Journal of Geology & Geophysics

Open Access

ISSN: 2381-8719

ISSN: 2381-8719

Research Article - (2022)Volume 11, Issue 5

Soil stabilisation is the process of changing certain soil properties through different techniques, chemical, physical or mechanical, in order to enhance the soil sample, which has the most engineering properties needed. In the present study, the soil samples were stabilised by fly ash and rice husk ash wastes, which contribute a major part in increased disposal problems. In the present study fly ash and rice husk ash and the combination of fly ash and rice husk ash was added in varying percentages such as 5%, 10%, 15%, 20% and 25% to improve the soil properties. Different laboratory tests such as compaction, box shear, liquid limit and plastic limit tests were carried on soil samples. Maximum dry density and optimum moisture content with varying percentages of fly ash, rice husk ash, and fly ash and rice husk ash combinations have been found to be increased compared to unreinforced soil. Compared to unreinforced soil, the cohesion (C) and internal friction angle (Ø) of the soil with differing percentages of fly ash, rice husk ash and the mixture of fly ash and rice husk ash have decreased. It has been concluded that with the addition of fly ash and rice husk ash and the combination of fly ash and rice husk ash, some soil properties can be improved.

Stability; Industrial waste; Rice husk ash; Fly ash

When an engineer has to carry out the various construction activities even on problematic soil, the importance of ground improvement techniques rises. Therefore, nowadays soil stabilizations are gaining more importance. Since last few years due to increase in population, socioeconomic activities and social developments, the quantity of waste produced in the world has increased. These wastes generate from various constructional activities like industrial, agricultural and commercial. One of the most common methods of waste management has now been the reduction and reuse of waste. In order to solve the problem of low soil stability, engineers and researchers have now begun using these wastes in soil stabilization. Soil stabilization accomplished by increasing the density of the soil, which can achieve by adding admixtures and applying mechanical energy to compress the soil. It is a more cost-effective approach to boost the efficiency of problematic soils by increasing their cementation and reducing their moisture sensitivity. For construction purposes most commonly, cement, lime and fly ash have been used for to strengthen weak soils and to make it strong for all types of paved areas, to improve the condition of the base and as a lining for trenches and earthwork stakes. Several research works have confirmed the usefulness of fly ash by showing that when added to expansive soils it reduces the plasticity index, the amount of clay size particles and their swell potential. Researchers have concentrated more on using potentially cost-effective materials which are available from local industrial and agricultural waste in order to make deficient soils useful and meet the criteria of geotechnical engineering design to improve the properties of deficient soils.

Prabhakar, et al. [1], found that, in terms of geotechnical grounds, construction of any infrastructure over a soft and weak soil is very common as the soil undergoes differential settlements, high compressibility and low shear strength. In order to increase the load bearing ability of the soil, their paper identified the behavioral aspects of soil mixed with fly ash. Brooks, [2], suggested that with the use of Rice Husk Ash (RHA) and fly ash, which are waste materials, expansive soil can be modified as a building material. To find the strength, they have blended remoulded expansive clay with RHA and fly ash. For the planning of the sub-base of a highway project with and without admixture stabilization, the authors carried out cost comparison studies. Mallikarjuna, et al. [3], studied the possibility of utilizing fly ash in the construction of embankments, road subgrades and stabilization of a wide range of soils. Their research aims to find the Optimum Fly Ash (OFA) for mechanical stabilization of expansive soils. They concluded that when soils are added at a given content of fly ash, an increase in maximum dry density and unconfined compressive strengths and a decrease in optimum moisture content, liquid limit, plastic limit and plasticity index have been observed. Chebet, et al. [4], carried out laboratory research on reuse of polyethylene (Plastic) bag waste material for soil reinforcement in geotechnical engineering; a laboratory research related to a sequence of direct shear tests and plate loading tests carried out on plastic strengthened soil specimen organized from sandy soils blended with random inclusions of plastic strips received from excessive density polyethylene purchasing bags. The impact of the plastic strips at the soil power parameters become studied with the aid of using including strips at concentrations of as much as 0.3% with the aid of using weight and ranging the lengths and widths. From the results of the direct shear test, an increase of more than 20% of the soil resistance parameter of the internal friction angle in sandy soils was obtained, which implies an increase in the shear strength with the addition of plastic strips.

Prasanna, et al. [5], conducted a study on soil stabilization for Indian soils by adding waste coconut shell powder to the soil samples. Results showed that maximum dry density and optimum moisture content attained maximum values at 0.8% of addition of coconut ash to the soil sample. Friction and cohesion values attained at 0.4% to 0.8% of the addition of wastes. Gupta, et al. [6], carried out a study on stabilized soil incorporating combinations of Rice Husk Ash (RHA), Pond Ash (PA) and cement. Compaction tests, Unconfined Compressive Strength tests (UCS), and Split Tensile Strength tests (STS) on fresh and stabilized soil are used to assess the influence of stabilizer kinds and dose on fresh and mechanical characteristics. Authors concluded that when clay was replaced with 40% PA, 10% RHA, and 4% cement, the total mix's strength (UCS and STS) increased when compared to mixtures where PA and RHA were utilized separately with cement. The developed stabilized soil mixes have demonstrated adequate strength and may be used for low-cost road infrastructure development. Prasanna, et al. [7], carried out a project on utilization of waste plastic shreds for soil stabilization. In this paper author found a result for the addition of plastic shred wastes at 2%, 4%, 6%, 8%, and 10% percentages to the soil samples. Author concluded that maximum dry density, optimum moisture content and cohesion values decreased and friction increased slightly with the addition of waste plastic shreds to the soil samples. Abdullah, et al. [8], studied the effect of soil stabilization on subgrade soil using cement, lime and fly ash. A study was conducted to enhance the characteristics of a sample subgrade soil by stabilizing it with three distinct addition materials of varying properties and amounts. The following materials were used: (Ordinary Portland cement), (limestone powder), and (fly ash) in percentages of 3%, 6%, and 10%, respectively. The results of the modified mixture tests (Proctor test), Unconfined Compression Strength (UCS), and California Bearing Ratio (CBR test) revealed that stabilizing the subgrade soil with varying percentages of those additives enhanced the subgrade soil's mechanical characteristics.

This study aimed at examining the effect of industrial wastes rice husk ash and fly ash on soft soil stabilization. This paper attempted to improve the geotechnical properties of a soil replaced by Rice Husk Ash (RHA) and fly ash with pozzolonic importance (FA). In the present study industrial wastes such as fly ash and rice husk ash and the combination of fly ash and rice husk ash were added in varying percentages like 5%, 10%, 15%, 20% and 25% to analyze engineering properties of the soil.

Undisturbed soil samples collected from Margao railway station, Goa state. The study area falls under the Taluka of Salcete district of South Goa. From the local industry fly ash and rice husk ash has been collected. Experimental studies on the impact of fly ash and rice husk ash studied in this paper to increase the strength of the soil. Various laboratory tests conducted on soil samples without adding industrial waste (unreinforced soil). In addition, experiments on soil samples also carried out by adding different percentages of combinations of fly ash and rice husk ash, only fly ash and only rice husk ash after being referred to here as reinforced soil. The samples were subjected to various laboratory tests, such as particle size distribution, Atterberg limits, compaction tests, and direct shear tests. The soil is graded as silty soil based on the study of particle size distribution. The findings of the other experiments are shown in Table 1.

| Soil Properties | Values |

|---|---|

| Percentage of gravel | 0.04% |

| Percentage of sand | 11.27% |

| Percentage of silt and clay | 88.69% |

| Average water content | 56.60% |

| Liquid limit | 57.57% |

| Plastic limit | 32.94 % |

| Maximum dry density | 1.38 g/cc |

| Optimum moisture content | 16% |

| Cohesion | 4.8 kg/cm² |

| Angle of friction | 36° |

Table 1: Chemical composition of rock samples. The concentrations of major elements are expressed in % of oxide, those of trace elements in μg/g.

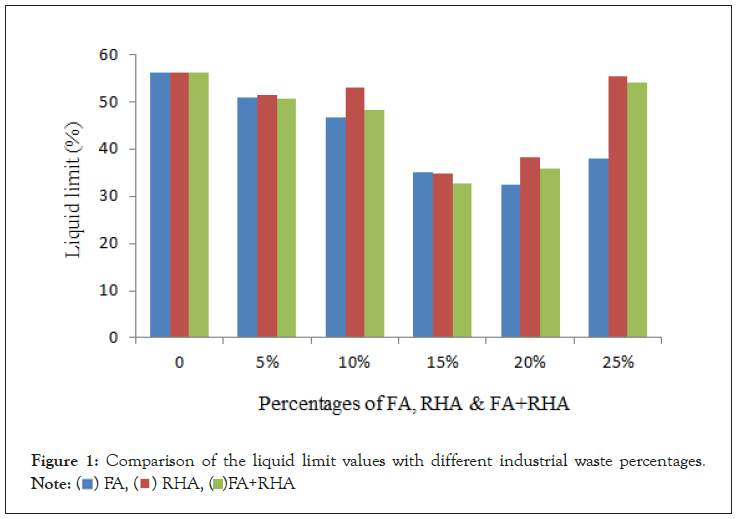

On unreinforced soil samples, Atterberg's limit test (Liquid limit and Plastic limit) was performed. The Liquid Limit (LL) and Plastic Limit (PL) values obtained were 56.20 and 32.94%, respectively. With the addition of 5% of Fly Ash (FA) on soil sample, LL and PL values changed to 51% and 27.59% respectively. It can be observed that both LL and PL values decreased after the addition of 5% of fly ash. By adding 10% of FA the LL and PL were reduced to 46.8% and 31.55% respectively. Same trend observed with the addition of 15%, 20% and 25% of FA to the soil sample. In the next trial Rice Husk Ash (RHA) was added in different percentages like 5%, 10%, 15%, 20%, and 25%. The corresponding LL values like 51.4%, 53%, 34.9%, 38.23%, 55.55% and PL values such as 39.91%, 48.89%, 30.74%, 28.91%, and 45.32% obtained. Here also it can be seen that almost decrease in the LL and PL values. In last trial combination of FA and RHA means for the addition of 5% of industrial waste 2.5% FA and 2.5% RHA used. Similarly for 10%, 5% of FA and 5% of RHA added, like that 15% (7.5% FA and 7.5% RHA), 20% (10% FA and 10% RHA) and 25% (12.5% FA and 12.5% RHA) added and determined LL and values. Tables 2 and 3 gives the detailed results. By comparing all the observations, it can be inferred that, after the addition of 20% of FA, the liquid limit decreased to 32.51% from 56.2%. With the addition of 10% of RHA, the plastic limit increased from 32.94 percent to 48.89 percent (Figures 1 and 2). Bhasin, et al. [9], investigated the stabilization of black cotton soil as a pavement material using RHA, as well as other industrial wastes such as fly ash, bagasse ash, lime sludge, and black sulphite liquor, both with and without lime. Because it contains a larger amount of reactive silica, the RHA improves the environment more than other wastes. The characteristics of black cotton soil were considerably enhanced when RHA was used in conjunction with lime. Similar trend was observed in the present study also. Slight improvement in LL and PL values can be observed.

| Unreinforced soil (without FA, RA) | % | FA | RHA | Combination of FA and RHA |

|---|---|---|---|---|

| 56.20 (%) | 5 | 51 | 51.4 | 50.7 |

| 10 | 46.8 | 53 | 48.2 | |

| 15 | 35.20 | 34.9 | 32.79 | |

| 20 | 32.51 | 38.23 | 35.79 | |

| 25 | 38.04 | 55.55 | 54.2 |

Table 2: Liquid limit values for unreinforced and reinforced soil (with varying percentages of wastes).

| Unreinforced soil (without FA, RA) | % | FA | RHA | Combination of FA and RHA |

|---|---|---|---|---|

| 32.94 (%) | 5 | 27.59 | 39.91 | 11.53 |

| 10 | 31.55 | 48.89 | 24.83 | |

| 15 | 42.66 | 30.74 | 44.77 | |

| 20 | 20.79 | 28.91 | 21.05 | |

| 25 | 29.12 | 45.32 | 30.10 |

Table 3: Plastic limit values for unreinforced and reinforced soil (with varying percentages of wastes).

Figure 1: Comparison of the liquid limit values with different industrial waste percentages. Note:  FA+RHA

FA+RHA

Figure 2: Comparison of plastic limits values with different industrial

wastes percentages. Note:  FA+RHA

FA+RHA

Next, compaction test results were analyzed for both reinforced and unreinforced soil samples. The Optimum Moisture Content (OMC) and Maximum Dry Density (MDD) are 16 % and 1.38 g/ cc for the unreinforced soil sample. The following findings were obtained after the addition of fly ash as reinforcement in several percentages. For 5% of FA, OMC and MDD values are 24.6% and 1.59 g/cc. This indicates that there is a rise in OMC and MDD after addiction of 5% fly ash. The same findings showed that 10%, 15%, 20% and 25% of fly ash were added to the soil sample. Similarly, RHA added in different percentages and the results shown in Table 4. In the last trial combinations of FA and RHA added in percentages as mentioned earlier. Table 4 gives the detailed results. It can be inferred, by comparing all the observations, that OMC increased to 31.34% from 16% after the addition of 10% of FA. MDD increased from 1.38 g/cc to 1.59 g/cc with the addition of 5% of FA and 5% of RHA (Figures 3 and 4).

| Unreinforced soil (without FA, RA) | % | FA | RHA | Combination of FA and RHA | ||||

|---|---|---|---|---|---|---|---|---|

| MDD (g/cc) | OMC (%) |

MDD (g/cc) |

OMC (%) |

MDD (g/cc) |

OMC (%) |

MDD (g/cc) |

OMC (%) |

|

| 1.38 | 16 | 5 | 1.59 | 24.6 | 1.51 | 25.58 | 1.59 | 26 |

| 10 | 1.45 | 31.34 | 1.47 | 23.89 | 1.56 | 24.28 | ||

| 15 | 1.54 | 20.04 | 1.56 | 21.22 | 1.49 | 19.99 | ||

| 20 | 1.58 | 19.60 | 1.45 | 25.91 | 1.41 | 22.31 | ||

| 25 | 1.54 | 24.95 | 1.31 | 30.29 | 1.44 | 26.68 | ||

Table 4: MDD and OMC values for unreinforced and reinforced soil (with varying percentages of wastes).

Figure 3: Comparison of maximum dry density values with different

industrial wastes percentages. Note:  FA+RHA

FA+RHA

Figure 4: Comparison of optimum moisture content values with different

industrial wastes percentages. Note:  FA+RHA

FA+RHA

The direct shear test was performed to determine the shear strength parameters. The cohesion (C) and angle of friction (Ø) parameters of shear strength were determined. First, research was performed for unreinforced soil without adding FA and RHA percentages. The following results were obtained: C=4.8 kg/cm2 and Ø=36°. In general, higher values of C and Ø are stronger than the shear strength of the soil and the stability of the slope. Basha, et al. [10], had examined the effects of RHA and cement on plasticity and compaction characteristics of expansive soil (bentonite) and had advised that 10%-15% of RHA and 6%-8% of cement as ideal amounts for stabilisation.

Then different percentages of FA and RHA added to the soil. First 5% of FA added to the soil and observed decrease of C (3.5 Kg/ cm²) and Ø (20°) value. Almost same observations found with 10%, 15%, 20% and 25% of FA when added to the soil. In the next case 5%, 10%, 15%, 20% and 25% of RHA added and determined cohesion and friction values. Here also cohesion value decreased from 4.8 kg/cm to 2.2 kg/cm and friction value reduced from 36° to 10°. In the last trial combination of FA and RHA added and found the results. Here also similar trend observed between cohesion and friction values. Cohesion and friction value reduced invariably in all cases. It can be inferred, by comparing all the findings, that adding different percentages of FA and RHA to the soil will minimise both cohesion and friction values. Table 5 and Figures 5 and 6 indicates detailed results. Muntohar, et al. [11], investigated the stabilizing effects of RHA and lime on engineering characteristics of expansive soil and discovered improvements in IP, CBR, shear strength parameters, and other engineering variables. Same observations were found in the present study also.

| Unreinforced soil (without FA, RA) |

% | FA | RHA | Combination of FA and RHA |

||||

|---|---|---|---|---|---|---|---|---|

| C Kg/cm² |

Ø (°) | C Kg/cm² |

Ø (°) | C Kg/cm² |

Ø (°) | C Kg/cm² |

Ø (°) | |

| 4.8 | 36 | 5 | 3.50 | 20 | 3.35 | 16 | 2.75 | 16 |

| 10 | 1.35 | 15 | 2.20 | 32 | 3.70 | 12 | ||

| 15 | 2.25 | 20 | 2.40 | 10 | 2.50 | 14 | ||

| 20 | 1.40 | 24 | 2.60 | 11 | 3.00 | 11 | ||

| 25 | 2.35 | 27 | 2.70 | 19 | 3.95 | 6 | ||

Table 5: Cohesion and friction values for unreinforced and reinforced soil (with varying percentages of wastes).

Figure 5: Comparison of cohesion values with different industrial wastes

percentages. Note:  FA+RHA

FA+RHA

Figure 6: Comparison of friction values with different industrial wastes

percentages. Note:  FA+RHA

FA+RHA

Liquid limit results shows that with the addition of FA, RHA and combination FA and RHA, there would be decrease in liquid limit values as compared to unreinforced soil. However, in case of plastic limit values, some variations found with different percentages of FA means slightly decrease in plastic limit values, but when RHA added in some percentages plastic limit values increased and combinations of both FA and RHA again there is decrease in plastic limit values. Based on the results of the compaction test on soil with differing percentages of fly ash, rice husk ash and a mixture of both fly ash and rice husk ash, an improvement in the overall dry density and optimum moisture content of the soil relative to the unreinforced soil is observed in all three situations. The variation of maximum dry density and optimum moisture content of soil in the above-mentioned three cases is a nonlinear variation. Direct shear test results indicate that cohesion and friction values decreased relative to unreinforced soil with the addition of various percentages of fly ash, rice husk ash and fly ash and rice husk ash mixture. Therefore, after the addition of waste material as reinforcement, it represents a non-uniform variance. Fly ash is an efficient stabilizer for improving the geotechnical properties of soil compared to rice husk ash and when used in conjunction with rice husk ash, by comparing the results of all three cases. So it could be concluded that stabilization of soil using wastes improves the geotechnical properties of weak soil.

Citation: Prasanna S (2022) Utilisation of Fly Ash and Rice Husk in Soil Stabilization. J Geol Geophys. 11:1032.

Received: 07-Jun-2022, Manuscript No. JGG-22-17347; Editor assigned: 09-Jun-2022, Pre QC No. JGG-22-17347 (PQ); Reviewed: 23-Jun-2022, QC No. JGG-22-17347; Revised: 30-Jun-2022, Manuscript No. JGG-22-17347 (R); Published: 08-Jul-2022 , DOI: 10.35248/2381-8719.22.11.1032

Copyright: © 2022 Prasanna S. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.