [57] believe that the reason for the inhibition is the interaction of a Cl radical with an ethylene molecule and the formation of an inactive vinyl radical and an HCl molecule.

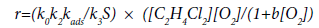

An analysis of the change in the selectivity of the EDC pyrolysis in the presence of ethylene, carried out in [57], showed that the introduction of 0.1% ethylene into the system promotes an increase in butadiene content in pyrolysis products from 40 to 110 ppm. It should be noted that an increase in the ethylene content above 0.3% contributes to an exponential increase in the rate of butadiene formation. The authors of [57] believe that butadiene is formed by dimerization of the vinyl radical, which, in turn, is formed, when the vinyl chloride decomposes according to the total reaction:

Under normal conditions of thermal pyrolysis, the formation of the vinyl radical proceeds at a low rate, and the concentration of the CH2=CH radical is small; therefore, butadiene is formed in small amounts. Ethylene introduced into the system can easy, virtually without an energy barrier (Eakt ~ 8 kJ/ol), interact with the chlorine atom, forming the radical responsible for the formation of butadiene. Such mechanism excludes the effect of ethylene on the formation of other impurities, which was confirmed experimentally in [57].

In this connection, the method proposed in [58] for carrying out the pyrolysis of EDC in the presence of ethylene in an amount of 0.02-0.1 mole per mole of EDC is of great doubt. The process indicators obtained by the authors, the EDC conversion of 66% at 390-420°C, indicate that the initiating effect of ethylene should be virtually at the chlorine level, which is not confirmed neither by the results of other researchers, nor by the experience of industrial use of the process.

The authors of [59] studied the effect of moisture additives on the pyrolysis of EDC. It is shown that in the range of water concentrations in the raw EDC of 25-1475 ppm, the rate of dehydrochlorination is independent of its content in the raw product. Water also has no effect on the yield of low-boiling by-products, such as ethylene, acetylene, methyl chloride, butadiene, etc. In contrast to this, the selectivity of the formation of certain high-boiling impurities varies: for example, the content of perchlorethylene and 1,1-dichloroethane in the process products reduces by 3-5 times, and that of vinylidene chloride and chloroform increases by 1.5-2 times. No mechanism of this effect is given by the authors of [59].

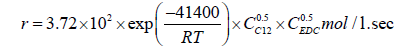

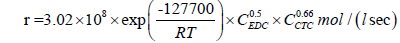

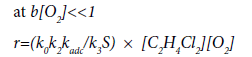

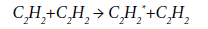

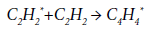

The conformities in the formation of by-products and coke during the thermal pyrolysis of EDC were studied in [27,60,61]. The authors of [27] when studying the process of EDC pyrolysis in a quartz reactor showed that the share of by-product acetylene and chloroprene is 70-80% in the total balance of the by-products formed. Acetylene is formed due to a partial decomposition of vinyl chloride according to the reaction:

The rate of acetylene formation is described in [27] by the first order equation:

(37)

(37)

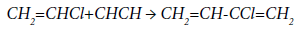

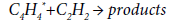

Most likely, chloroprene is the product of the interaction of vinyl chloride with acetylene:

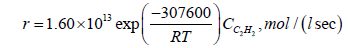

The kinetic equation of the reaction of chloroprene formation is:

(38)

(38)

Thus, the rate of formation of acetylene and chloroprene is a function of VCM concentration, so an increase in the EDC conversion with a corresponding increase in the concentration of VCM inevitably leads to an increase in the concentration of these by-products. The obtained results show that an increase in the EDC conversion due to a change in the main process parameters (increase in temperature, residence time of EDC, surface of the reaction zone, or initiation of the process) leads to a decrease in the selectivity of the formation of the desired product, VCM. The experimental data given in [27] confirm this conclusion: in the temperature range of 460-500°C the increase in the conversion of EDC from 24.5 to 45% leads to a decrease in the selectivity of VCM production from 99.6 to 98.4%. Simultaneously, the selectivity of acetylene formation increases from 0.15 to 0.68% and that of chloroprene increases from 0.1 to 0.6%.

In [60], the effect of metals on the EDC pyrolysis indicators was studied. It is established that the introduction of metal plates made of heat-resistant steel ХН78Т (analog of N06025, hereinafter referred to as “N06025” for clarity) (content of nickel 70-81%, of chromium 19-22%) and stainless steel 12Х18Н10Т (analog of AISI 321, hereinafter referred to as “321 SS” for clarity) (content of nickel 9-11%, of chromium 17- 19%), significantly changes the process indicators in comparison with the system containing only quartz elements in it. In particular, the conversion of EDC increases by 10-15%, and this is accompanied by a drastic (from 99 to 96.5-97%) decrease in the selectivity of VCM formation. The selectivity of acetylene and chloroprene formation increases from 0.5 to 1.2-1.7%. There was also a significant increase in the selectivity of the ethylene formation due to the reaction of EDC dechlorination - up to 0.2-0.3%. As far as the surface is being coked, the selectivity of ethylene formation is somewhat reduced. The steel 321 SS is more active with respect to by-reactions compared to the N06025 steel.

The authors of [61] considered the effect of additions of trichlorethylene and benzene on the indicators of EDC pyrolysis. It was shown that trichlorethylene is a weak initiator of the process. The increase in its share in the being pyrolyzed EDC to 0.8% leads to an increase in the EDC conversion by 4-5%, while decreasing the selectivity of VCM formation by 0.7-1% due, first of all, to the corresponding increase in the share of by-reactions of acetylene and chloroprene formation. The activation energy of the process initiated by trichlorethylene is equal to 128,300 J/mol.

In accordance with [61], the presence of benzene in the concentration range of (0.1-0.8)% in the system exerts virtually no effect on the EDC conversion rates, the selectivity of VCM formation and the by-product acetylene and chloroprene. Benzene fed to pyrolysis with EDC, converts to (13-16)%. The products of its conversion are the chlorine derivatives of benzene.

These results differ from the data of [34], according to which benzene at low concentrations (up to 0.2%) is an inhibitor of the process; at the same time a further increase in the benzene concentration to 0.5% leads to some increase in the EDC conversion, which, however, does not reach the values obtained in the thermal pyrolysis. The author [34] points out that since benzene has a significant reactivity, its introduction in small amounts leads to the binding of Cl. radicals, contributing to inhibition of the process.

Another by-product that is always formed during the EDC pyrolysis is methyl chloride. According to [48], the selectivity of its formation also increases (from 20 to 100 ppm) with an increase in the EDC conversion from 20 to 70%.

The influence of hydrogen on the EDC pyrolysis was considered in [62,63]. The authors showed [62] that hydrogen has a noticeable inhibitory effect, with the maximum inhibitory effect being achieved at 430-480°C and hydrogen concentration of 2-3%. The kinetic equation (39) is given:

(39)

(39)

The authors believe that the inhibition of the reaction is primarily due to the fact that the presence of hydrogen promotes chain termination with the formation of atomic hydrogen, which does not participate in the propagation of the reaction chain. The authors of [62] believe that a reduction in the formation of carbon deposits is due specifically to the effect of inhibition, however, they do not preset any experimental confirmation of this thesis.

The decrease in the selectivity of the formation of by-products in the presence of hydrogen in the system is pointed out in [63]. With an increase in the hydrogen concentration in the reaction gases up to 0.3%, the content of acetylene in the pyrolysis products falls from 0.39 to 0.06%. The effect of hydrogen concentration on the methyl chloride content is relatively small (yield of the latter increases from 0.2 to 0.4%). Dependence of butadiene content on hydrogen concentration is extremal. The maximum amount of butadiene (0.11%) is observed with the addition of 0.2% hydrogen. An increase in the hydrogen concentration to 0.55% leads to an increase in the ethylene content from 0.14 to 5.7%. A further increase in the hydrogen concentration to 1.2% leads to a slight decrease in the ethylene content. In addition, it was shown that an increase in the concentration of hydrogen in the reaction mixture causes a gradual decrease in the content of chloroprene, chloroform, chlorobenzene and their subsequent disappearance, as well as an increase in the yield of propane, propylene and isobutylene [63].

According to [64], the pyrolysis of EDC with the hydrogen concentration of 0.2-1.0% mol. leads to a decrease in the selectivity of the formation of chloroprene by 25-45%, the selectivity of acetylene formation decreases negligible with that. The positive effect, according to [64], is also that the hydrogen concentration based on the EDC fed at the level not exceeding 1% mol. has no effect on the EDC conversion, which, as the temperature changes from 460 to 480°C, increases from 40 to 58%.

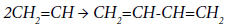

The conformities of the thermal decomposition of acetylene at 400-1500 K are considered in [65]. The first stage is the excitation of acetylene molecule according to the reaction:

Further, the reaction of dimerization proceeds to form an excited vinylacetylene molecule:

and then:

It is assumed that the activation energy of the reaction of primary excitation of acetylene molecule is in the range of 230-251 kJ/mol. These values are too large for realization of this scheme under the conditions of EDC pyrolysis. For this reason, the formation of a spectrum of byproducts in the pyrolysis process, obviously, proceeds along other paths, including the reactions of acetylene trimerization or its condensation, both with the target VCM and with other by-products.

The formation of solid carbon deposits, the so-called “coke”, during the EDC pyrolysis is one of the most important operational characteristics of the process. The relative amount of coke produced in the industrial furnaces on the base of the reacted EDC is small and is amounted to hundredths of a percent. However, all companies that produce VCM give top priority to this indicator.

The main problems emerging in the use of industrial furnaces for EDC pyrolysis while the coke deposition increases, can be divided into three groups. First, a coke layer on the coil walls leads to a decrease in the heat transfer factor, which requires an increase in the temperature of fuel burning to achieve the required conversion of dichloroethane. Second, the coke layer gradually reduces the cross-section of the pipes, which leads to an increase in the pressure drop and, eventually, to the furnace shutdown for regeneration. Third, the coke particles contained in the gas stream must be removed from the liquid after the quench column in order to avoid contamination of other process units [66].

In general case, Bukharkin [67] represents the overall process of carbonaceous products formation in the vapor phase, typical of the thermal pyrolysis of hydrocarbons in industrial conditions as including the following stages:

- decomposition of hydrocarbons in the gas phase, accumulation of unsaturated and aromatic compounds, their condensation and/or polymerization;

- formation of polyacetylenes and analogous compounds with subsequent ring closure;

- growth of carbon particles (nuclei) and decomposition of hydrocarbons on the surface of these nuclei;

- agglomeration of the formed nuclei and their deactivation; formation of the wall “coke” deposit.

It was pointed out in [68] that benzene promotes the formation of “nuclei” during pyrolysis, and in the formation of the latter the following substances involve with different rates and activities:

Allen → 1,3-Butadiene → Acetylene

Compounds in which the vinyl group is coupled to an electron withdrawing group (for example, vinyl acetylene) form dimers and polymers at temperatures of the order of 573-773 K, which are then converted to polycyclic aromatic hydrocarbons and coke deposits [69].

Albright et al. [70] stated the general principles of coke formation in the form of three parallel mechanisms using the ethylene formation process by raw petroleum pyrolysis as an example:

Filamentous coke, which formation is catalyzed by metals. Intermediates are metal hydrides. The filamentous coke exists in the form of needles or fibers. Carbon filaments are formed on catalytically active areas of the surface containing metal atoms of the iron group. The length of such carbon filaments is several orders of magnitude greater than their diameter.

Pyrocarbon is formed from polynuclear aromatic viscous droplets, which convert themselves into coke when contacting with a hot surface, whereas the coke morphology is dependent on the viscosity of the droplets.

The reaction of olefin, diene, acetylene compounds, as well as free radicals with free radicals on the coked surface. The coke layer formed according to the mechanisms 1 and 2 grows through the mechanism 3.

The authors of [70] also point out that these principles are valid for the process of EDC pyrolysis as well.

Catalytic coke formed from hydrocarbons on the metal surfaces has a fibrous structure; intermediates in its formation are metal carbides [71]. Catalytic coke provides higher density than that of non-catalytic one formed by tar droplet formation.

The authors of [72] investigated the influence of various factors on the formation of coke during the EDC pyrolysis in a laboratory quartz reactor. It is shown that the formation of coke changes simbatically with the EDC conversion and depends on a number of factors, one of which is the EDC composition at the reactor inlet. At the same time, the introduction of carbon tetrachloride into the system indirectly, through an increase in the EDC conversion, promotes the increasing of coke formation. The authors of [72] also showed that the main precursor of coke is chloroprene. Using 14C-labeled isotopes, it was shown that 50- 60% of the carbon contained in chloroprene is converted into coke. The presence in the system of benzene, as well as acetylene, has practically no effect on the formation of coke.

Borsa et al. [66] points out that two different types of coke are deposited on the walls of the reactor: “Hard” coke is formed in the hot zone of the reactor and soft coke is formed in the colder zone at the exit of the reactor. According to [63], hard coke is similar to pyrolytic graphite in structure. Borsa also points out that the tar droplets, which are mainly fragments of C4 hydrocarbons, are formed in the gas phase. Then they impinge on the surface where they undergo dehydrogenation and dechlorination, and coalesce to form coke [73].

Detailed studies of the quantitative characteristics of coke formation, as well as the structure of coke deposits, were carried out [27]. The authors confirm that chloroprene is the main precursor of coke [72]. It is shown that a decrease in the selectivity of VCM formation from 99.6 to 98.4% due to an increase in the yield of the byproduct acetylene and chloroprene is accompanied by a drastic (by 4-6 times) increase in coke deposits on the walls of the reactor.

To assess the intensity of coke formation, Borsa et al. introduced the concept of “coke index” [66]. The coke index (I) is the ratio per unit area of the coke weight deposited on the surface to the reacted EDC weight. According to [66], under the conditions of a laboratory quartz reactor with the conversion of EDC at the level of 50-55%, the value of I is (7.5-11) × 10-8 1/cm2. These data agree with [27], according to which the value of I for the reaction zone and the exit zone is equal to (7.2- 7.7) × 10-8 1/cm2. The overheating zone is characterized by a lower coke formation intensity: I=3.9 × 10-8 1/cm2.

The data of physical and chemical studies of coke carried out, among other, with the help of a scanning electron microscope, allows suggesting the following mechanism for the coke deposits formation [27]. At the initial stage of the EDC thermal destruction, the difference in the composition of the intermediate compounds containing in the reaction mixture in the form of the gas phase is assumed. The authors of [27] confirmed this assumption by the different composition of coke deposited in the overheating zone. At low temperatures (350-390°C), the most probable is the decomposition of EDC with the formation of chlorinated ethane and ethylene, which contribute to the production of low-temperature pyrolytic carbon. Building-up of the pyrolytic carbon leads to the formation of the so-called “column structure”.

The formation of pyrolytic carbon on a solid surface occurs simultaneously with the formation of dense anisotropic coke, which is a spherical agglomerate of 70-200 nm in diameter. These reactions proceed in parallel and are competing.

Another type of deposit is a turbostatic carbon with particle size of 1.3-1.5 μm formed by the products of polymerization and polycondensation of aromatic hydrocarbons. In total, the authors of [27] point out to three types of coke deposits: pyrocarbon, anisotropic coke, and turbostatic carbon formed by the products of polymerization and polycondensation of aromatic hydrocarbons.

For a more accurate quantitative assessment of the process of coke formation occurring in industrial furnaces for EDC pyrolysis, a number of authors have studied the influence of metals on the intensity of coke formation and its structure [60,66,73-75]. According to [74], the coke deposits on the stainless-steel elements in the reactor are significantly higher than that on quartz or ceramic elements. The process of coke deposition on the metal surface is accompanied by the formation of FeCl2, which in turn is a catalyst for the formation of coke.

The catalytic effect of iron dichloride on the formation of coke was confirmed in [66]; however, it was concluded that the nature of the metal (Cr, Ni, Fe, stainless steel) does not fundamentally affect the character of the coke formed: hard or soft coke. In all cases, the presence of metal in the system under 480°C leads to an increase in the EDC conversion from 43 to 61% and an increase in the intensity of coke formation. The increase in the metal surface also promotes an increase in the EDC conversion and in the associated amount of coke produced. Analyzes of metal plates subjected to coke deposition point out, as well as in [72], the presence of FeCl2 on the metal surface.

According to [75], iron and iron oxide can form an active surface for carbon deposits, since iron oxide reacts readily with chlorohydrocarbons to form iron (II) chloride. The surface of iron chloride initiates a radicalchain reaction according to the oxidation-reduction mechanism and accelerates the polymerization of chloroolefins. It was suggested [75] that hydrogen chloride released during the thermal decomposition of EDC, as well as other impurity chlorinated hydrocarbons, can cause surface corrosion with the formation of iron chloride accelerating the formation of carbon deposits.

A series of experiments was carried out in [60] to determine the quantitative characteristics of the formation of carbon deposits when inserting plates made of N06025 and 321 SS steels into the laboratory quartz reactor (for the content of metals in these steels, see the section “The issues of the selectivity of EDC pyrolysis”). The presence of metal plates in the system contributes, along with an increase in the conversion of EDC and a decrease in the selectivity of the VCM formation, a drastic increase in the intensity of the formation of carbon deposits. The authors pointed out that the most intensive deposition of coke occurs on the elements with a high nickel content (N06025 steel, containing up to 80% of Ni). The coke index in the reaction zone is 1.4 × 10-4 1/cm2, i.e., it by more than three orders of magnitude exceeds the corresponding value for the quartz surface.

The steel 321 SS is less active in the process of coke formation: the coke index in the reaction zone is 9.7 × 10-6 1/cm2, which is 15-16 times lower in comparison with the N06025 steel, although it exceeds the corresponding value for the quartz surface by 1.5-2 orders of magnitude.

According to [60], the antibate selectivity of chloroprene formation and of the coke index for the N06025 and 321 SS steels takes place. Although the selectivity of chloroprene formation on N06025 steel is ~1.5 times lower in comparison with that of 321 SS, the coke index for N06025 exceeds the corresponding value for 321 SS by an order of magnitude. Based on this, the authors conclude that nickel is a more effective catalyst for the formation of coke deposits from chloroprene. By estimations, on the N06025 plates up to 25% of chloroprene formed during pyrolysis is further converted into coke; the corresponding value for 321 SS steel is 2.5-3%.

Studies of the structure of carbon deposits formed showed [60] that the coke is not completely carbonized, 35-45% of carbon atoms are bonded to hydrogen. This indicates a decrease in the share of dehydrogenation reactions compared to the quartz surface. It is also shown that metals migrate from the surface of the plates to coke deposits, and the rate of iron migration significantly exceeds the rate of migration of nickel and chromium. The chromium content in the coke deposits is two orders of magnitude lower than that of iron and nickel. The authors also showed that polycondensation occurs on the surface of metal plates during the adsorption of chloroprene, whereas each cluster of coke is formed from 3-4 chloroprene molecules. When such clusters are formed, an average of 2 molecules of hydrogen chloride are released, with the transition of the latter to the gas phase.

The obtained results in general correlate with the data of [67,70,76-78], in which the effect of metals on the parameters of raw hydrocarbons processing is considered. According to [76], during the pyrolysis of petroleum raw materials the coke formation is promoted to the greatest extent by iron and nickel. By activity to coke formation, the metals are arranged in the following order:

Fe > Ni > Ti > Zr > Cu > W

Under process conditions that promote the formation of oxides on the surface, coke deposition in the pyrolysis reactor is enhanced. The materials contributing to the reduction of coke deposits include chromium oxide, and silicon, aluminum, titanium and niobium compounds [76].

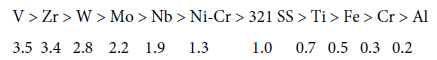

Bukharkin [67] points out that by the relative activity in the reactions leading to the accumulation of compaction products in the high-temperature zone (up to 625°C) (321 SS activity is taken as 1) the metals and alloys can be arranged as follows:

All these data indicate that nickel included in most of the heatresistant alloys contributes to an increase in the intensity of the compaction products deposition on the coil walls of the pyrolysis furnaces.

These conformities are confirmed by Albright et al. [61,70,78], who considered the formation of the compaction products in the processes of ethylene obtaining by the pyrolysis of raw petroleum. In particular, it is shown in these studies that coke contains iron, nickel and chromium, which migrate to carbon deposits from the metal surface. It should be noted that the migration of chromium is maximum from the clean walls of the reactor, then it slows down significantly. Nickel in [77] is designated as the most active catalyst in coke formation.

The foregoing points to similar conformities of coke formation in the pyrolysis of EDC and raw petroleum.

As mentioned above, the selectivity of EDC pyrolysis, as well as the intensity of the formation of carbon deposits, are a function of the EDC conversion, regardless of the reason for the change in conversion. The pyrolysis of EDC with benzene additives is subjected to a somewhat different conformities. According to [61], an increase in the mass fraction of benzene in EDC to 0.8% at 480°C leads to an increase in coke deposition in ~1.5 times in comparison with the EDC pyrolysis without benzene. As noted above, the presence of benzene in the system does not affect the EDC conversion and the selectivity of VCM and by-products formation.

Based on the data of physical and chemical studies of coke samples carried out in [61], the authors make an assumption about the coke formation pattern. Condensation of aromatic rings is accompanied with microradicals formation. Various radicals existing in the reaction mixture add themselves to carbon atoms with free valences. Consequently, each addition of benzene to the EDC pyrolysis, involving into the process unsaturated chlorinated and other hydrocarbons, such as acetylene, chloroprene, etc., leads to an increase in the formation of polycondensed organic polymers of various sizes and structures. Most of them, upon reaching the saturated vapor state, settle on a hot surface at a practically constant rate. Such assumption is confirmed by the data of the elemental composition of cokes, according to which hydrogen content in the range of (1-3)% and high chlorine content at the level of (15-23)% may point out the formation of high molecular weight aromatic condensed systems, where the lack of hydrogen atoms is compensated by chlorine atoms. Thus, the coke formed during benzene conversions within the EDC pyrolysis is obtained in parallel with the coke formed directly from EDC, VCM and products of their secondary transformations. The authors of [61] recommend carrying out the pyrolysis process in industrial conditions, using EDC with a benzene content of at most 0.1%, as these concentrations have no fundamental effect on the amount of coke formed.